Preparation and applications for efficient MXene titanium carbide battery catalyst

A titanium carbide and catalyst technology is applied in the field of battery catalysts for preparing a modified two-dimensional material MXenes titanium carbide, which can solve the problems of high cost, accelerated oxygen reduction, and unrealistic large-scale commercial production of catalysts, and achieves good catalytic structure. , good dispersion, the effect of promoting rapid diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

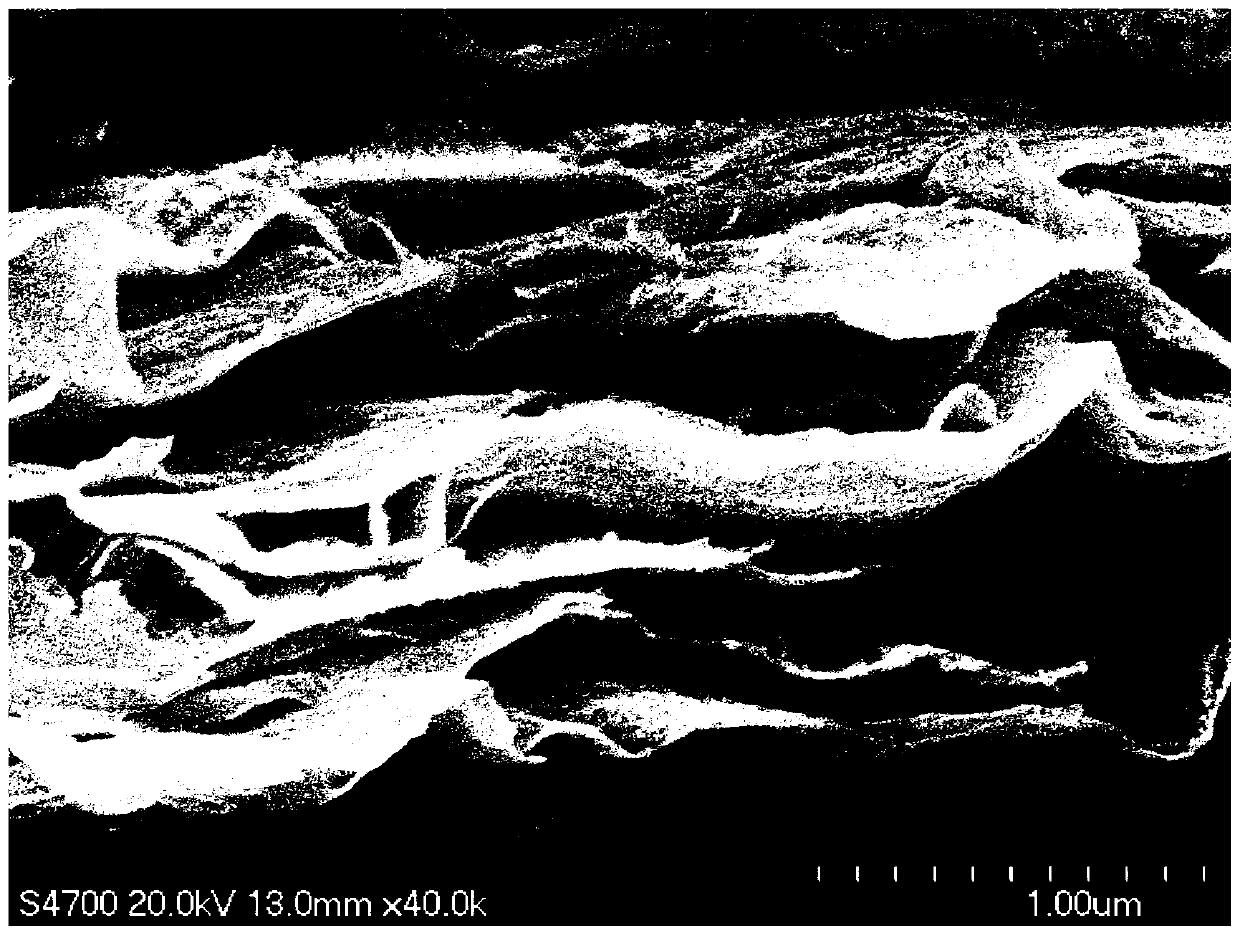

[0025] Preparation of MXenes. 1g lithium fluoride and 9M 20mL hydrochloric acid were stirred in a tetrafluoroethylene beaker for 30min. Slowly add 1gMAX-Ti 3 AlC 2 , Stirring was continued at 35°C for 24h. Centrifuge repeatedly with deionized water at a speed of 3500 rpm until the pH reaches neutral. The lower precipitate was collected, filtered and dried.

[0026] Preparation of MXene / ZIF. Weigh 10 mg of MXene and add it to 30 mL of DMSO for ultrasonic dispersion, dissolve 2 mM cobalt nitrate in the DMSO dispersion of MXene, then add 10 mM dimethylimidazole to the above solution, collect the product by centrifugation, and wash with methanol and deionized water Three times, vacuum dry.

[0027] Dissolve the MXene / ZIF obtained above in methanol solution, add hexachlorocyclotriphosphazene and 4,4-p-dihydroxydiphenyl sulfone at a molar ratio of 1:1, add triethylamine dropwise, and stir for 18 hours. Get MXene / ZIF / PZS.

[0028] The MXene / ZIF / PZS was raised to 700 °C at a r...

Embodiment 2

[0030] Preparation of MXenes. 1g lithium fluoride and 9M 20mL hydrochloric acid were stirred in a tetrafluoroethylene beaker for 30min. Slowly add 1gMAX-Ti 3 AlC 2 , Stirring was continued at 35°C for 24h. Centrifuge repeatedly with deionized water at a speed of 3500 rpm until the pH reaches neutral. The lower precipitate was collected, filtered and dried.

[0031] Preparation of MXene / ZIF. Weigh 20mg of MXene and add it to 30mL of DMSO for ultrasonic dispersion, dissolve 2mM cobalt nitrate in the DMSO dispersion of MXene, then add 10mM dimethylimidazole to the above solution, collect the product by centrifugation, wash with methanol and deionized water Three times, vacuum dry.

[0032] Dissolve the MXene / ZIF obtained above in methanol solution, add hexachlorocyclotriphosphazene and 4,4-p-dihydroxydiphenyl sulfone at a molar ratio of 1:1, add triethylamine dropwise, and stir for 18 hours. Get MXene / ZIF / PZS.

[0033] The MXene / ZIF / PZS was raised to 700 °C at a rate of 5...

Embodiment 3

[0035] Preparation of MXenes. 1g lithium fluoride and 9M 20mL hydrochloric acid were stirred in a tetrafluoroethylene beaker for 30min. Slowly add 1gMAX-Ti 3 AlC 2 , Stirring was continued at 35°C for 24h. Centrifuge repeatedly with deionized water at a speed of 3500 rpm until the pH reaches neutral. The lower precipitate was collected, filtered and dried.

[0036]Preparation of MXene / ZIF. Weigh 30mg of MXene and add it to 30mL of DMSO for ultrasonic dispersion, dissolve 2mM cobalt nitrate in the DMSO dispersion of MXene, then add 10mM dimethylimidazole to the above solution, collect the product by centrifugation, wash with methanol and deionized water Three times, vacuum dry.

[0037] Dissolve the MXene / ZIF obtained above in methanol solution, add hexachlorocyclotriphosphazene and 4,4-p-dihydroxydiphenyl sulfone at a molar ratio of 1:1, add triethylamine dropwise, and stir for 18 hours. Get MXene / ZIF / PZS.

[0038] The MXene / ZIF / PZS was raised to 700 °C at a rate of 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com