Motor assembly, exhaust assembly and exhaust method of dust collector, and dust collector

A technology for motor components and vacuum cleaners, which is applied in the installation of vacuum cleaners, exhaust diffusers, motor fan components, etc. It can solve the problems of affecting the heat dissipation of motors, increasing the consumption of consumables and processing costs, and the noise of vacuum cleaners, etc., to improve heat dissipation performance , Reduce the consumption of consumables, improve the effect of heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

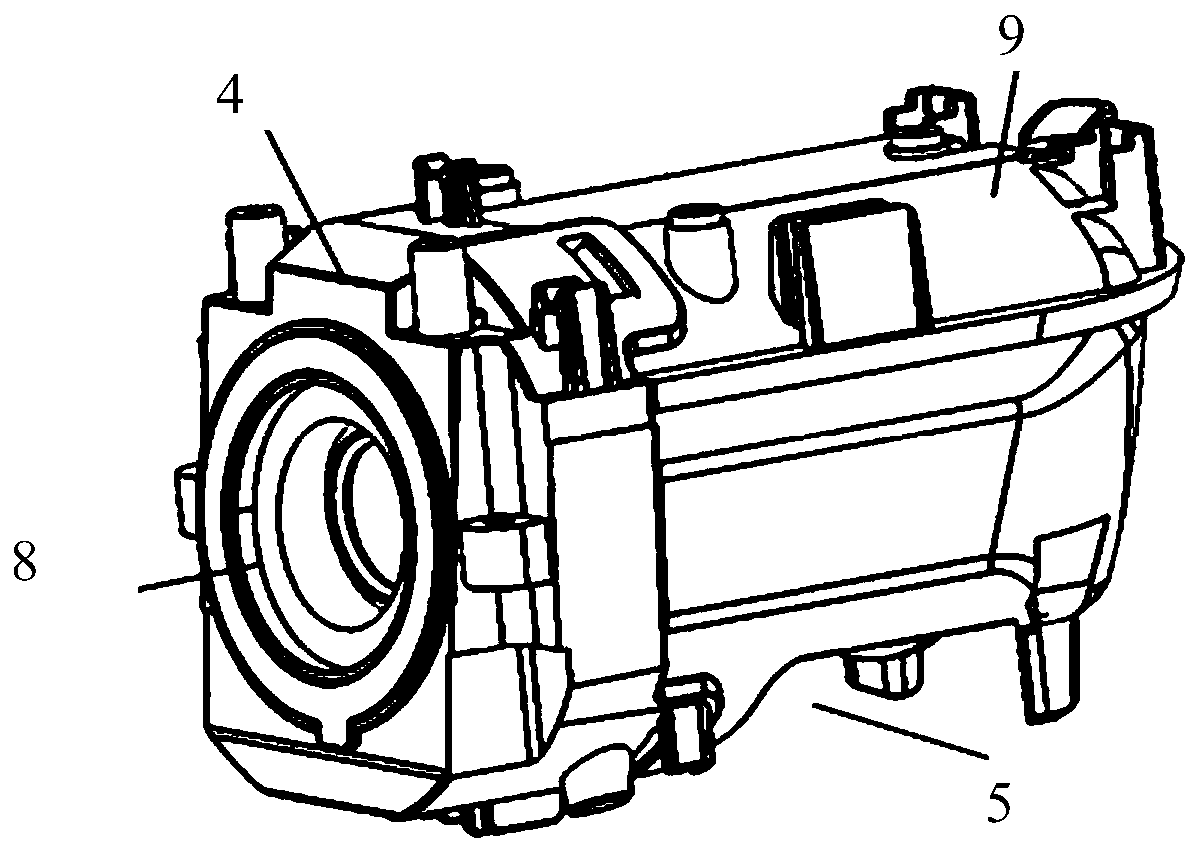

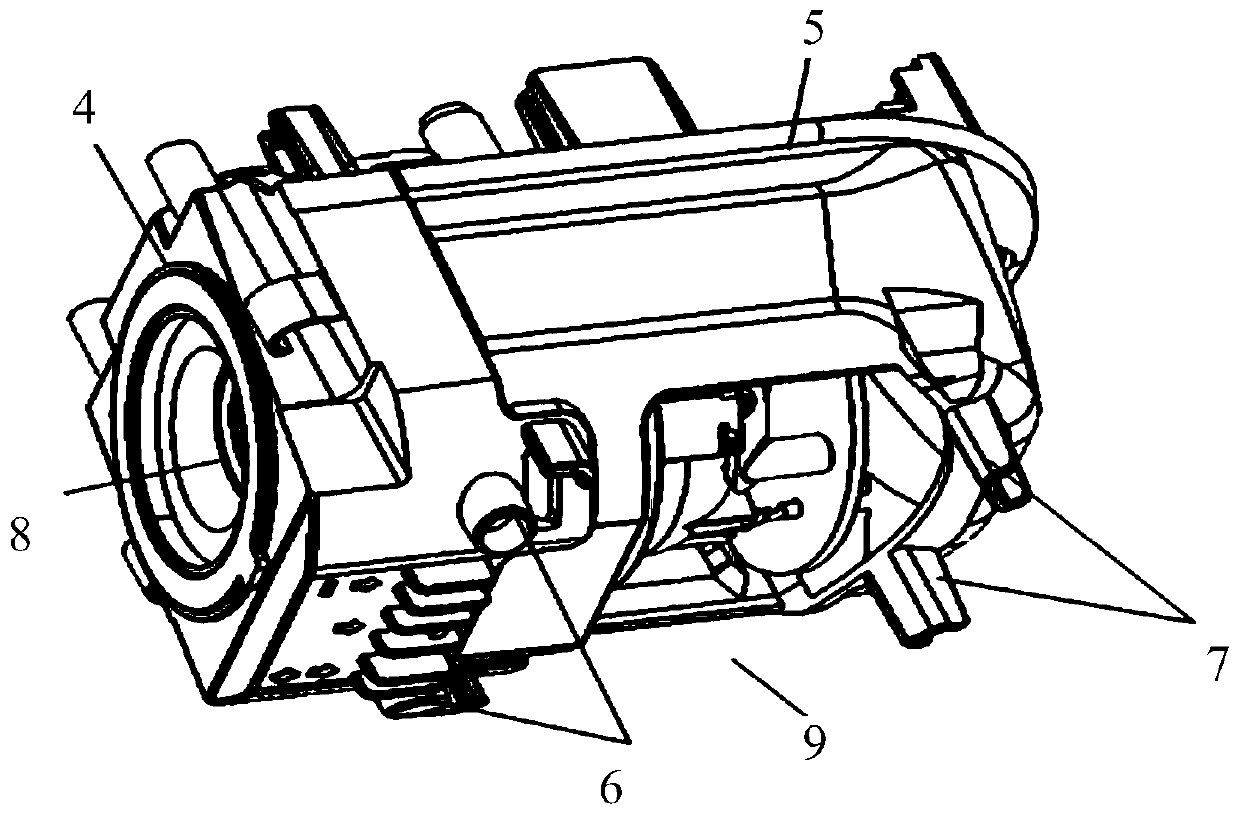

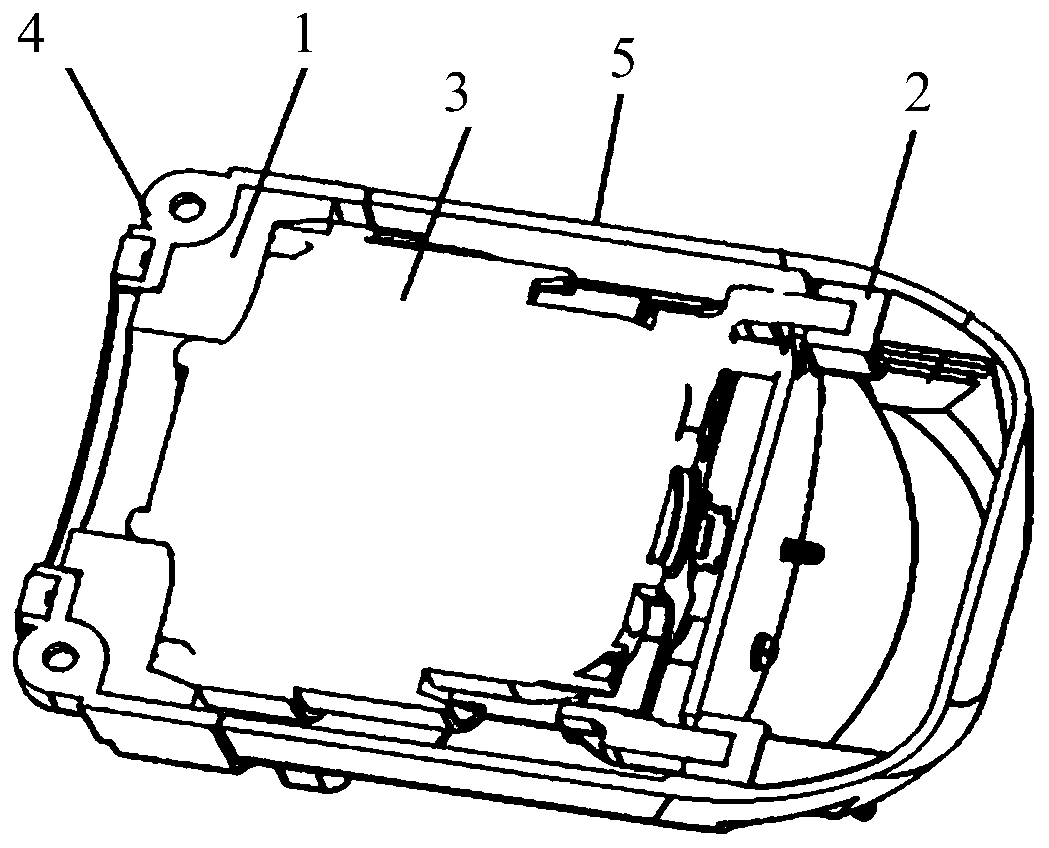

[0053] This embodiment provides a motor assembly, see Figure 1 to Figure 5, including a motor housing, a motor body 3 and a shock absorber assembly disposed in the motor housing, the shock absorber assembly is a split structure, including a shock absorber 1 at the air inlet end and a shock absorber 2 at the air outlet end. Wherein, the shock absorber 1 at the air inlet end is arranged between the air inlet end of the motor housing and the air inlet end of the motor body 3, the shock absorber 1 at the air inlet end is set on the outer wall of the air inlet end of the motor body 3, and the air inlet end is cushioned. The air inlet surface and the side surface of the vibration part 1 are respectively in contact with the inner wall of the motor housing, and the shock absorbing part 2 at the air outlet end is arranged between the air outlet end of the motor housing and the air outlet end of the motor body 3, and the air outlet end is cushioned Part 2 is sleeved on the outer wall o...

Embodiment 2

[0063] This embodiment provides a vacuum cleaner exhaust assembly, see Figure 6 , including the motor assembly provided in the first embodiment, the motor assembly is arranged above the handle 10 of the vacuum cleaner.

[0064] Compared with the prior art, the beneficial effects of the exhaust assembly of the vacuum cleaner provided in this embodiment are basically the same as those of the motor assembly provided in Embodiment 1, and will not be repeated here.

[0065] It can be understood that, in order to realize the exhaust function of the above-mentioned exhaust assembly, it may also include a main exhaust passage 11 , a main exhaust hole 12 , an auxiliary exhaust passage 13 and an auxiliary exhaust hole 14 . Wherein, the main exhaust duct 11 is arranged in the handle, and the main exhaust hole 12 is arranged at the bottom of the handle. One end of the main exhaust duct 11 is communicated with the air outlet of the motor housing, and the other end is communicated with the...

Embodiment 3

[0076] This embodiment provides a vacuum cleaner, see Figure 7 , along the intake direction of the vacuum cleaner, sequentially include the front-end unit and the exhaust assembly provided by the second embodiment.

[0077] Compared with the prior art, the beneficial effects of the vacuum cleaner provided by this embodiment are basically the same as those of the exhaust assembly provided by Embodiment 2, and will not be repeated here.

[0078] It can be understood that the above-mentioned vacuum cleaner can also include a hanger for the vacuum cleaner, see Figure 8 to Figure 9 , the vacuum cleaner hanger includes a body and a connector. The connector is set on the body and protrudes from the body to form a hanging structure. The base of the main unit of the vacuum cleaner is hung on the connector. The groove realizes the connection between the base and the hanger of the vacuum cleaner by placing the connecting piece in the connecting groove. The above-mentioned vacuum clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com