Planetary stirring device with stirring paddle capable of vertical reciprocating motion and method

A reciprocating motion and planetary stirring technology, which is applied to mixers with rotating stirring devices, transportation and packaging, chemical instruments and methods, etc., can solve the problems of unstable stirring devices, prone to periodic vibration, and low stirring efficiency. Achieve the effect of overcoming the instability of the stirring device, avoiding uneven stirring effect, and good stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

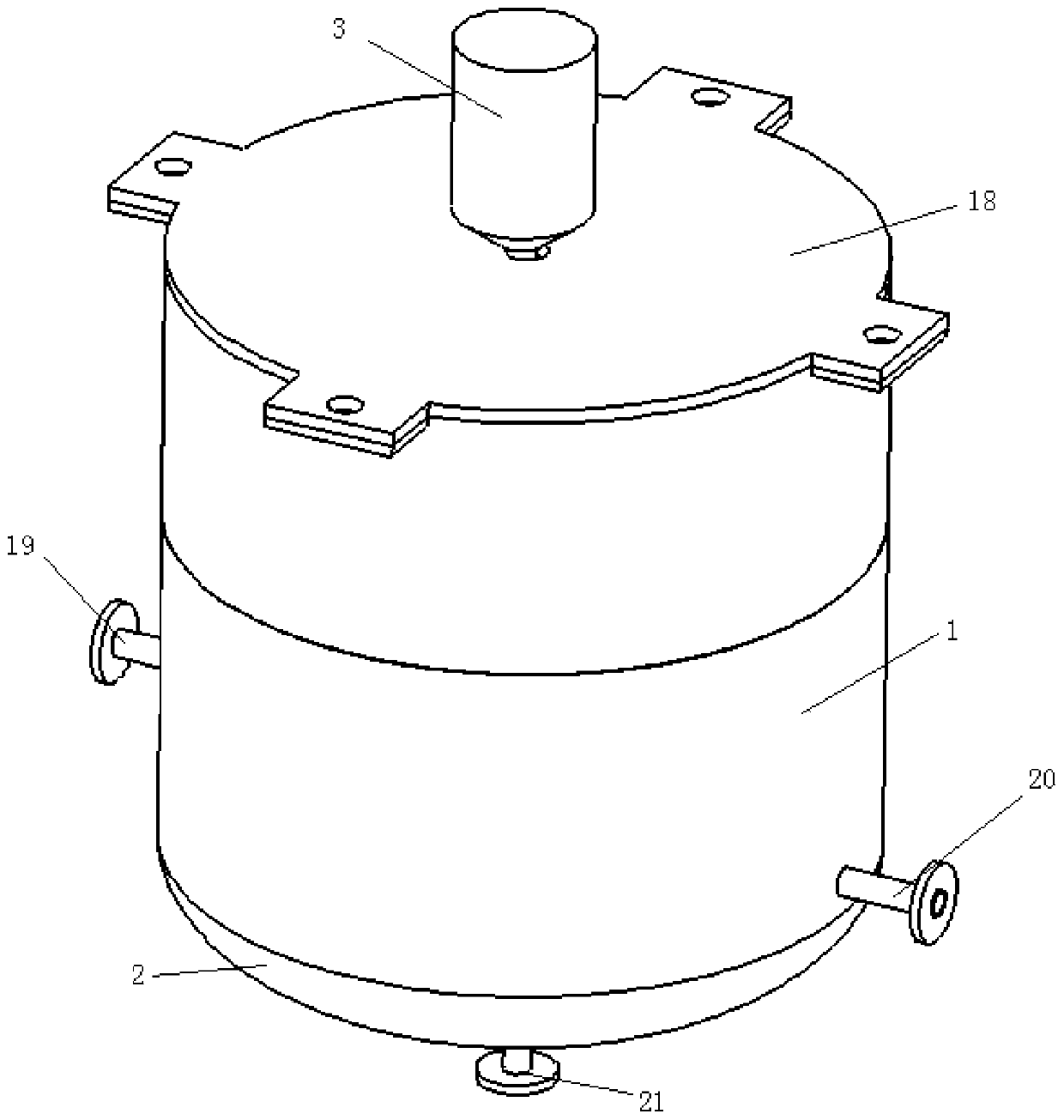

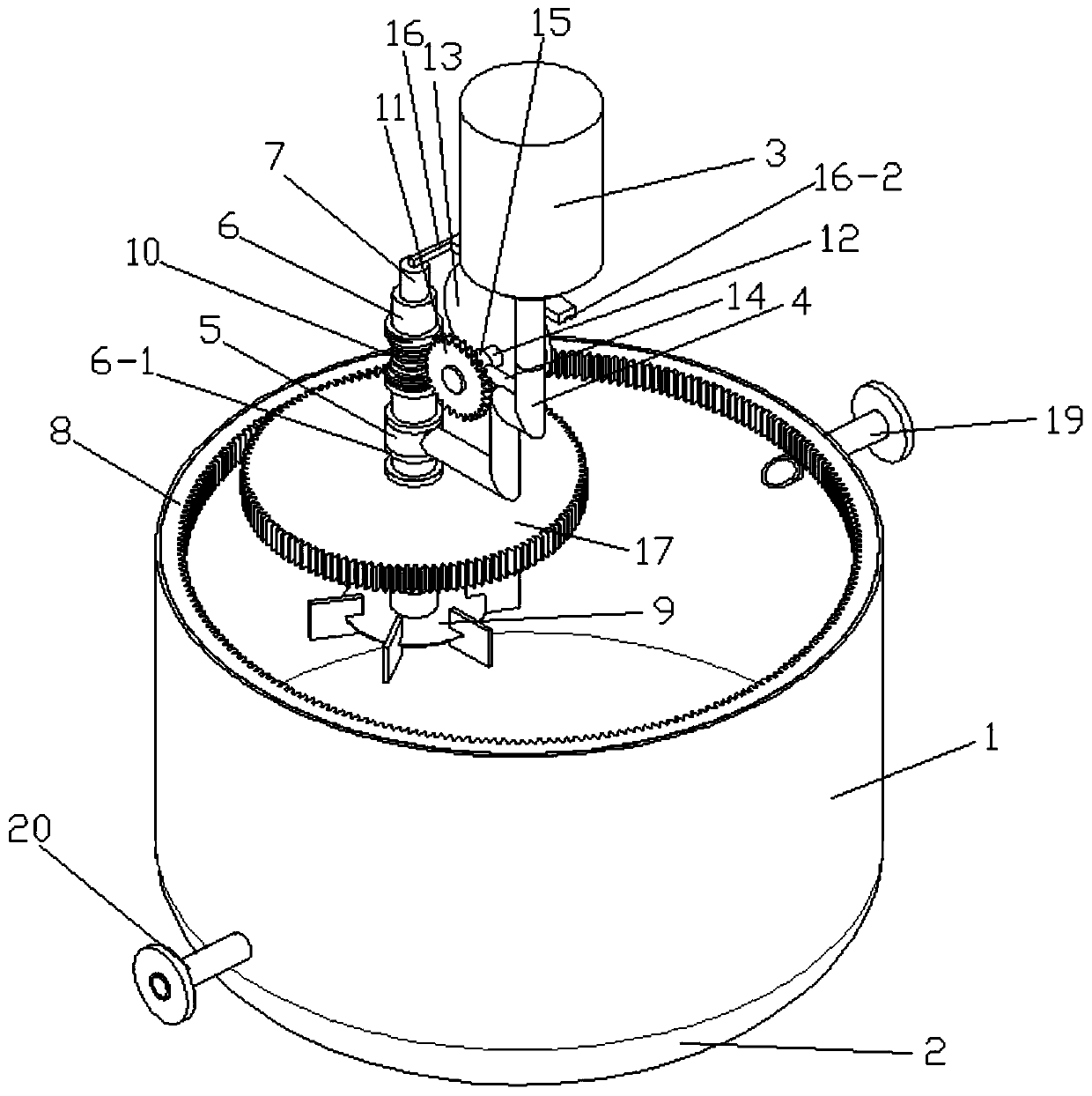

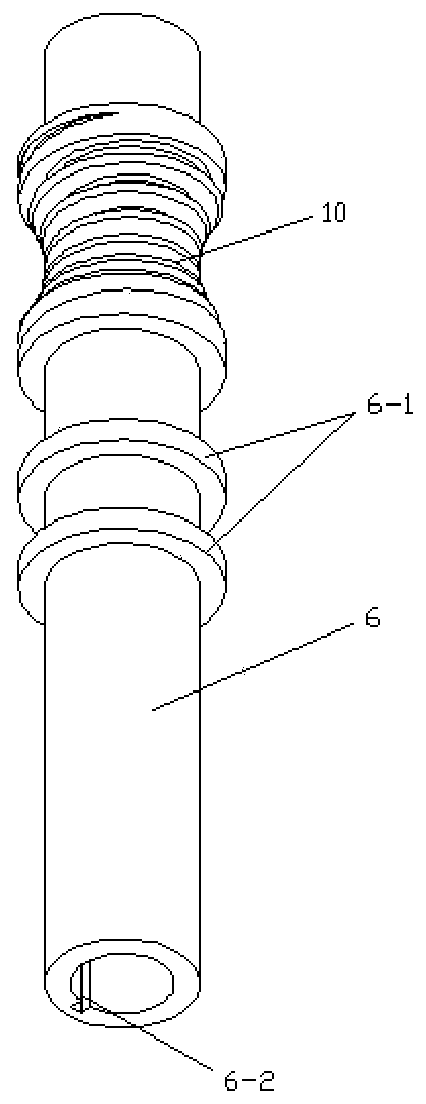

[0046] This embodiment discloses a working method of a planetary stirring device with vertical reciprocating motion of the stirring paddle: the staff injects materials into the barrel through the feeding pipe, the deceleration motor drives the rotating arm to rotate, and the stirring shaft assembly moves along the set circle. The track makes a revolution movement, and at the same time, under the meshing action of the gear and the inner ring gear, the stirring shaft assembly rotates around its own axis, the inner stirring shaft drives the stirring paddle to rotate, and the material is stirred, and the rotation of the outer stirring shaft can pass through the worm gear and the transmission shaft The cam is driven to rotate, and the cam is in contact with the top plate, which can drive the top plate to reciprocate in the vertical direction, thereby driving the inner stirring shaft and the stirring paddle to reciprocate in the vertical direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com