A textile printing machine

A technology of textile fabrics and printing machines, applied in printing, typewriters, printing devices, etc., can solve the problems of increasing printing difficulty, confusing printing patterns, affecting printing quality, etc., and achieve the effect of improving the effect and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0027] see Figure 1-Figure 10 , the specific embodiments of the present invention are as follows:

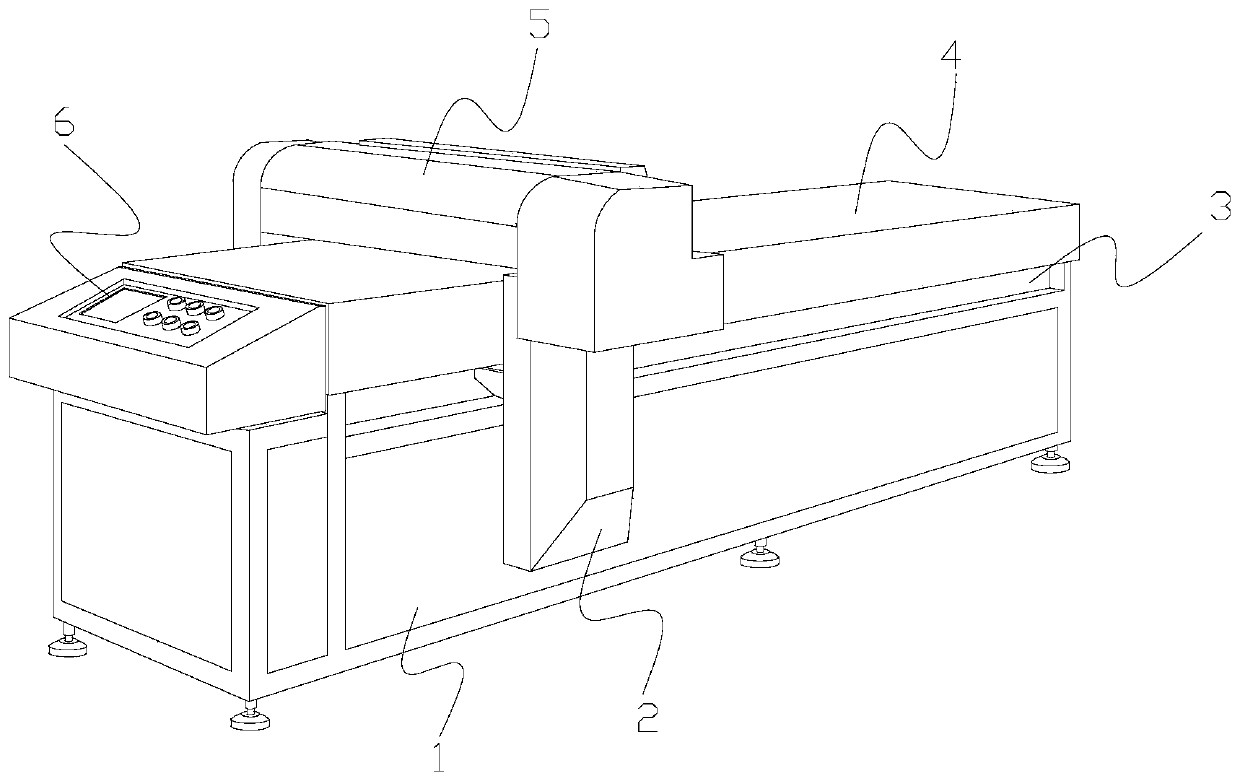

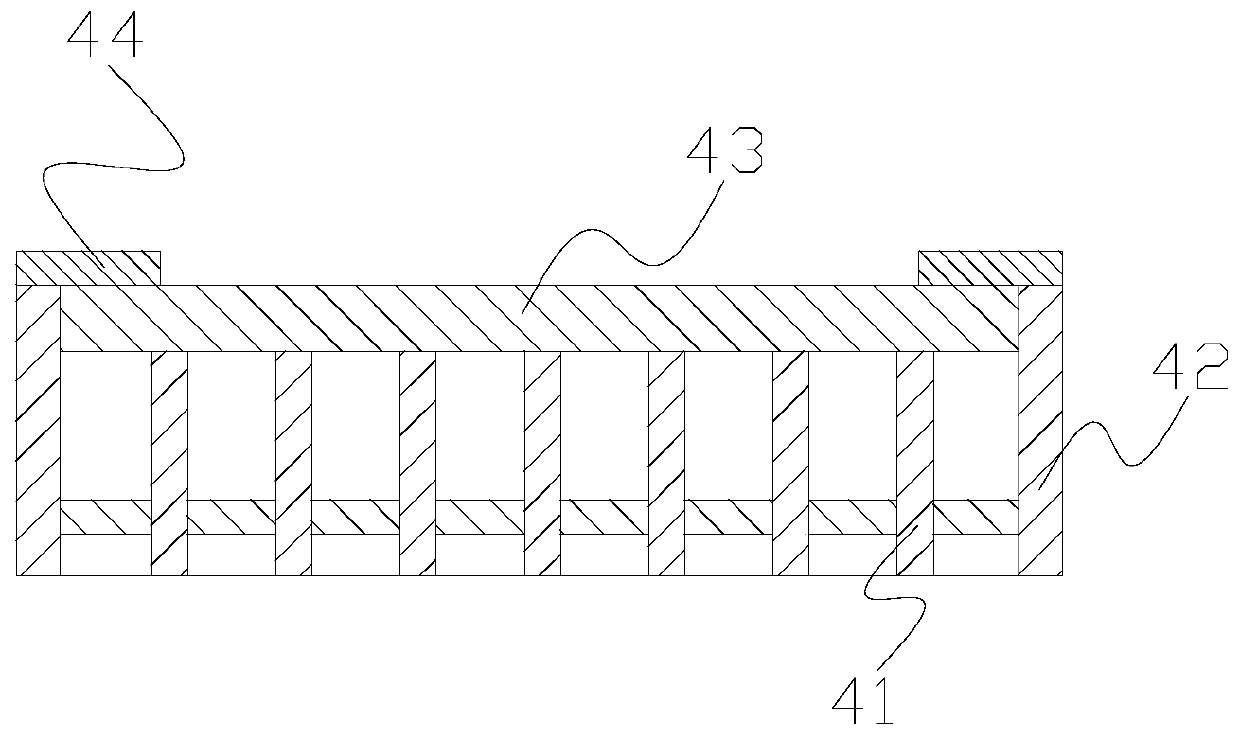

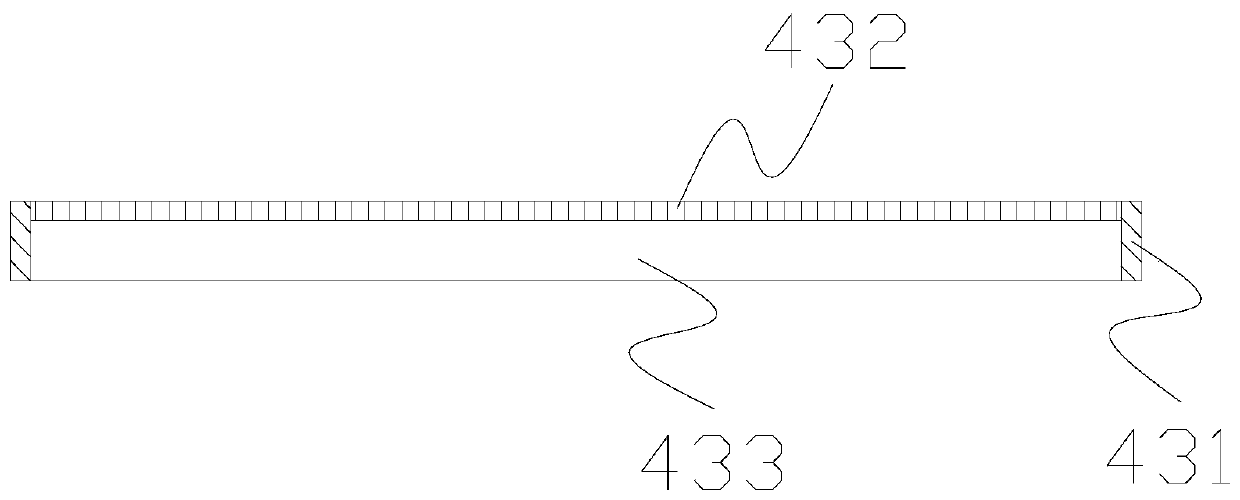

[0028] Its structure includes a chassis 1, a lateral movement box 2, a guide rail 3, a textile fabric paving structure 4, a printing chassis 5, and a control box 6. The guide rail 3 is embedded and installed at the upper end of the inner side of the chassis 1, and the lateral movement box 2 is arranged on the chassis. 1. The front and the back are movably connected with the guide rail 3. The textile fabric paving structure 4 is horizontally installed on the upper end of the cabinet 1. The printing cabinet 5 is located above the textile fabric paving structure 4 and is horizontally installed on the upper end of the laterally moving box 2. The control box 6 is installed on the upper end of the cabinet 1; the textile fabric paving structure 4 includes a support 41, a side plate 42, a placement structure 43, and a side paving mechanism 44, and the side plate 42 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com