Patents

Literature

32results about How to "Location effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

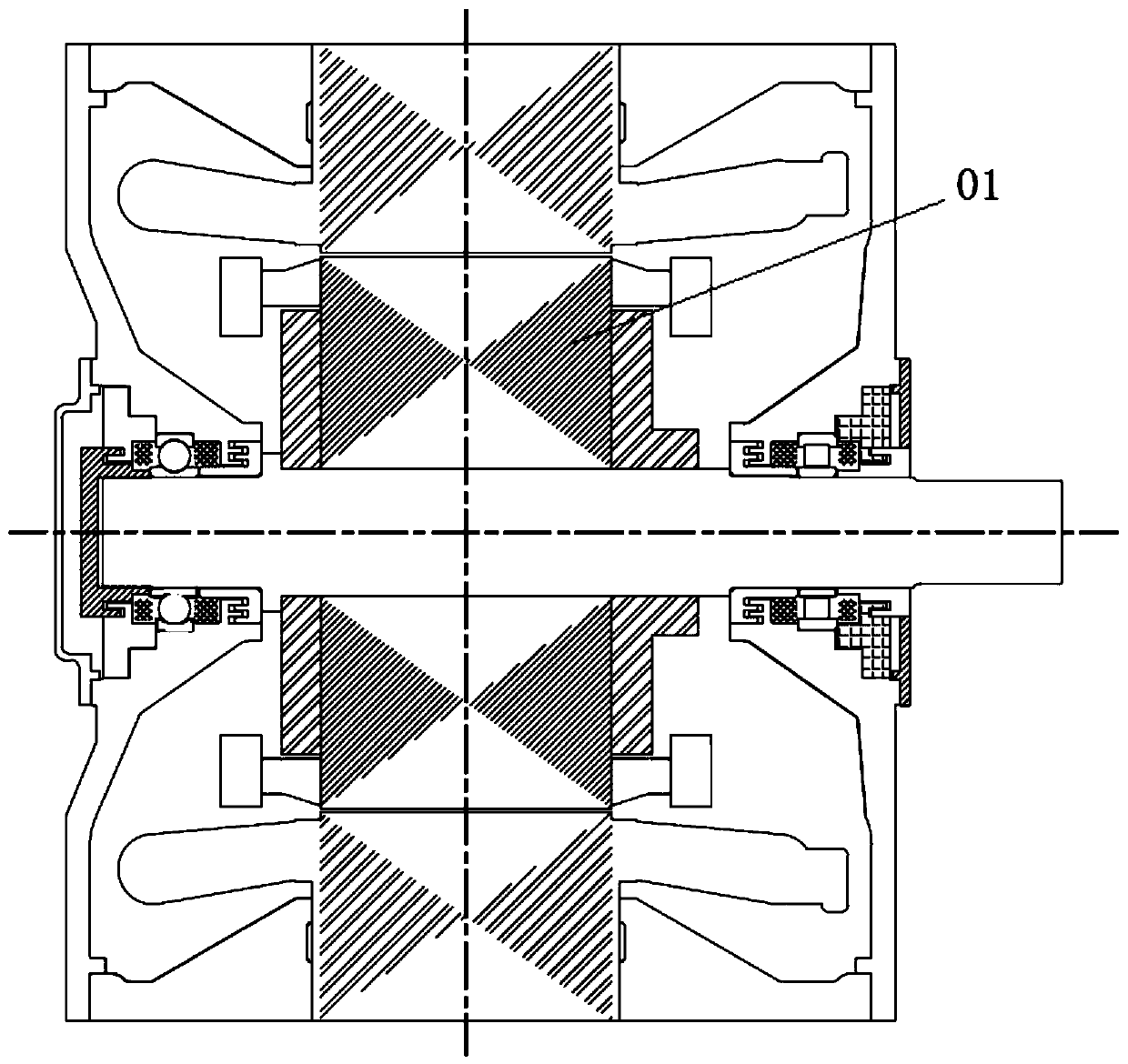

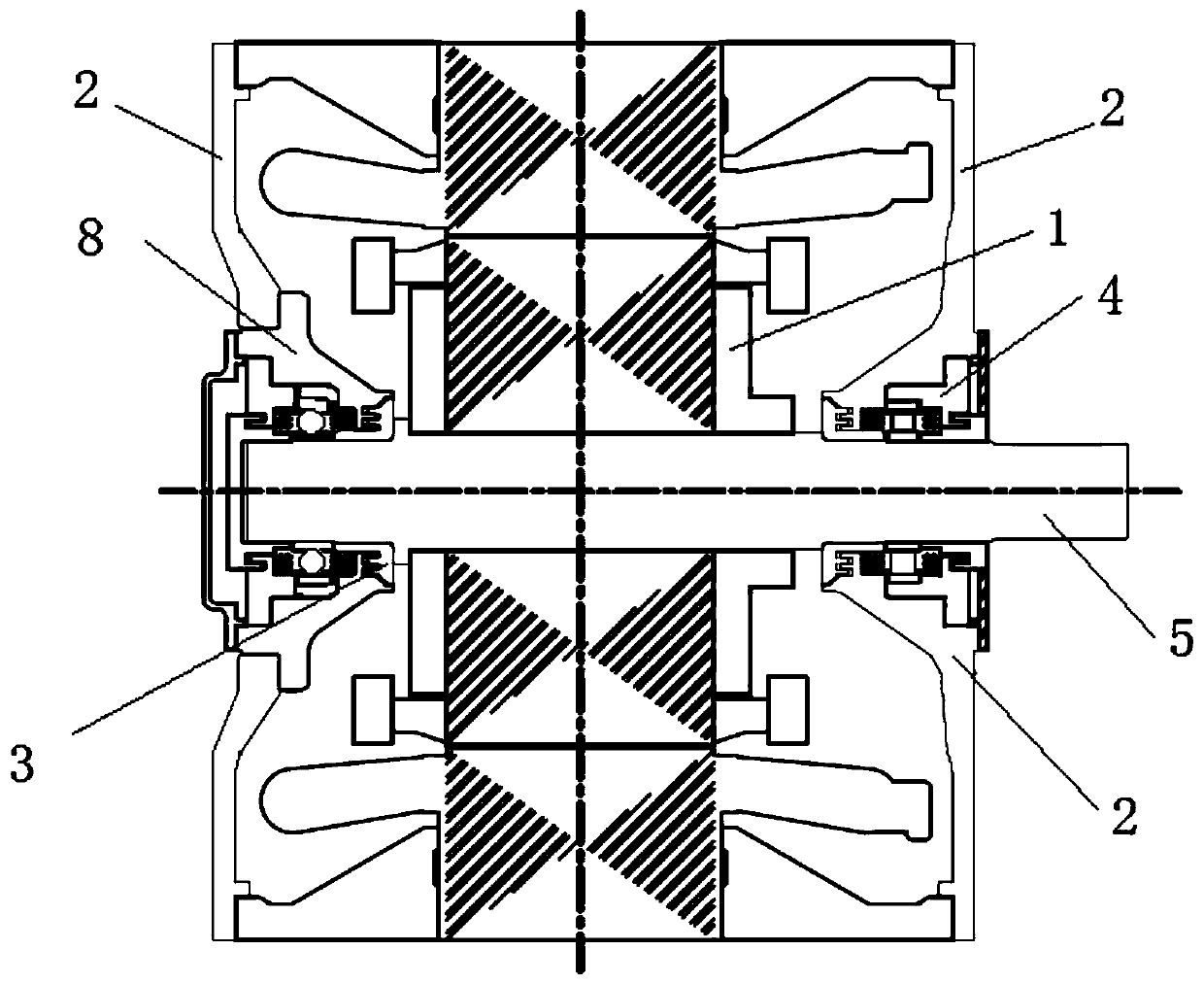

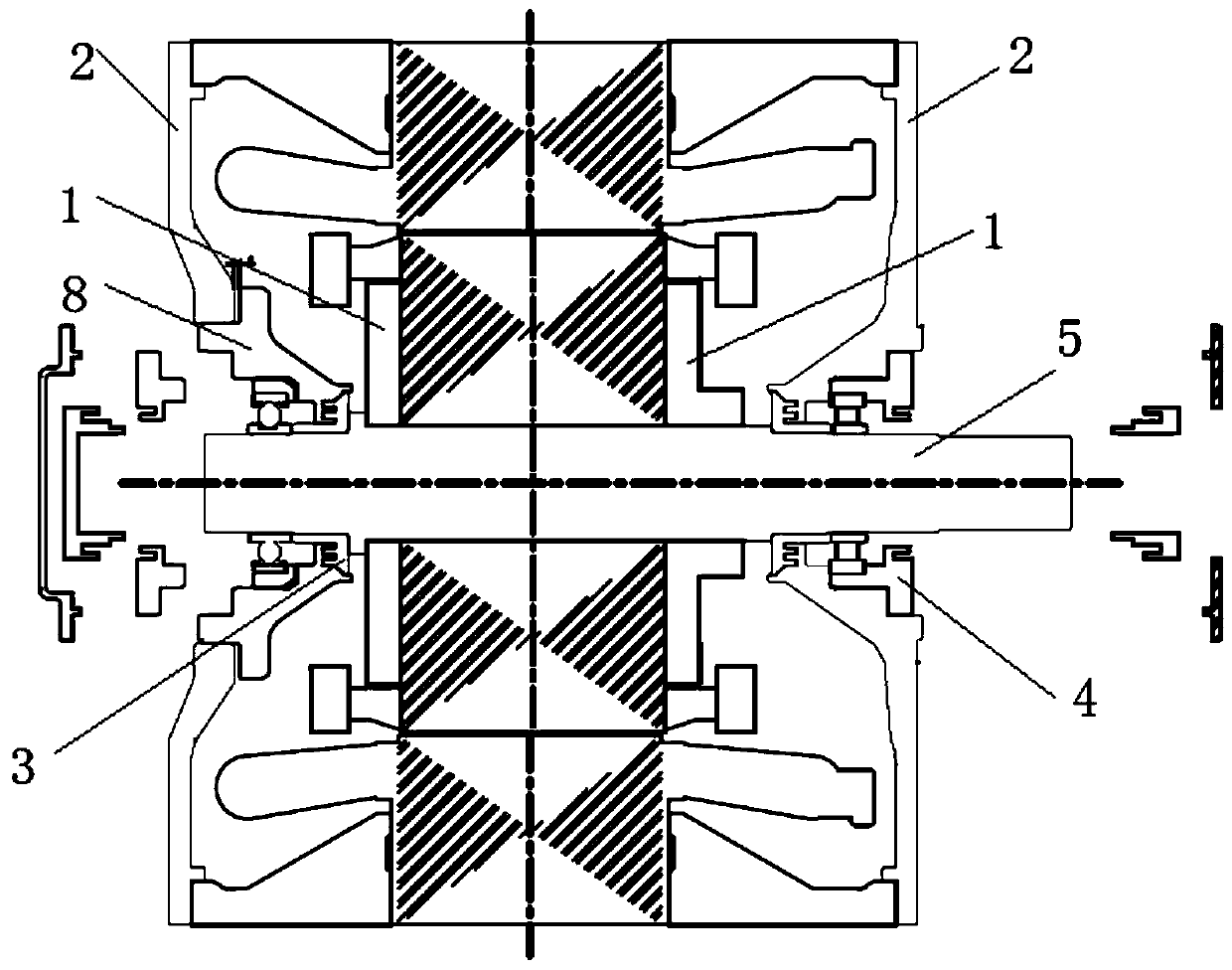

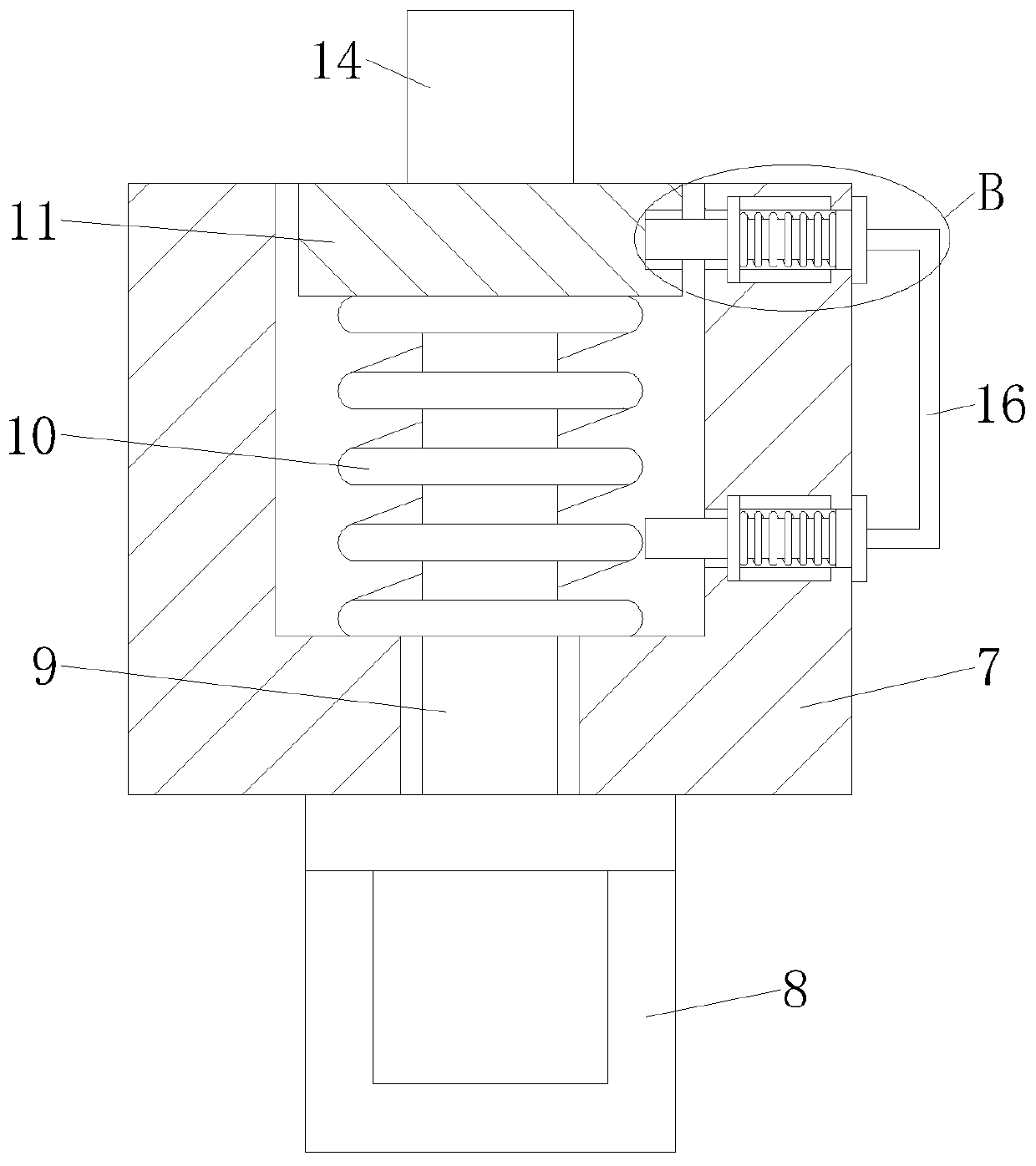

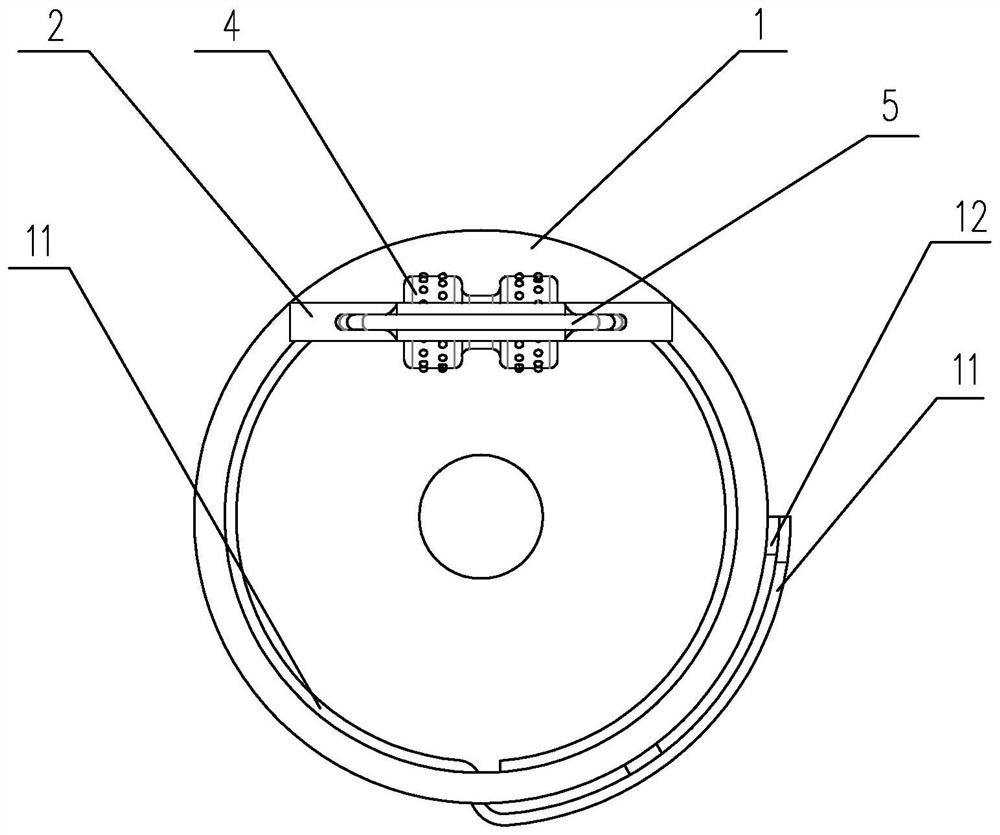

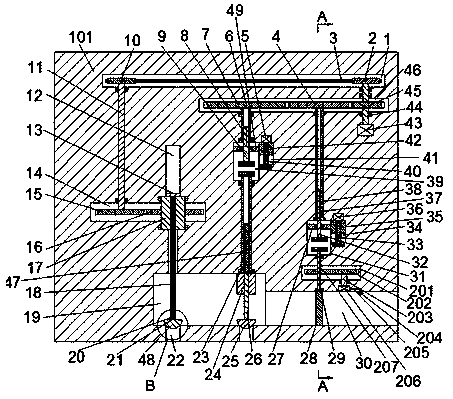

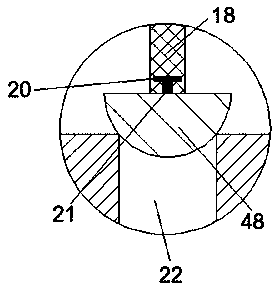

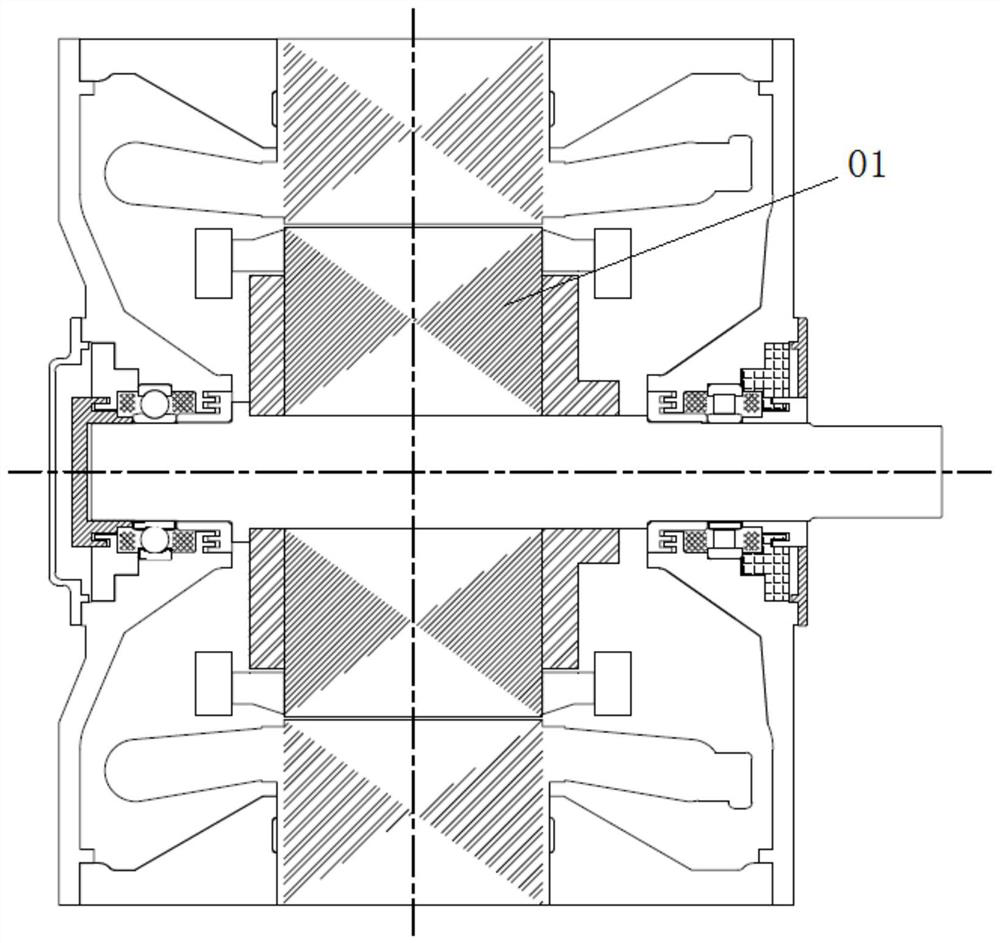

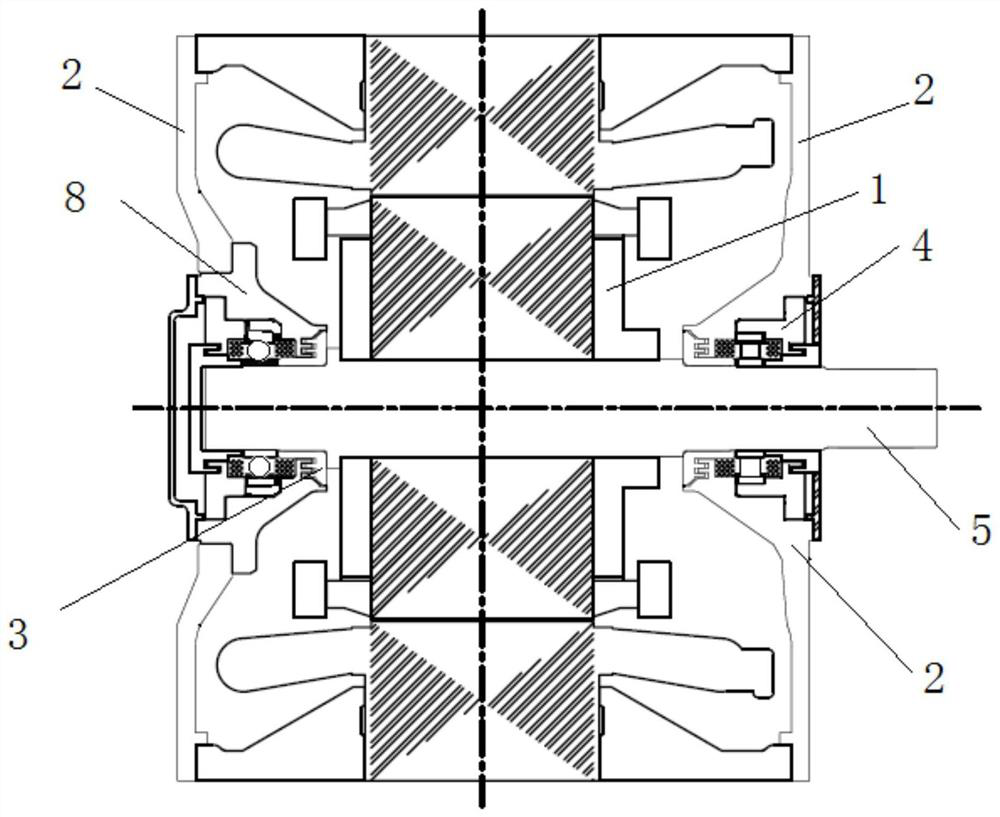

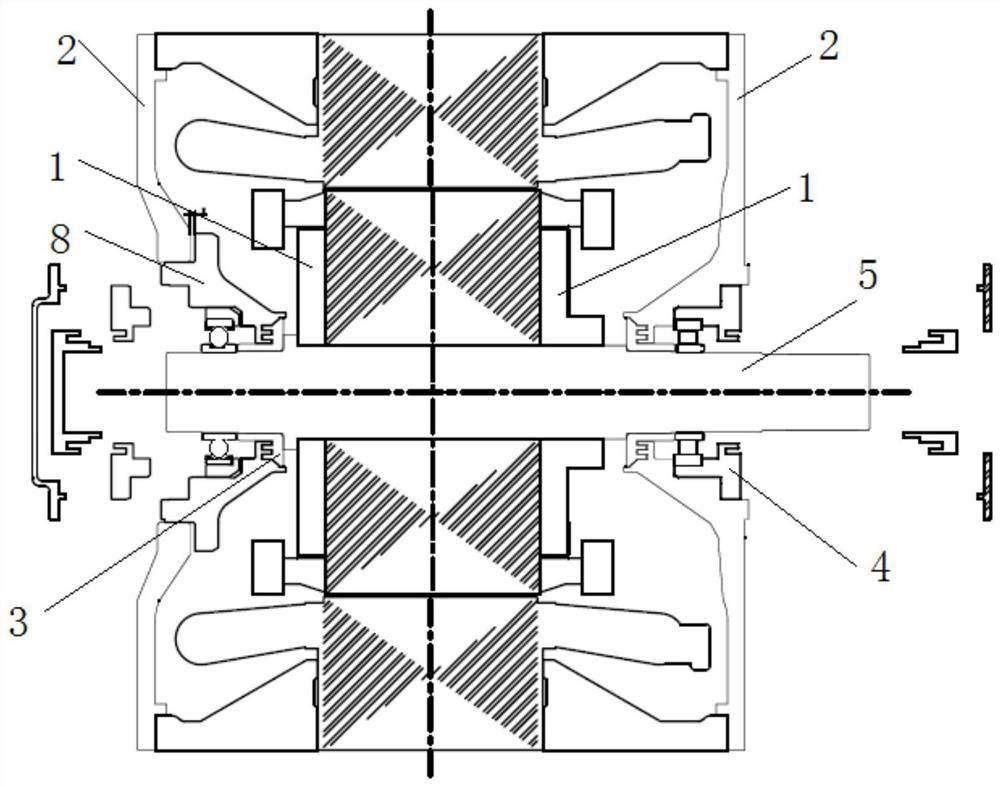

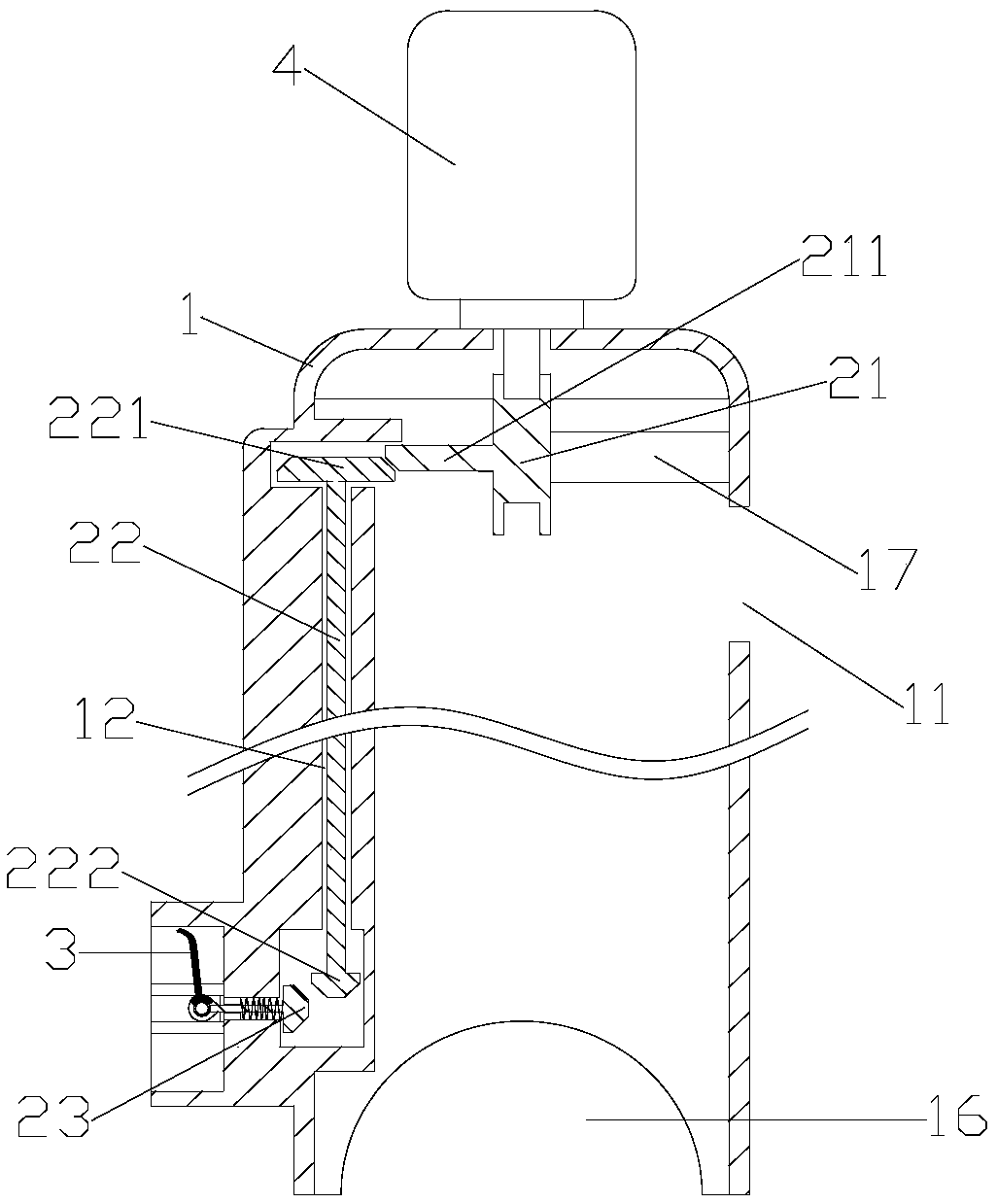

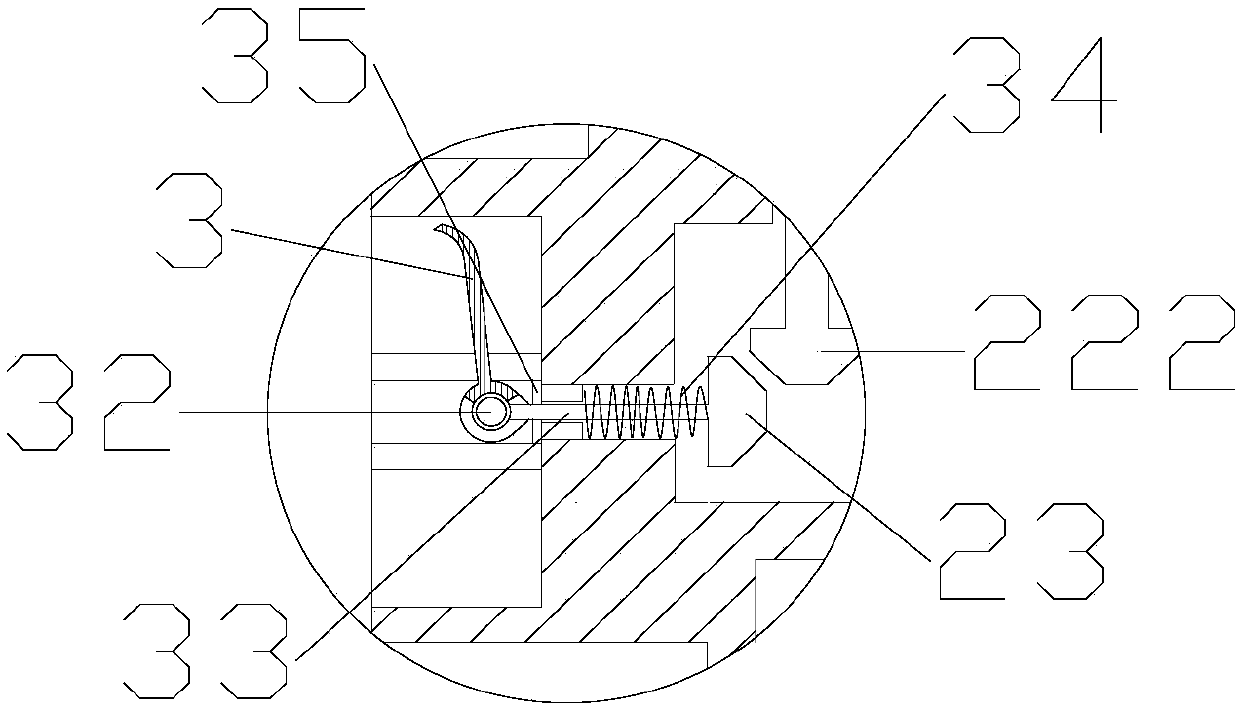

Dismounting device of traction motor bearing and method applied to device

ActiveCN110829746ASave disassembly timeAvoid disassemblyRoller bearingsShaftsControl engineeringElectric machinery

The invention discloses a dismounting device of a traction motor bearing, which comprises a positioning mechanism fixedly arranged on a rotor assembly and a moving mechanism movably arranged relativeto the positioning mechanism, wherein the positioning mechanism is provided with a positioning surface, and the moving mechanism is provided with a matching surface which is used for matching with thepositioning surface to realize radial and axial positioning of the rotor assembly. Compared with the prior art, the dismounting device provided by the invention of the traction motor bearing avoids the bearing dismounting process after the rotor assembly and the stator assembly are separated, so that the dismounting process of the traction motor bearing is simplified, the configuration requirements and cost of human resources and material resources in the bearing dismounting process are reduced, the dismounting time of the traction motor bearing is shortened, and the working efficiency is improved. The invention further discloses a dismounting method of the traction motor bearing, which is applied to the dismounting device of the traction motor bearing.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

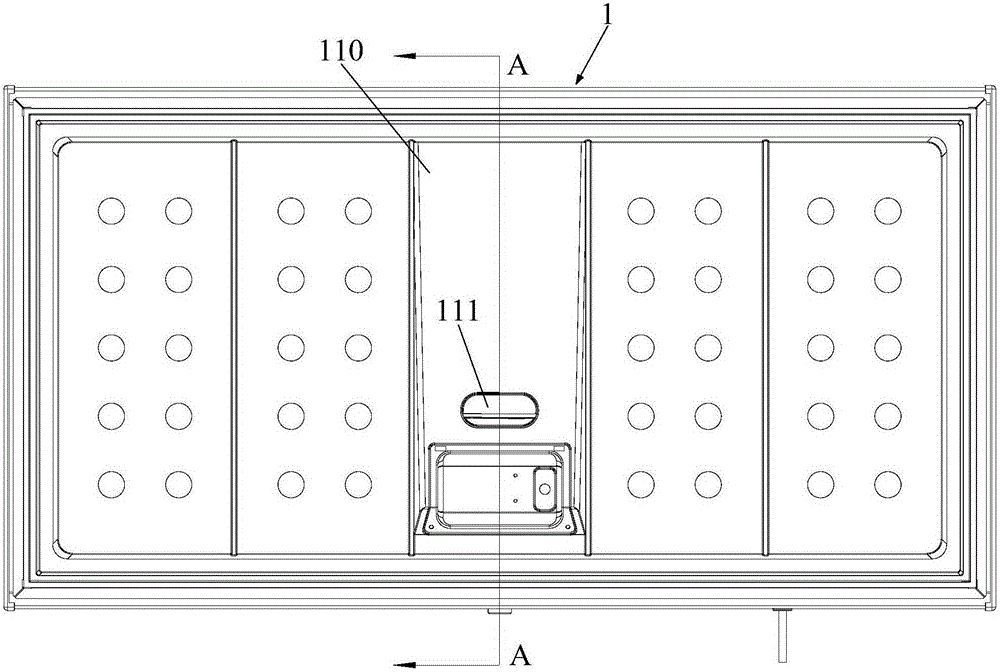

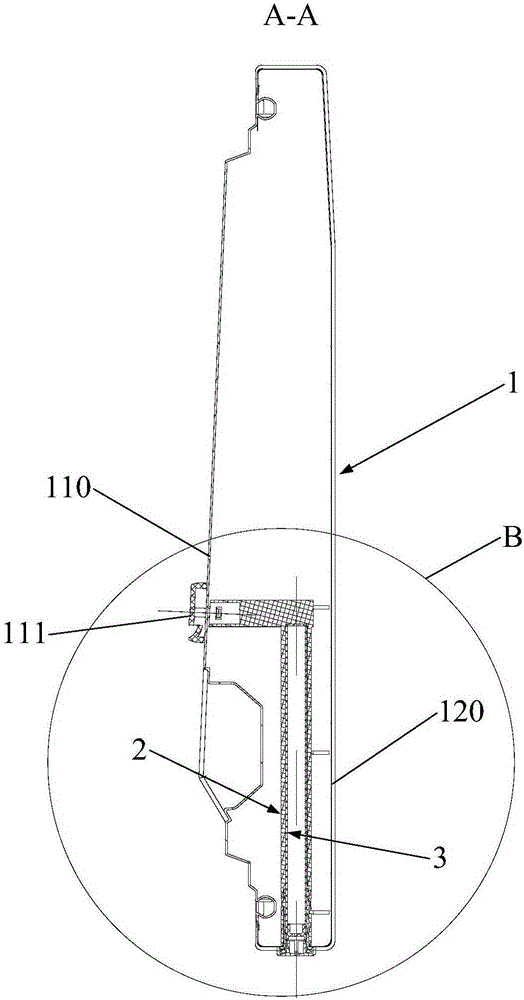

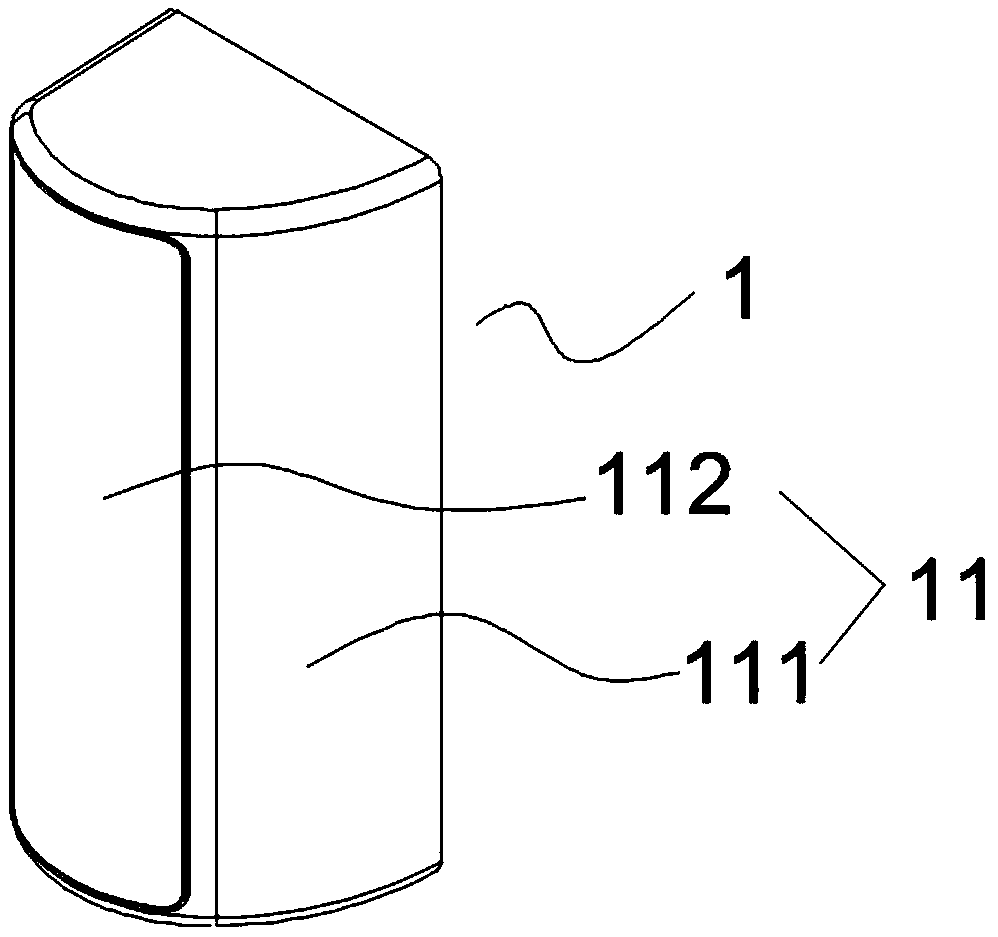

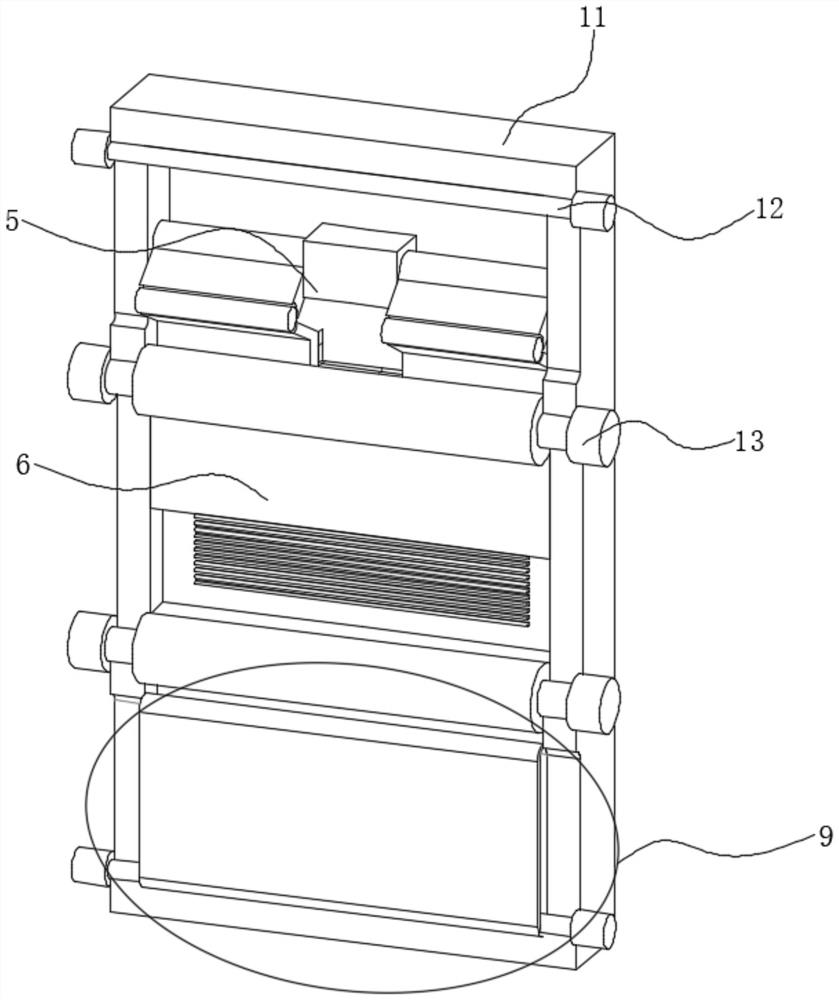

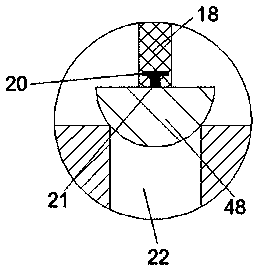

Ventilated frost reduction device, door body and freezer with door body

InactiveCN105157321AReduce the amount of frostingReduce energy consumptionLighting and heating apparatusDefrostingMolecular sieveFrost

The invention provides a ventilated frost reduction device, a door body and a freezer. The freezer comprises the door body. The ventilated frost reduction device comprises an embedded piece and a molecular sieve assembly. The embedded piece is arranged in the door body and has a first end and a second end; the first end and the second end are communicated; and when the door body is closed, the first end is communicated with the external environment, and the second end is communicated with the interior of the freezer. The molecular sieve assembly is detachably assembled in the embedded piece and used for ventilation and gas filtration. The door body is provided with the ventilated frost reduction device, and the freezer comprises the door body. The ventilated frost reduction device is easy to install in production, productivity can be improved, a filter substance and a drying agent can be replaced, and the excellent performance of the freezer can be kept all the time.

Owner:HEFEI HUALING CO LTD +1

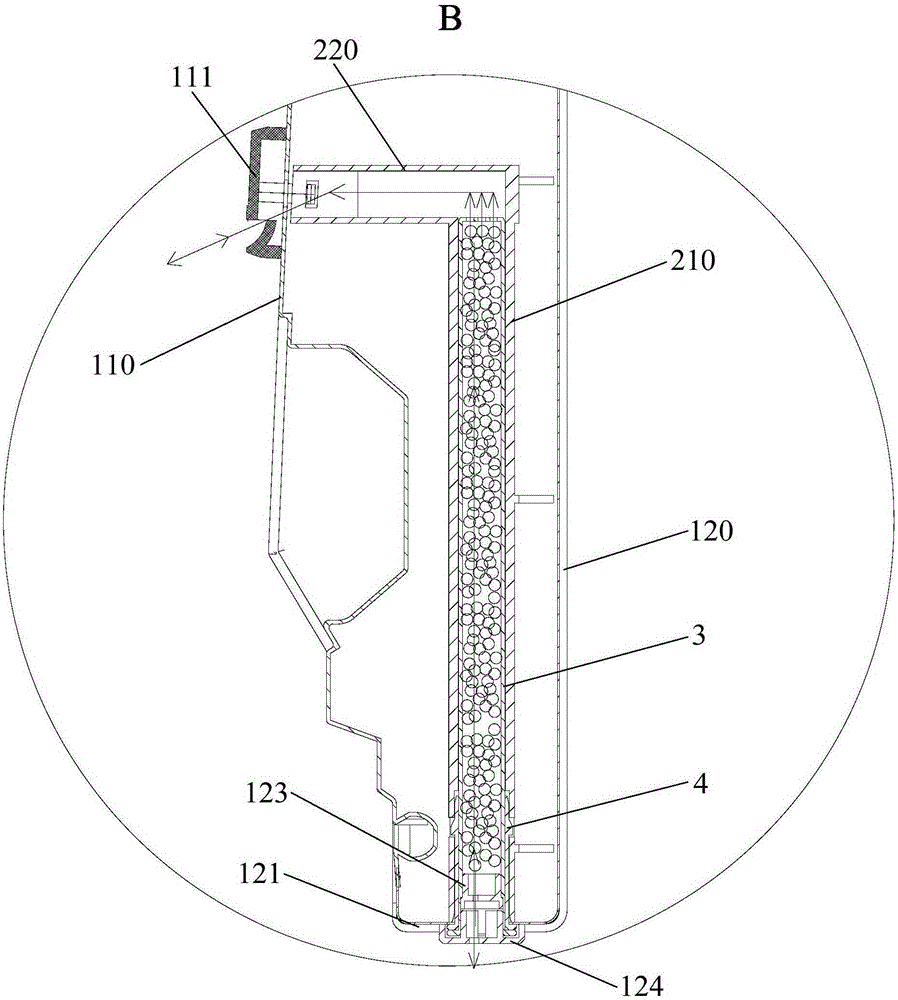

Discharging mechanism of extrusion molding mold for plastic production

The invention discloses a discharging mechanism of an extrusion molding mold for plastic production. The discharging mechanism comprises an extrusion molding mold body. An extrusion head body is arranged at the right side of the extrusion molding mold body. A first connecting sleeve sleeves the left side of the extrusion head body. By arranging the extrusion molding mold body, the extrusion head body, the first connecting sleeve, a first clamping groove, a second connecting sleeve, a first clamping block, a shell, a pull ring, a fixing rod, a first spring, a connecting plate, a stabilizing mechanism, a limiting groove, a second clamping block, a second clamping groove, a handle, a fixing handle, a fixing plate, a groove, a connecting rod and a movable sleeve, the problems that an existingdischarging mechanism of the extrusion molding mold for plastic production is not convenient to assemble or disassemble, a large amount of time and essence of a user can be consumed in the assemblingand disassembling process, the working efficiency of the user is affected, no supporting effect is achieved, a machined plastic product cannot be supported, and therefore the quality of the machined plastic product is affected, and inconvenience is brought to the user are solved.

Owner:张丽

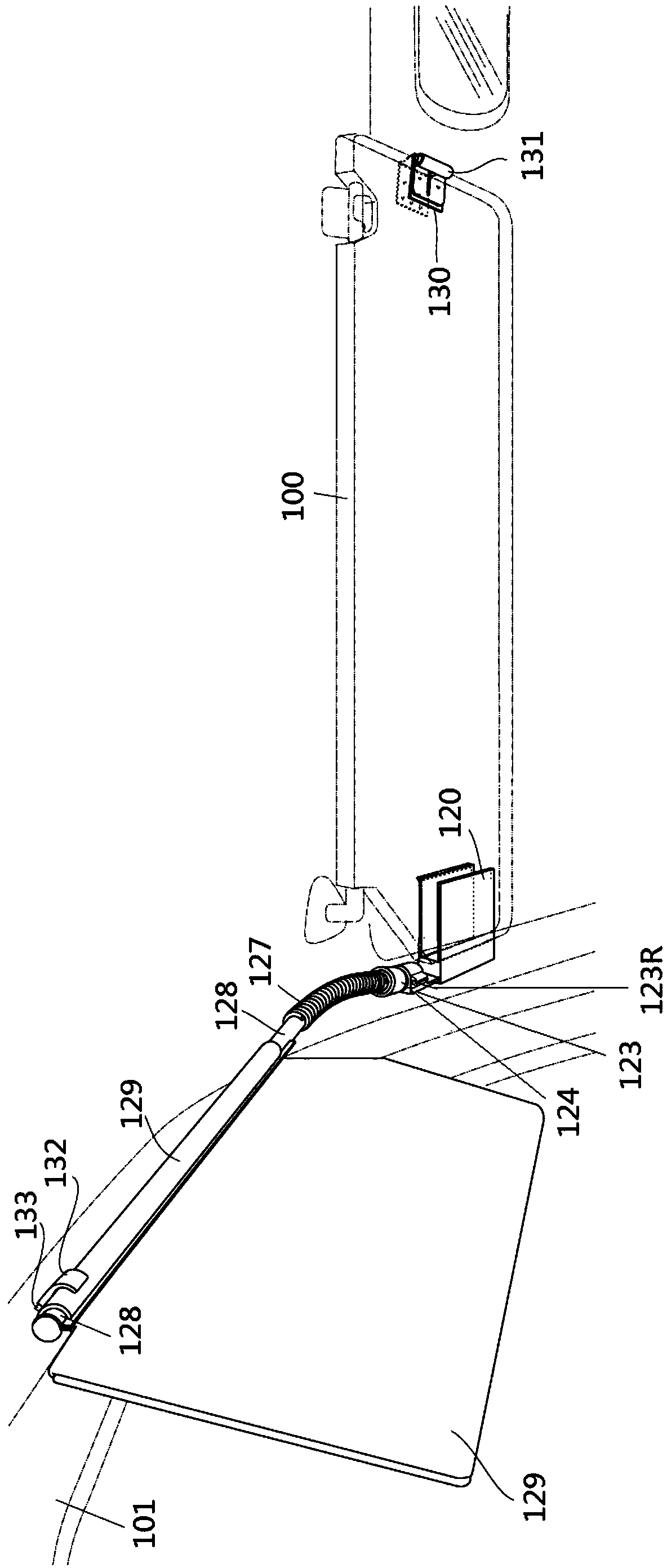

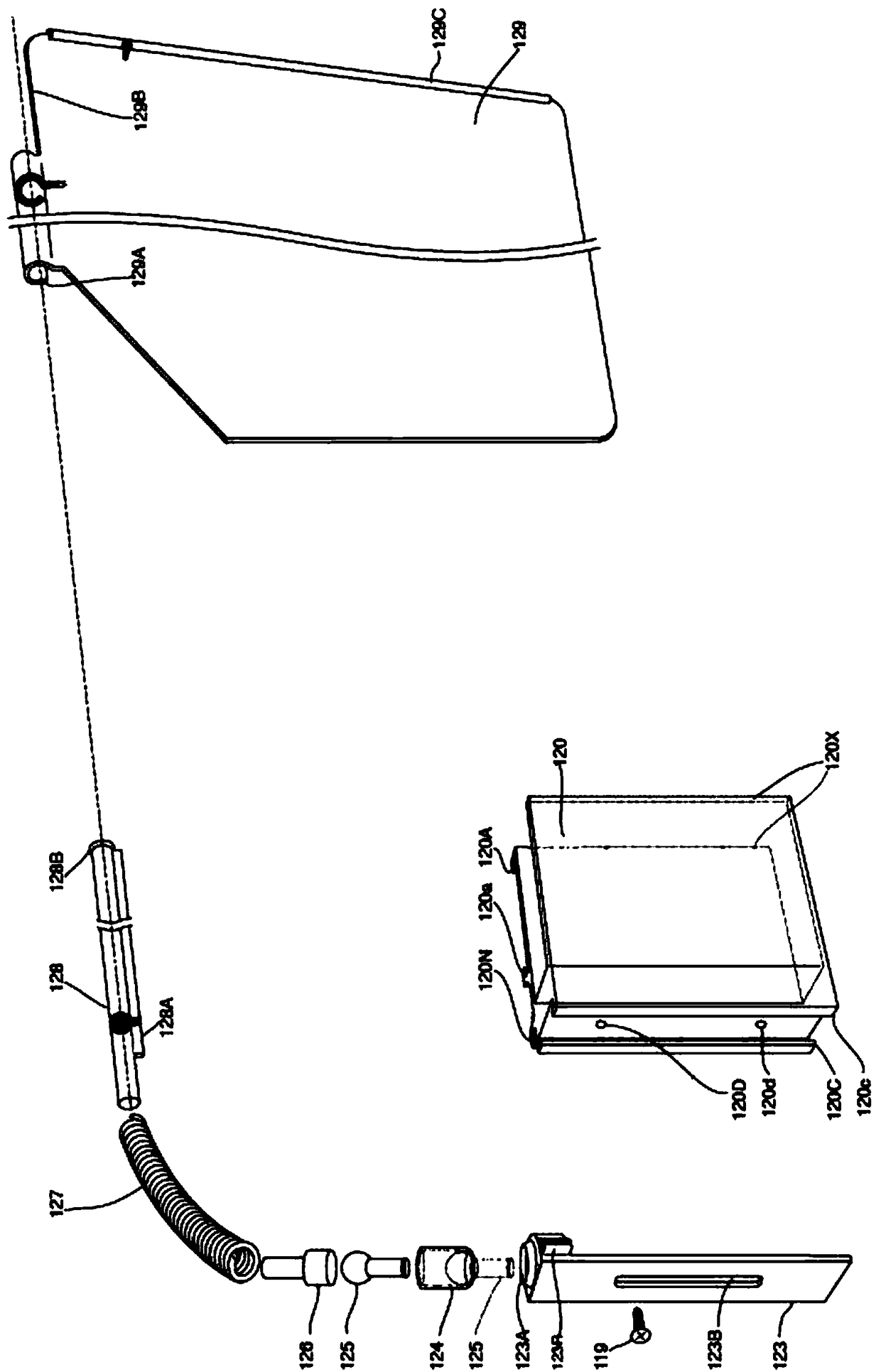

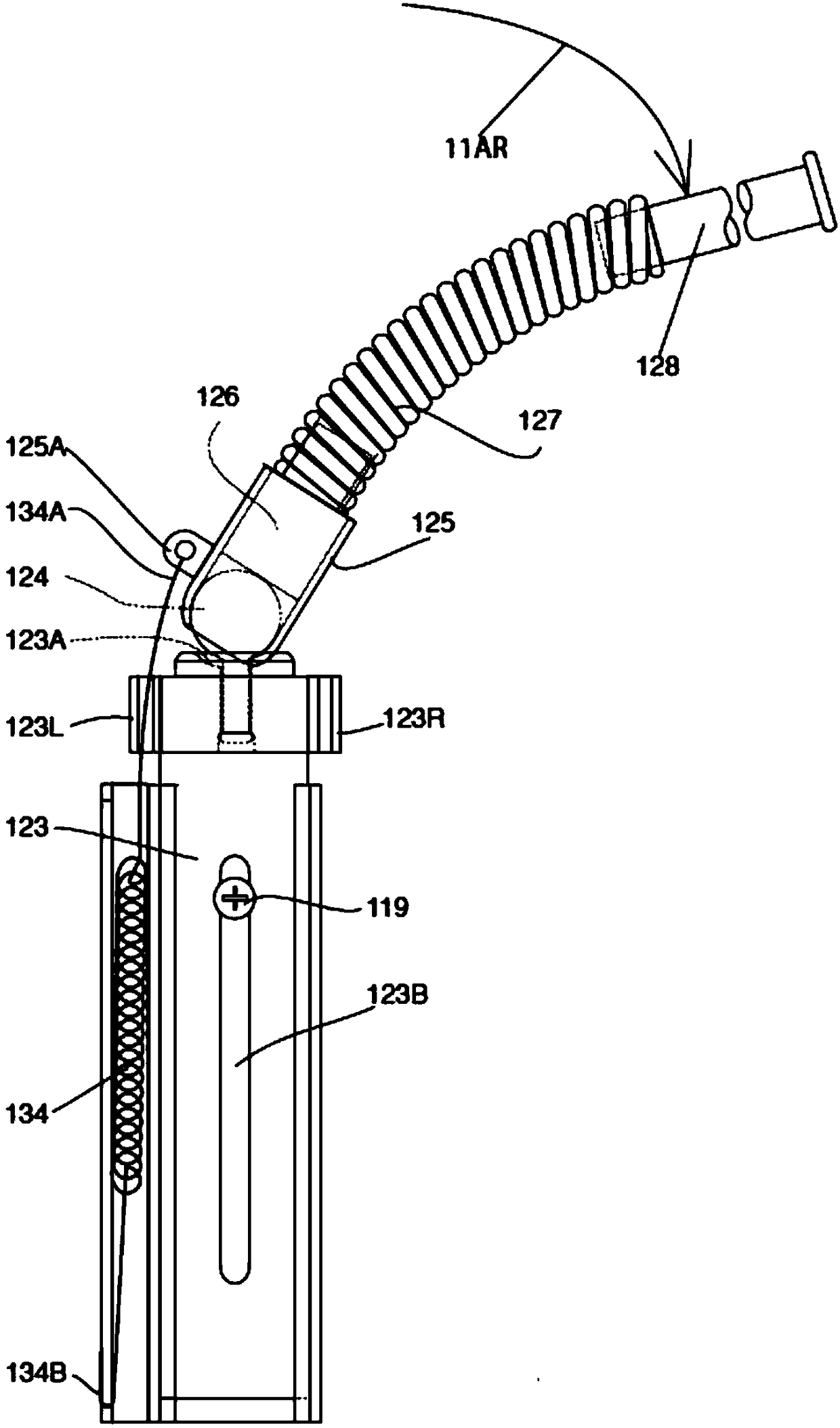

Auxiliary solar protection device

Owner:俞经初

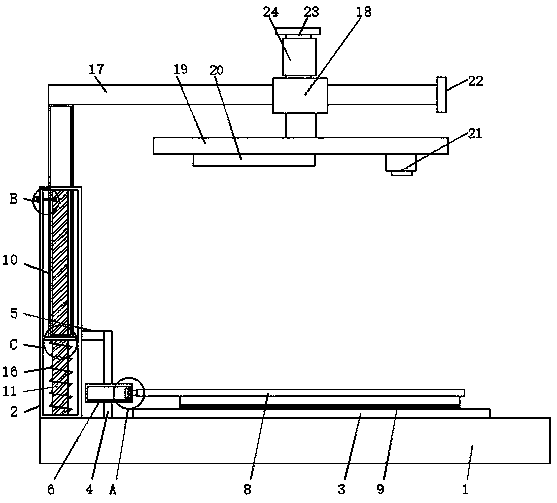

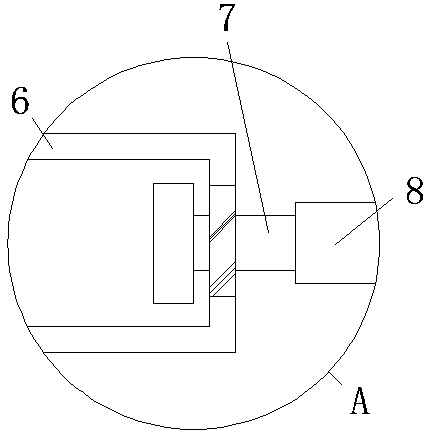

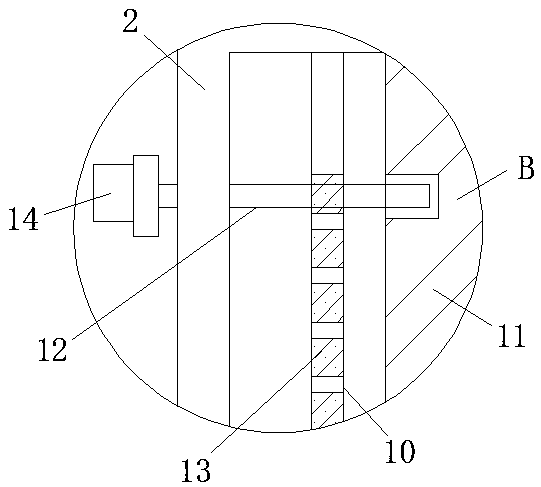

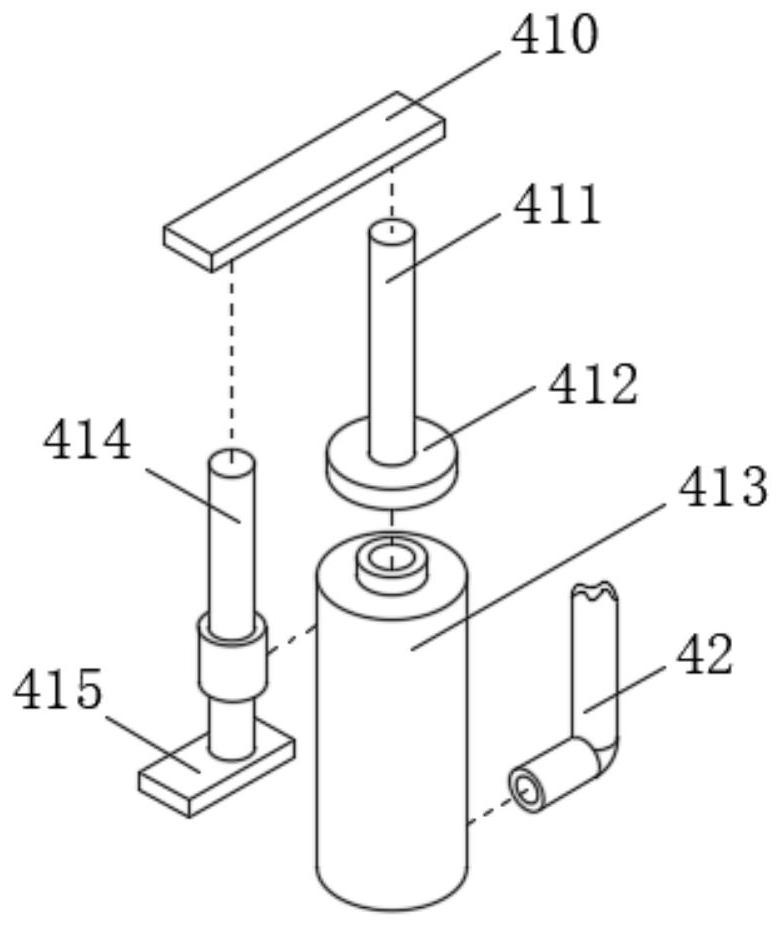

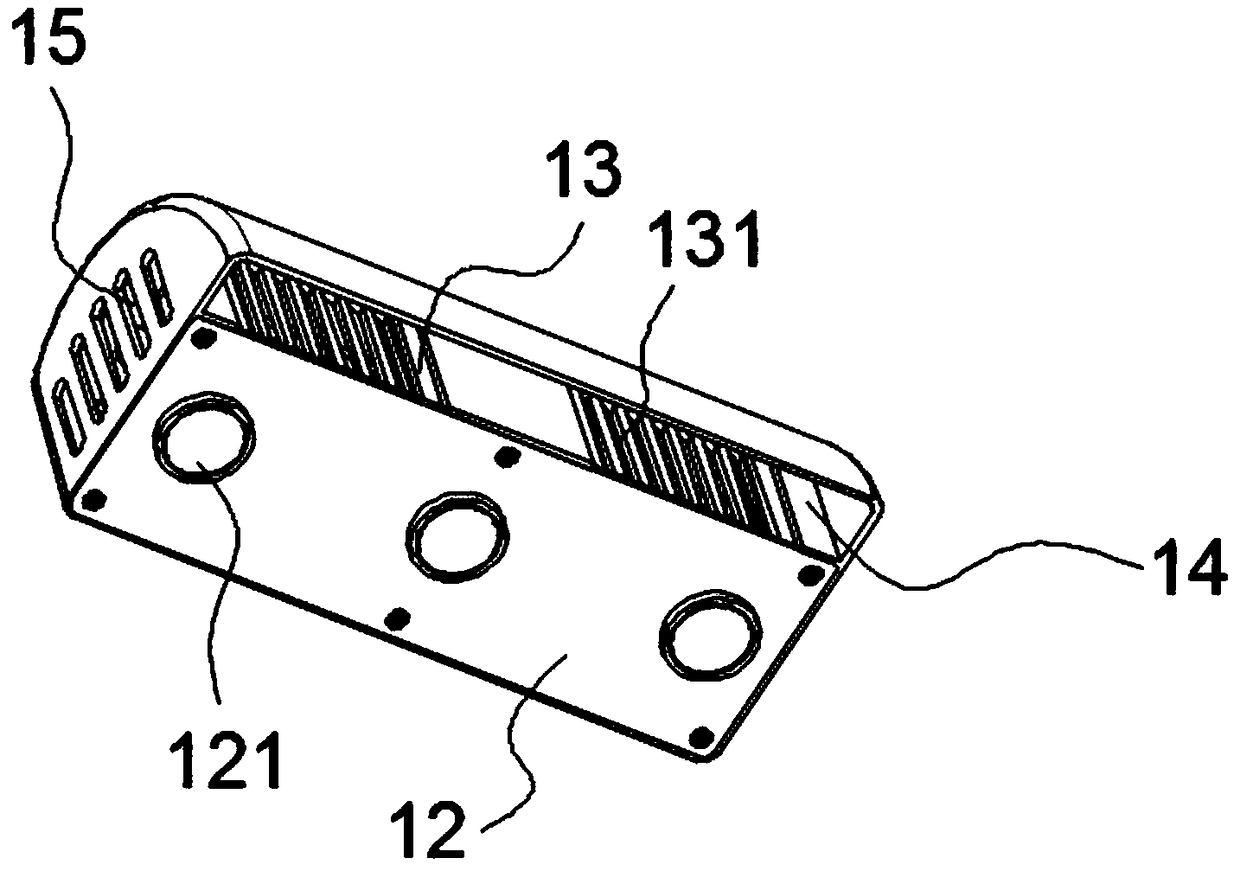

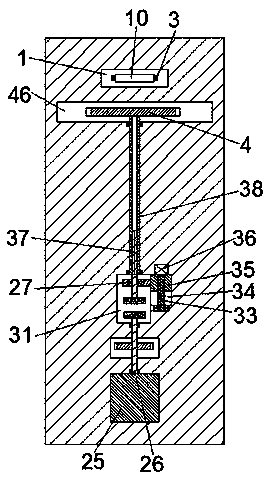

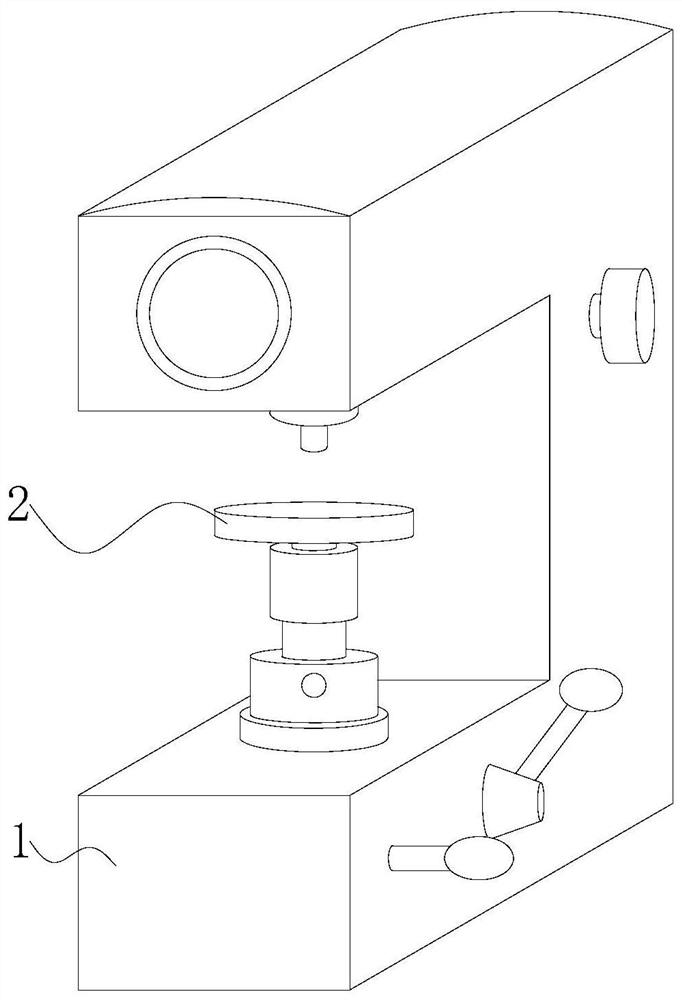

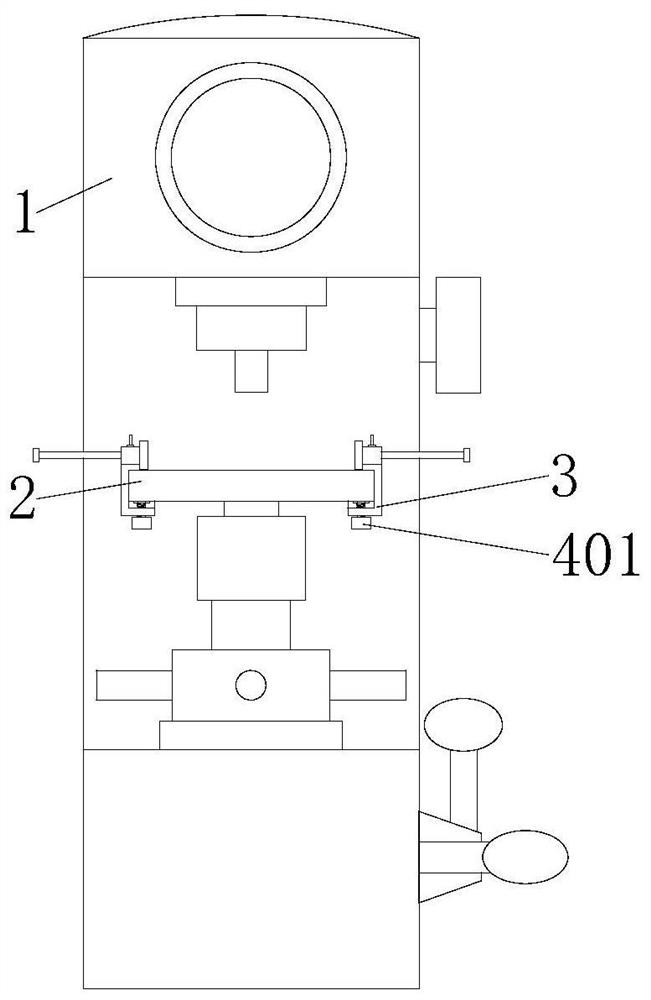

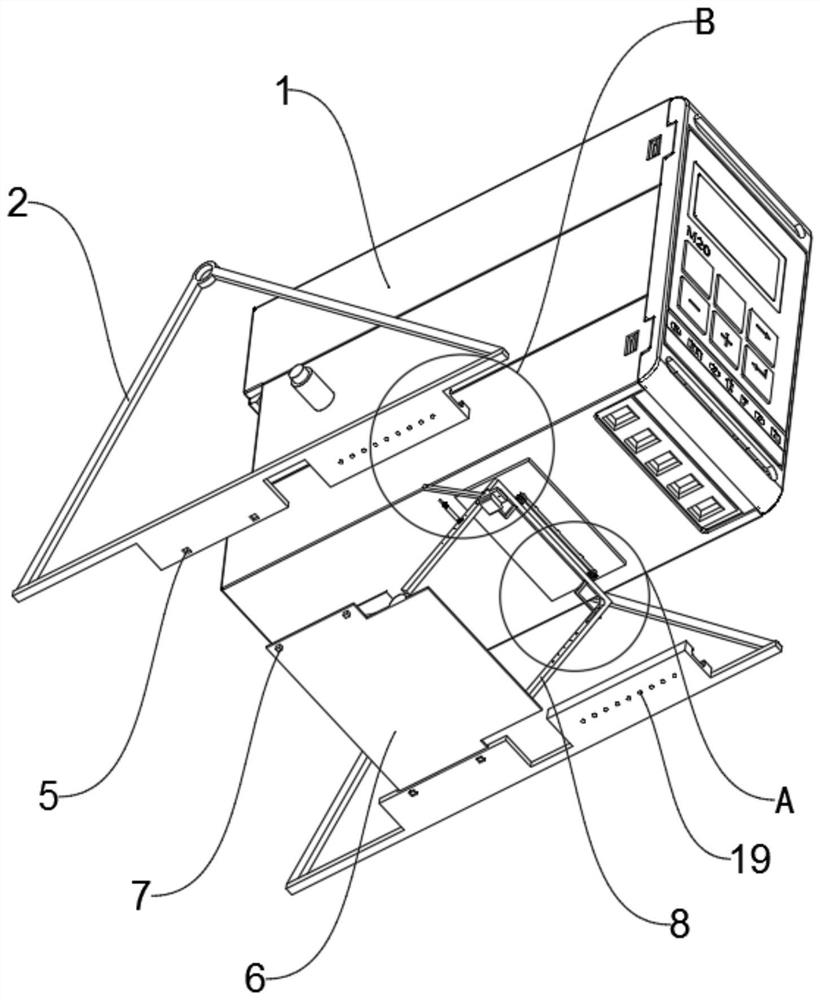

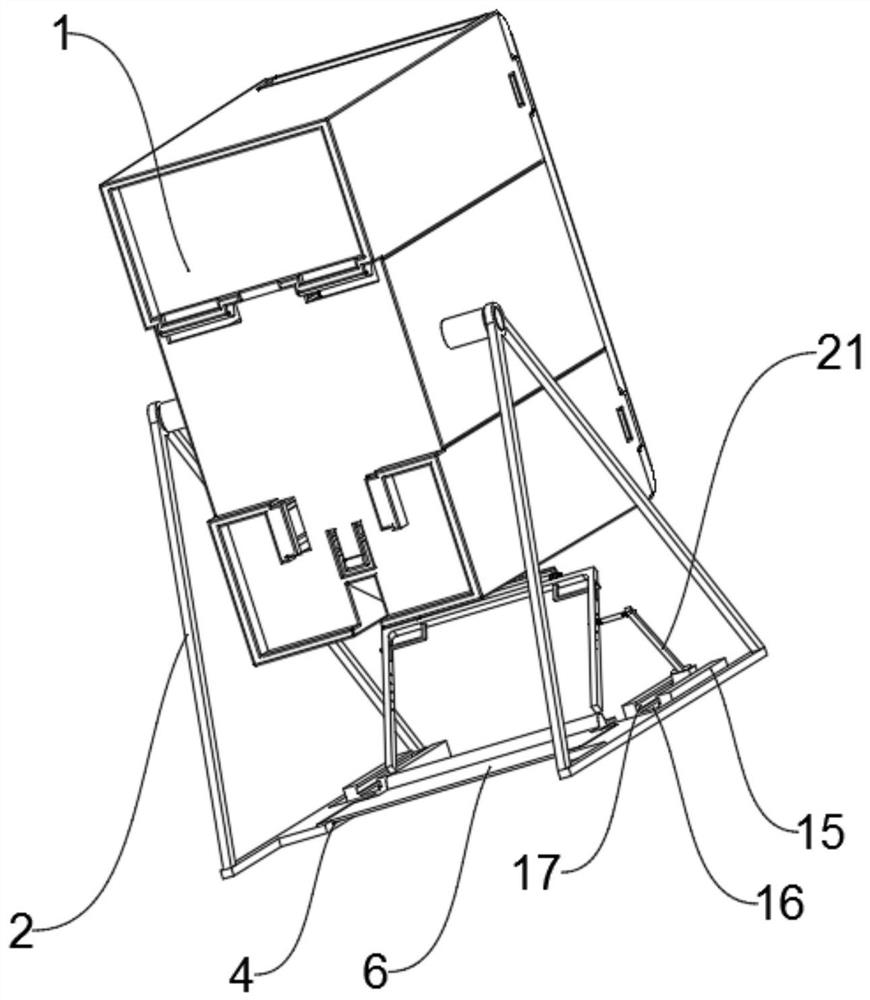

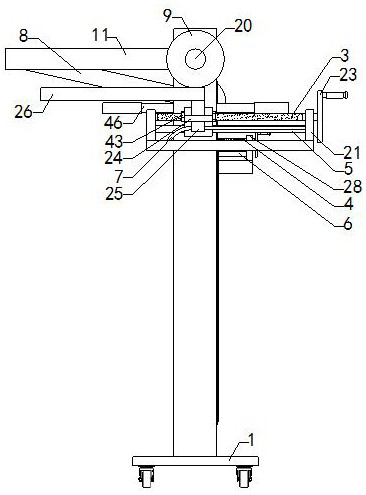

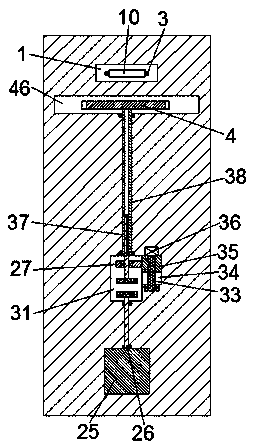

Document scanner convenient for adjustment

InactiveCN108429870AEasy to adjustHeight adjustablePictoral communicationPaper documentDocument preparation

The invention relates to the technical field of a document scanner and particularly relates to a document scanner convenient for adjustment. The document scanner comprises a chassis, wherein a fixingpost is fixedly connected with the side face on the top of the chassis; a lifting rod is inserted into the top of the fixing post; a fixing frame is fixedly connected with the top of the lifting rod;a slide sleeve is in slide connection with the outer surface of the fixing frame; an electric appliance box is fixedly connected with the bottom of the slide sleeve; a light supplement lamp and a scancamera are fixedly connected with the bottom of the electric appliance box; an iron rod is fixedly connected with the bottom of the inner cavity of the fixing post; a fixing plate is fixedly connected with the bottom of the end of the lifting rod located in the inner cavity of the fixing post; a magnetic rod is inserted into the top of the fixing rod at the side away from paper; and the end of the magnetic rod located in the inner cavity of the fixing post penetrates the lifting rod and is inserted into the side face of the iron rod. According to the document scanner, the magnetic rod is separated away from the lifting rod and the iron rod by pulling a pull handle, the lifting rod is lifted or pushed down, the height of the scan camera can be adjusted conveniently, and the paper scan precision is improved.

Owner:ANHUI BAOHULU INFORMATION TECH GRP

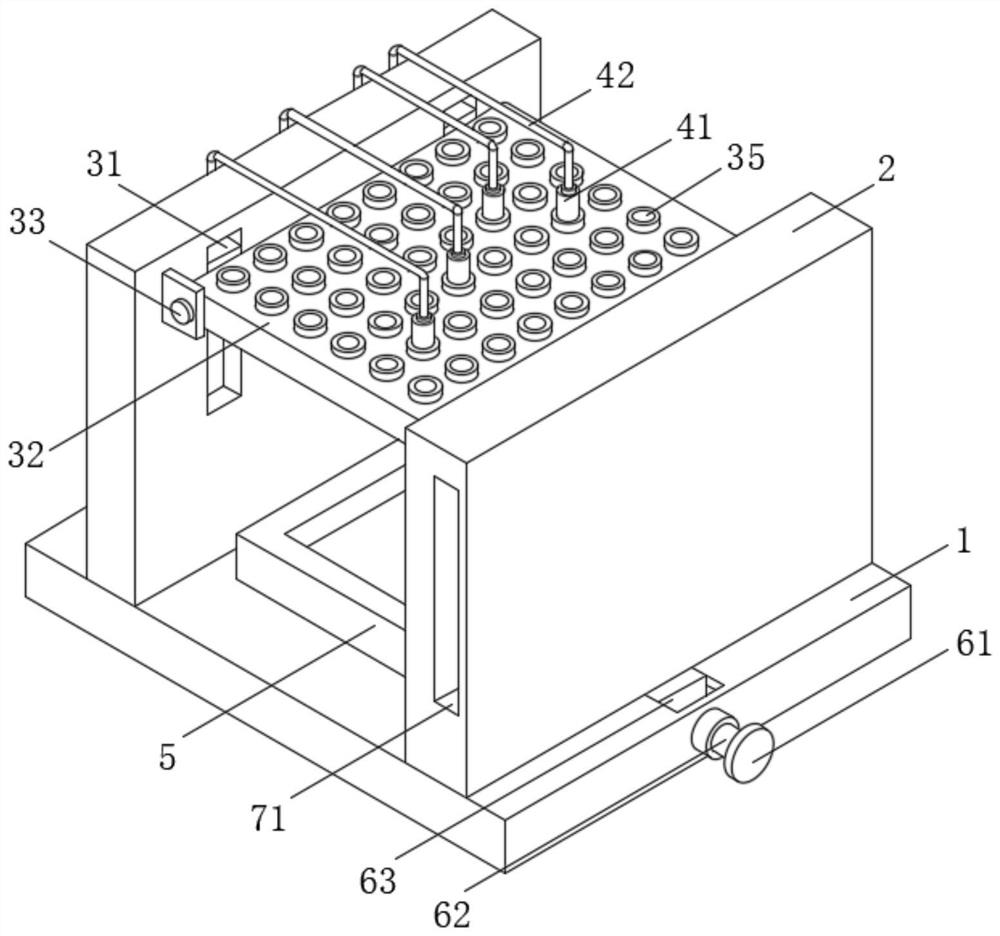

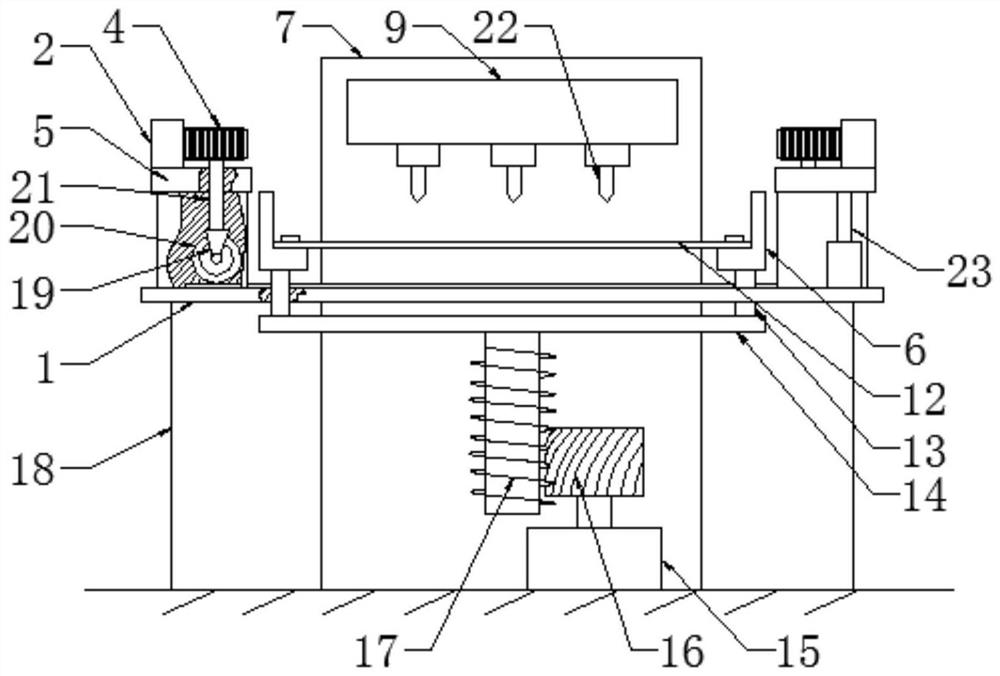

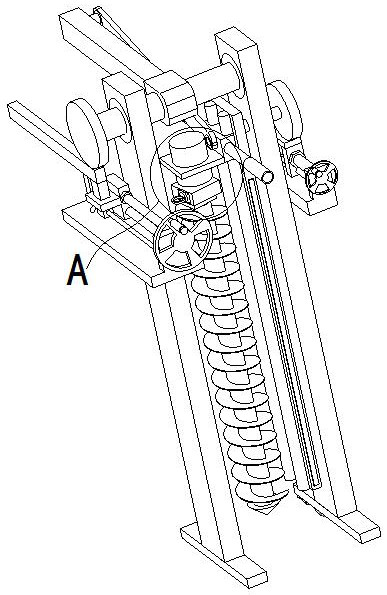

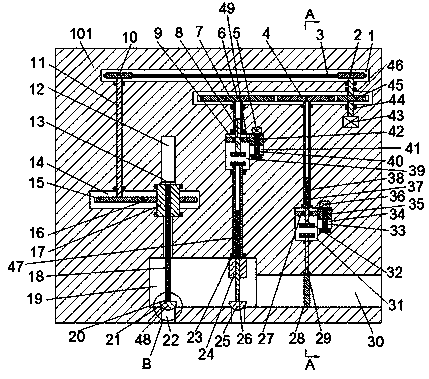

PCB detection jig processing device and using method thereof

ActiveCN113253098AEasy to detectEasy to usePrinted circuit testingMeasurement instrument housingStructural engineeringBackplane

The invention discloses a PCB detection jig machining device and a using method thereof, and belongs to the technical field of PCBs, the PCB detection jig machining device comprises a bottom plate and side plates, the side plates are arranged on the left side and the right side of the upper surface of the bottom plate, the left side plate is fixedly connected to the upper surface of the bottom plate, the lower surface of the right side plate is attached to the upper surface of the bottom plate, the lower surface of the right side plate is fixedly connected with an adjusting mechanism used for adjusting the position of the side plate and indirectly controlling the positioning mechanism to adjust, and the adjusting mechanism is arranged in the bottom plate. According to the invention, the detection mechanism is arranged, pressing blocks are controlled to drive a second sliding rod to move downwards, the second sliding rod drives a pressing rod to move downwards through a pressing plate, the pressing rod drives a piston block to move downwards, the piston block extrudes air in a second air cylinder, and a detection head can detect a connection point; in the detection process, multiple different pressing blocks are pressed, and a plurality of different detection heads move downwards and are matched with one another to achieve a good detection effect on different PCBs, so that normal use of people is greatly facilitated.

Owner:深圳市顺天祥电子有限公司

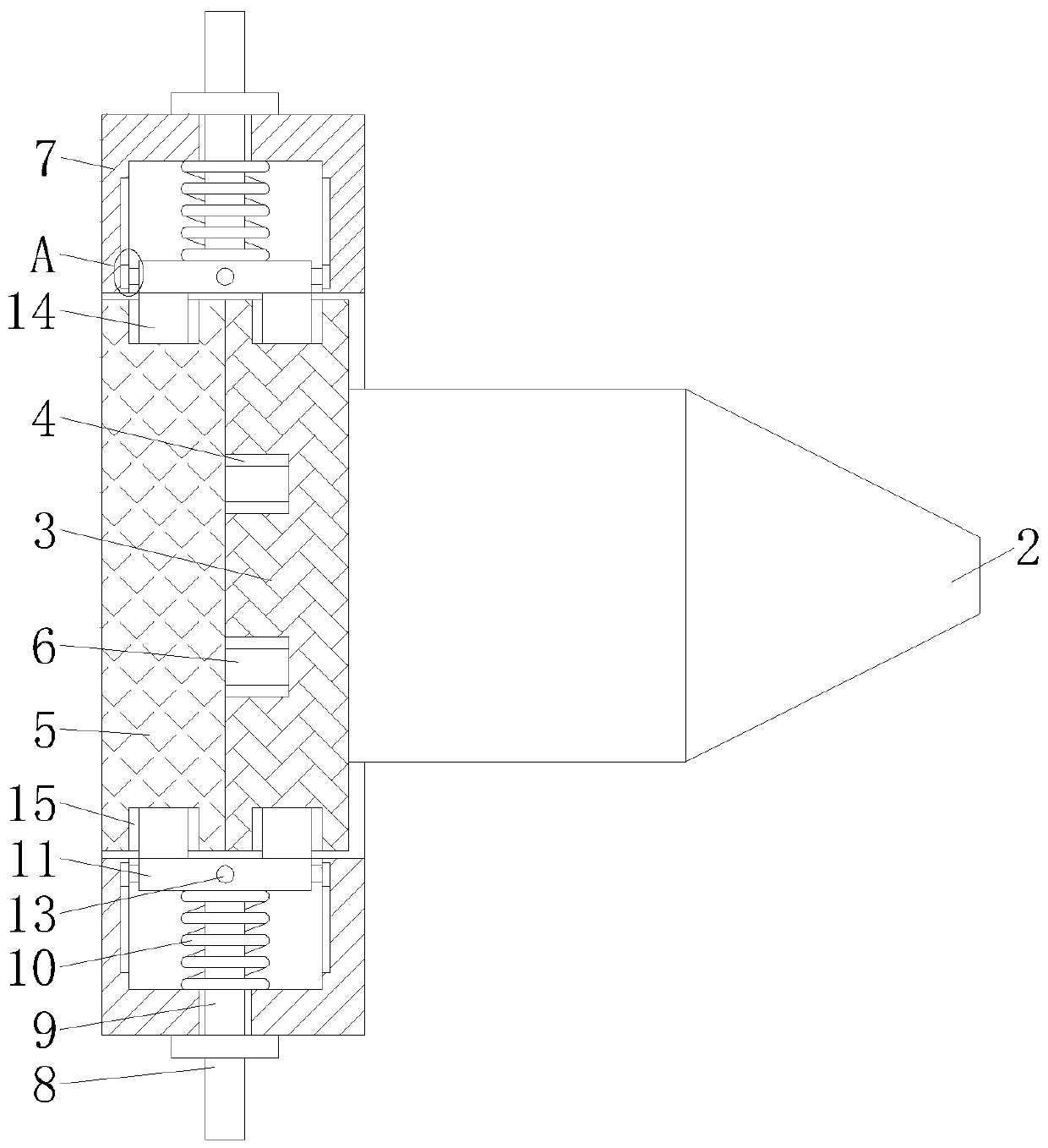

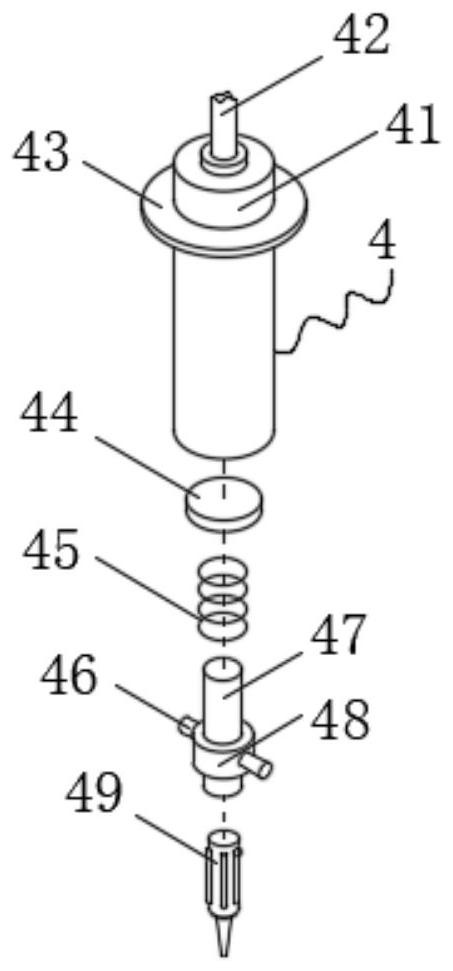

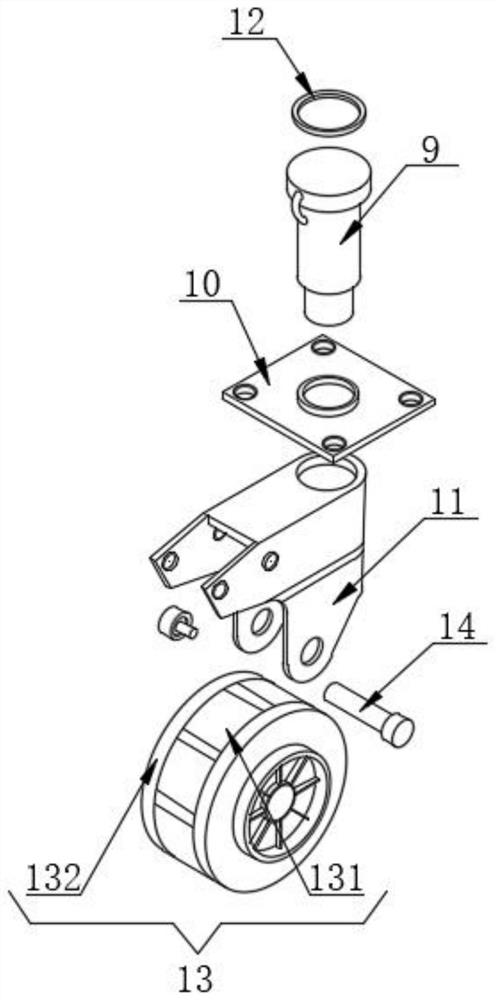

Fixing device used for fixing rat testis for injection

The invention discloses a fixing device used for fixing the rat testis for injection. The fixing device comprises a positioning tube, wherein one end of the positioning tube is cone-shaped, a bearingtable is arranged at the other end of the positioning tube, a binding part is arranged in the positioning tube, a sliding groove is formed in the bearing table, a propping seat is arranged in the sliding groove, a propping cam is rotationally arranged on the propping seat, a hole seat is arranged on the bearing table, a U-shaped elastic binding arm is arranged on the hole seat in a swinging manner, two free ends of the elastic binding arm are bent to form inserting pins which are inserted into the hole seat, a first positioning groove, a first converging bulge, a second positioning groove, a second converging bulge and a third positioning groove are sequentially formed in the matched surface, attached to the outer wall of the hole seat, of the elastic binding arm, and the second positioning groove is deeper than the first positioning groove and the third positioning groove. The fixing device is simple in overall structure and can fix the rate testis, thereby facilitating cell transplantation tests.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

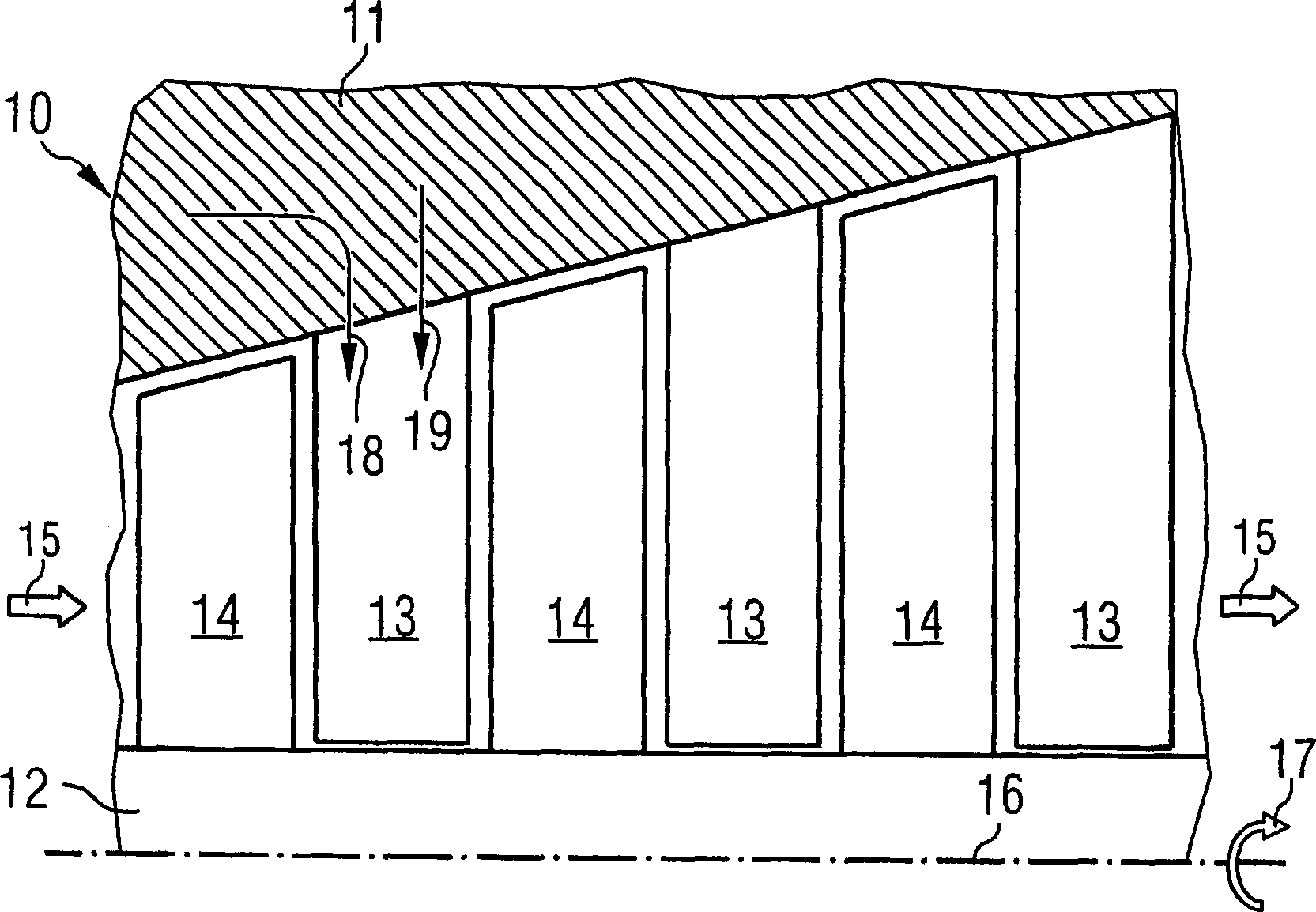

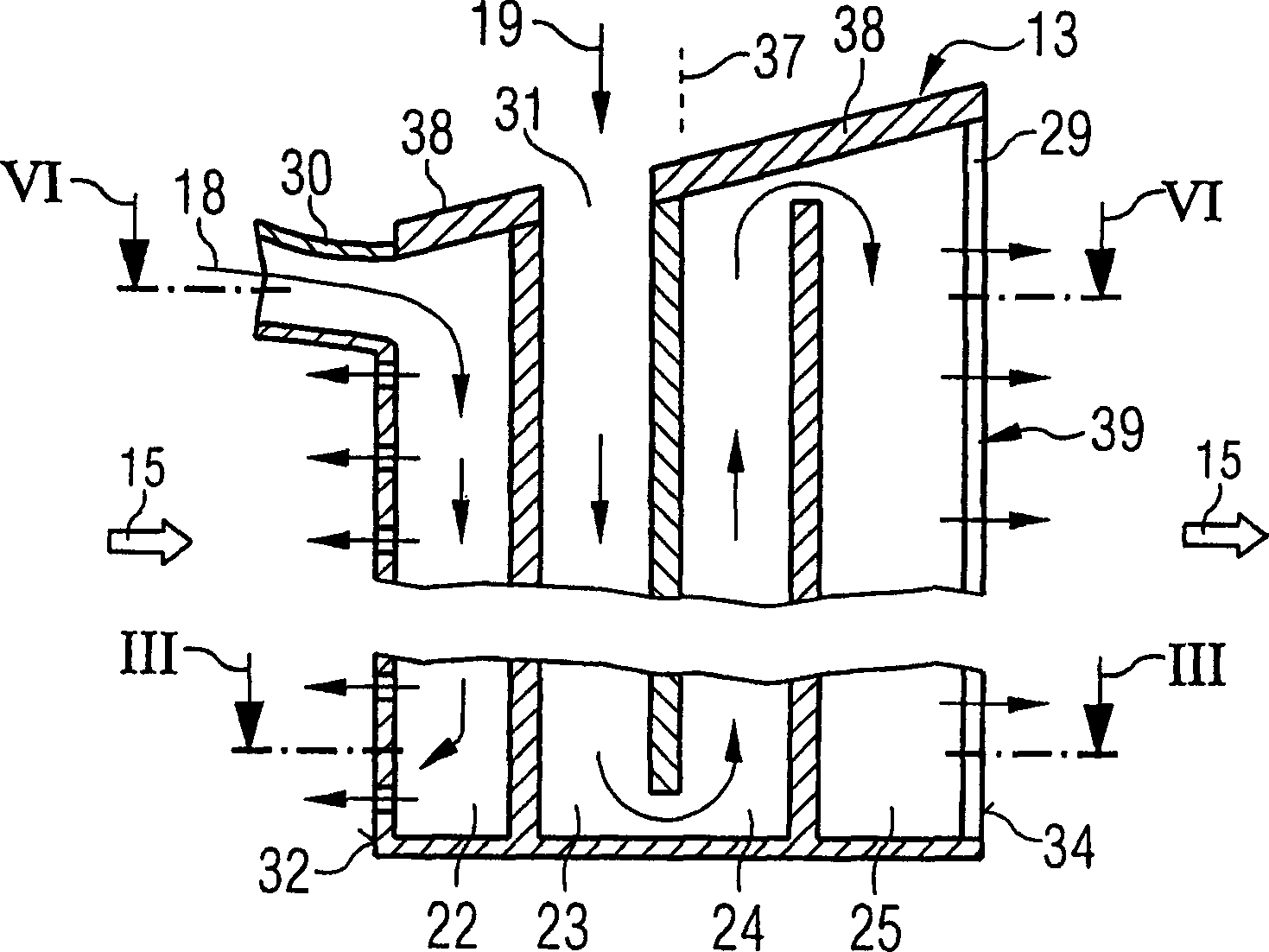

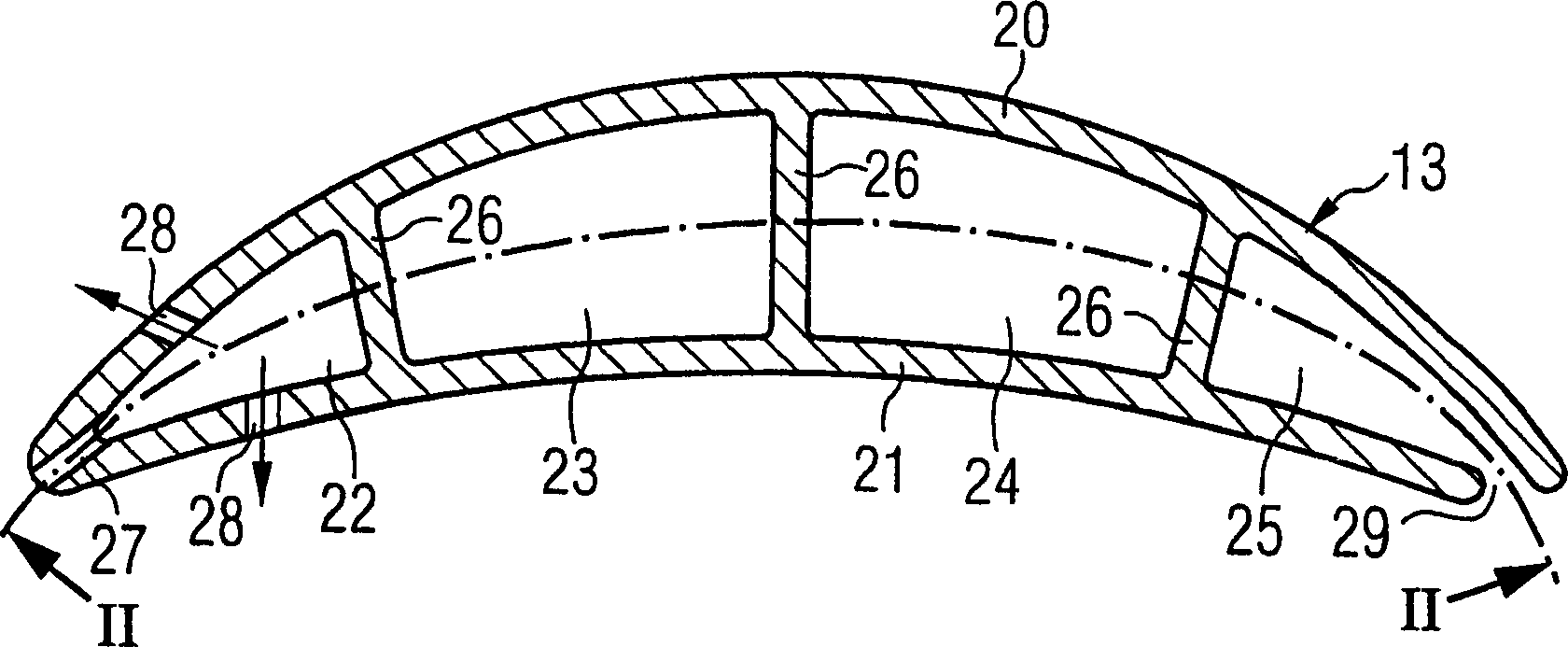

Method for manufacturing turbine blade and turbine blade

InactiveCN1380486AImprove cooling effectLocation effectBlade accessoriesGas turbine plantsTurbine bladeVertical axis

The invention relates to a method for producing a turbine blade (13, 14) having at least one chamber (22; 23, 24, 25) and at least one inlet channel (30, 31) for feeding a cooling medium into the chamber ), the input channel (30) forms an included angle with the longitudinal axis (37) of the turbine blades (13, 14). According to the invention, a core (35) with a lug (33) is used to form the inlet channel (30), the core is separated from the mold (40), and after being removed from the mold, the inlet channel of the turbine blade (30) is initially closed and can be opened by post-processing. The invention also relates to a turbine blade, in particular a turbine blade for a gas turbine (10), manufactured by the method described above, wherein the inlet channel (30) forms an angle and is substantially parallel to the longitudinal axis (37) of the turbine blade In the flow direction (15) of the working medium through the turbine (10). Therefore, the cooling medium can be introduced along the axial direction of the turbine (10).

Owner:SIEMENS AG

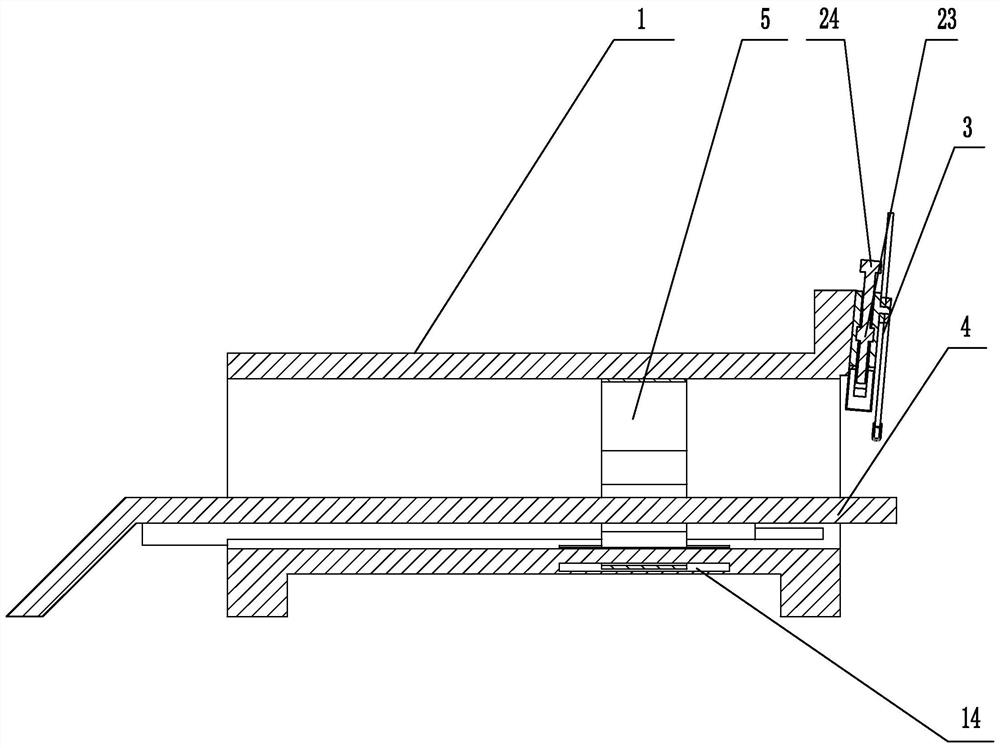

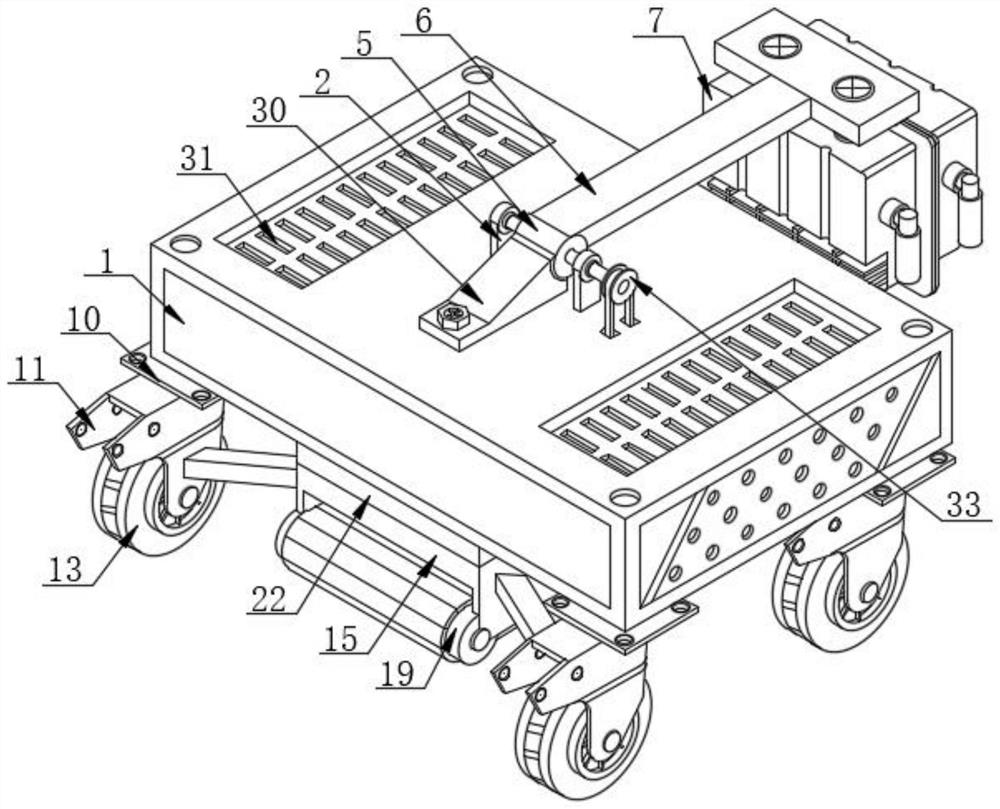

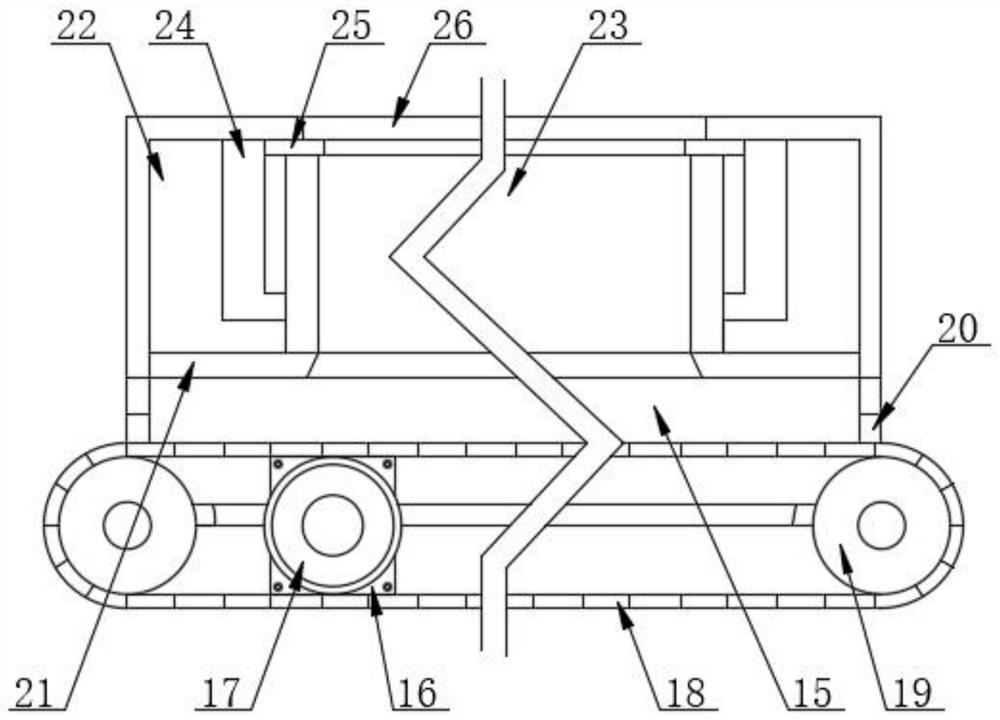

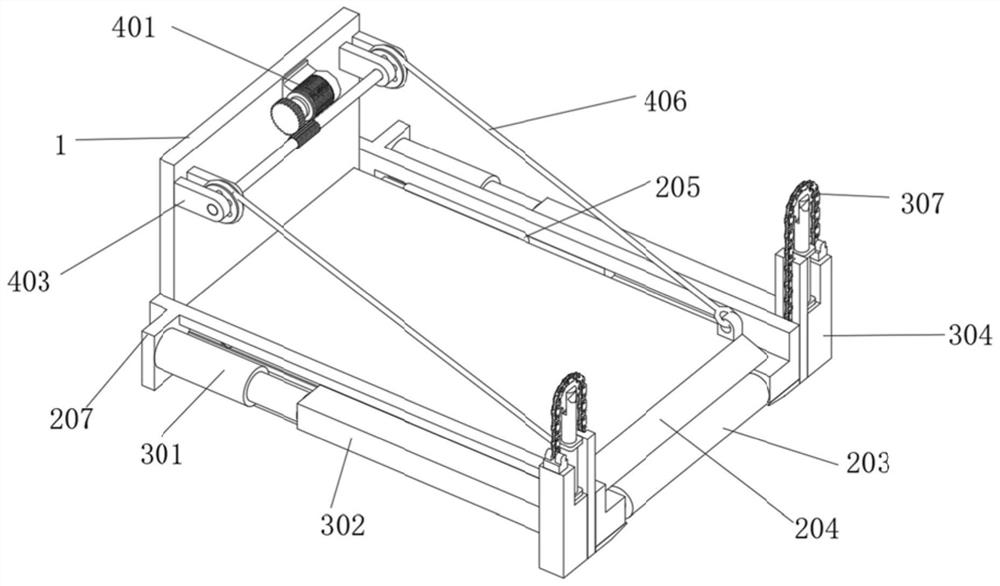

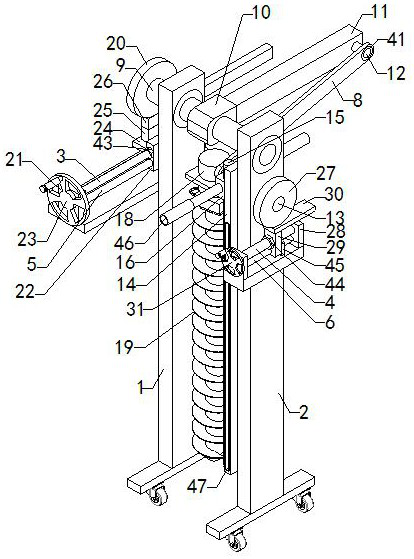

Mechanical lifting type construction machine transfer device

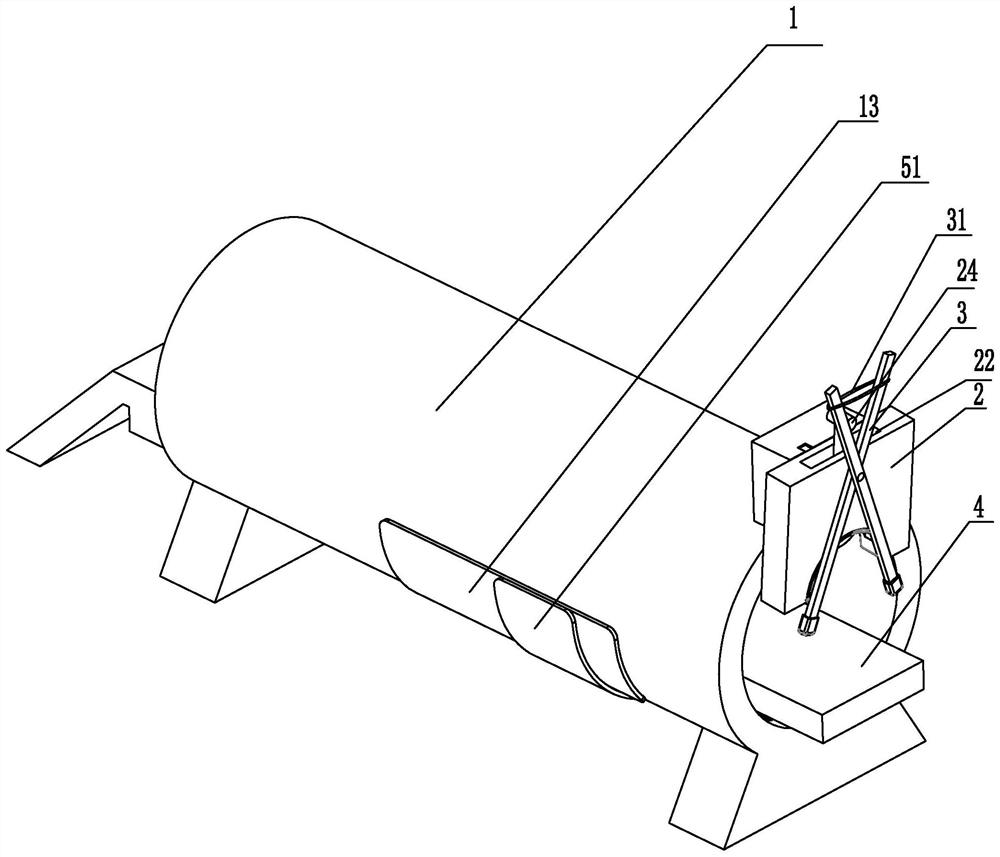

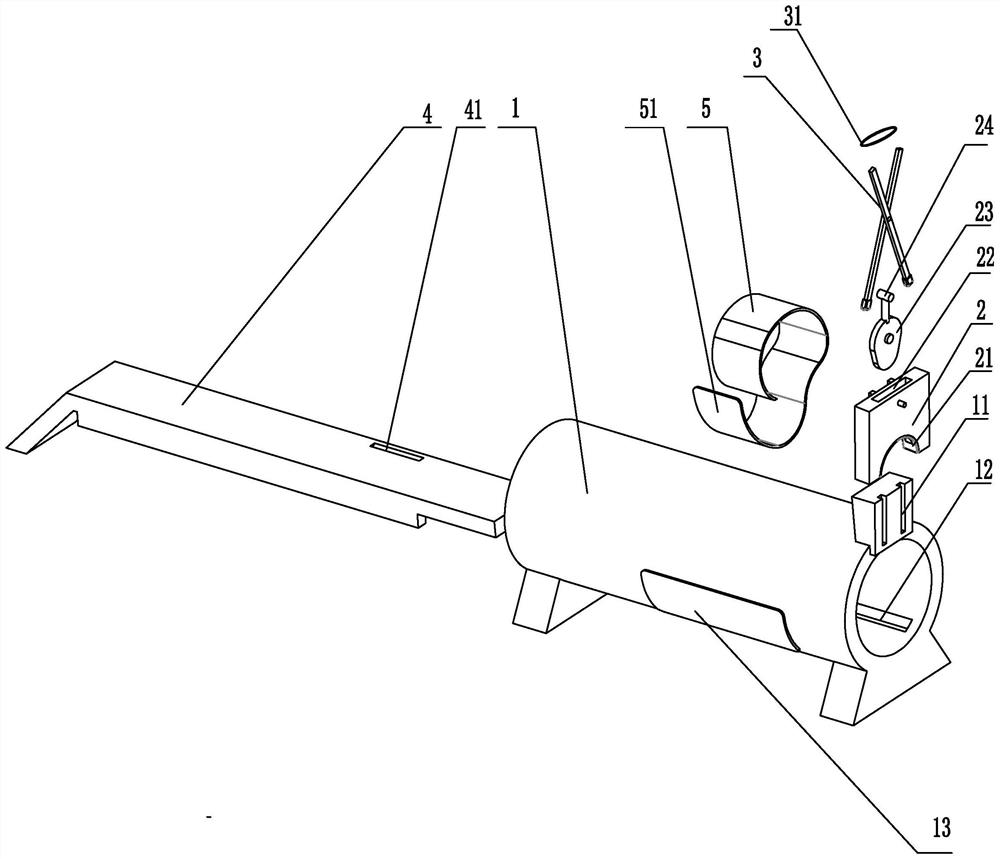

ActiveCN112110371AEasy transferCushion the shockLifting framesWinding mechanismsElectric machineryEngineering

The invention discloses a mechanical lifting type construction machine transfer device, and relates to the technical field of mechanical equipment transportation. The device comprises a mounting plate, a bottom assembly, a lifting assembly and a turbine assembly. A bottom frame is mounted at the bottom of the bottom assembly, the bottom assembly is positioned on the front side of the mounting plate, and through grooves are formed in both the two sides of the bottom frame. A roller is transversely arranged in the middle of the front side of the bottom frame, movable blocks are arranged in the through grooves, a movable plate is arranged between the two movable blocks, the movable plate and the movable blocks are connected through pin roll rods, lifting ring seats are fixed to the upper surface of the left side and the upper surface of the right side of the front side of the movable plate respectively, and side wing plates are fixed to both the left side and the right side of the rear side of the bottom frame. Air cylinders are installed on the two sides of the lifting assembly, the lifting assembly is located on the two sides of the bottom assembly, a motor is installed on the top of the turbine assembly, and the turbine assembly is located above the front side of the mounting plate. With the mechanical lifting type construction machine transfer device, manpower and material resources needed in the machine transportation process can be reduced, the structure is simple, and the efficiency is high.

Owner:WENZHOU POLYTECHNIC

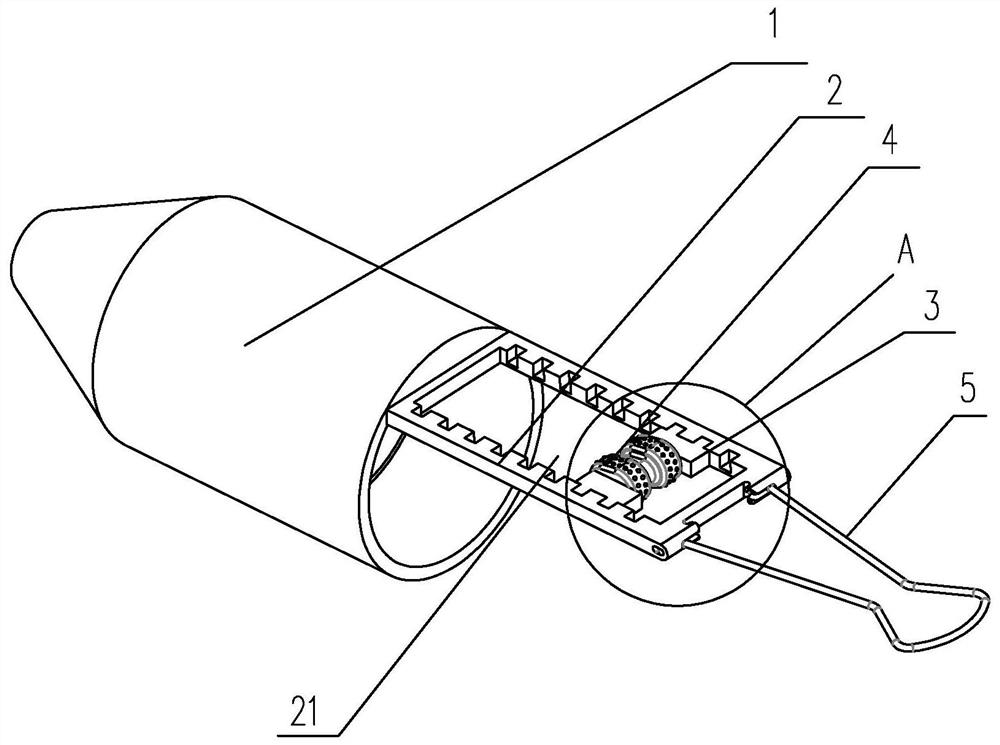

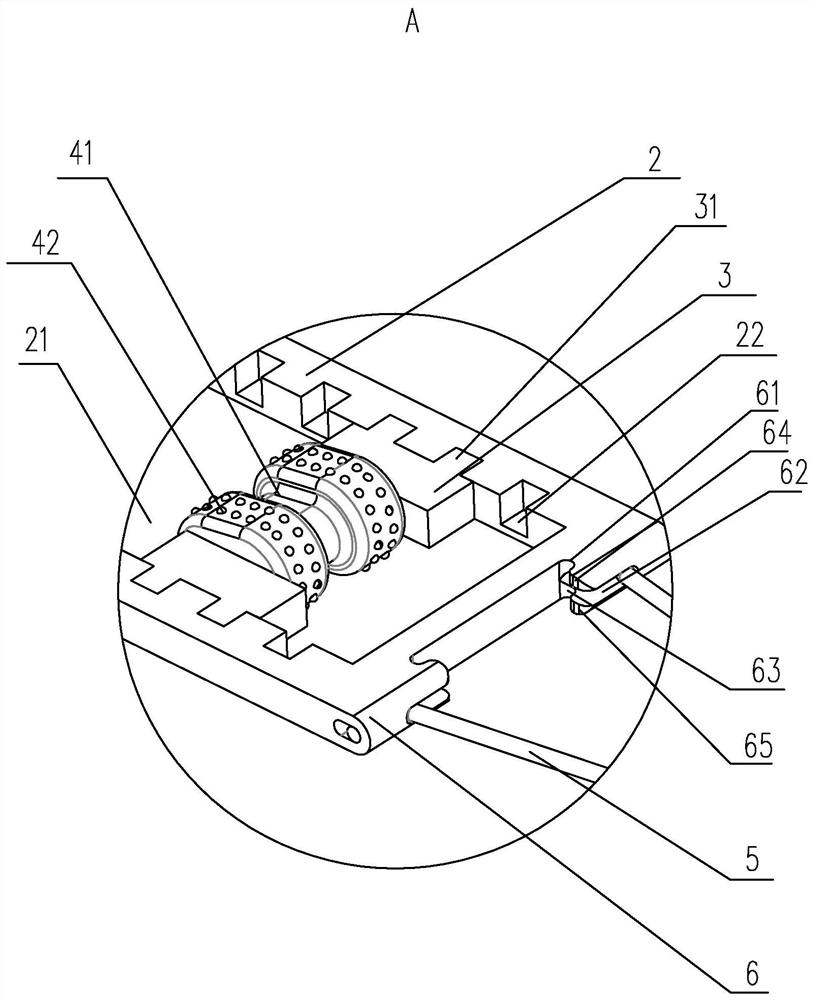

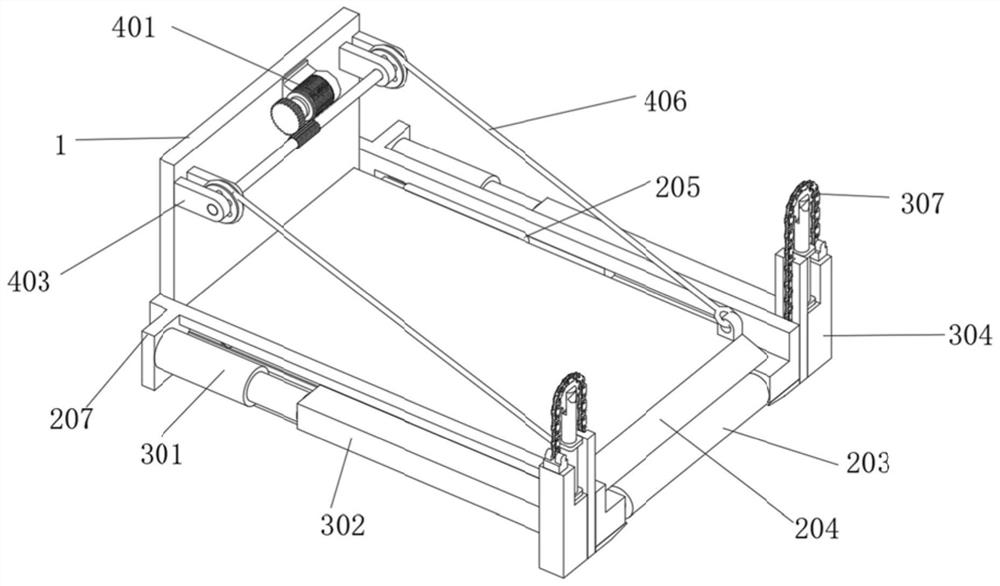

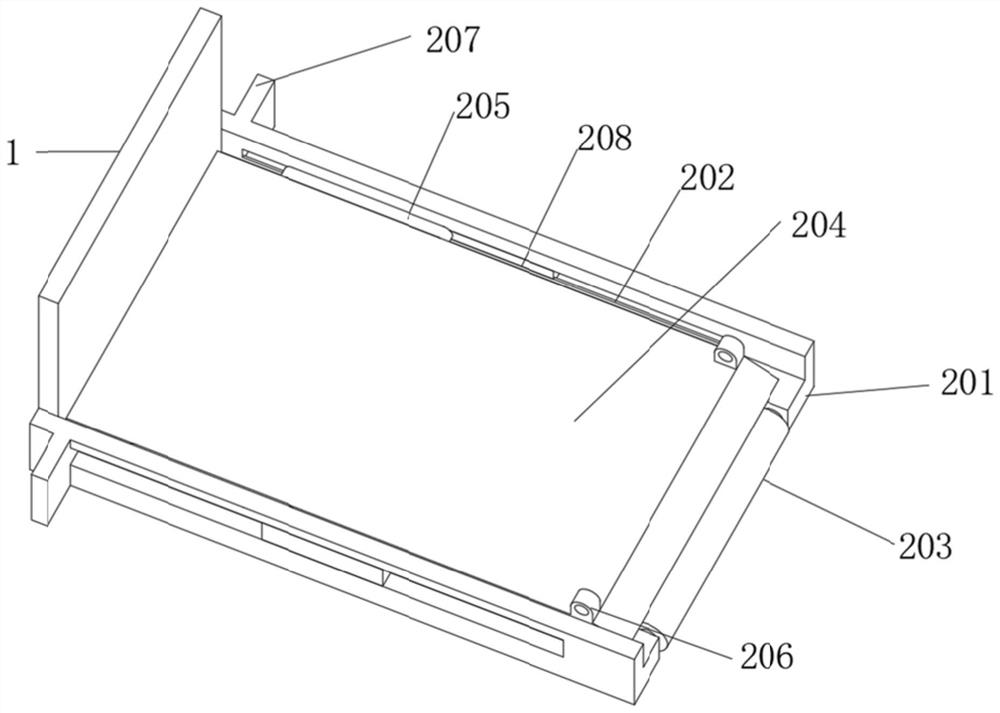

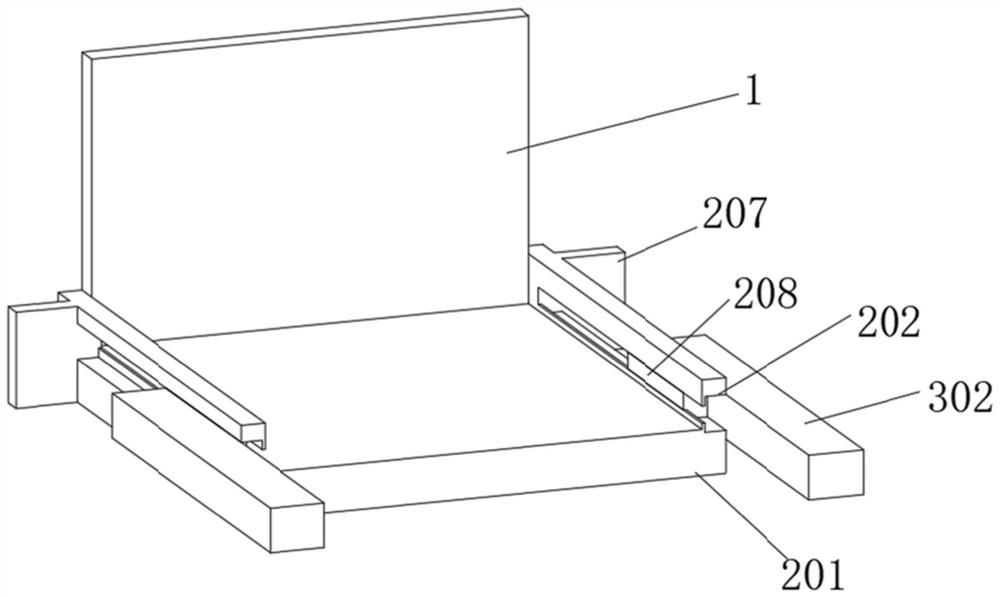

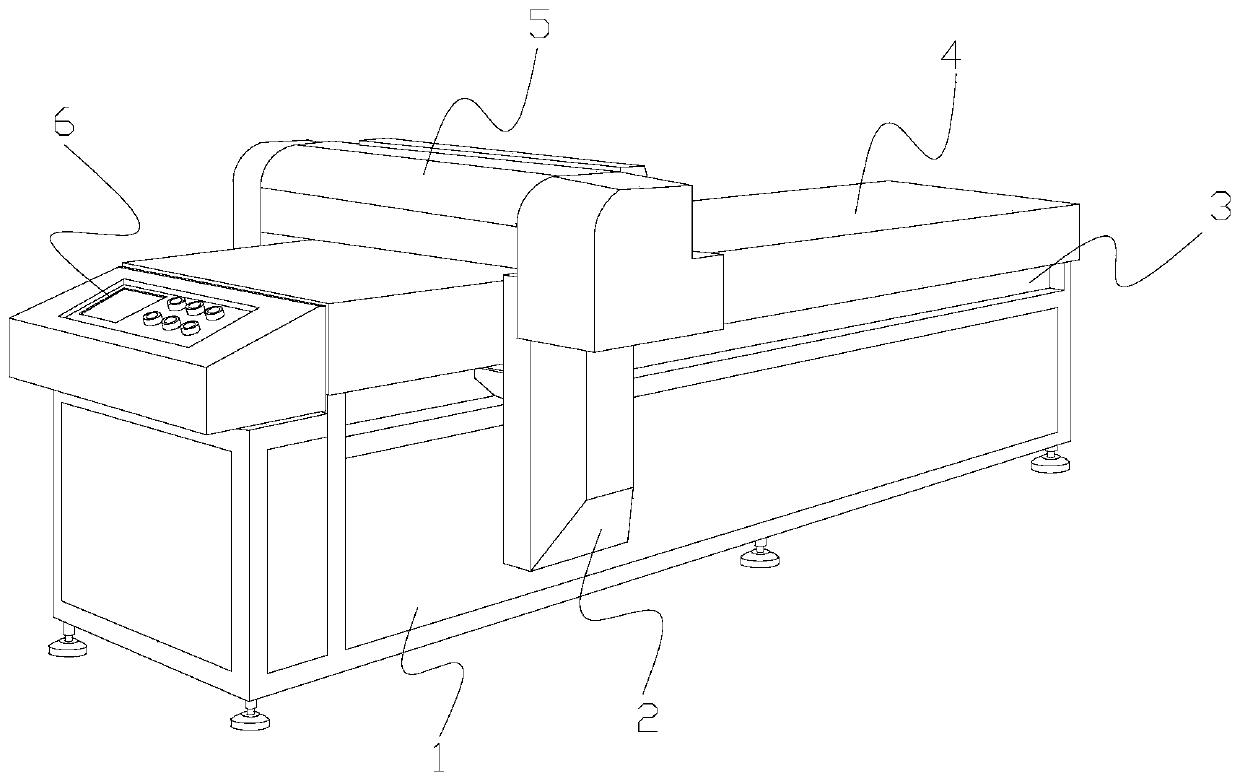

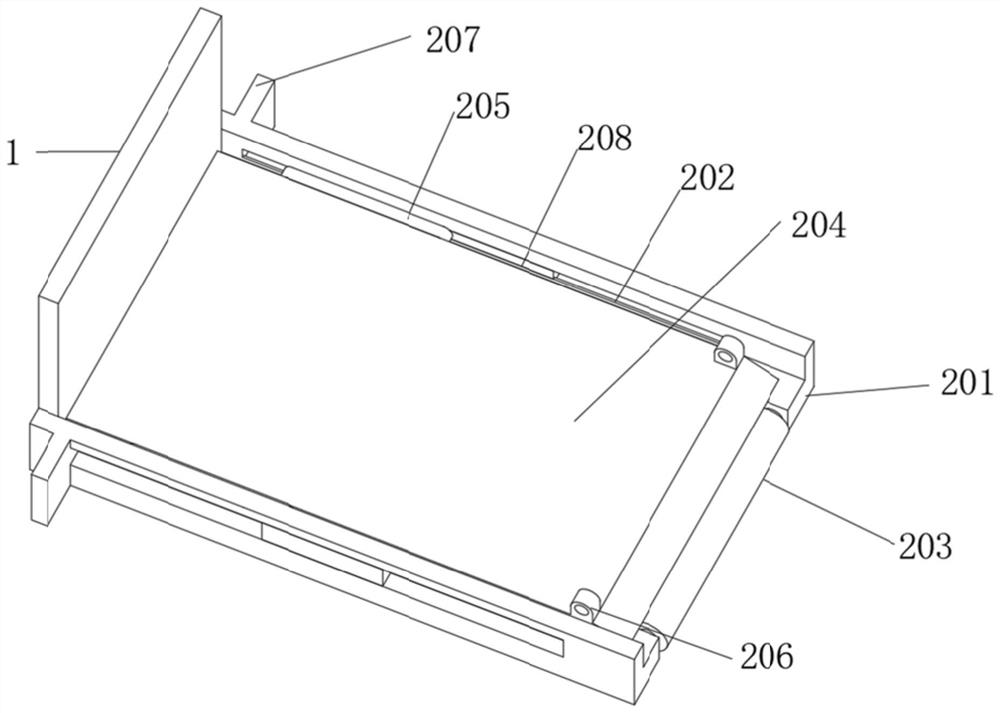

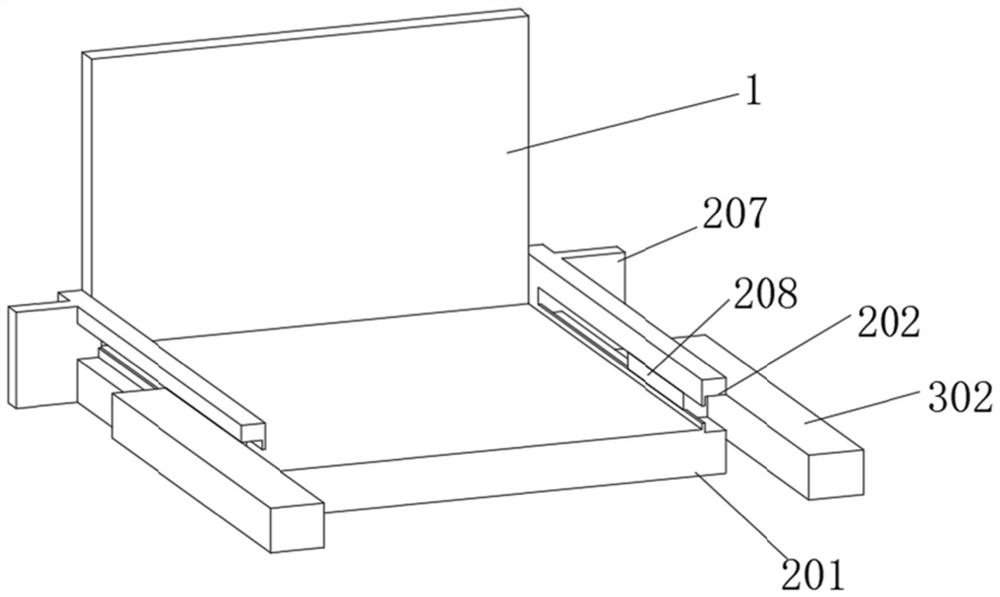

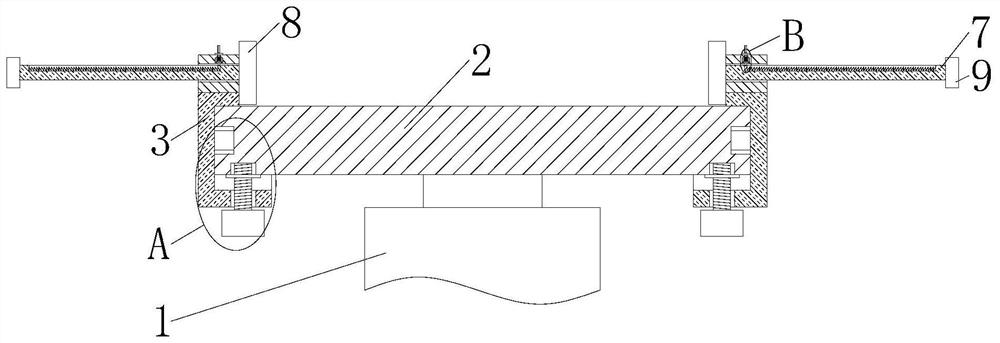

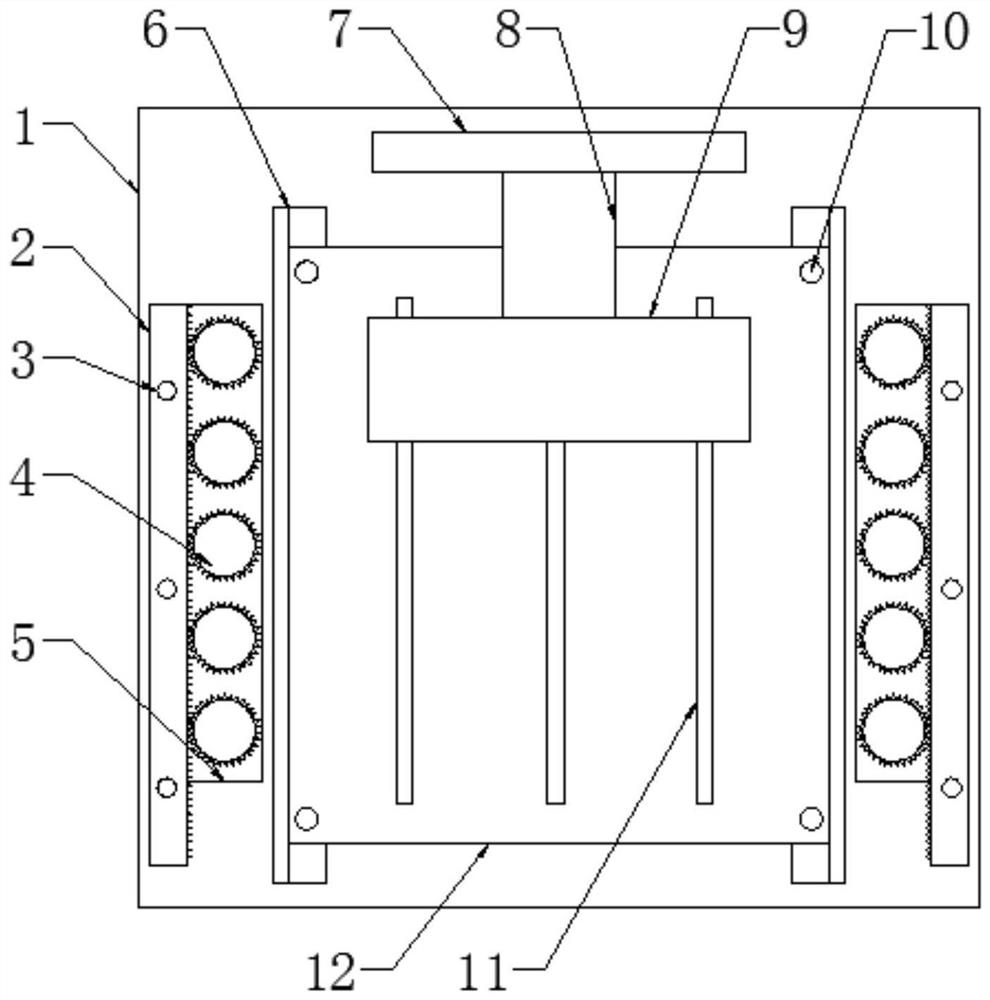

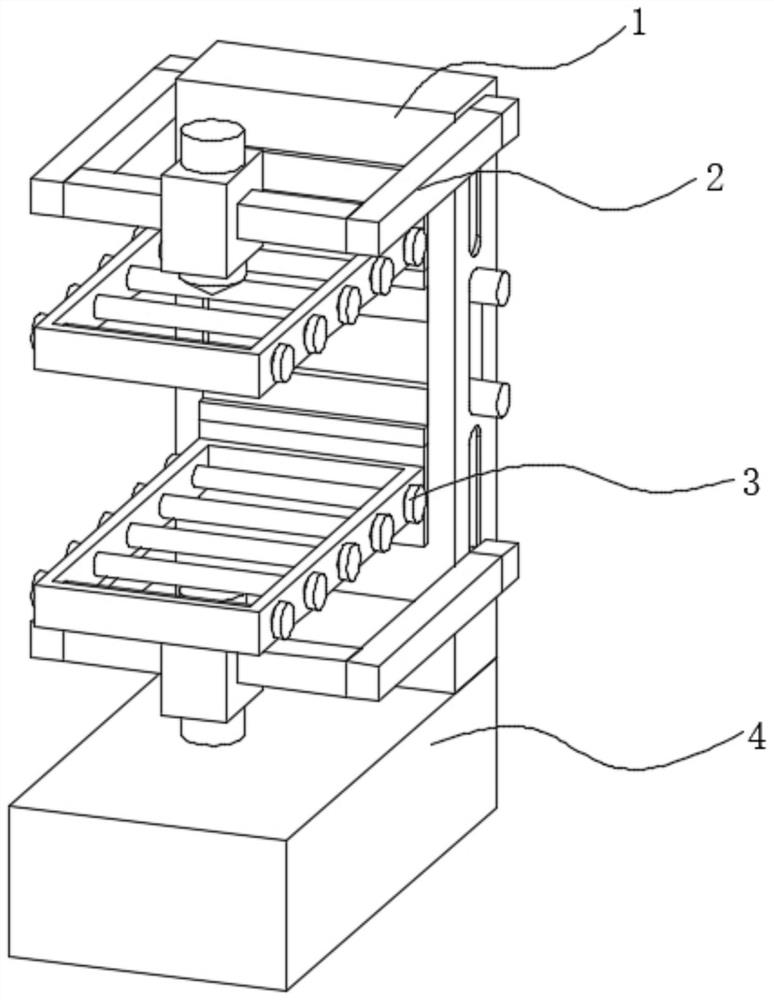

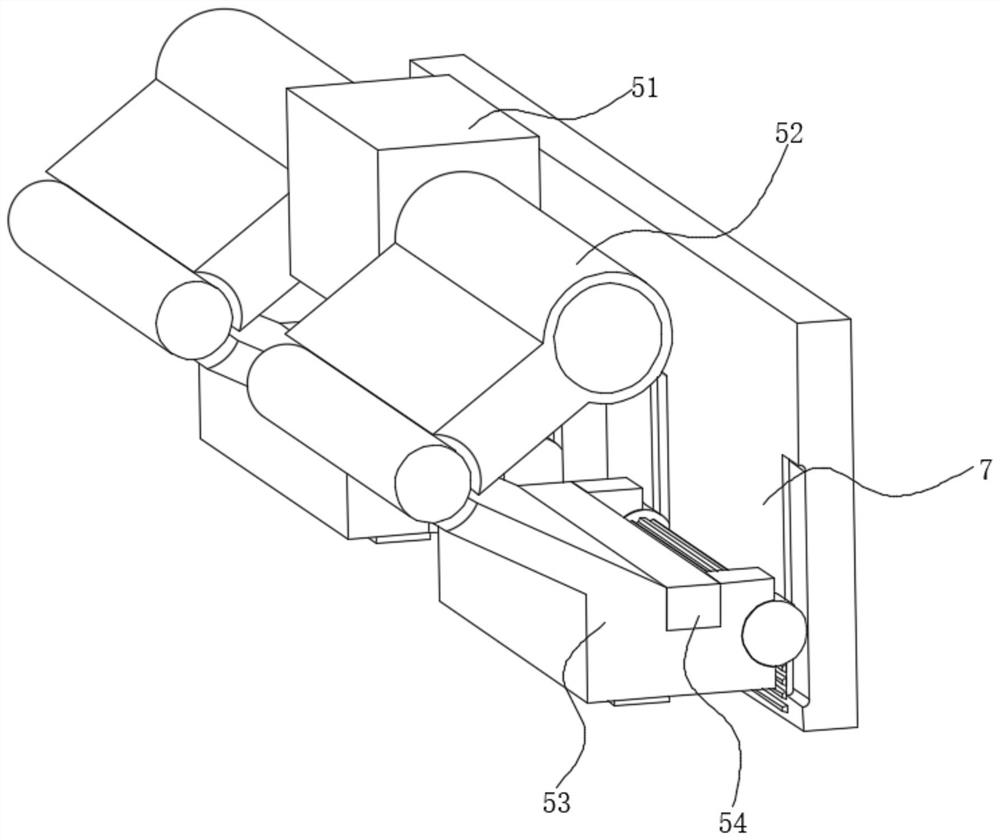

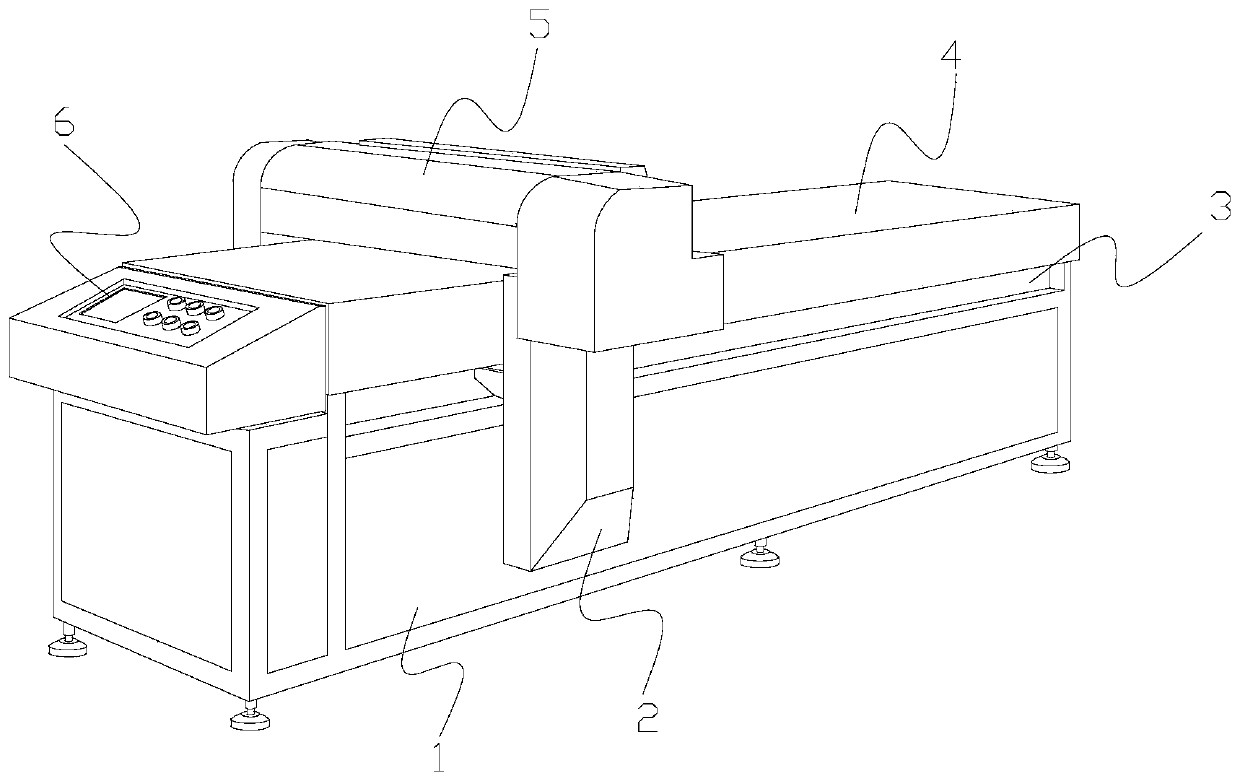

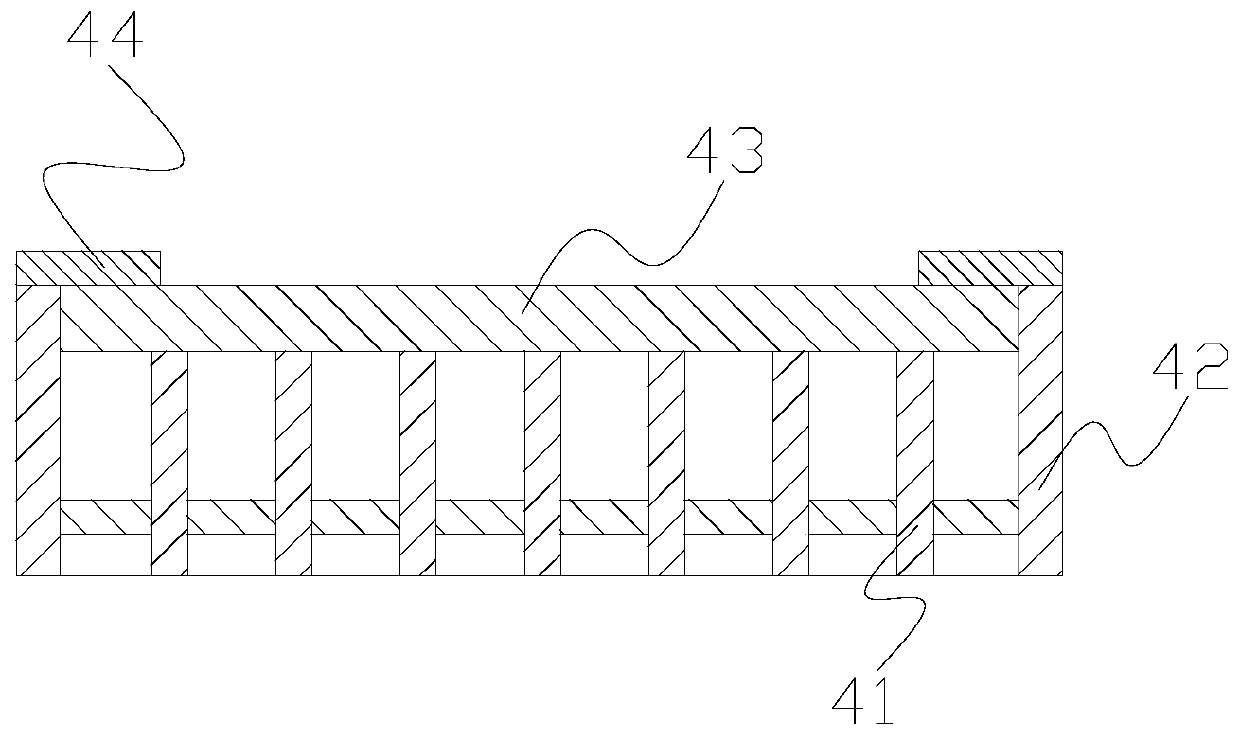

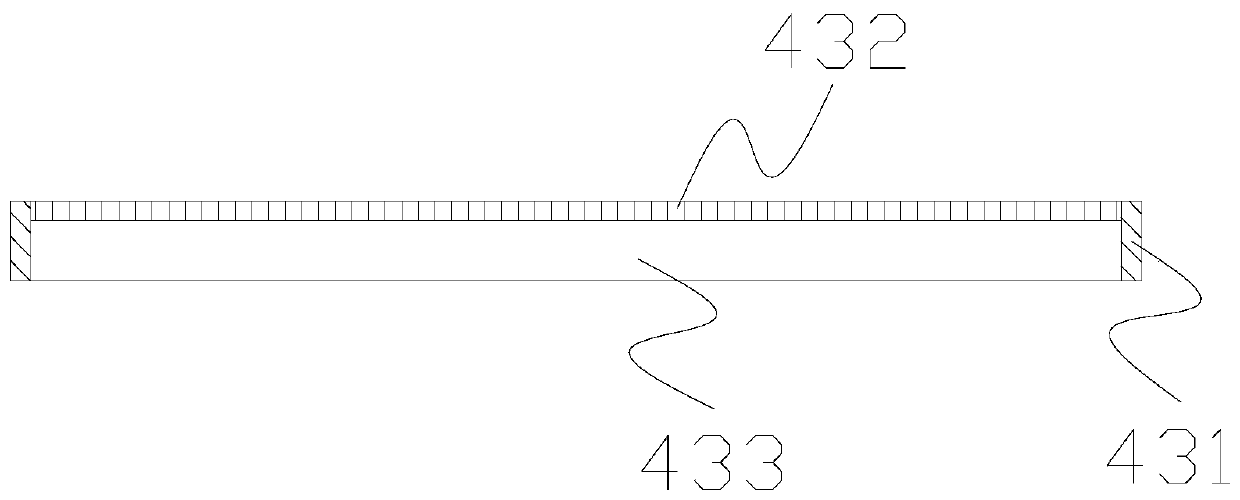

Textile fabric printing machine

ActiveCN110481170APaved and fixedLocation effectTypewritersOther printing apparatusEngineeringMechanical engineering

The invention discloses a textile fabric printing machine. The textile fabric printing machine structurally comprises a machine case, transverse moving cases, a guide rail, a textile fabric paving structure, a printing machine case and a control case. The guide rail is embedded in the upper end of the inner side of the machine case; the transverse moving cases are arranged on the front surface andthe back surface of the machine case and are movably connected with the guide rail; the textile fabric paving structure is horizontally arranged at the upper end of the machine case; and the printingmachine case is positioned above the textile fabric paving structure and is horizontally arranged at the upper end of the transverse moving case, and the control case is arranged at the upper end ofthe machine box. The textile fabric paving structure comprises a support, a side plate, a placing structure and a side paving mechanism, wherein the side plate is installed on the outer side of the support, the placing structure is horizontally installed at the upper end of the support and is located on the inner side of the side plate, and the side paving mechanism is horizontally installed at the upper end of the placing structure. According to the textile fabric printing machine, the side paving mechanism is arranged at the upper end of the placing structure, so that the textile fabric canbe well paved and fixed, the influence of the sprayed air on the position of the textile fabric is effectively prevented, and the printing effect and quality are improved.

Owner:广州南沙经济技术开发区冠丽印花有限公司

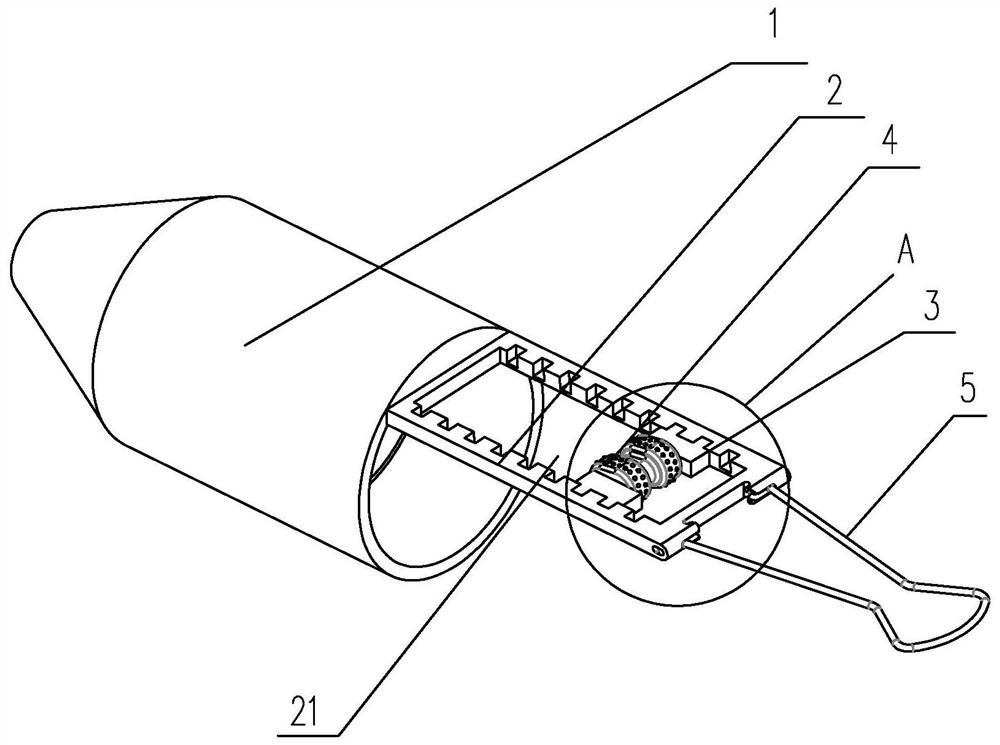

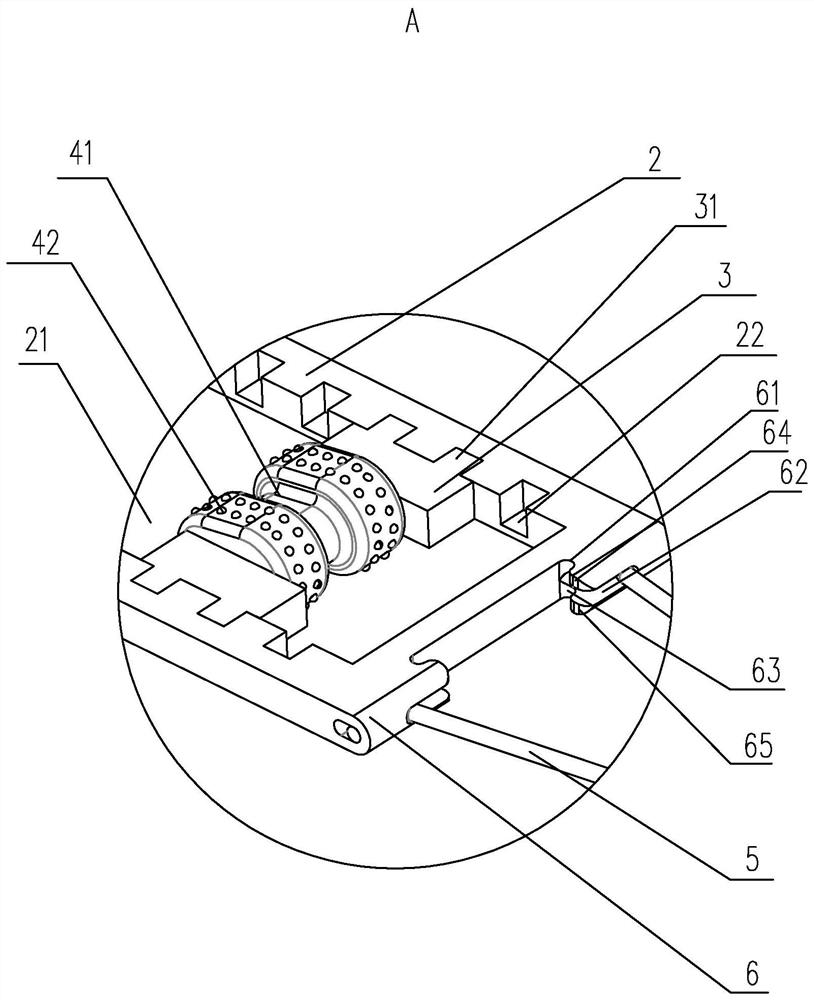

Fixing device for positioning rat for intragastric administration operation

The invention discloses a fixing device for positioning a rat for intragastric administration operation. The fixing device comprises a transparent tube body, wherein one end of the tube body is an inlet end, the other end of the tube body is an operation end, slide rails are arranged on the outer wall of the operation end of the tube body in the radial direction of the tube body, a positioning seat is slidably arranged on the slide rails, a positioning groove allowing the head of the rat to go out is formed in the positioning seat, clamping arms are arranged on the end surface of the positioning groove in a swing manner, the two clamping arms are staggered and mutually hinged, and hoop sleeves for tightening the clamping arms are arranged at the ends, away from the positioning groove, of the two clamping arms in a sleeving manner, a rotating through groove is formed in the positioning groove, an abutting cam is rotationally arranged in the rotating through groove, and a binding mechanism for fixing the body of the rat is also arranged on the tube body. The fixing device is simple in structure, can effectively position the fat and facilitates intragastric administration operation.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

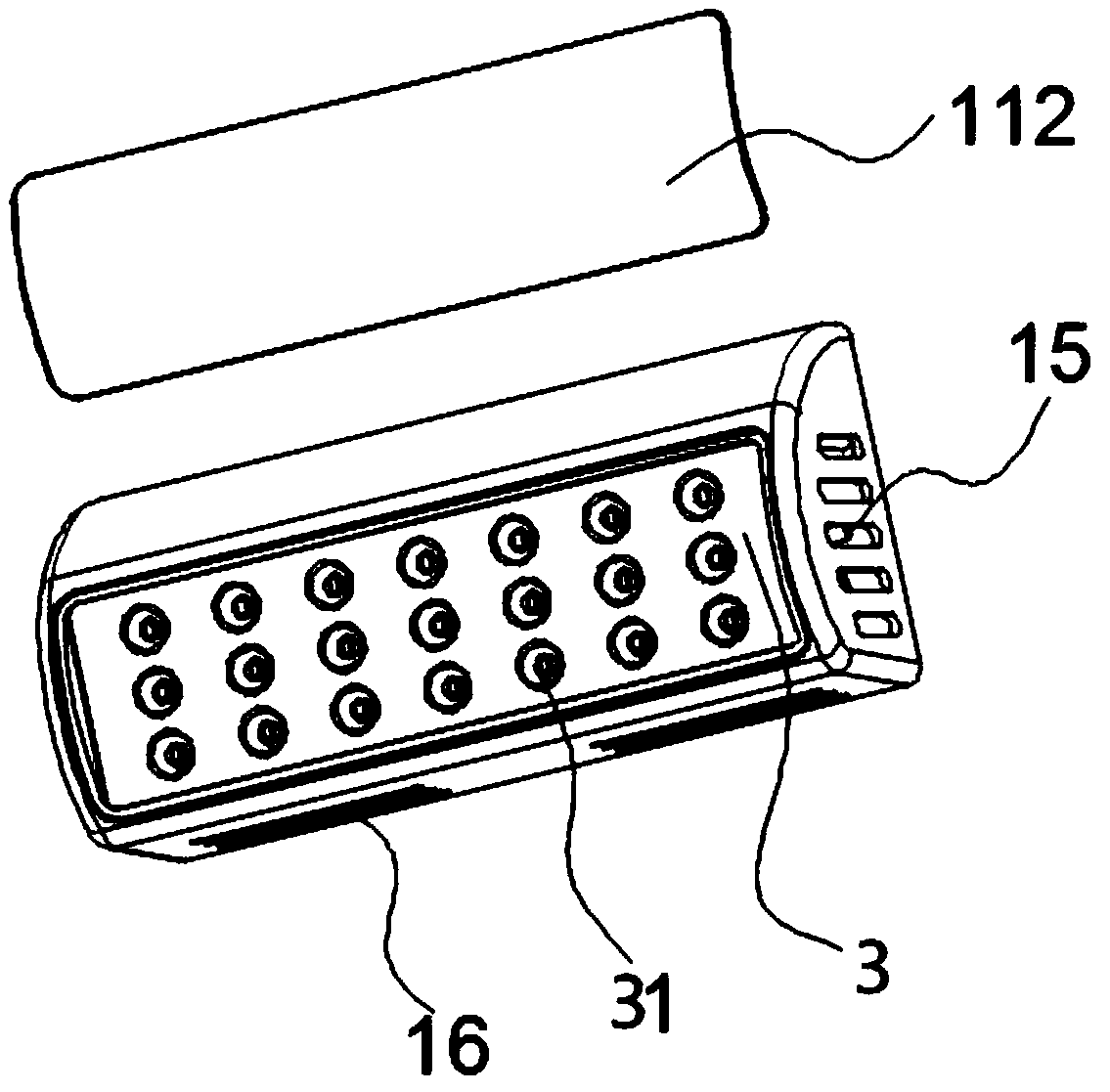

Safety lamp

PendingCN108621919AServe as a safety warningEasy to installWind energy with electric storageLighting elementsWind drivenEngineering

Owner:GUANGDONG QIMENG IND DESIGN CO LTD

Adjusting device for gas input amount of turbine and using method thereof

The invention discloses an adjusting device for the gas input amount of a turbine. The adjusting device comprises a base body. A first cavity extending left and right is formed in the base body. A second cavity is formed below the right side of the first cavity. A first rotating shaft extending up and down is installed in the upper end wall and the lower end wall of the second cavity through a bearing in a rotating manner. The upper end of the first rotating shaft extends into the first cavity and is fixedly connected with a first belt wheel. A rotating motor in power connection with the firstrotating shaft is arranged at the lower end of the second cavity. A second belt wheel connected with the first belt wheel through a belt is arranged on the left side in the first cavity. A third cavity is formed below the left side of the first cavity. A second rotating shaft is installed between the first cavity and the third cavity through a bearing in a rotating manner. The upper end of the second rotating shaft extends into the first cavity and is fixedly connected with the second belt wheel.

Owner:毛玲波

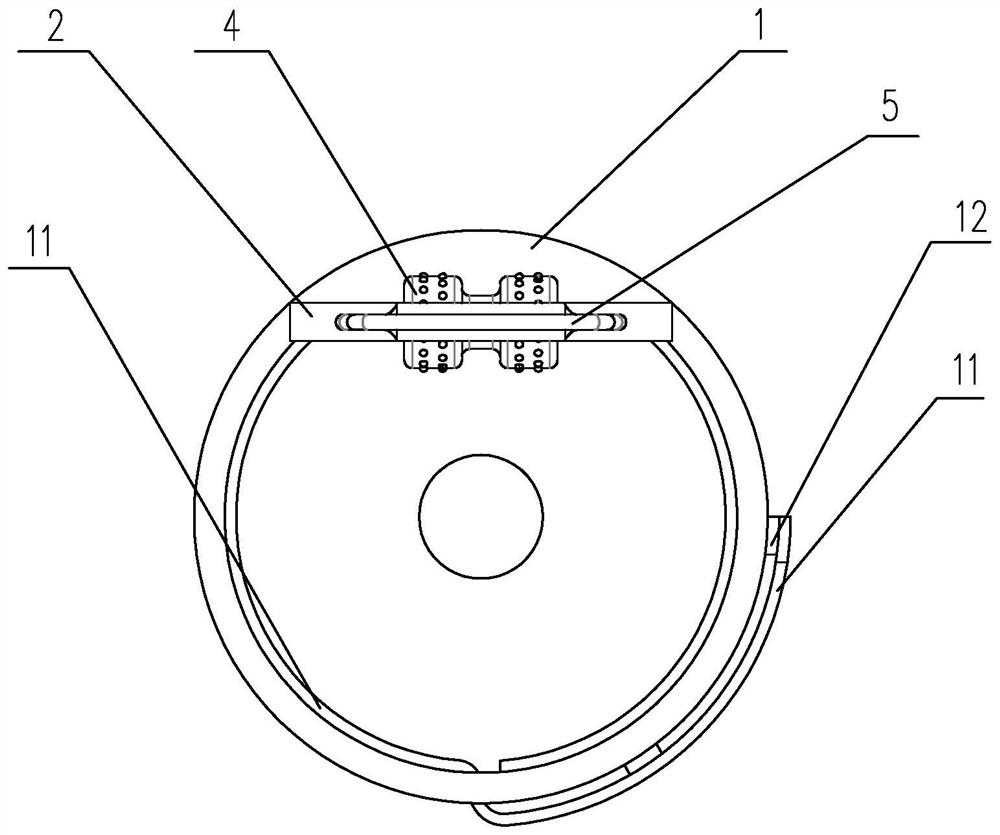

Annular welding device for wind power tower drum and use method thereof

PendingCN113231774ALocation effectReduce riskWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelStructural engineering

The invention discloses an annular welding device for a wind power tower drum and a use method thereof, and particularly relates to the technical field of wind power tower drums. The annular welding device comprises a reinforcing shell; two retainers are fixedly connected to the upper surface of the reinforcing shell; two bearings are clamped to the upper surfaces of the two retainers, respectively; the same connecting shaft is sleeved into the two bearings; the outer surface of the connecting shaft is fixedly connected with a mounting sleeve; and the outer surface of the mounting sleeve is fixedly connected with the front surface of a welding frame. According to the annular welding device, a magnetic sheet crawler belt, a driving wheel and the reinforcing shell are arranged, so that when the annular welding device is used for welding a wind power tower drum assembly through a welding device, the welding effect is not prone to being influenced by external wind power and gravity factors, and the influence on the welding effect due to dislocation of welding parts is reduced; and the worker can conveniently adjust the position of the annular welding device, so that the dangerousness when the worker climbs up and down the wind power tower drum assembly is reduced, and the safety of the worker is guaranteed.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Fixtures for Immobilizing Rat Testicles for Injection

ActiveCN111616825BEffective bondageRestricted movementAnimal fetteringStructural engineeringMechanical engineering

The invention discloses a fixing device for fixing testicles of rats for injection, which includes a positioning tube, one end of the positioning tube is tapered, and a bearing platform is set at the other end, a binding piece is set in the positioning tube, and A sliding groove is provided on the carrying platform, and a collision seat is arranged in the sliding groove, and a collision cam is rotated on the collision seat, and a hole seat is provided on the carrying platform, and a hole seat is oscillatingly arranged on the hole seat. U-shaped elastic restraint arm, the two free ends of the elastic restraint arm are bent to form pins, the pins are inserted into the hole seat, and the elastic restraint arm is closely attached to the mating surface of the outer wall of the hole seat A first positioning groove, a first converging protrusion, a second positioning groove, a second converging protrusion and a third positioning groove are formed, and the second positioning groove is deeper than the first positioning groove and the third positioning groove. The overall structure is simple, and the testis of rats can be fixed, thereby facilitating cell transplantation experiments.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

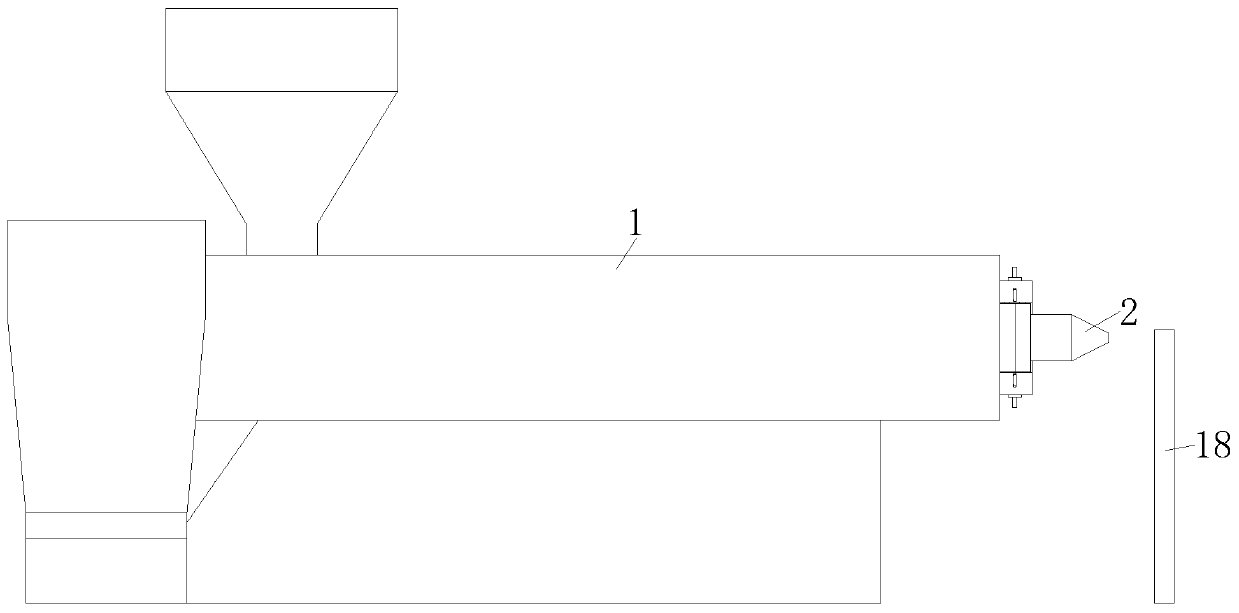

Electric heating pipe assembly production method

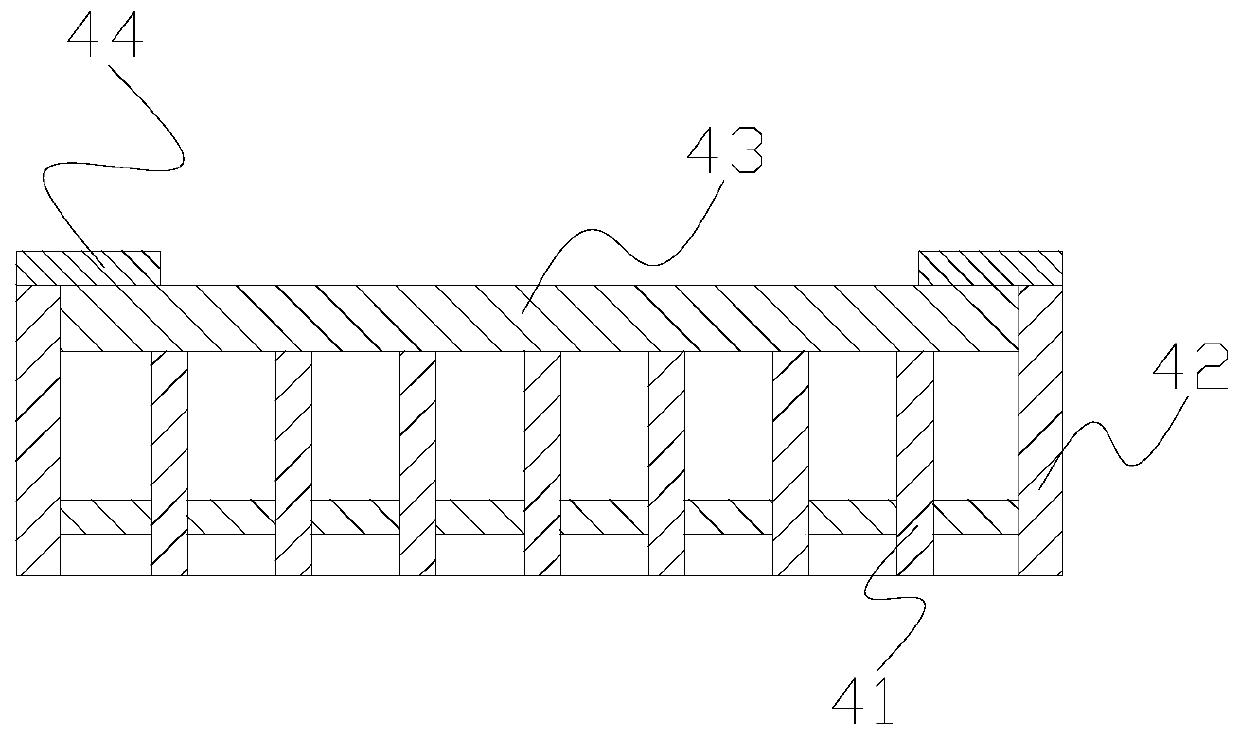

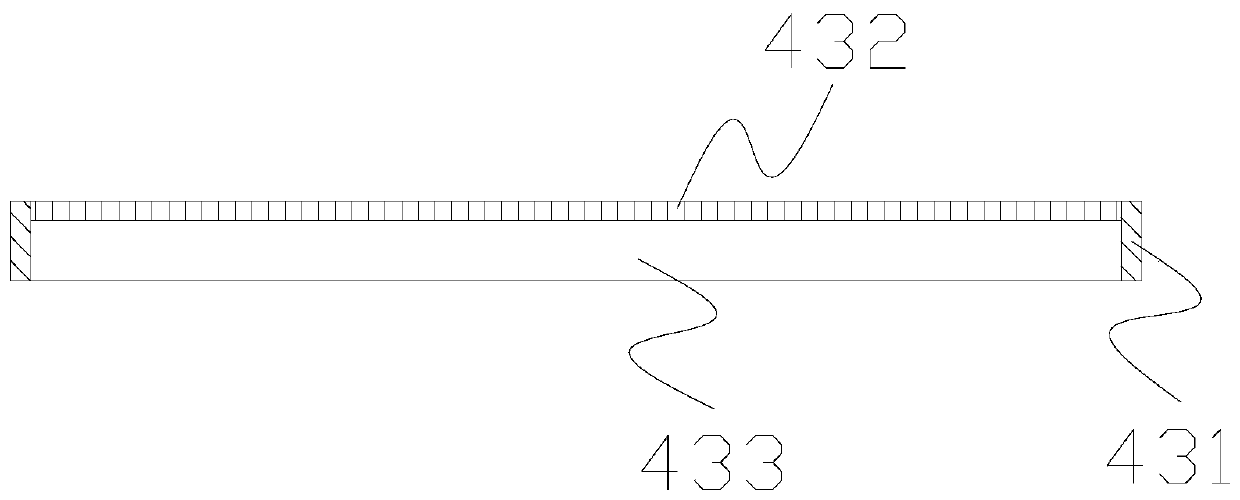

InactiveCN106332331ALocation effectEasy to set upHeating element shapesElectrical resistance and conductanceMetal

The invention relates to an electric heating pipe assembly production method. The electric heating pipe assembly production method comprises steps that 1) an electric resistance wire having a preset length is coiled; 2) the electric resistance wire assembly is disposed in a metal tube, a powder feeding machine is used to feed magnesium oxide powder in the metal tube, and a powder vibrating machine is used to vibrate the powder, and then the blank piece of the electric heating pipe assembly is acquired; 3) a pipe contracting machine is used for the pipe concreting of the electric heating pipe assembly according to a preset size, and the inner wall of the metal tube is contacted with a magnesium oxide base, and finally the production of the electric heating pipe assembly is completed. The magnesium oxide base is a cuboid column, the side wall of which is provided with a flat cable hole. The electric heating pipe assembly production method is advantageous in that the flat cable hole is used for fixing the position of the electric resistance wire, and the cuboid magnesium oxide pipe base is used to limit the position of the electric resistance wire, and therefore the powder vibration has no influences on the position of the electric resistance wire, and the cuboid magnesium oxide pipe base is used for limiting the contracted pipe.

Owner:扬中市华荣电器设备有限公司

A mechanical lifting type construction machinery transfer device

ActiveCN112110371BEasy transferCushion the shockLifting framesWinding mechanismsMechanical liftElectric machinery

The invention discloses a mechanical lifting construction machinery transfer device in the technical field of mechanical equipment transportation, which includes a mounting plate, a bottom assembly, a lifting assembly and a turbine assembly. On the front side of the bottom frame, there are through grooves on both sides of the bottom frame, and a roller is arranged horizontally in the middle of the front side of the bottom frame, a movable block is arranged inside the through groove, and a movable plate is arranged between the two groups of movable blocks, and the movable plate There are pin shaft rods between the movable block and the upper surface of the front side, left and right sides of the movable plate are fixed with ring seats, the rear side of the bottom frame is fixed with side wings, and the two sides of the lifting and lowering components are installed with cylinders. And the lift assembly is located on both sides of the bottom assembly, the motor is installed on the top of the turbine assembly, and the turbine assembly is located above the front side of the mounting plate, this mechanical lifting construction machinery transfer device can simplify the manpower required for mechanical transportation Material resources, simple structure and high efficiency.

Owner:WENZHOU POLYTECHNIC

A device for removing a bearing of a traction motor and a method applied to the device

ActiveCN110829746BAchieve positioningLocation effectRoller bearingsShaftsControl engineeringElectric machinery

The invention discloses a device for dismounting a bearing of a traction motor, comprising: a positioning mechanism fixedly arranged on a rotor assembly and a moving mechanism movable relative to the positioning mechanism; the positioning mechanism is provided with a positioning surface, and the moving mechanism is provided with a The positioning surface cooperates to enable the rotor assembly to achieve radial and axial positioning. Compared with the prior art, the dismantling device of the traction motor bearing provided by the present invention avoids the dismantling process of the bearing after the rotor assembly is separated from the stator assembly, simplifies the dismantling process of the traction motor bearing, and reduces the cost of bearing disassembly. The configuration requirements and costs of human resources and material resources shorten the disassembly time of traction motor bearings and improve work efficiency. The invention also discloses a dismantling method of the traction motor bearing applied to the dismantling device of the traction motor bearing.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

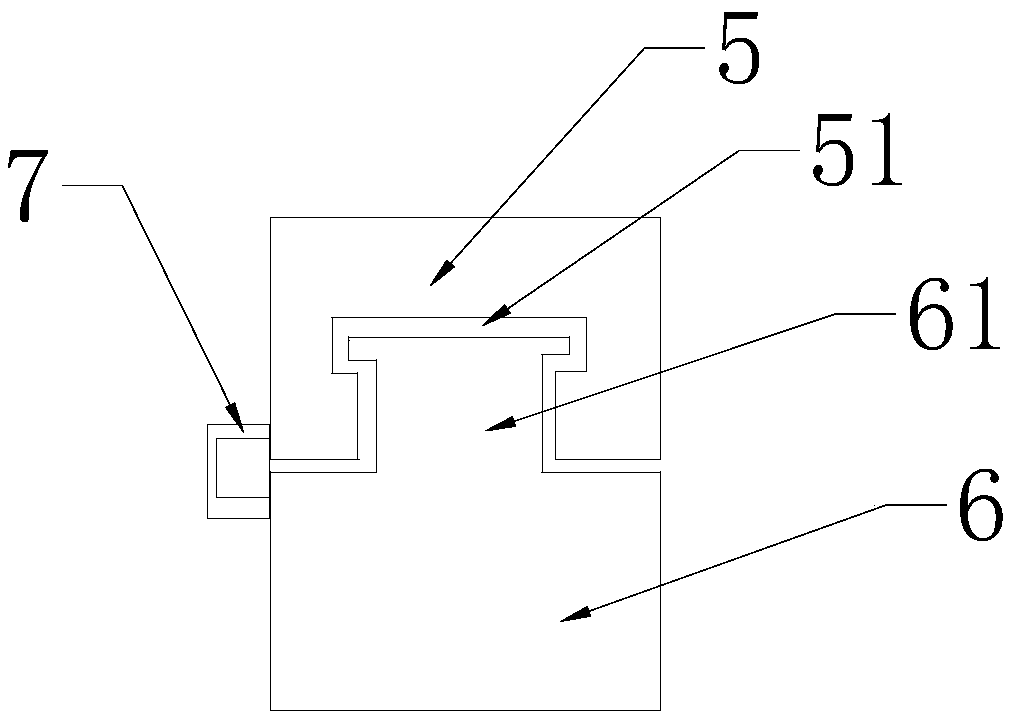

Mold measuring device with protection function

PendingCN112378439AImprove the protective effectPlay a fixed roleMeasurement apparatus caging devicesMeasurement deviceFixed frame

The invention discloses a mold measuring device with a protection function, which comprises a measuring device body, a placing plate body is arranged in the measuring device body, fixing frames sleevetwo sides of the placing plate body, and fixing mechanisms matched with the placing plate body for use are arranged at the bottoms of the fixing frames. Through cooperative use of the measuring device body, the placing plate body, the fixing frames, the fixing mechanisms, the fixing grooves, the positioning sleeves, the connecting rods, clamping plates, limiting rings, grooves, positioning mechanisms, limiting grooves, teeth, positioning grooves, positioning blocks, through openings, sliding blocks and sliding grooves, the problem that an existing mold measuring device cannot fix the positionof a mold in the using process and is poor in protection effect, the position of a mold is prone to deviating, the measurement experiment of a user on the mold is affected, and inconvenience is brought to the user is solved, and the mold measuring device with the protection function has the advantage of being good in protection effect.

Owner:XINGFA ALUMINUM CHENGDU

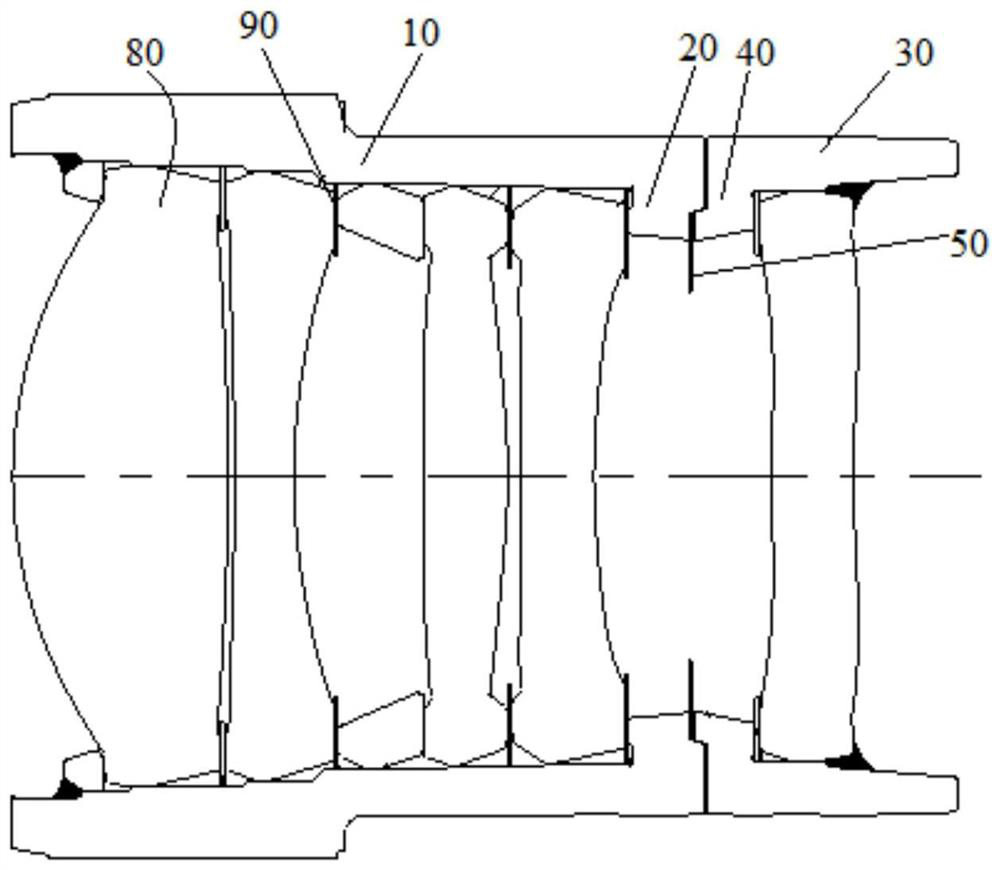

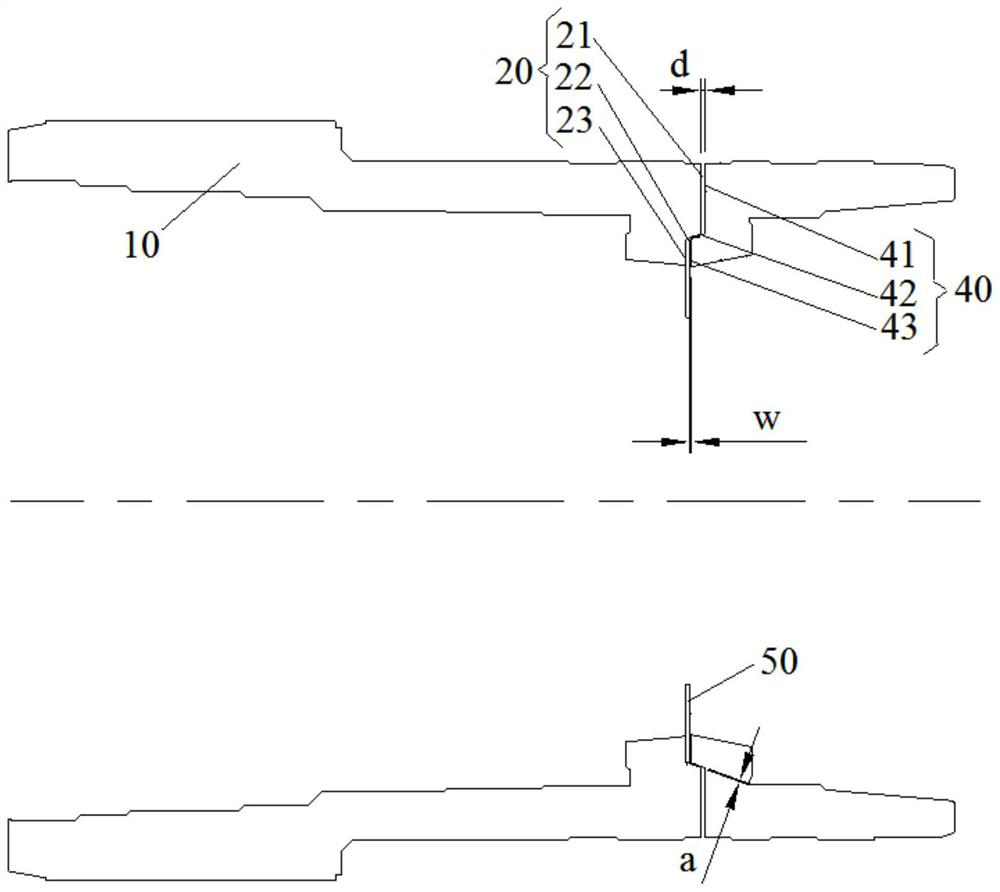

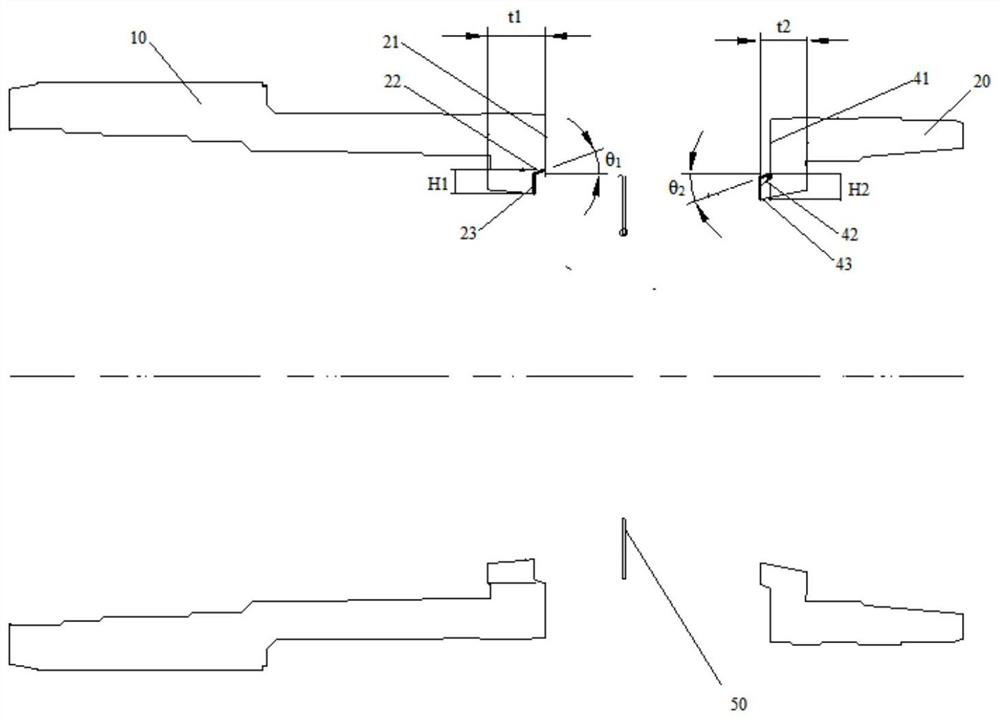

Lens barrel, optical imaging lens and electronic device

The invention provides a lens barrel, an optical imaging lens and an electronic device. The lens barrel includes: a first lens barrel having a first connection structure at an object-side end thereof;a second lens barrel having a second connecting structure matched with the first connecting structure at an image-side end thereof; and an anti-dazzling screen arranged between the first connecting structure and the second connecting structure. The problem that in the prior art, it is difficult to adjust the anti-dazzling screen of the optical imaging lens to a proper cutting position is solved.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

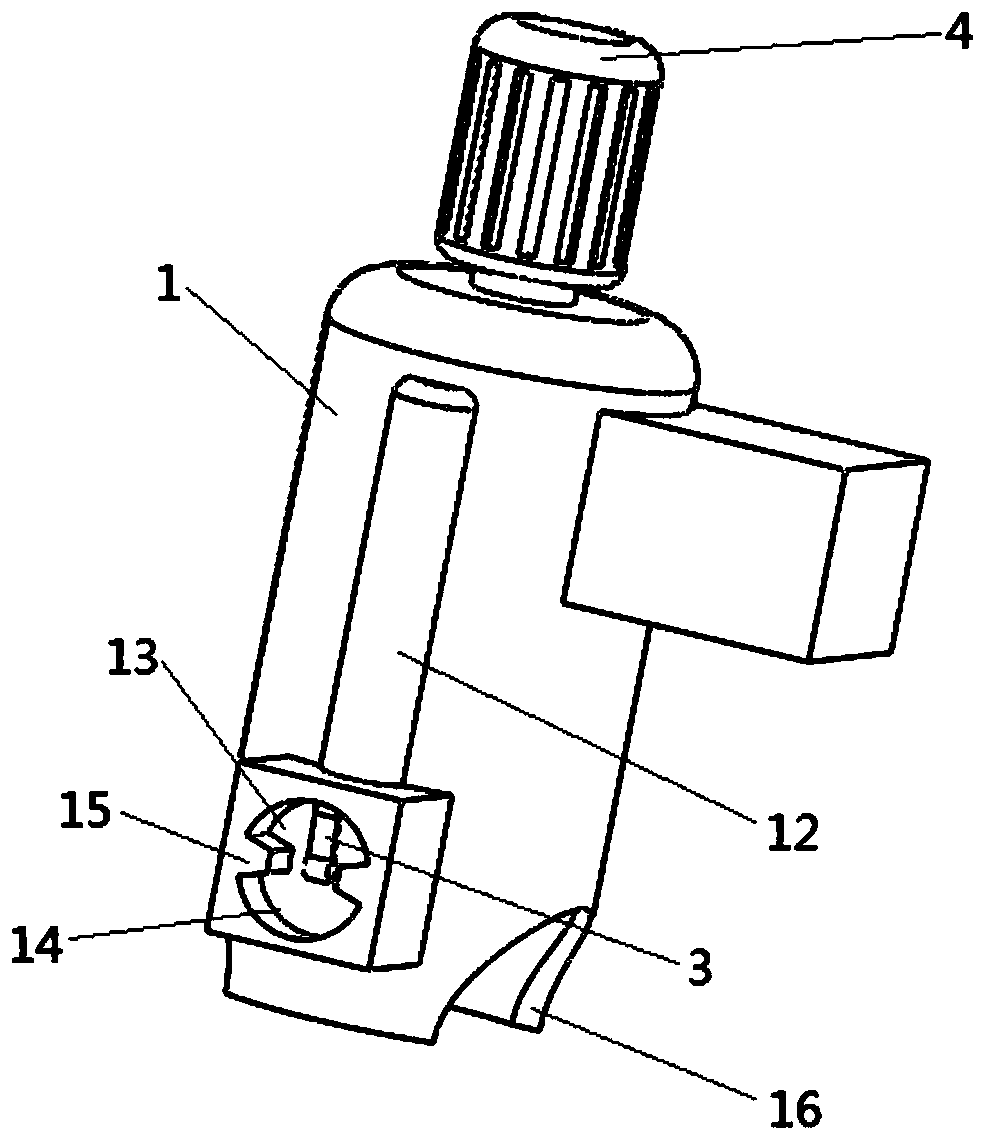

Angular stroke low-temperature valve electric executing mechanism

PendingCN110864154APromote repairLocation effectOperating means/releasing devices for valvesBevel gearIndustrial engineering

The invention provides an angular stroke low-temperature valve electric executing mechanism. A shell, a handle and a transmission unit are included. The shell can sleeve a valve stuffing box and downwards extends. The handle is arranged at the lower portion of the shell, and a manual bevel gear is arranged in the shell to be connected with the handle. The transmission unit comprises a connecting shaft rod arranged on the top of the shell, the connecting shaft rod extends towards the lateral side to form a connecting shaft rod bevel gear, one transmission rod is parallel to the height directionof the shell, the top of the transmission rod is provided with a transmission rod upper bevel gear engaged with the connecting shaft rod bevel gear, and a transmission rod lower bevel gear is arranged at the bottom of the transmission rod and can be engaged with the manual bevel gear. The shell is used for sleeving the valve stuffing box, the height of the handle for manual valve control is downwards adjusted to the place adjacent to a pipeline, and the valve can be conveniently opened and closed during power failures. When micro leakage happens to the pipeline, the opening and closing handleis close to the pipeline, and maintenance personnel can conveniently control the valve in the pipeline maintaining process.

Owner:天津市北方阀门控制设备有限公司

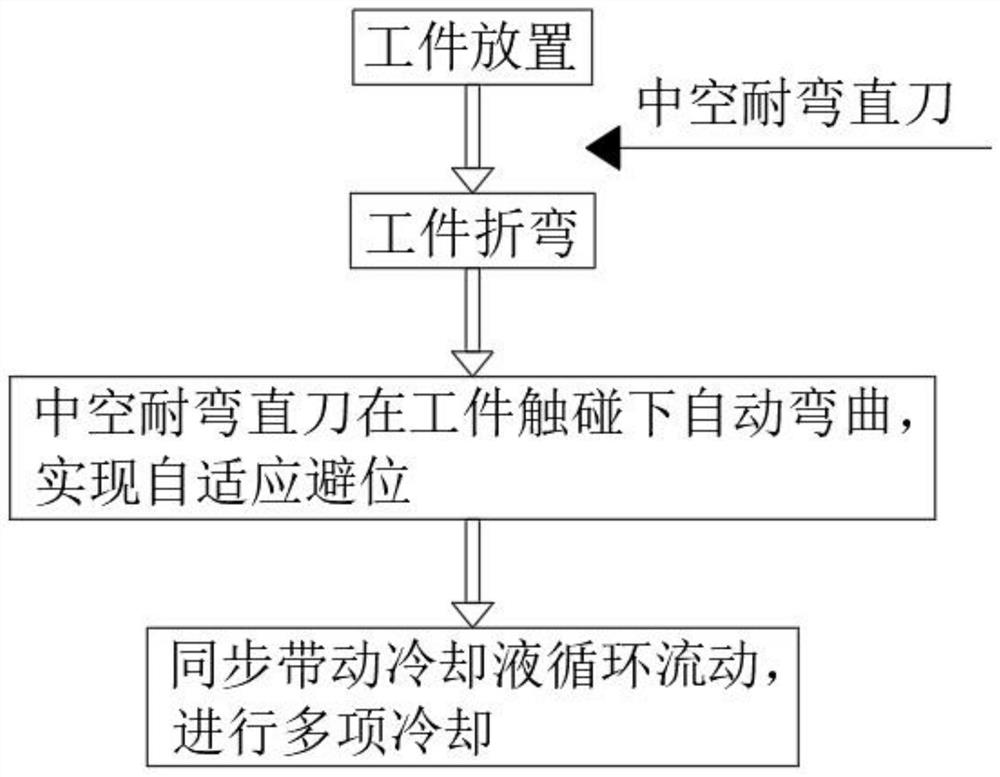

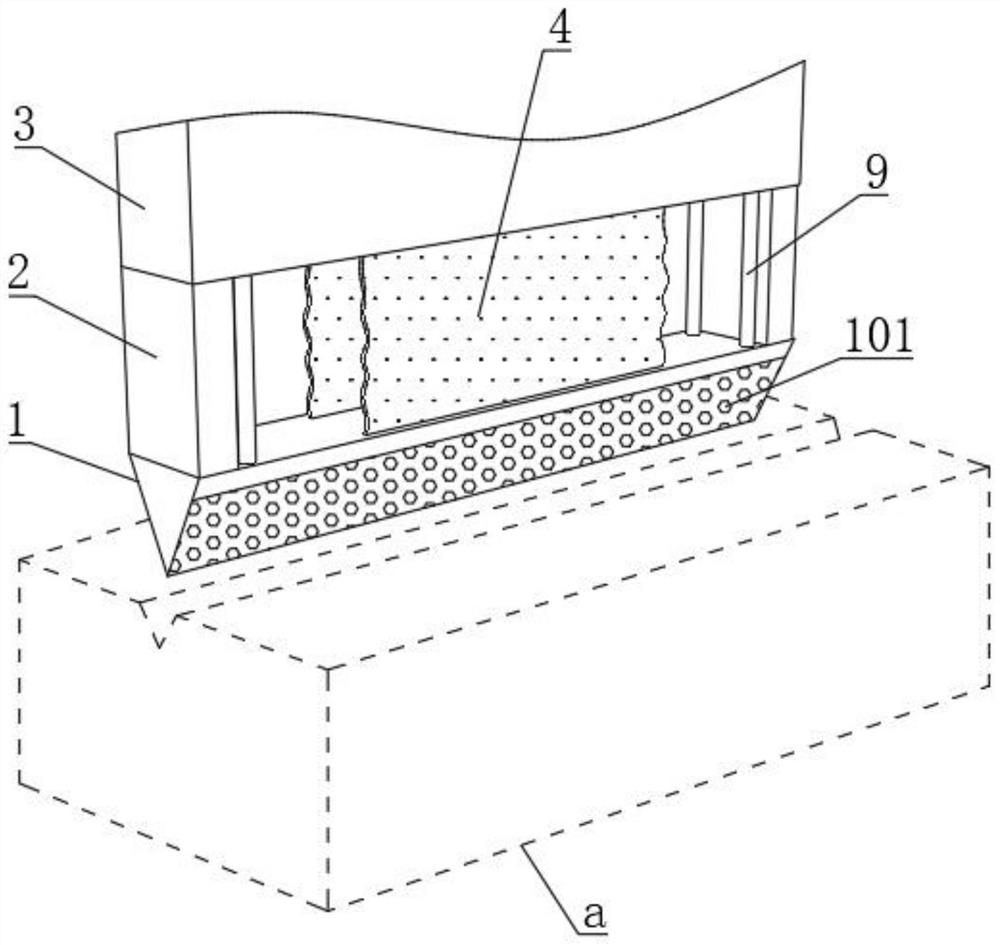

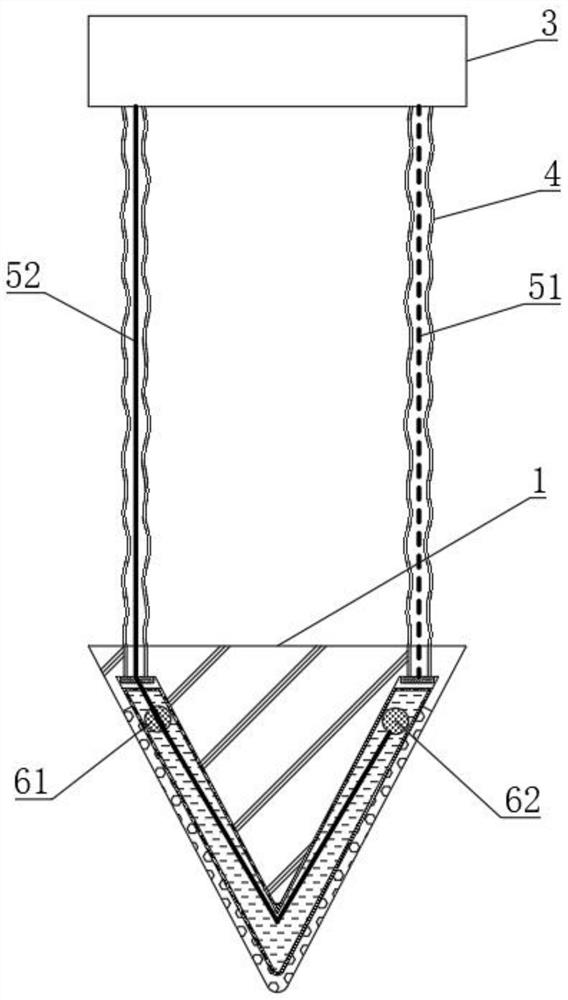

Cold-rolled steel sheet metal part bending process

ActiveCN113020337ARealize adaptive avoidanceNot easy to reboundShaping toolsUltimate tensile strengthCooling fluid

The invention discloses a cold-rolled steel sheet metal part bending process, and belongs to the field of bending technology. A hollow bending-resistant straight knife is adopted for extruding and bending a cold-rolled steel sheet metal part, on one hand, the hollow bending-resistant straight knife can correspondingly bend and deform along with touch of the cold-rolled steel sheet metal part, self-adaptive avoidance of the cold-rolled steel sheet metal part is achieved, compared with the bending process of first quantitative bending and then edge pressing in the prior art, direct bending operation of multiple bends can be achieved, the bending efficiency is greatly improved, meanwhile, the accuracy of the bending size is also improved, and on the other hand, the hollow bending-resistant straight knife synchronously drives cooling liquid therein to circulate during self-adaptive avoidance, self-circulating cooling of the cooling liquid and circulating cooling of the cold-rolled steel sheet metal part and the hollow bending-resistant straight knife are achieved, the influence of heat on the hardness and strength of the cold-rolled steel sheet metal part is reduced, and the cold-rolled steel sheet metal part is not prone to springback after being bent.

Owner:广州安彤实业有限公司

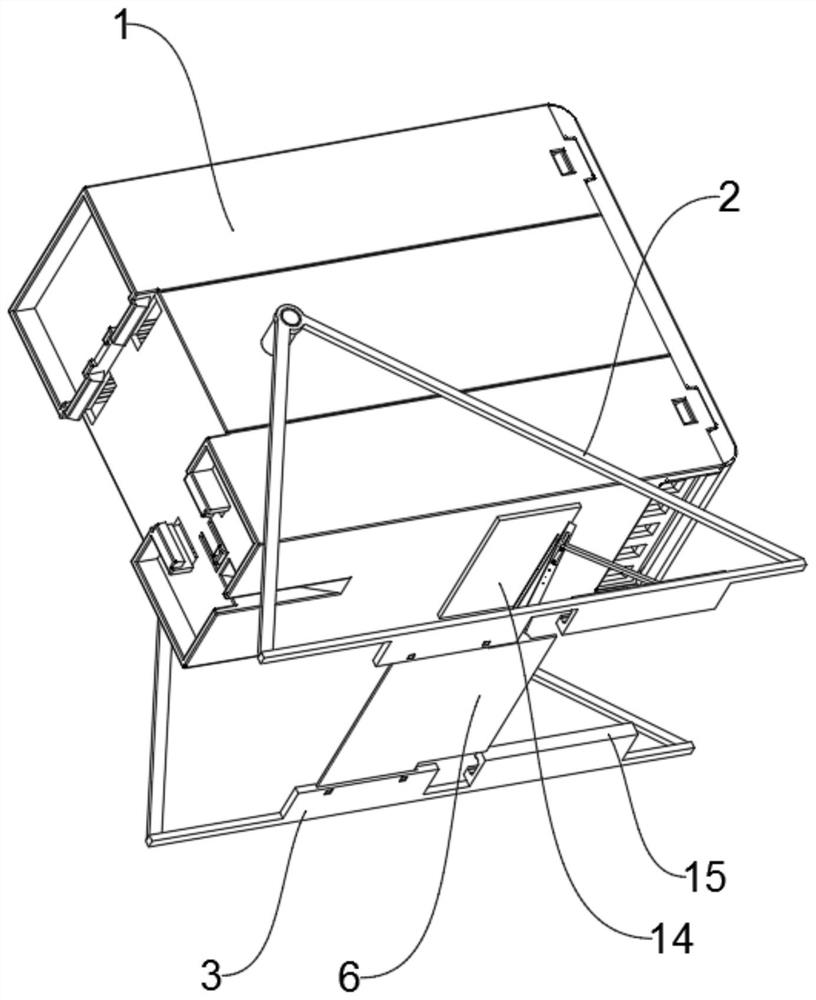

State monitoring system based on Internet of Things of power system

PendingCN114217133AAvoid adverse consequencesAngle stableImpedence measurementsInformation technology support systemElectric power systemThe Internet

The invention discloses a state monitoring system based on the Internet of Things of a power system, which comprises a power monitor, triangular rods are hinged to the two ends of the power monitor, and side blocks are fixedly connected to the side walls of the triangular rods. According to the power monitor, the triangular rods are installed at the two ends of the power monitor, the triangular rods can rotate at the two ends of the power monitor, and the connecting plates are clamped with the grooves formed in the side blocks, so that the clamping blocks fixedly connected to the bottoms of the connecting plates extend into the clamping grooves penetrating through the grooves, and the positions of the connecting plates can be fixed; due to the fact that connection is tight when the clamping blocks and the clamping grooves are clamped, the clamping blocks cannot be separated from the clamping grooves, the connecting plates can be stably clamped with the grooves, the connecting plates cannot be separated from the grooves, the connecting plates cannot be affected even if the rotating rods are subjected to external force, and the connecting plates can keep the positions stable and are more stable. And adverse consequences on the rotating rod under the action of external force can be effectively prevented.

Owner:DALIAN POWER SUPPLY COMPANY STATE GRID LIAONING ELECTRIC POWER

Metal sheet surface milling device

InactiveCN112828621ALocation effectAvoid random rotationMilling machinesPositioning apparatusGear wheelMetal sheet

The invention discloses a sheet metal surface milling device in the technical field of machining. The sheet metal surface milling device comprises a rack, a storage table, a milling mechanism fixed to the rack and two fixing mechanisms used for pressing a sheet metal. The number of the fixing mechanisms is two, and the two fixing mechanisms are located on the two sides of the milling mechanism correspondingly. Each fixing mechanism comprises a supporting table, a lifting machine, a rack and a pressing strip, wherein the lifting machine supports the supporting table above the storage table, the rack is in sliding connection with the supporting table, threaded holes corresponding in position are formed in the rack and the supporting table, and bolts are connected into the threaded holes. The pressing strips are located between the supporting tables and the storage table and fixedly connected with connecting rods, the connecting rods penetrate through the supporting tables in a sliding mode, each connecting rod is fixedly connected with two clamping plates making contact with the upper surface and the lower surface of the corresponding supporting table correspondingly, the tops of the connecting rods are fixedly connected with gears, and the gears are engaged with the racks. According to the scheme, the positions of the fixing mechanisms are not likely to change, and unnecessary trouble brought to workers is avoided.

Owner:宁波信基机械科技有限公司

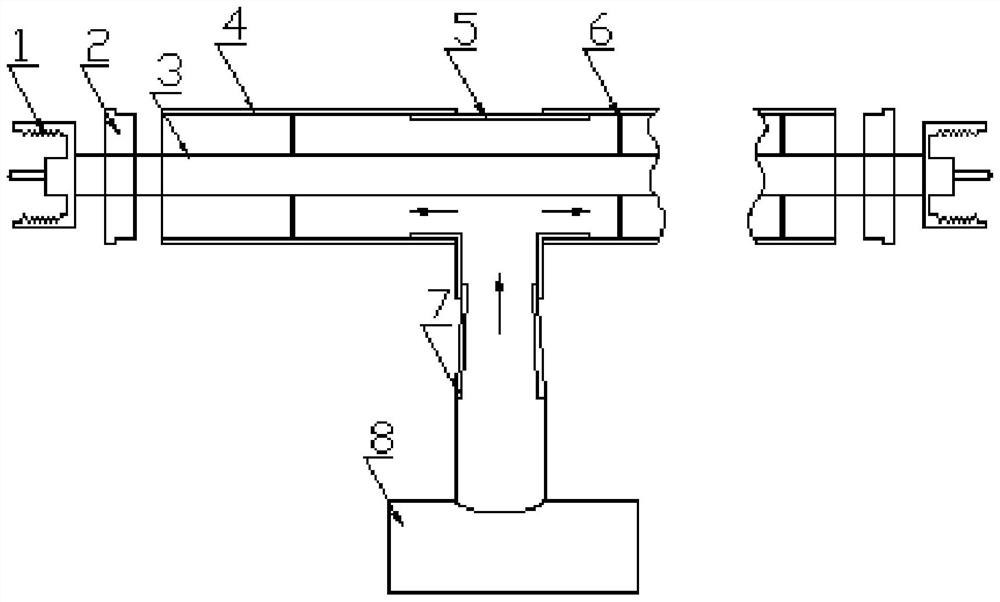

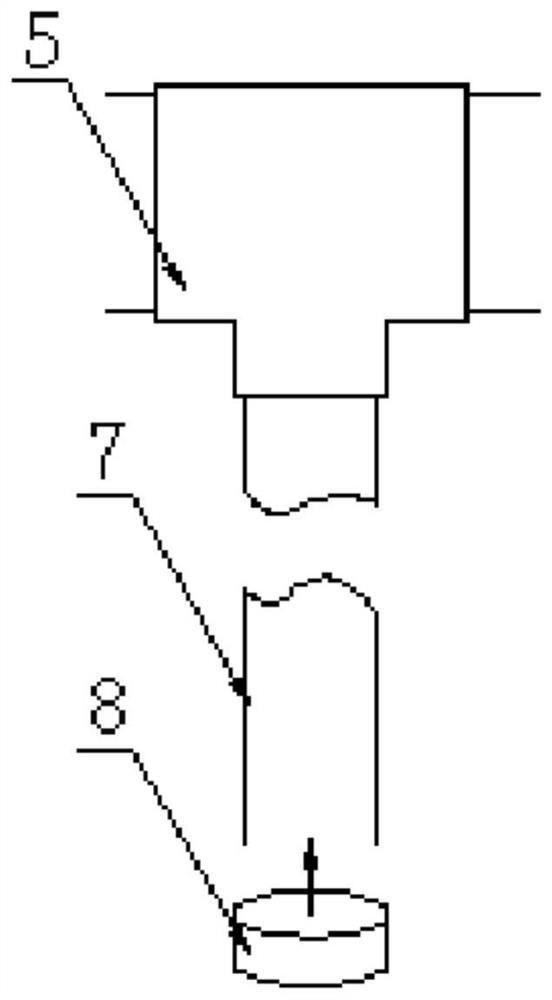

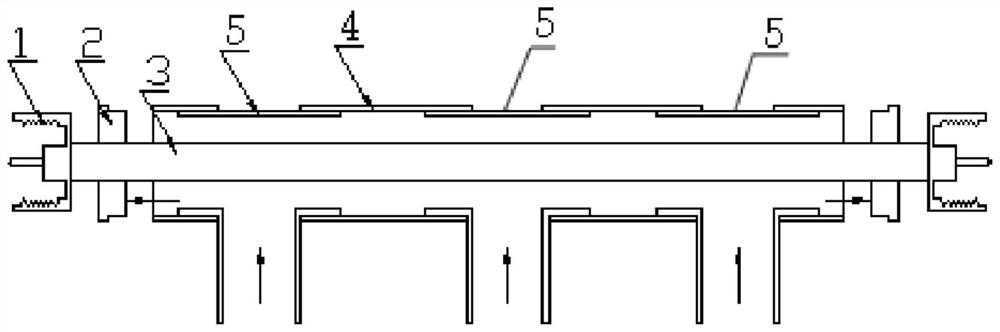

Axial thermal convection cooling device for radio frequency cable

PendingCN112272498ARapid coolingStable outputModifications using gaseous coolantsConvection heatRadio frequency

The invention relates to an axial thermal convection cooling device for a radio frequency cable. The device is used for cooling the radio frequency cable and comprises a trapezoidal joint, a first guide pipe, a T-shaped joint, a bracket, a second guide pipe and cooling medium input equipment, the radio frequency cable is installed in the first guide pipe, and the first guide pipe supports the radio frequency cable through a support. The first guide pipe is of a sectional structure, a T-shaped connector is connected between every two adjacent sections of the first guide pipe, and the T-shaped connectors are further connected with cooling medium input equipment through second guide pipes; trapezoidal connectors are arranged at the two ends of the whole first guide pipe and provided with through holes allowing radio frequency cables to penetrate through, and the cooling medium input device is used for inputting convection media. Compared with the prior art, axial heat convection heat dissipation cooling of the radio frequency cable is achieved, cooling of the radio frequency cable is accelerated, and a radio frequency power supply can stably output in a normal high-power working state.

Owner:苏州科中方源电子科技有限公司

Multifunctional earth boring machine for environment improvement

InactiveCN113374410ALocation effectReduce processing difficultyEarth drilling toolsConstructionsDrive shaftMachine

The invention relates to the technical field of environment-friendly accessory devices, in particular to a multifunctional earth boring machine for environment improvement. The multifunctional earth boring machine is simple in structure, reduces the processing difficulty, facilitates inclined hole digging and improves the practicability. The multifunctional earth boring machine comprises a front support, a rear support, a first threaded rod, a second threaded rod, a first guide rod, a second guide rod, a guide rail and a driving arm; the front support and the rear support are inverted-T-shaped, first bearings are arranged at the top ends of the front support and the rear support, inner rings of the two first bearings are connected with a driving shaft, and the driving shaft is fixedly connected with a driving ring; a transverse rod is fixedly connected to one end of the driving ring, a connecting shaft is fixedly connected to the end, far away from the driving shaft, of the transverse rod, a second bearing is arranged in an upper half area of the rear support, a rotating shaft is arranged on an inner ring of the second bearing, a base plate is fixed to the front end of the rotating shaft, two sets of rails are arranged at the side, close to the front support, of the base plate, and sliding blocks are slidably connected to the two sets of rails; and the sliding blocks are fixedly connected with a fixing shaft, and the fixing shaft and the rotating shaft are coaxial.

Owner:蔡素娟

Double-sided boring and milling machine based on fixed shaft layering principle

InactiveCN113977309ATroubleshooting Position Calibration IssuesProduction efficiency doubledMilling machinesMetal working apparatusMilling cutterEngineering

The invention belongs to the field of machining, and particularly relates to a double-sided boring and milling machine based on a fixed shaft layering principle. The boring and milling machine comprises a lifting plate, the bottom end of the lifting plate is fixedly connected with a bottom table, the middle part of an inner cavity of the lifting plate is slidably connected with a double-sided clamping plate, the rear end of the double-sided clamping plate is slidably connected with the back surface of the lifting plate through a slot, an intercepting column is clamped in inner cavity of the double-face clamping plate, milling cutter force arms are slidably connected to the two ends of an inner cavity of the lifting plate, and a milling cutter head is fixedly connected to the front end of each milling cutter force arm. When the device is used for machining an object, as the milling cutter force arms on the two sides are symmetrical, the milling effects of the two faces of the object are almost the same, the milled object does not need to be turned over for multiple milling machining, the problem that much time is spent on position calibration of the turned-over object is solved, the production efficiency is doubled by adopting the process method of milling the two surfaces at the same time, and the production cost is reduced.

Owner:施建华

A textile printing machine

ActiveCN110481170BPaved and fixedLocation effectTypewritersOther printing apparatusTextile printerEngineering

The invention discloses a textile fabric printing machine. The textile fabric printing machine structurally comprises a machine case, transverse moving cases, a guide rail, a textile fabric paving structure, a printing machine case and a control case. The guide rail is embedded in the upper end of the inner side of the machine case; the transverse moving cases are arranged on the front surface andthe back surface of the machine case and are movably connected with the guide rail; the textile fabric paving structure is horizontally arranged at the upper end of the machine case; and the printingmachine case is positioned above the textile fabric paving structure and is horizontally arranged at the upper end of the transverse moving case, and the control case is arranged at the upper end ofthe machine box. The textile fabric paving structure comprises a support, a side plate, a placing structure and a side paving mechanism, wherein the side plate is installed on the outer side of the support, the placing structure is horizontally installed at the upper end of the support and is located on the inner side of the side plate, and the side paving mechanism is horizontally installed at the upper end of the placing structure. According to the textile fabric printing machine, the side paving mechanism is arranged at the upper end of the placing structure, so that the textile fabric canbe well paved and fixed, the influence of the sprayed air on the position of the textile fabric is effectively prevented, and the printing effect and quality are improved.

Owner:广州南沙经济技术开发区冠丽印花有限公司

Adjusting device for single-cylinder turbine

The invention discloses an adjusting device for a single-cylinder turbine. The adjusting device comprises a base body. A left-right-extending first cavity is formed in the base body. A second cavity is formed below the right side of the first cavity. The upper end wall and the lower end wall of the second cavity are rotationally provided with an up-down-extending first rotation shaft through bearings. The upper end of the first rotation shaft stretches into the first cavity and is fixedly connected with a first belt wheel. The lower end of the second cavity is provided with a rotation motor which is in power connection with the first rotation shaft. The left side in the first cavity is provided with a second belt wheel which is connected with the first belt wheel through a belt. A third cavity is formed below the left side of the first cavity. A second rotation shaft is rotationally arranged between the first cavity and the third cavity through a bearing. The upper end of the second rotation shaft stretches into the first cavity and is fixedly connected with the second belt wheel.

Owner:毛玲波

LED street lamp with guardrail

InactiveCN110864255ALocation effectSolve puzzles set in the roadMechanical apparatusLighting support devicesStructural engineeringLight head

Owner:江苏华夏灯业制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com