Double-sided boring and milling machine based on fixed shaft layering principle

A boring and milling machine, double-sided technology, applied in the field of double-sided boring and milling machines, can solve the problems of low production efficiency, scrapped objects, and high production costs, and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

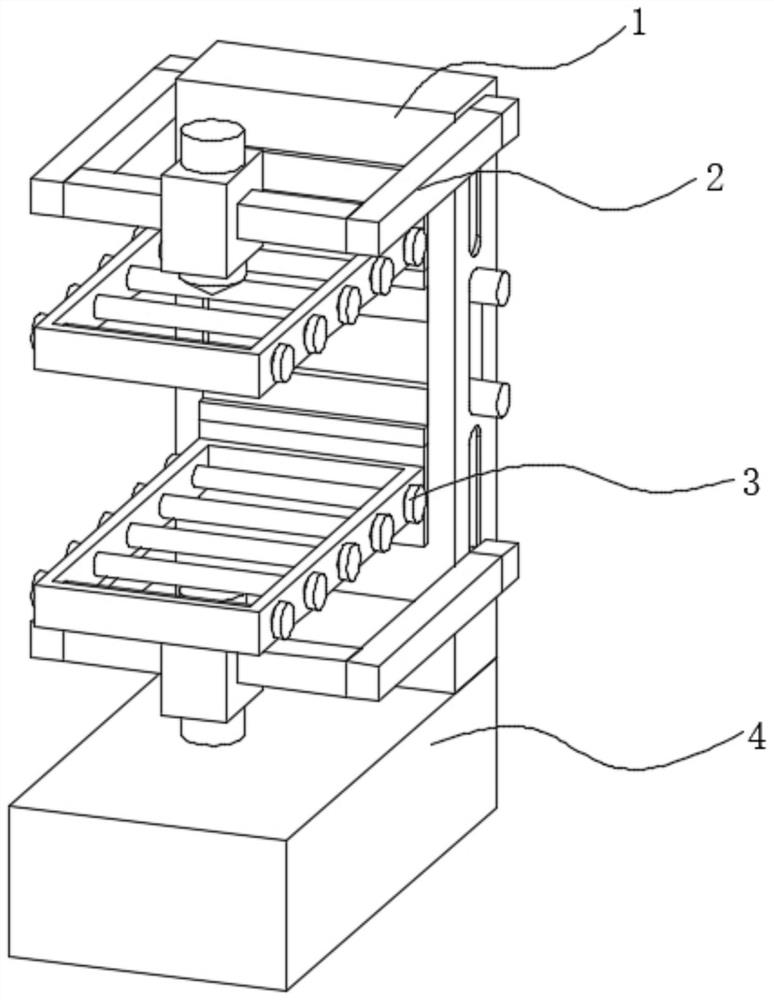

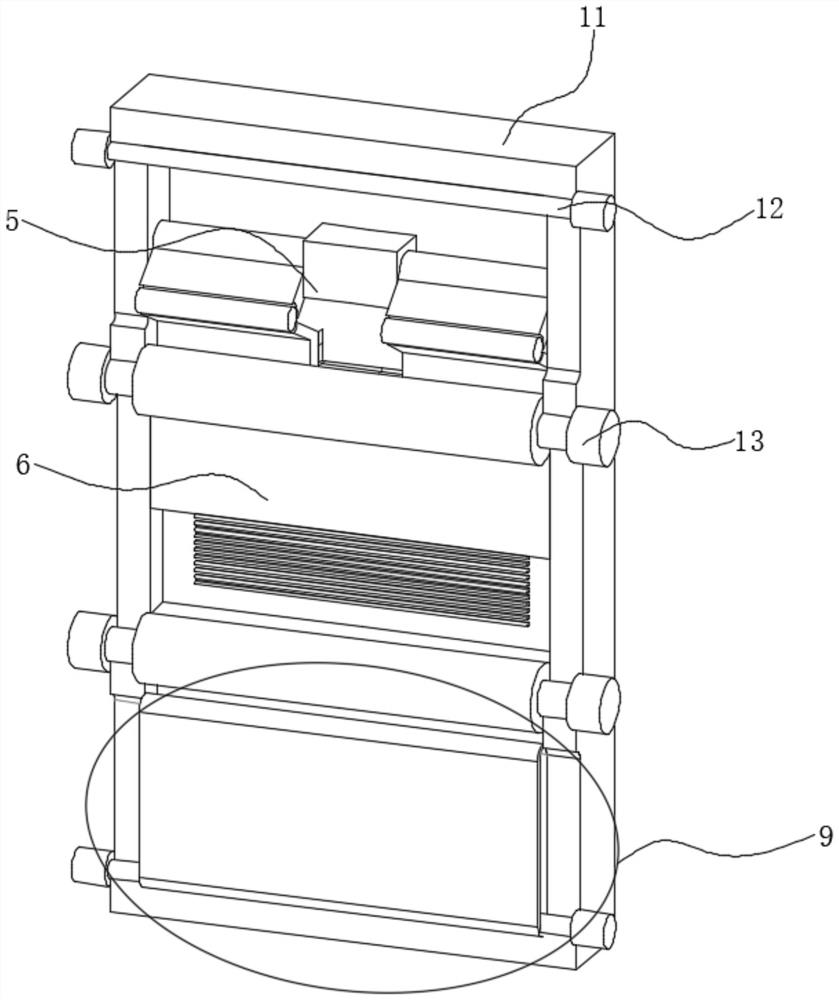

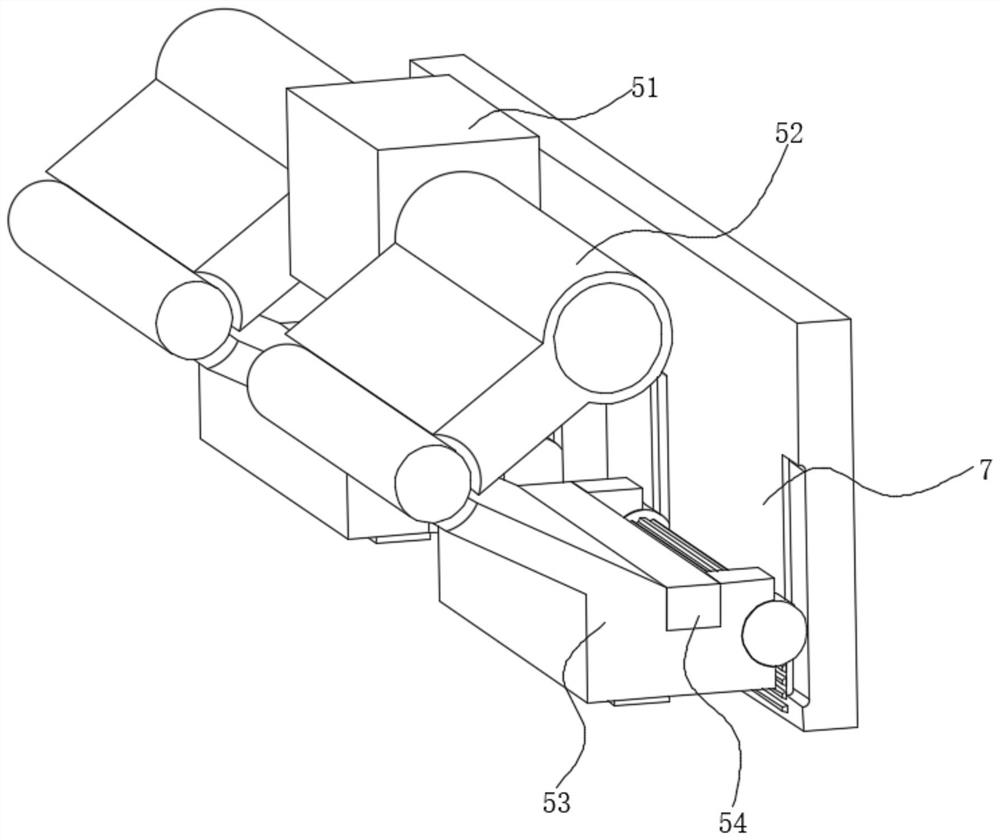

[0024] use Figure 1-Figure 7 A double-sided boring and milling machine based on the principle of fixed-axis layering according to an embodiment of the present invention is described as follows.

[0025] Such as Figure 1-Figure 7 As shown, a double-sided boring and milling machine based on the principle of fixed axis layering according to the present invention includes a lifting plate 1, the bottom end of the lifting plate 1 is fixedly connected with a base 4, and the lifting plate 1 The middle part of the inner cavity is slidably connected with a double-sided splint 3, and the rear end of the double-sided splint 3 is slidably connected with the back of the lifting plate 1 through a slot. Both ends of the inner cavity of the lifting plate 1 are slidably connected with a milling cutter force arm 2, and the front end of the milling cutter force arm 2 is fixedly connected with a milling cutter head. Clamp the object in the vertical position, and remove the intercepting column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com