Novel flat-belt press vulcanizer and operation method thereof

A technology of flat vulcanizing machine and operation method, which is applied to belts, other household appliances, household appliances, etc., can solve the problems of inconsistent width of two product belts, difficult to shift, too narrow and too wide, etc., to expand the scope of equipment use, The effect of increased machine utilization and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

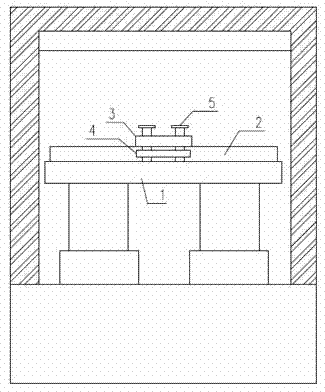

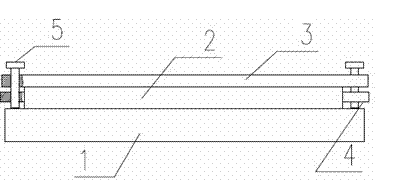

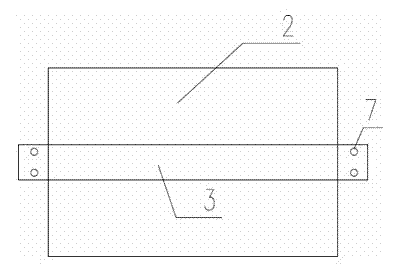

[0025] Such as figure 1 , figure 2 and image 3 As shown, a novel flat-belt plate vulcanizing machine includes a main engine, and the main engine includes a lower frame; it is characterized in that the lower frame includes a fixed flat plate 1, a lower heating plate 2, an isolation plate 3 and a positioning device, and the lower layer The width of the hot plate is 2.6 meters, and the length is 10 meters. The width of the isolation plate is 0.26 meters, and the length is 10.6 meters. The length of the isolation plate is 0.6 meters longer than the length of the lower thermal plate. The pin hole part 4 and the pin 5 at the inlet and outlet ends, the two ends of the isolation plate are provided with holes 7 equal in size to the pin holes, after aligning the holes on the isolation plate with the pin holes, fix them with the pin 5, and the isolation plate 3 is located in the middle of the lower hot plate, the two ends of the isolation plate are 0.3 meters beyond the lower hot pla...

Embodiment 2

[0034] Such as figure 1 , figure 2 and image 3 As shown, a novel flat-belt plate vulcanizing machine includes a main engine, and the main engine includes a lower frame; it is characterized in that the lower frame includes a fixed flat plate 1, a lower heating plate 2, an isolation plate 3 and a positioning device, and the lower layer The width of the hot plate is 2.4 meters, and the length is 12 meters. The width of the isolation plate is 0.24 meters, and the length is 12.6 meters. The length of the isolation plate is 0.6 meters longer than the length of the lower thermal plate. The pin hole part 4 and the pin 5 at the inlet and outlet ends, the two ends of the isolation plate are provided with holes 7 equal in size to the pin holes, after aligning the holes on the isolation plate with the pin holes, fix them with the pin 5, and the isolation plate 3 is located in the middle of the lower heating plate, the two ends of the isolation plate are 0.3 meters beyond the lower hea...

Embodiment 3

[0037] Such as figure 1 , figure 2 and image 3 As shown, a novel flat-belt plate vulcanizing machine includes a main engine, and the main engine includes a lower frame; it is characterized in that the lower frame includes a fixed flat plate 1, a lower heating plate 2, an isolation plate 3 and a positioning device, and the lower layer The width of the hot plate is 1.8 meters, and the length is 8.5 meters. The width of the isolation plate is 0.18 meters, and the length is 9.1 meters. The length of the isolation plate is 0.6 meters longer than the length of the lower thermal plate. The pin hole part 4 and the pin 5 at the inlet and outlet ends, the two ends of the isolation plate are provided with holes 7 equal in size to the pin holes, after aligning the holes on the isolation plate with the pin holes, fix them with the pin 5, and the isolation plate 3 is located in the middle of the lower hot plate, the two ends of the isolation plate are 0.3 meters beyond the lower hot pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com