Metal sheet surface milling device

A technology of metal sheet and milling device, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems such as changing the position of the moving platen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

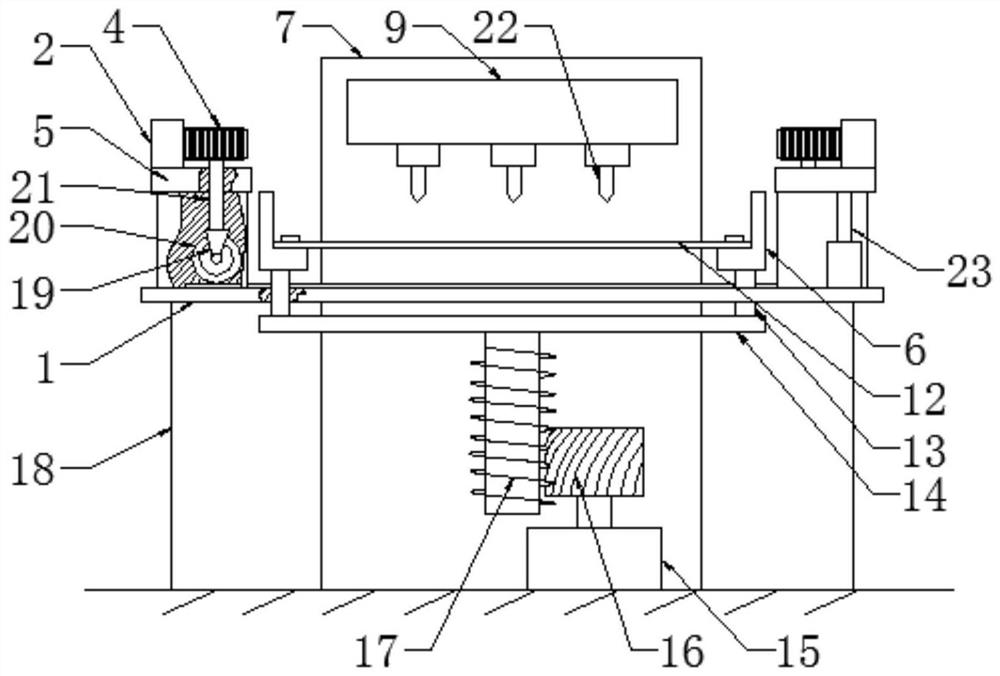

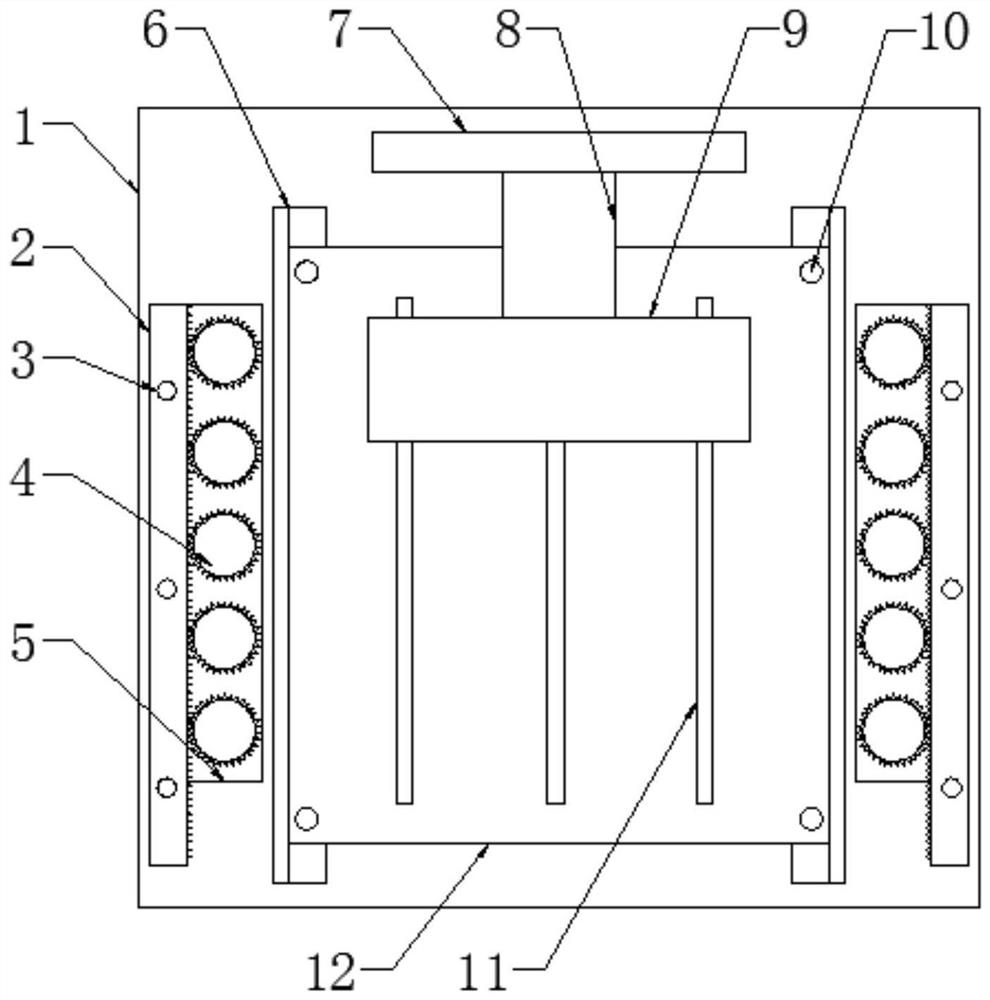

[0020] Embodiment 1 is basically as attached figure 1 with figure 2 Shown: a metal sheet surface milling device, including a frame 18, a storage table 1, a milling cutter limit mechanism, a milling mechanism fixed on the frame 18 and a fixing mechanism for pressing the metal sheet, the milling mechanism includes a connecting Milling cutter support 7 on frame 18, the cylinder 8 that is connected with milling cutter support 7, milling cutter 22 and the housing 9 that milling cutter 22 is installed, housing 9 is connected with cylinder 8 (milling mechanism is prior art, this Not much to do here), there are two fixing mechanisms, and the two fixing mechanisms are respectively located on both sides of the milling mechanism. The fixing mechanisms include a support table 5, a lifter 23, a rack 2 and five smooth cylindrical layering bars 20, The lifter 23 supports the support table 5 above the storage table 1, the rack 2 is slidably connected with the support table 5, and the rack 2...

Embodiment 2

[0022] The difference between embodiment 2 and embodiment 1 is that the lifting mechanism connected to the bottom of the support plate 14 is a hydraulic rod.

Embodiment 3

[0023] The difference between embodiment 3 and embodiment 1 is that the bead 20 is in the shape of a smooth cuboid.

[0024] Taking Embodiment 1 as an example, the specific implementation process of this scheme is as follows: the metal sheet is placed on the storage table 1, and the lifting of the support table 5 is adjusted through the elevator. Thin plate, the specific operation of this process is: the elevator descends to make the supporting platform 5 descend, the clamping plate fixes the connecting rod 21 to prevent it from sliding up and down relative to the supporting platform 5, and the bead 20 connected to the supporting platform 5 through the connecting rod 21 contacts and Stop the descent of the elevator after pressing the sheet metal.

[0025] The connecting rod 21 is connected with a gear 4, the gear 4 meshes with the rack 2, and the rack 2 is slidably connected to the support table 5, so the sliding rack 2 can make the gear 4 rotate, thereby driving the bead 20 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com