PCB detection jig processing device and using method thereof

A technology of PCB board and detection jig, applied in the direction of measuring device, measuring device casing, measuring electrical variables, etc., can solve the problems of low detection efficiency and troublesome use, and achieve the effect of convenient and normal use and avoid normal detection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

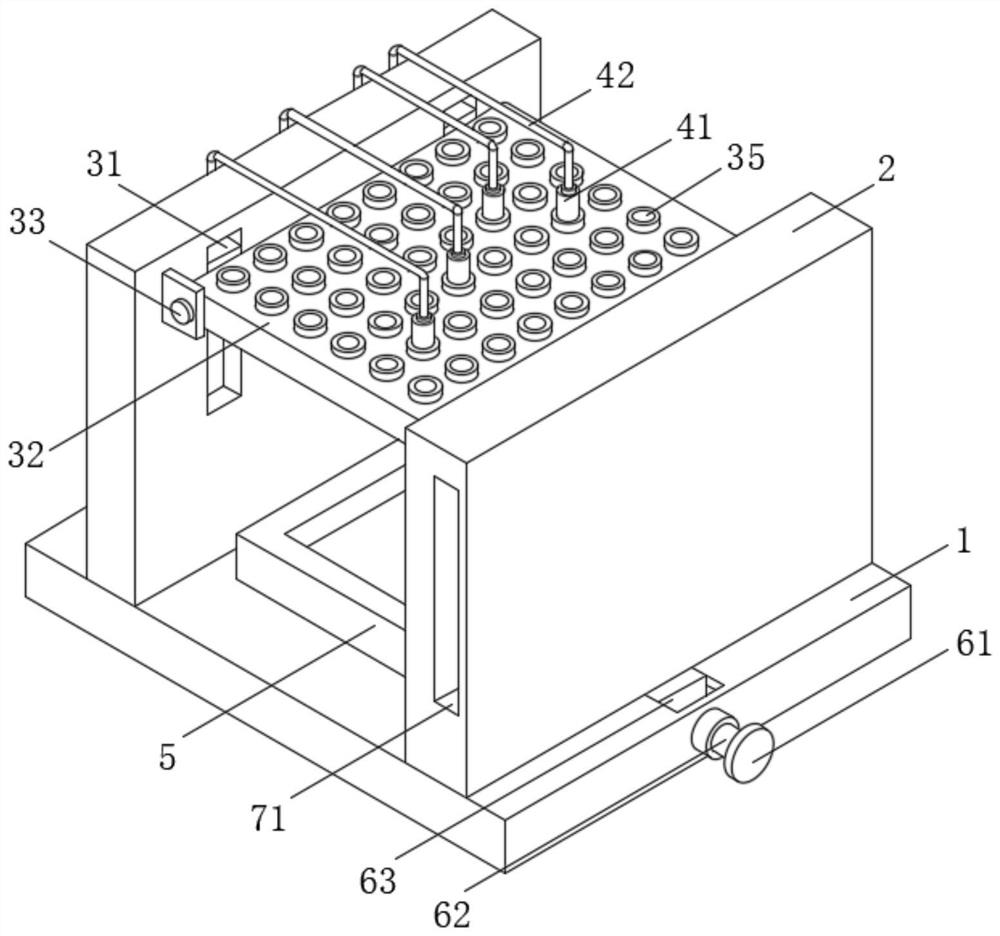

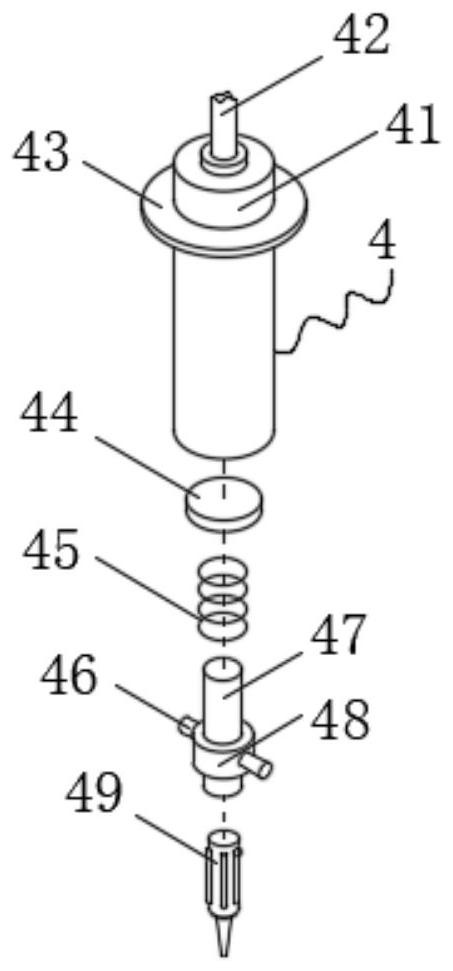

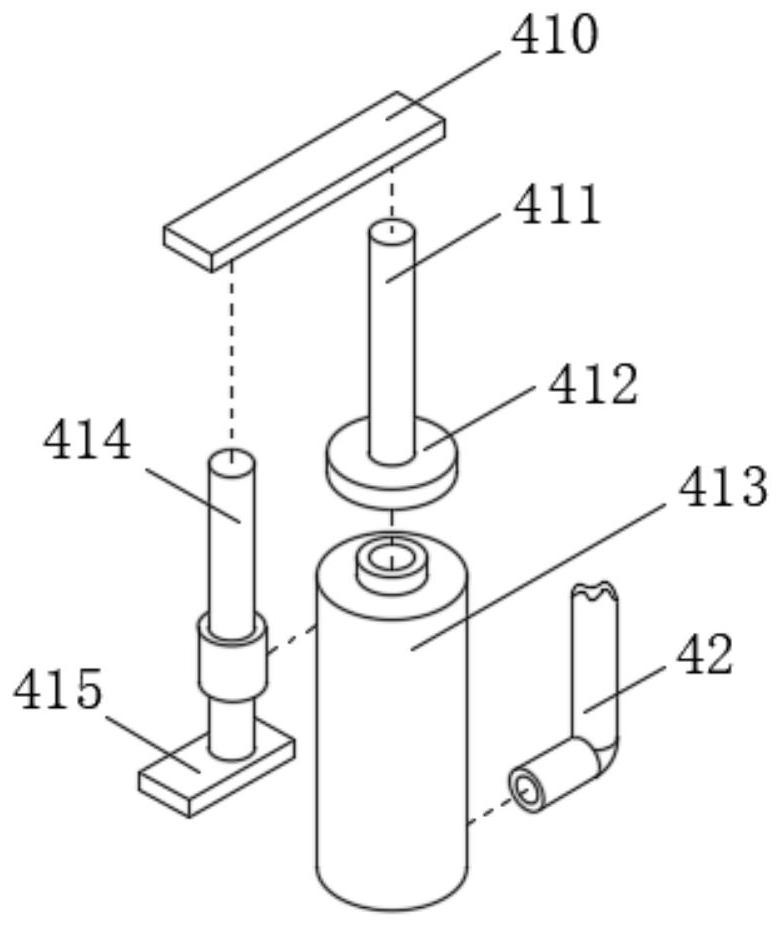

[0047] see Figure 1-7 , this embodiment discloses a PCB inspection fixture processing device, comprising a base plate 1 and a side plate 2, the left and right sides of the upper surface of the base plate 1 are provided with side plates 2, and the left side plate 2 is fixedly connected to the base plate 1, the lower surface of the right side plate 2 is attached to the upper surface of the bottom plate 1, and the lower surface of the right side plate 2 is fixedly connected with an adjustment mechanism 6 for adjusting the position of the side plate 2 and indirectly controlling the adjustment of the positioning mechanism 3. The adjustment mechanism 6 is arranged inside the base plate 1, and the adjustment mechanism 6 includes a second chute opened on the upper surface of the base plate 1, and a second slide block 63 is arranged in the second chute, and the upper surface of the second slide block 63 and the side The lower surface of the plate 2 is fixedly connected, the right side...

Embodiment 2

[0056] This embodiment discloses a method for using a PCB board detection fixture processing device, which specifically includes the following steps:

[0057] S1. Place the PCB board to be detected on the loading seat 5, and turn the screw block 61 to drive the threaded column 64 to rotate through the first rotating shaft 62. Under the action of the threaded cap, the second slider 63 can be stabilized along the track Left and right movement, the second slider 63 drives the side plate 2 to move and adjust the position, and the side plate 2 can be effectively kept fixed when it moves to any position;

[0058] S2. When the right side plate 2 moves close to the left side plate 2, the two side plates 2 approach each other and press against the positioning plate 32, and under the action of the fourth rotating shaft 36 and the fourth bearing, the positioning plate 32 is squeezed It can present an arc curved state. At this time, different rubber sleeves 35 on multiple positioning plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com