Wheel brush water outlet equipment of car washer

A car washing machine and wheel brush technology, which is applied in the field of car washing machines, can solve the problems of motor overload, incomplete washing, and low cleanliness, and achieve the effect of reasonable equipment structure, compact equipment structure, and improved cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

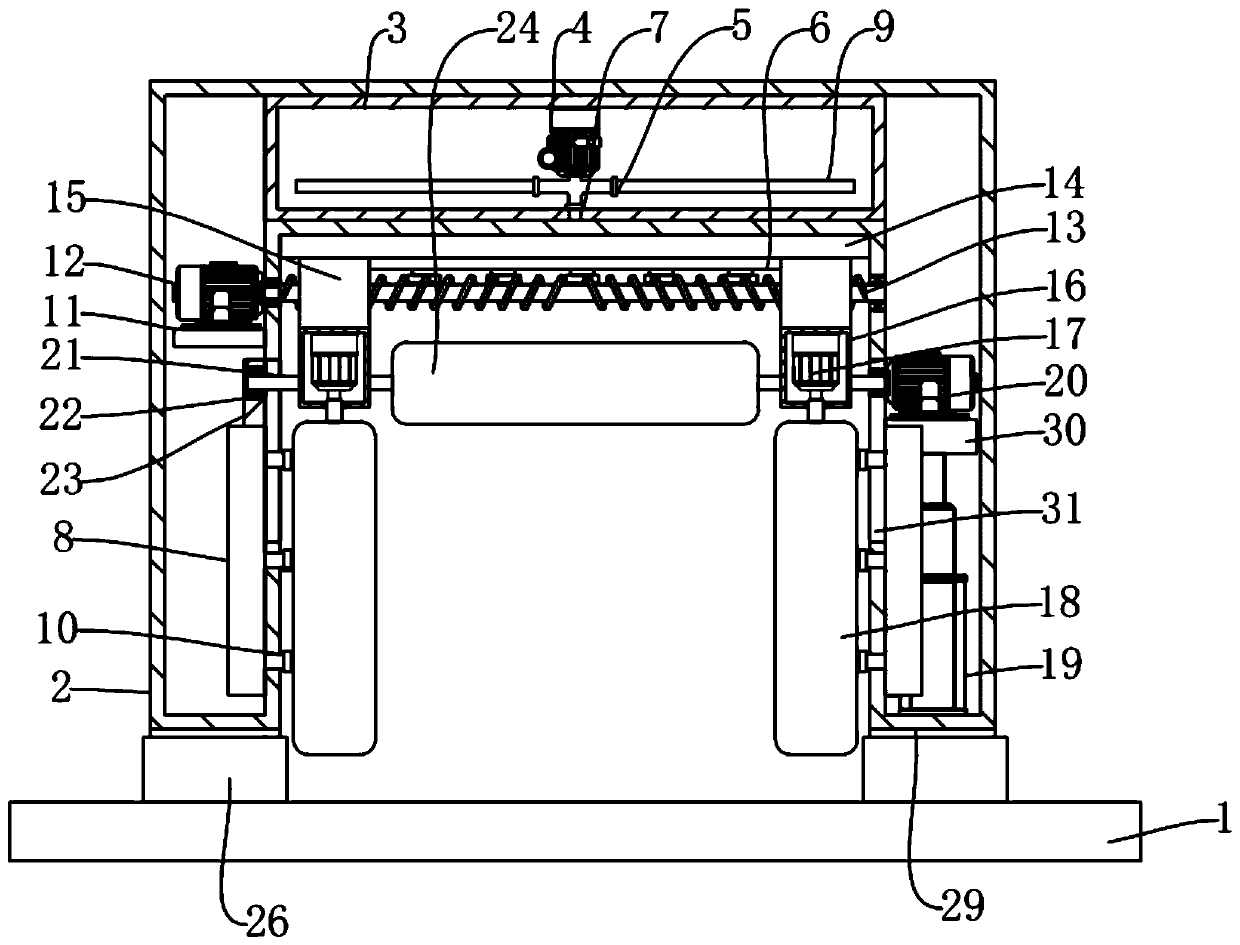

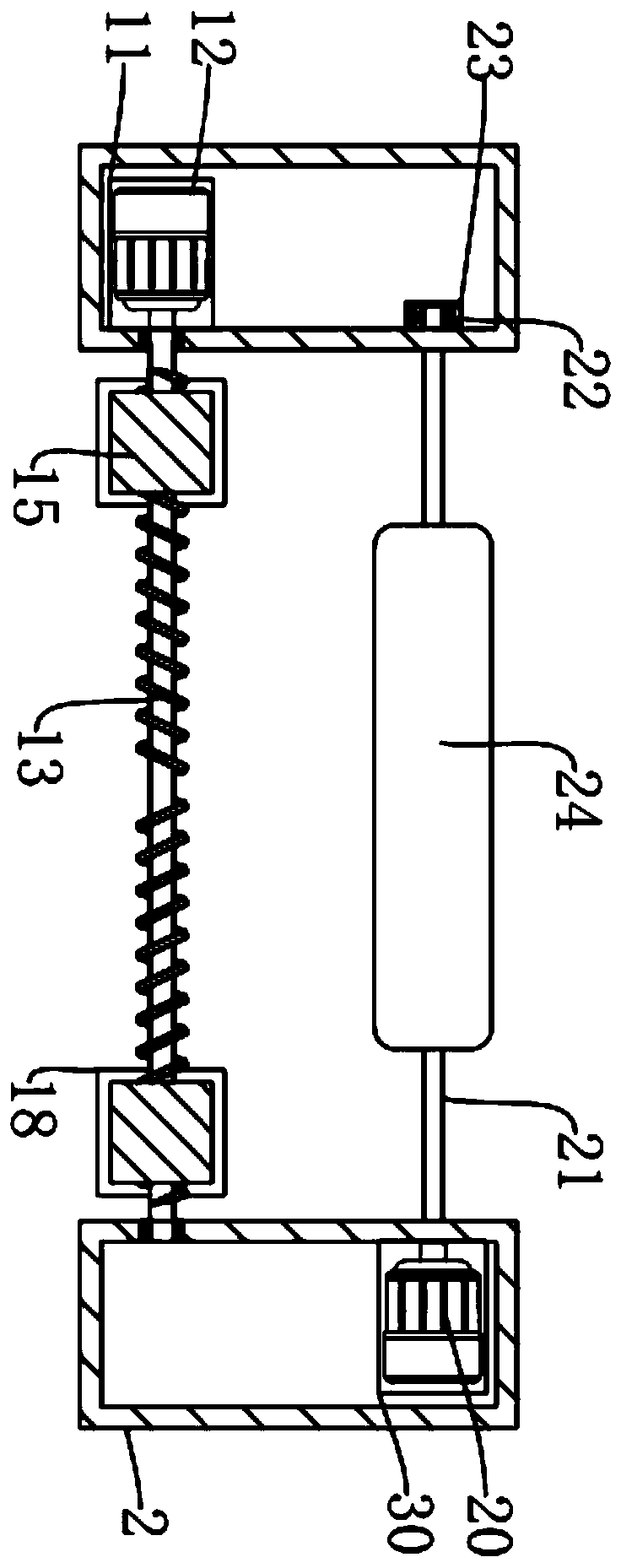

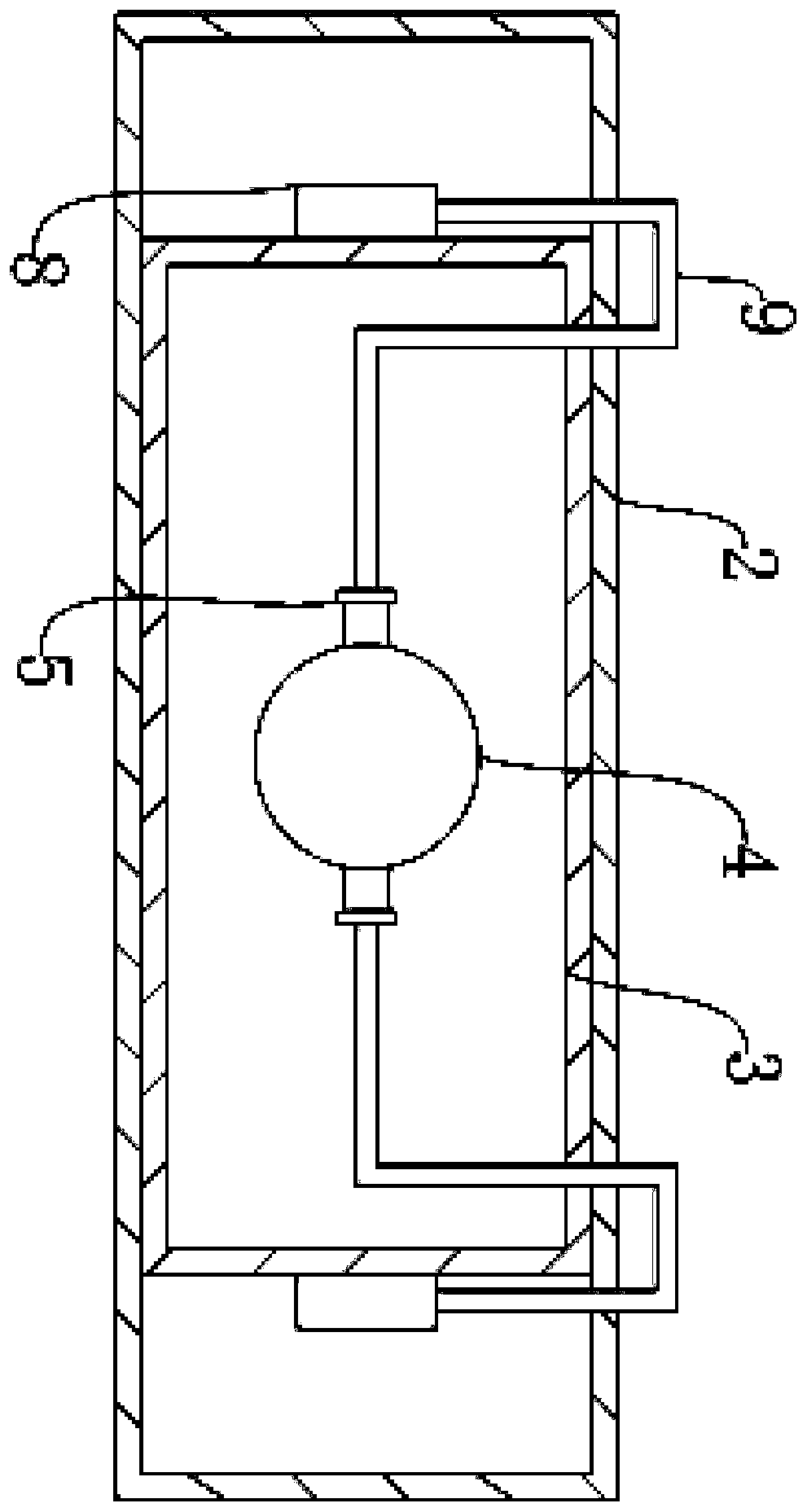

[0031] Embodiment: according to the attached Figure 1-4 It can be seen that when cleaning the car, the car is driven directly under the gantry 2, and the submersible pump 4 is turned on. The submersible pump 4 guides water from the water storage tank 3 into the four-way pipe 5, and the water flows through the four-way pipe 5 respectively. Into the first water spray box 6 and the second water spray box 8, through the high-pressure spray nozzle 10 comprehensive spray to the outer surface of the car, open the first motor 12, the first motor 12 drives the first threaded rod 13 to rotate, because the first Due to the limitation of the slide rail 14, the moving block 15 can only do inward clamping movement. At this time, the inward clamping degree of the moving block 15 can be adjusted according to the size of the vehicle, and the second motor 17 is turned on, and the second motor 17 drives The first wheel brush body 18 rotates, the first wheel brush body 18 scrubs the outer surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com