Low-temperature insulation box heat insulation cotton filling method for liquefied natural gas ship liquid cargo maintenance system

A technology of liquefied natural gas and maintenance system, which is applied to the filling field of thermal insulation cotton in the low-temperature insulation box of the liquid cargo maintenance system for liquefied natural gas ships, to achieve the effect of reducing over-tightening and uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment proposes a method for filling insulation cotton suitable for insulation boxes based on any of the above implementations or a combination thereof:

[0058] In the above embodiment, when the vibrating component is used to vibrate and enrich the insulating box of the vibrating station, the specific operation steps can be:

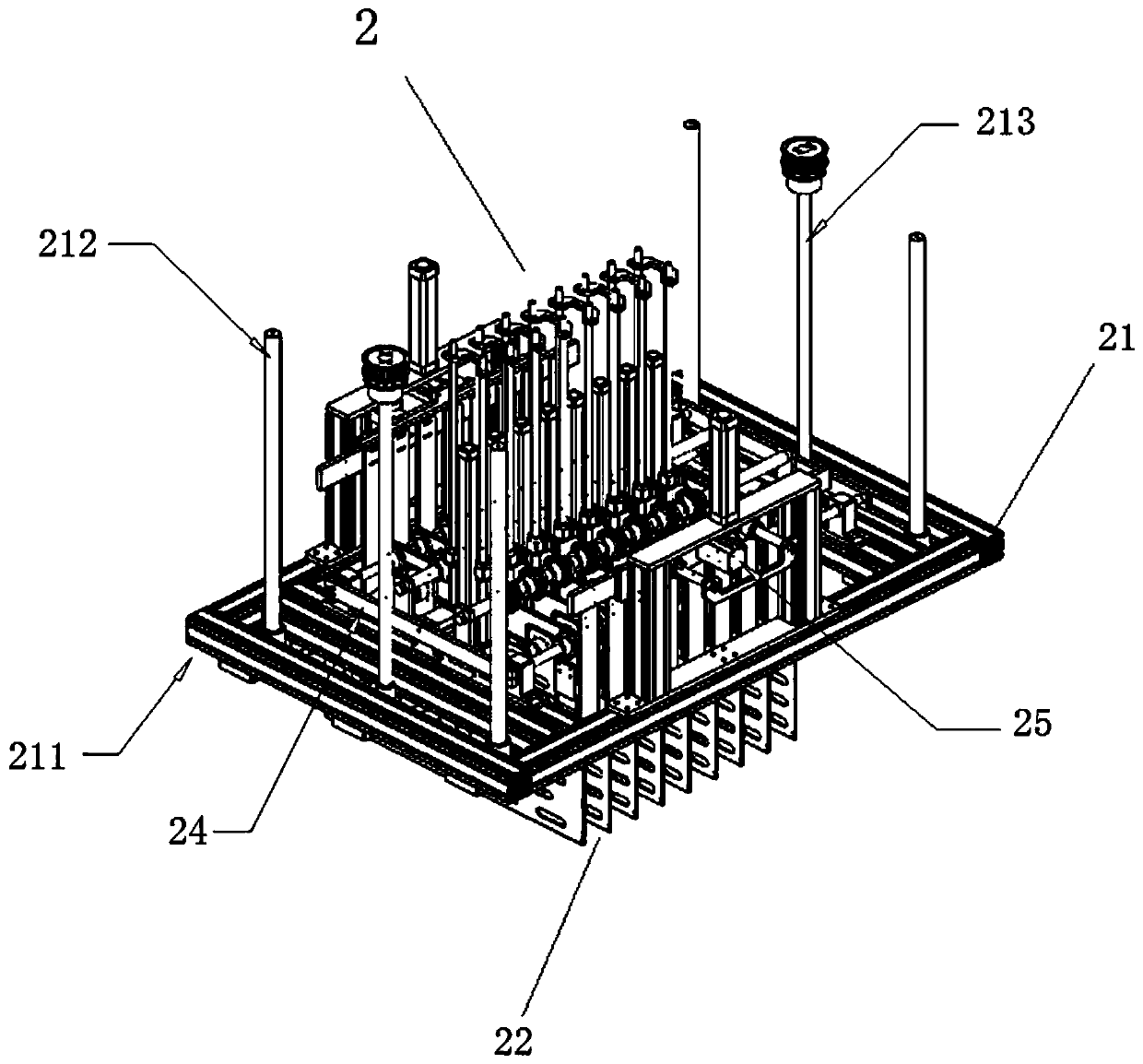

[0059] (1) After the insulating box is filled with insulation cotton at the filling station of the insulating box filling roller table 3, the filling effect is detected and processed by distance sensors and other equipment;

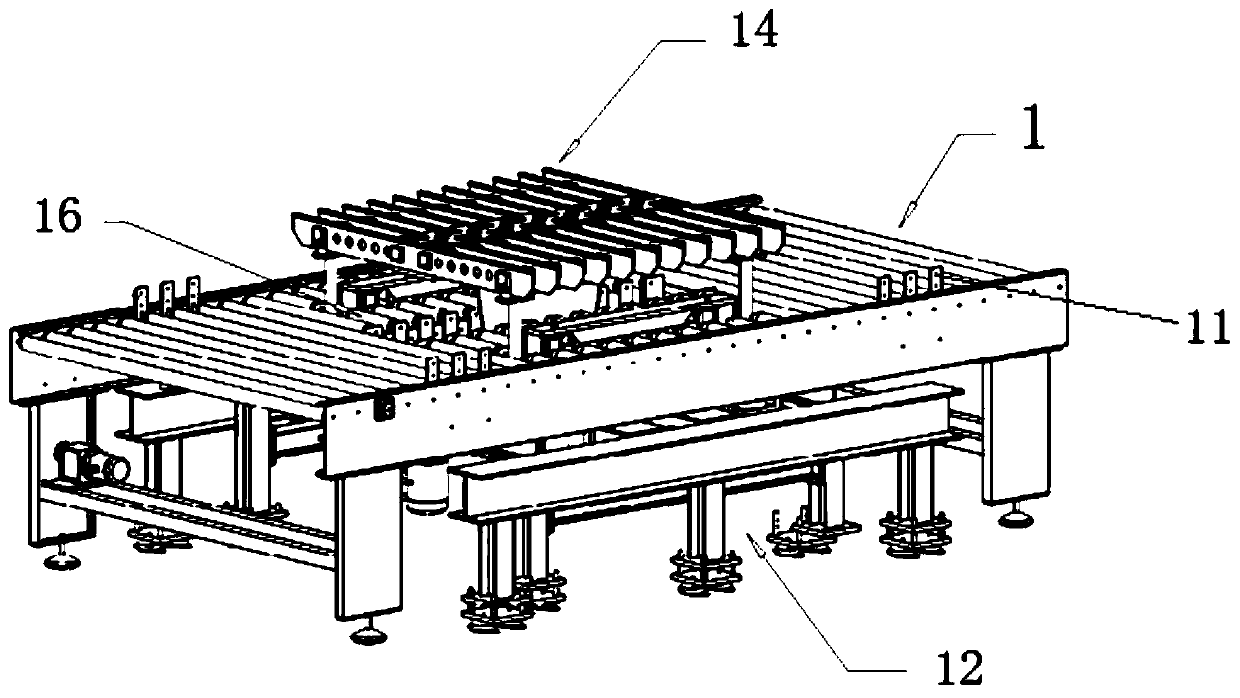

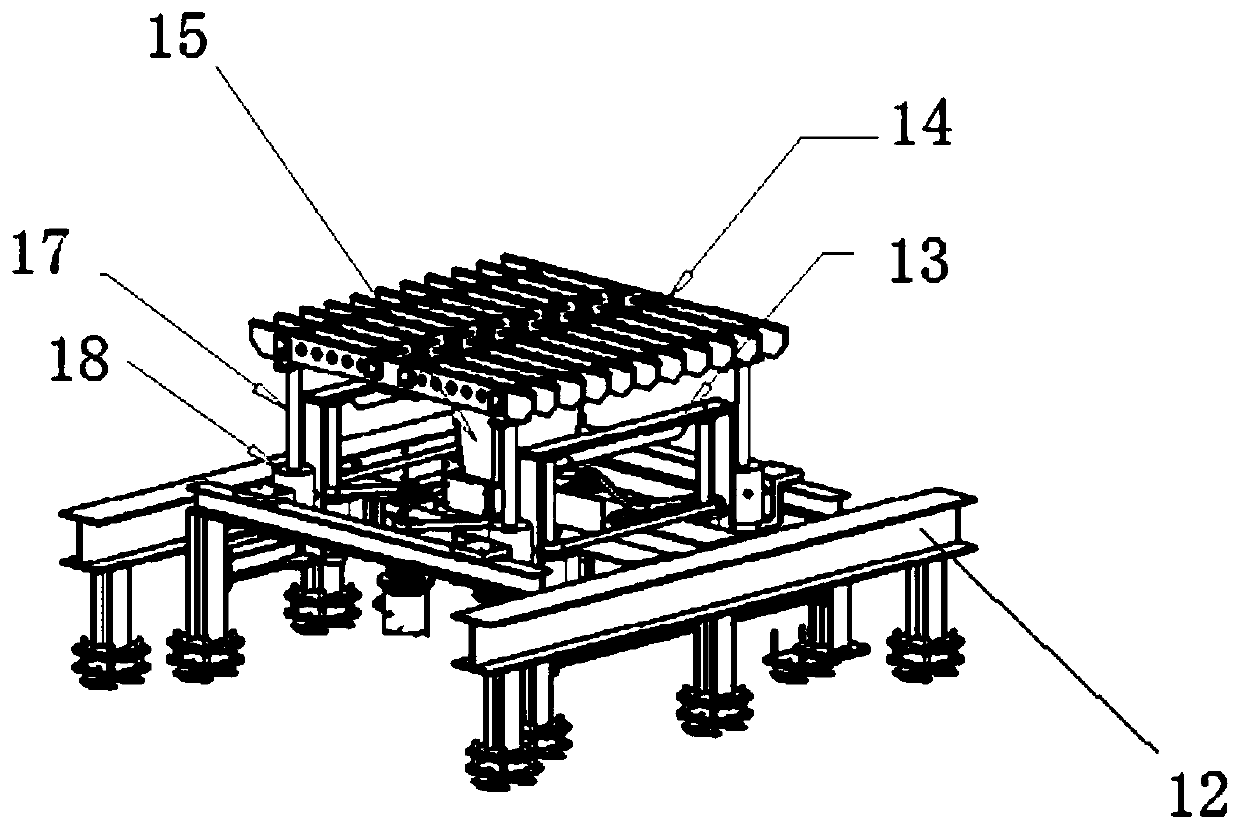

[0060] (2) Then, the qualified insulation box after the detection is transferred from the insulation box filling roller table 3 to the vibrating roller table 1, and the insulation box is stopped at the position directly above the vibrating sieve plate 14;

[0061] (3) Raise the vibrating lifting member 13 to drive the vibrating sieve plate 14 to lift, so that the vibrating sieve plate 14 carries the insulating box a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap