Integrated environment simulation box of liquid cooling heat-dissipation circuit board

A comprehensive environment, liquid cooling technology, applied in the field of detection, can solve the problems of slow temperature change rate, large energy consumption, large equipment space, etc., to achieve the effect of local temperature control, increase temperature change rate, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

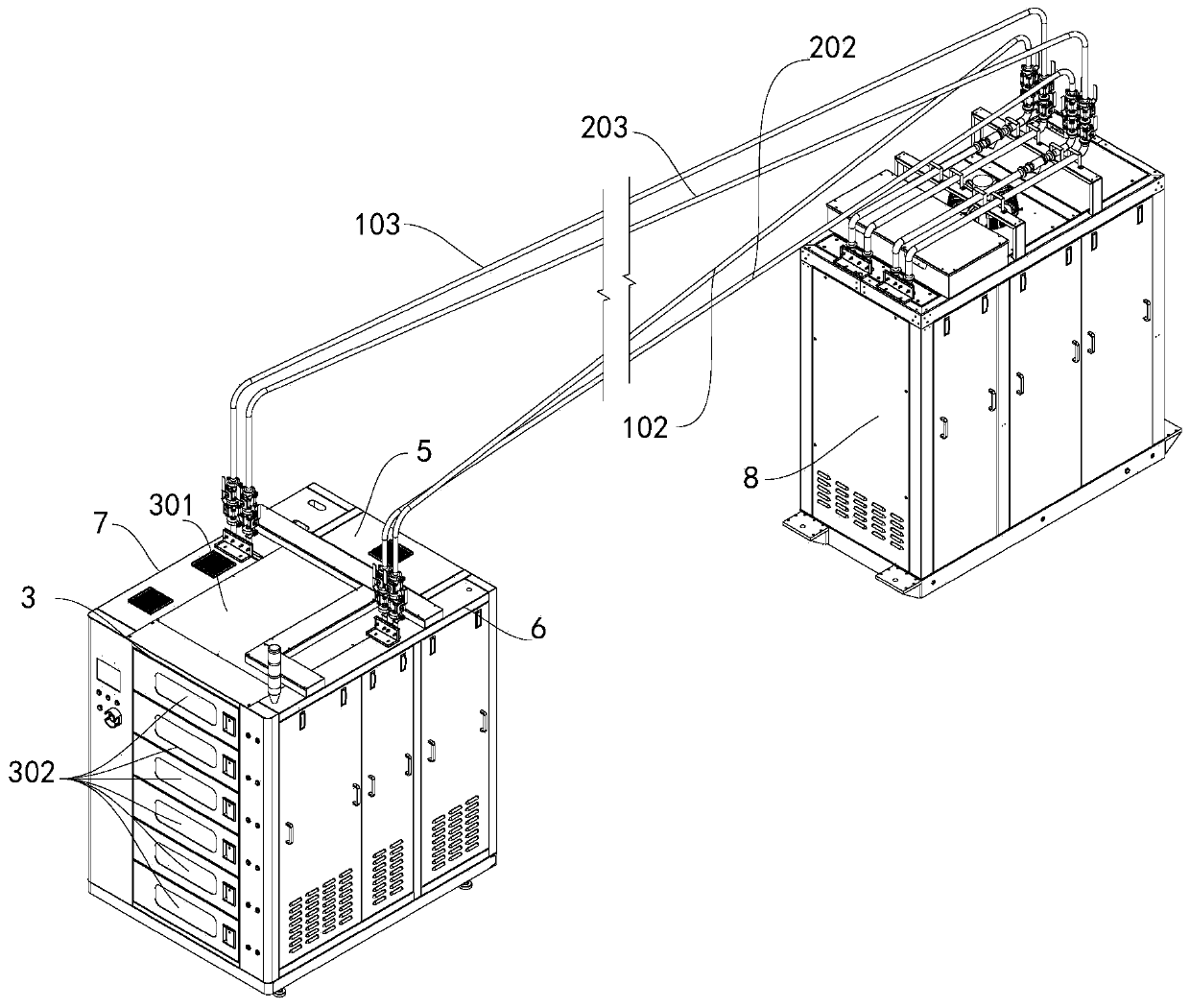

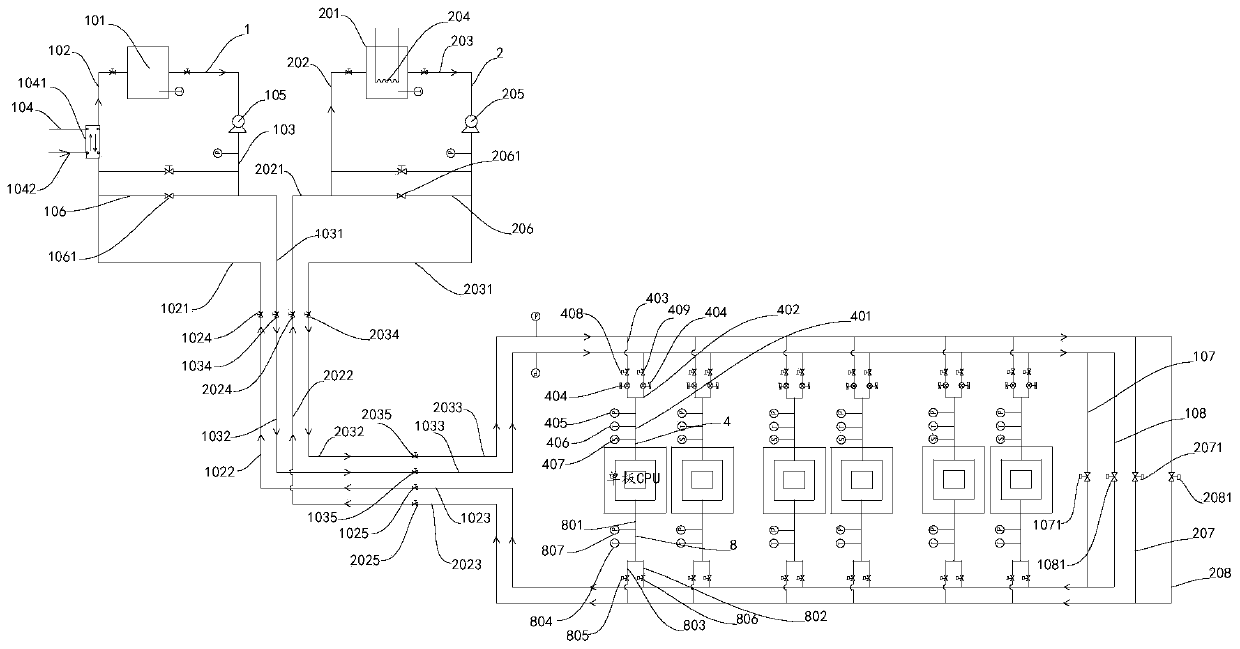

[0025] Such as figure 1 , figure 2 As shown, a liquid-cooled and heat-dissipating circuit board comprehensive environment simulation box includes a cold liquid supply assembly 1, a hot liquid supply assembly 2, a working box 3, and a liquid inlet mixing pipeline 4, and the liquid outlet of the cold liquid supply assembly 1 end is connected to the liquid inlet end of the liquid inlet mixing pipeline 4, that is, the cold liquid supply assembly 1 can supply cold liquid into the liquid inlet mixing pipeline 4, and the liquid outlet end of the hot liquid supply assembly 2 is connected to the liquid inlet mixing pipeline 4 is connected to the liquid inlet end, that is, the hot liquid liquid supply assembly 2 can supply hot liquid into the liquid inlet mixing line 4, and the liquid outlet end of the liquid inlet mixing line 4 extends into the sample test chamber of the working box 3.

Embodiment 2

[0027] Such as figure 1 , figure 2 As shown, a liquid-cooled and heat-dissipating circuit board comprehensive environment simulation box includes a cold liquid supply assembly 1, a hot liquid supply assembly 2, a working box 3, and a liquid inlet mixing pipeline 4, and the liquid outlet of the cold liquid supply assembly 1 end is connected to the liquid inlet end of the liquid inlet mixing pipeline 4, that is, the cold liquid supply assembly 1 can supply cold liquid into the liquid inlet mixing pipeline 4, and the liquid outlet end of the hot liquid supply assembly 2 is connected to the liquid inlet mixing pipeline 4 is connected to the liquid inlet end, that is, the hot liquid liquid supply assembly 2 can supply hot liquid into the liquid inlet mixing line 4, and the liquid outlet end of the liquid inlet mixing line 4 extends into the sample test chamber of the working box 3.

[0028] The liquid inlet mixing pipeline 4 includes a mixing liquid inlet pipe 401, a cold liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com