Novel cutting machine

A cutting machine, a new type of technology, applied in the direction of shearing devices, metal processing machinery parts, maintenance and safety accessories, etc., can solve problems such as operator hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

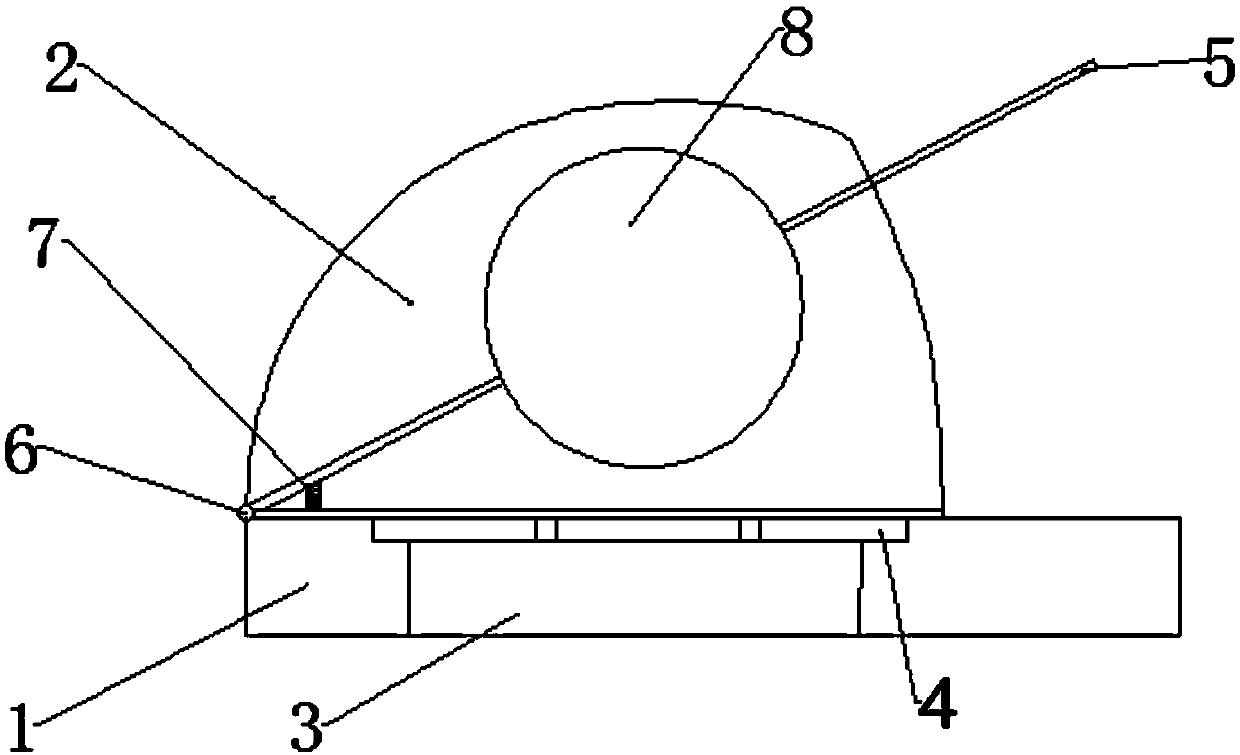

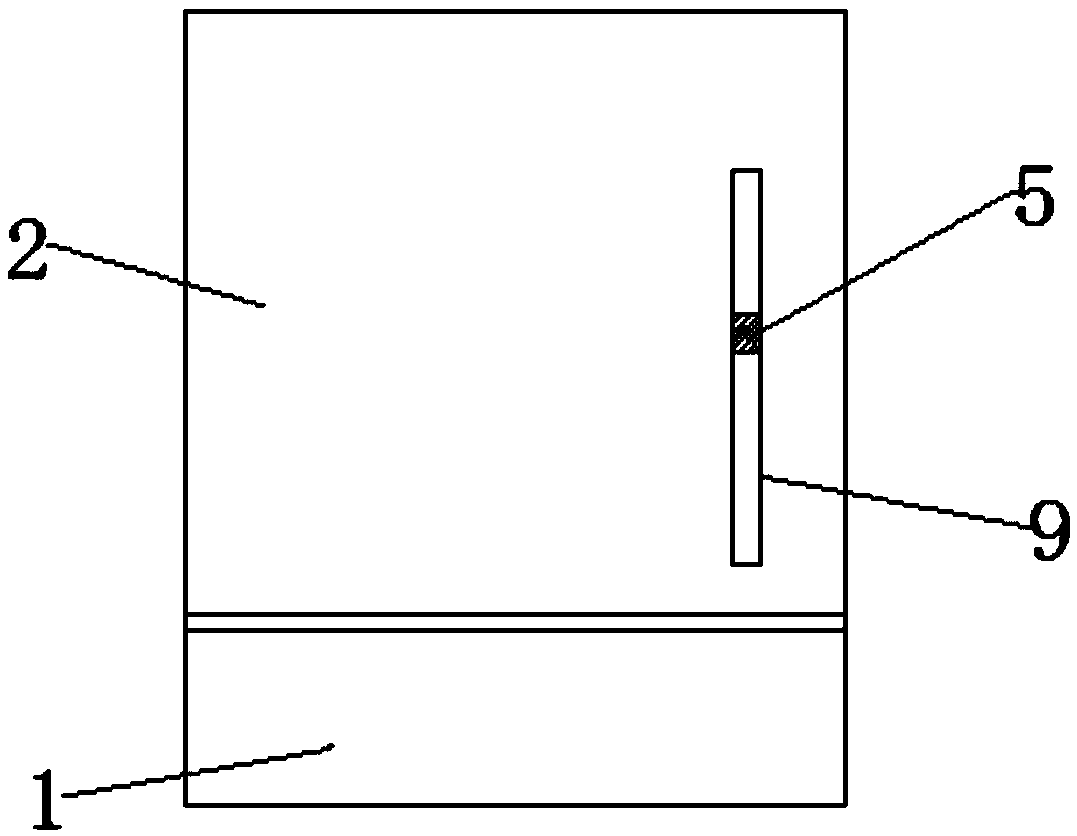

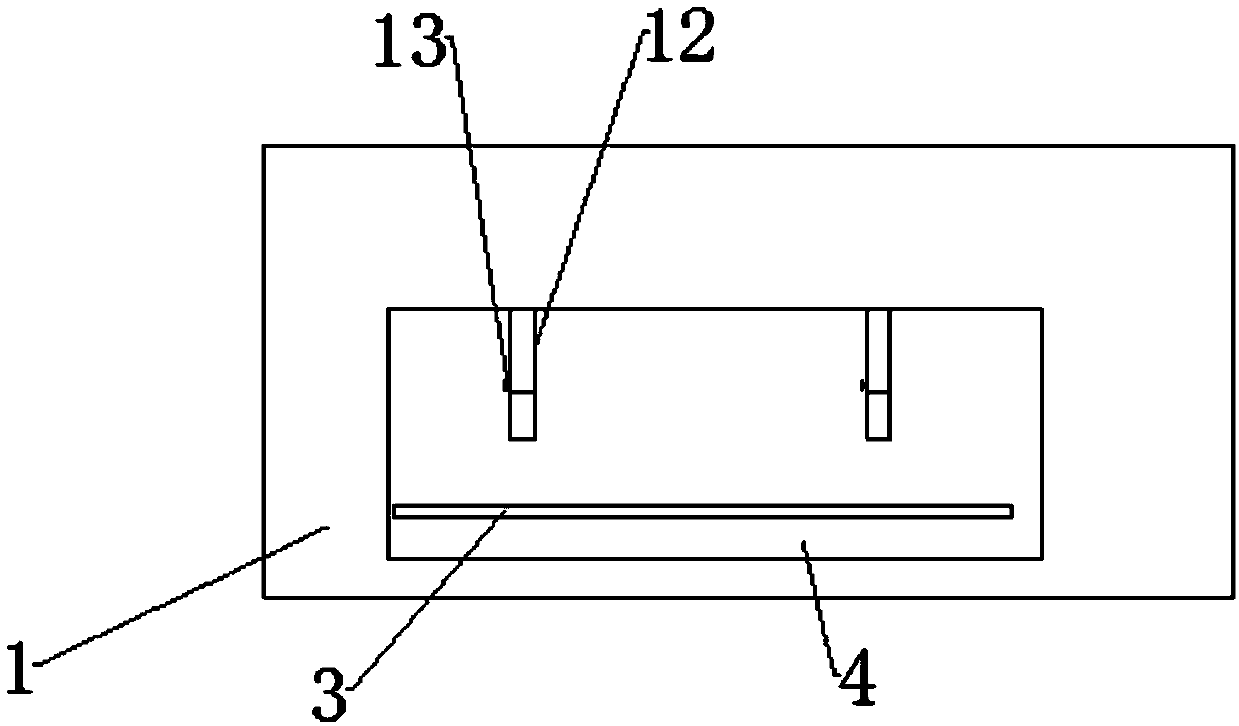

[0033] see Figure 1-5 , a new type of cutting machine, comprising a base 1, the upper surface of the base 1 is provided with a stage 4, the inner side of the stage 4 is fixedly connected with a telescopic rod 12, and one end of the telescopic rod 12 is connected with a fastening screw 13, and the loading The lower end of the platform 4 is provided with a base through groove 3, and one end of the upper surface of the base 1 is fixedly connected with a rotating shaft 6, and the base 1 is connected with a box cover 2 and a pressure rod 5 through the rotating shaft 6, and the inner lower surface of the box cover 2 is fixedly connected with a Compression spring 7, lid 2 and depression bar 5 are elastically connected by compression spring 7, and the front end of lid 2 is provided with the first through groove 9 of lid, and depression bar 5 passes in the first through groove 9 of lid, and lid The bottom surface of 2 is provided with the second through groove 10 of the box cover, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com