A method of processing ultra-high molecular weight polyethylene by spark plasma sintering

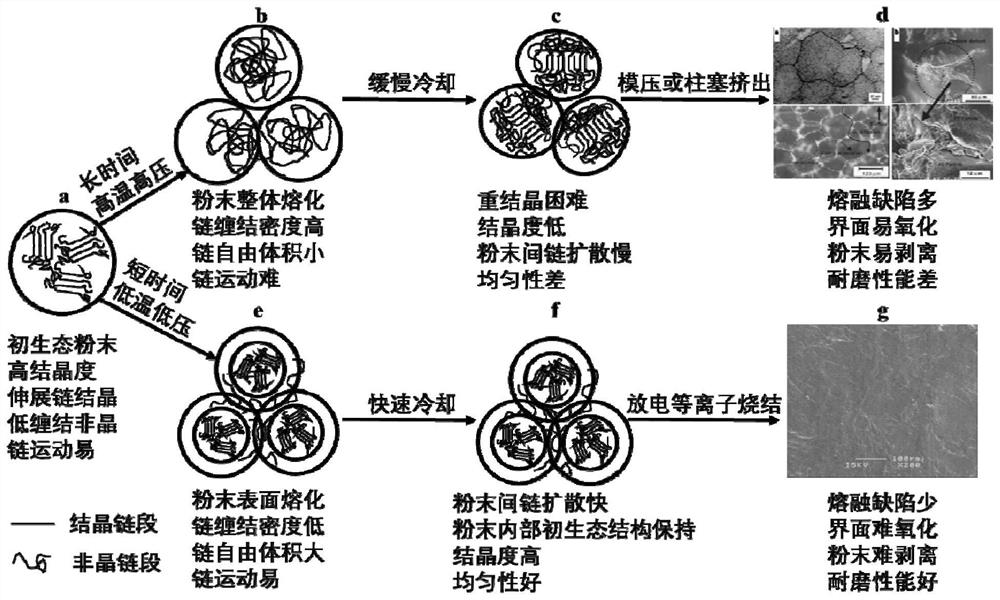

A spark plasma, ultra-high molecular weight technology, applied in the field of material processing, can solve the problems of limited chain motion, low crystallinity, difficult chain lamellae, etc., and achieve the effects of improving motion activity, improving wear performance, and reducing melting defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The powdered ultra-high molecular weight polyethylene was placed in an oven at 60° C. for 4 hours, and 0.847 g of ultra-high molecular weight polyethylene was filled and cold-pressed in a graphite mold with a pressure of 10 MPa. Then spark plasma sintering was performed in a vacuum (7Pa) atmosphere with a pulse time of 10 ms and an on-off ratio of 5:1. The initial sintering pressure was 10MPa, the initial sintering temperature was room temperature, the temperature was raised to 100°C at a rate of 25°C / min, and the temperature was maintained for 2 minutes; The sintering temperature was raised from 100 °C to 200 °C; then, the temperature was maintained for 1 min; finally, the pressure was maintained at 30 MPa, water cooled to 100 °C with the furnace, and then cooled to room temperature naturally, the mold was taken out, and the mold was disassembled to obtain UHMWPE-1.

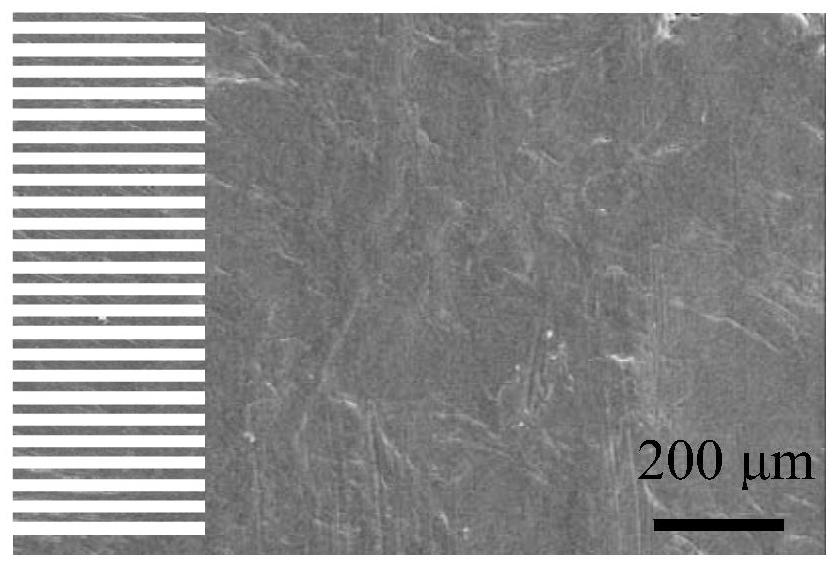

[0030] The characterization of the obtained sample 1 is shown in Figure 2 and image 3 , where Figure...

Embodiment 2

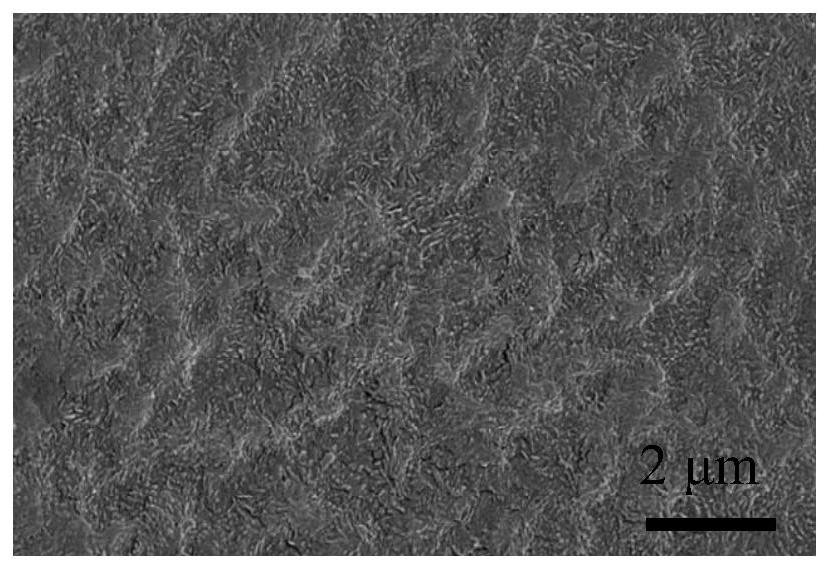

[0032] The powdered ultra-high molecular weight polyethylene was placed in an oven at 50° C. for 5 hours, and 0.984 g of ultra-high molecular weight polyethylene was taken and filled in a graphite mold for cold pressing, and the pressure was 20 MPa. Sintering was then carried out in a vacuum (10Pa) atmosphere with a pulse time of 15 ms and an on-off ratio of 10:1. The initial sintering pressure was 10MPa, the initial sintering temperature was room temperature, the temperature was raised to 100°C at a rate of 25°C / min, and the pressure was maintained for 2 minutes; The sintering temperature was raised from 100°C to 150°C; then, the temperature was maintained for 2 minutes; finally, the pressure was maintained at 50MPa, water-cooled to 120°C with the furnace, then cooled to room temperature naturally, and the mold was taken out to obtain UHMWPE-2. The SEM of the surface of the obtained sample 2 after the friction and wear test is shown in Figure 4 , showing that there are no p...

Embodiment 3

[0034] The powdered ultra-high molecular weight polyethylene was placed in an oven at 70° C. for 3 hours, and 1.052 g of ultra-high molecular weight polyethylene was taken and filled in a graphite mold for cold pressing at a pressure of 5 MPa. Sintering was carried out in a vacuum (4Pa) atmosphere with a pulse time of 3 ms and an on-off ratio of 3:1. The initial sintering pressure was 10MPa, the initial sintering temperature was room temperature, the temperature was raised to 100°C at a rate of 25°C / min, and the pressure was maintained for 2 minutes; then, the sintering pressure was maintained at 10MPa, and the sintering was carried out at a speed of 100°C / min. The temperature was raised from 100°C to 300°C; finally, the pressure was kept at 50 MPa, water cooled to 90°C with the furnace, and then cooled to room temperature naturally, and the mold was taken out to obtain UHMWPE-3. The infrared spectrum of the obtained sample 3 is shown in Figure 5 , not seen 900cm -1 (-CH=CH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com