Microparticle dispersing water-consuming system

A micro-particle and dispersed technology, which is applied in the direction of water aeration, water/sludge/sewage treatment, water/sewage treatment with added substances, etc., can solve the problems of concrete strength decline and inability to form strength, so as to reduce the water-cement ratio, Effect of shortening stirring time and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

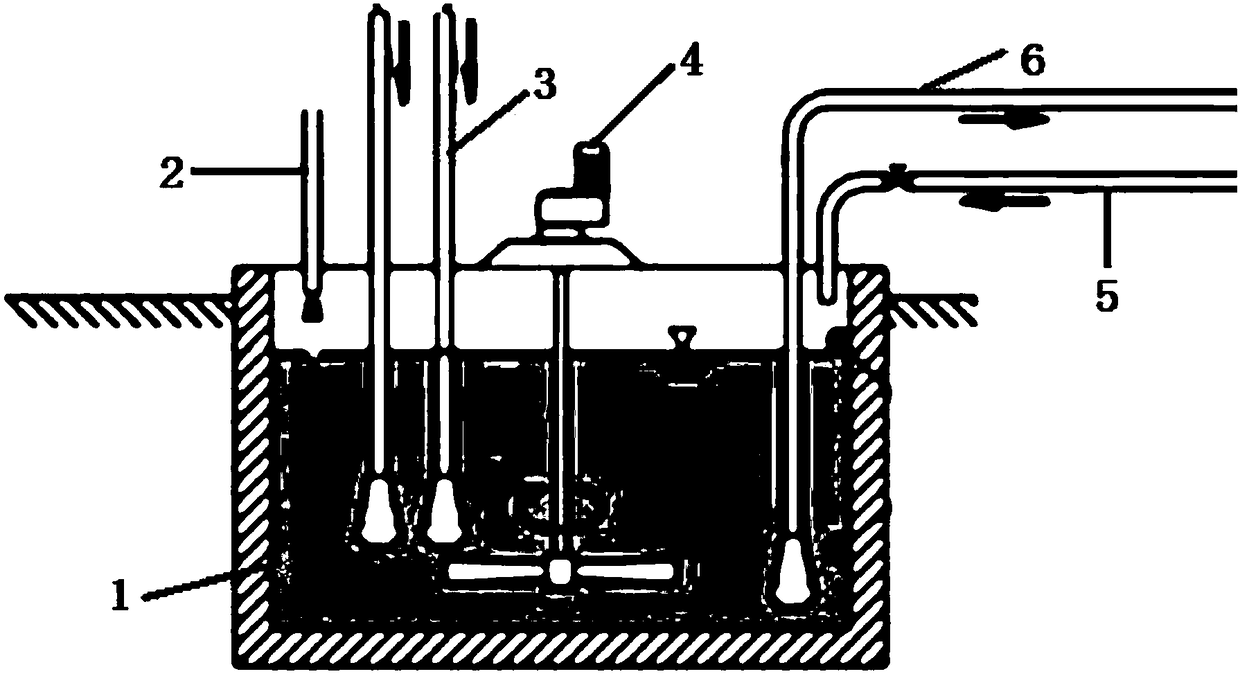

[0018] refer to figure 1 , a water system for microparticle dispersion, comprising a water storage tank 1 with a water inlet pipeline 5, a first pipeline 2 for adding an admixture, an air inlet pipe 3 of a nano aeration device, submerged into the water storage tank below the liquid level The dispersing device 4, and the water outlet pipe 6 that supplies water to the mixer; the lower end of the air inlet pipe is submerged below the liquid level of the water storage tank.

[0019] The additive is a surfactant or a surface modifier.

[0020] The gas used in the aeration device is air or nitrogen with a purity of 98%-99.9%.

[0021] The diameter of the gas generated by the nano aeration device is 2-500 μm.

[0022] Specifically, air can be pressed in during the aeration process, and nitrogen is preferably pressed in, because the selective and preferential adsorption of nitrogen through the pores on the surface of the microparticles hinders the pores from absorbing water and redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com