Weighing machine outlet power discharging device for strip-shaped materials

A discharge device, weighing machine technology, applied in the direction of transportation and packaging, loading/unloading, etc., can solve problems such as stuck, unable to work, rough surface, etc., to achieve the effect of accurate measurement, convenient adjustment, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

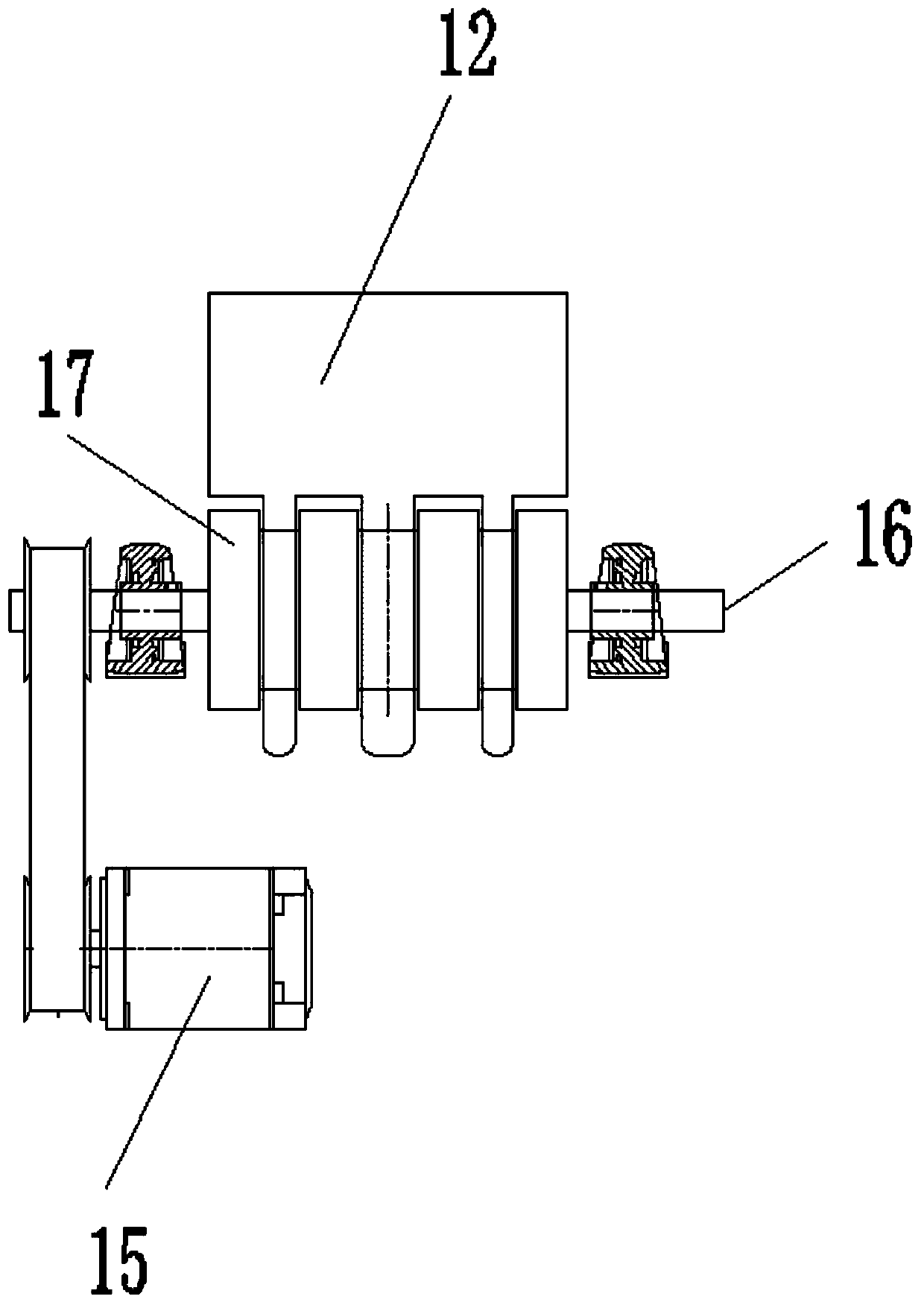

[0016] Second embodiment: the bottom of the outlet of the silo bottom plate 3 is equipped with a roller shaft 16 through a bearing, and an eccentric bump 17 is installed on the roller shaft 16, and an outlet supporting plate 12 is vertically installed above the eccentric bump 17, and the roller shaft 16 An output roller motor 15 is installed below the output roller motor 15, and the output end of the output roller motor 15 is connected to one end of the roller shaft 16 through the pulley mechanism, and the eccentric protrusion 17 on the roller shaft 16 is driven by the output roller motor 15 to rotate, thereby driving the export pallet 12 moves up and down, and cooperates with the bottom plate 3 of the hopper to realize the up and down staggered movement of the material, thereby realizing the whereabouts of the material.

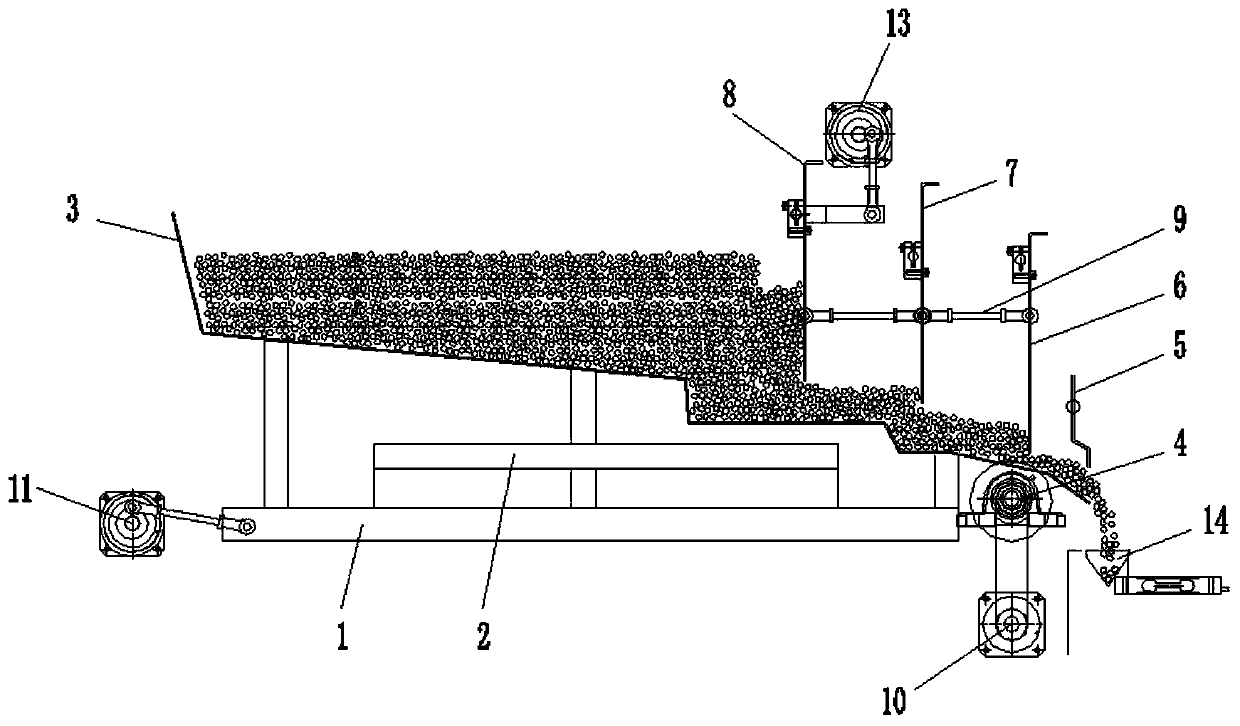

[0017] Working principle: when in use, the silo vibrating motor 11 works to drive the bottom bracket 1 of the silo to vibrate and perform reciprocating motio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com