Parallel twisted wire rope pre-deforming device

A technology of pre-deformer and steel wire rope, which is applied in the auxiliary device of rope making, textile and paper making, textile cable, etc. It can solve the problems of excessive difference in helix angle between inner and outer layers, loose stress, unevenness, etc., and achieve uniform internal stress and tension Consistent, compact wiring results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The core of the invention is to provide a parallel lay steel wire rope pre-deformer, which solves the technical problems of loose strands and uneven internal stress and tension.

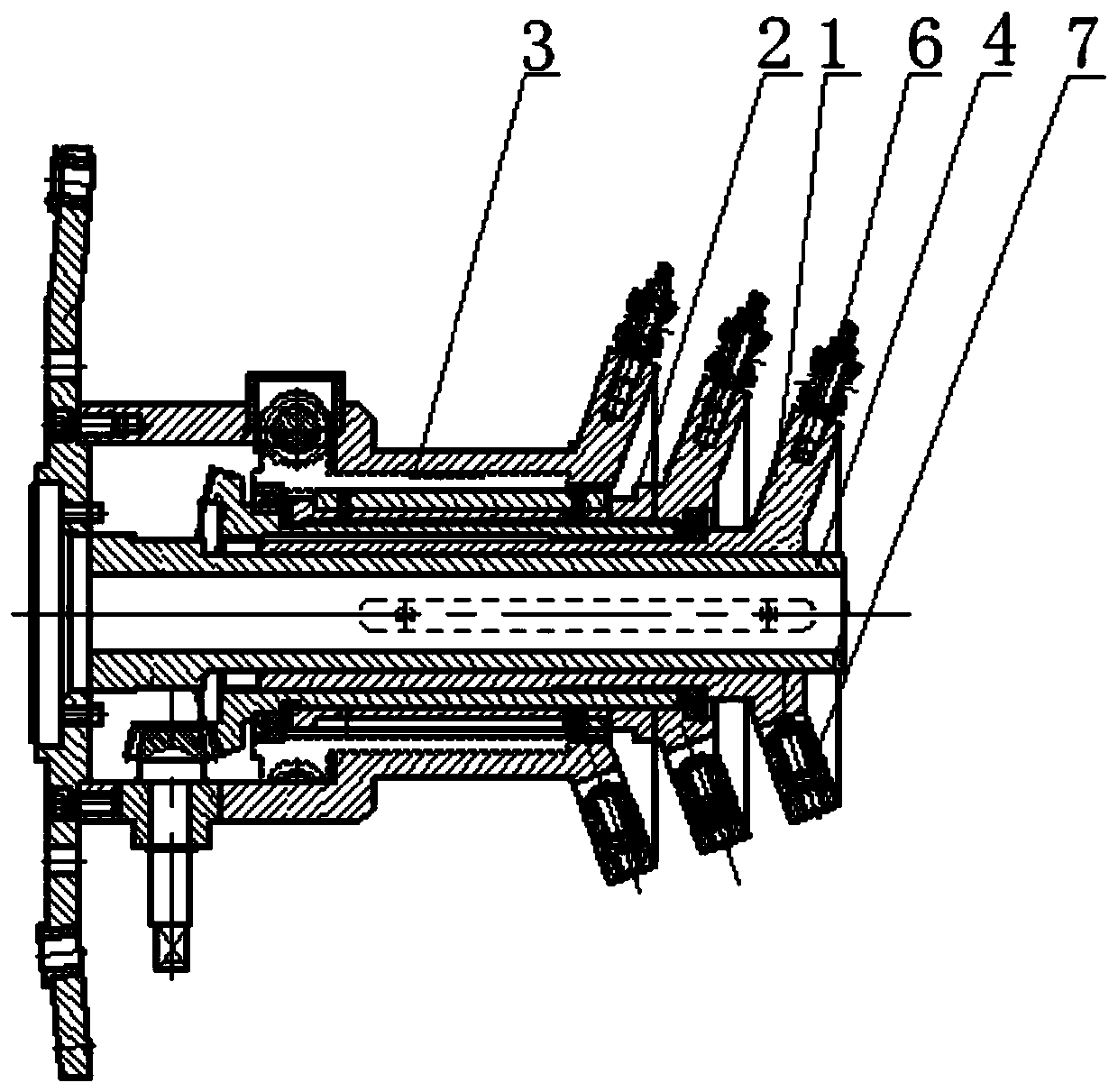

[0022] It should be noted that the directions of the orientation words "up and down" appearing in this article refer to figure 1 in the up and down direction; "front" refers to the figure 1 in the right direction; "rear" refers to the figure 1 in the left direction. The orientation words appearing in this article are established based on the customary usage of those skilled in the art and the drawings in the specification, and their appearance should not affect the protection scope of the present invention.

[0023] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

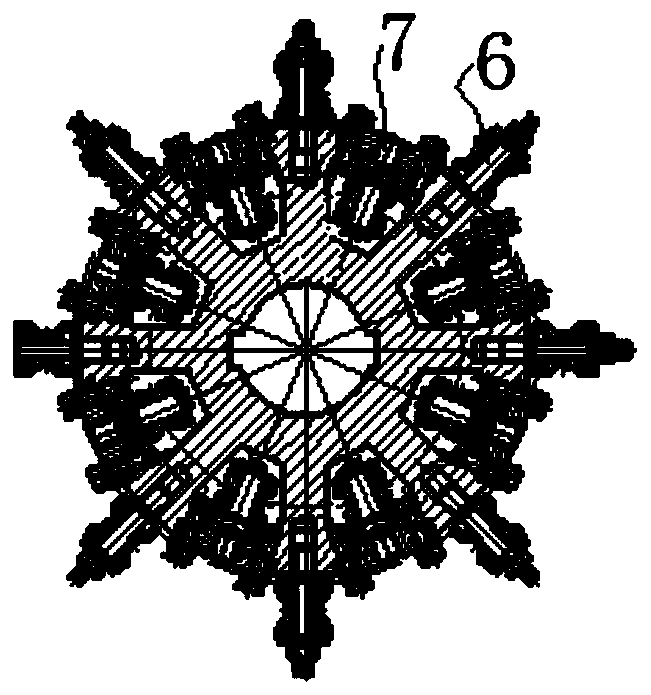

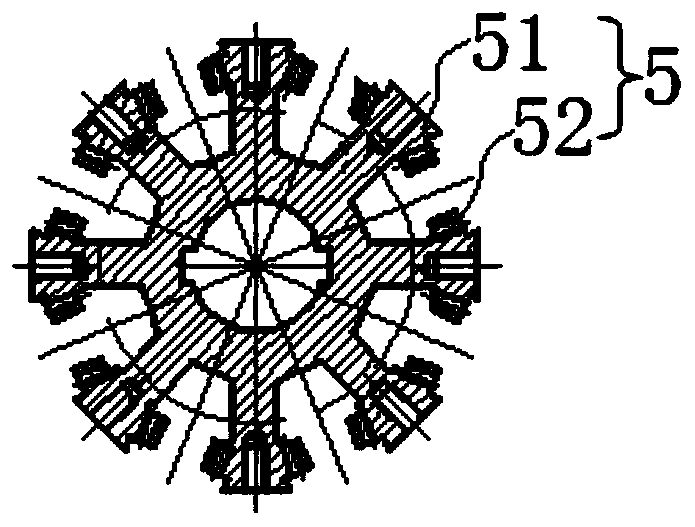

[0024] Please refer to Figure 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com