Anti-seepage wall grooving mould and high polymer anti-seepage wall grouting equipment

An anti-seepage wall and polymer technology, which is used in construction, infrastructure engineering and other directions, can solve the problems of inability to adjust the direction of the groove, the accuracy of the accumulated holes in the deviation, and the insufficiency, so as to achieve a dense and uniform wall quality and reduce deviations. Accumulate and improve the effect of nesting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

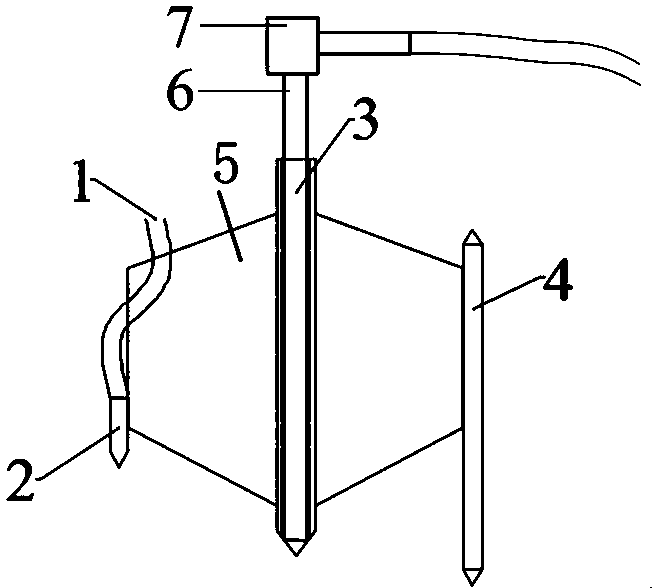

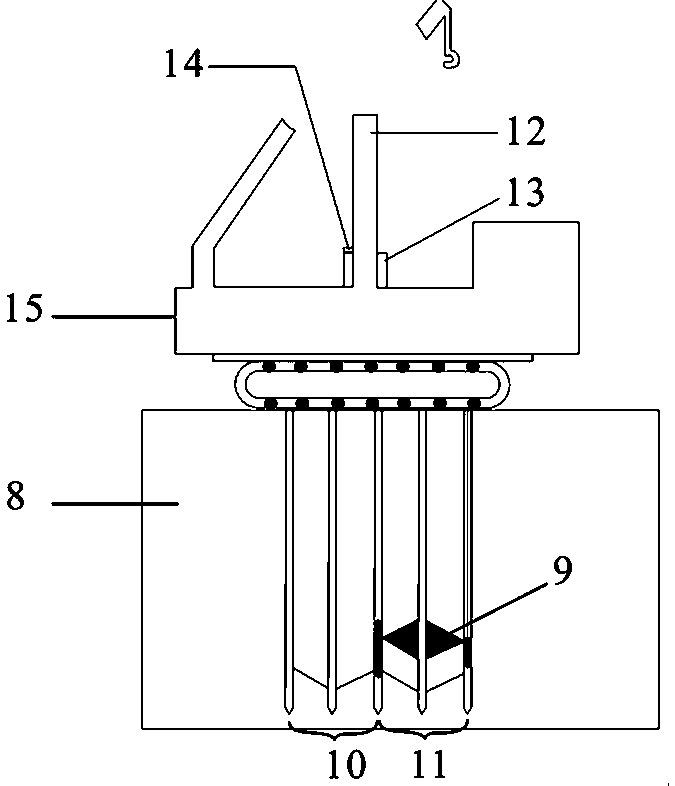

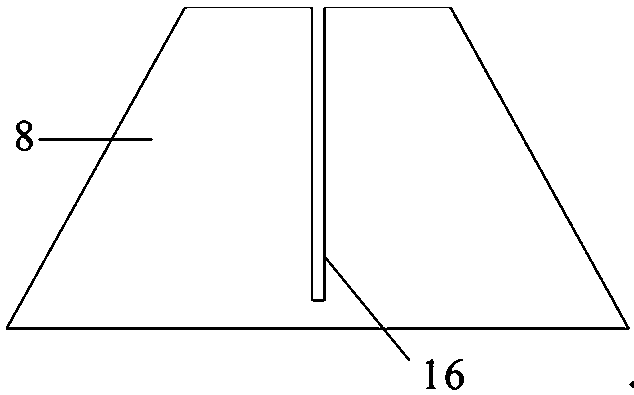

[0026] Such as figure 1 As shown, a cut-off wall grooving mold includes a grooving blade 5, a vertical middle taper rod 3 is installed in the middle of the grooving blade 5, and a vertical guide rod is installed on one side edge of the grooving blade 5 4. The lower end of the guide rod 4 protrudes downward along the lower end of the middle cone rod 3, and a detachable cone head 2 is installed on the other edge of the grooved blade 5. The upper end of the cone head 2 is connected with a rubber rod 1, a rubber rod 1 The upper end extends to the ground. Above-mentioned grooving blade 5 is made of left blade and right blade, and left blade and right blade are trapezoidal, as figure 1 shown. The lower end of the middle tapered rod 3 is tapered.

[0027] In order to realize simultaneous lifting and grouting, the middle taper rod 3 is a hollow structure, and the hollow body is used for installing the grouting pipe 6 . It can directly bring the grouting pipe to the specified depth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com