Walking and sliding integration life escape staircase for high-rise buildings, and manufacturing method and transforming method thereof

A technology for slides and stairs, which is applied in the direction of stairs, building structures, and ladder-like structures, and can solve the problems of escaping the elderly, the weak, the sick, the disabled, and the young, reducing the probability of escaping, and spending a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

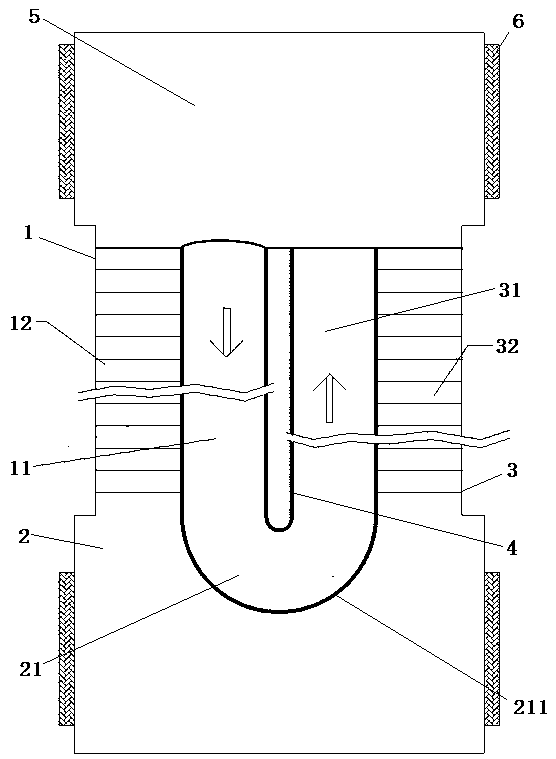

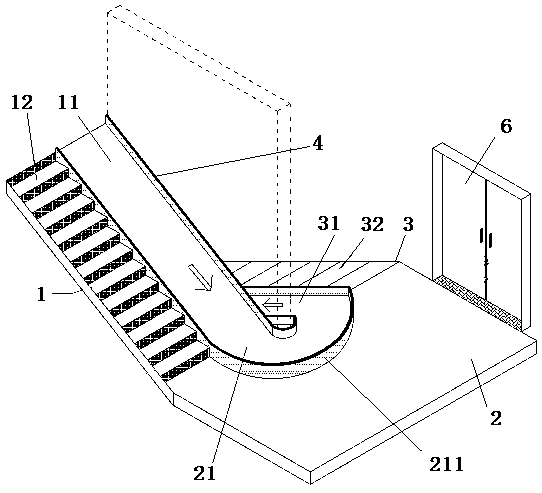

[0051] Such as figure 1 and figure 2 As shown, the present embodiment is a step-sliding integrated escape staircase for high-rise buildings, including an upper straight ladder 1 connected in sequence, a corner platform 2, a lower straight ladder 3 and a top platform 5, a corner platform 2 and a top platform 5 All are equipped with fire safety doors 6, wherein, the upper straight ladder 1 is integrally cast with steel concrete, the inner side is the upper level slide part 11, the outer side is the upper level step part 12, and the outer edge height of the upper level slide part 11 is the same as that of the upper level step part 12. The highest points of the steps are level, and the inner side of the corner platform 2 is provided with a curved part 21. The outer edge of the curved part 21 is higher than the corner platform to form a baffle 211. The lower straight ladder 3 is integrally cast with steel and concrete. , the outer side is the lower step part 32, the height of the...

Embodiment 2

[0053] A method for manufacturing the above-mentioned step-slide integrated escape staircase for high-rise buildings, wherein the slide part on the inner side of the stairs, the step part on the outer side, and the curve part set on the inner side of the corner platform are all prefabricated steel concrete components, According to the design and construction drawings of high-rise buildings, after confirming the parameters through three-dimensional images or solid model tests, enter the factory for customization, and pour the slide part and the ladder part into one piece, and then assemble on site with the construction progress and the curve part, then pour Forming, paint the interface until it is smooth and connected, and it can be put into use after cleaning and maintenance.

Embodiment 3

[0055] A transformation method for transforming the existing steel-concrete staircase into the above-mentioned step-sliding integrated escape staircase for high-rise buildings, wherein, according to the parameters of the existing staircase and corner platform, the components of the slide part and the components of the curve part are customized, and the slide part is referred to It is advisable to use mechanical profiling cutting to remove the corresponding parts of the stairs and corner platforms, so as not to damage the strength of the original load-bearing slab to the greatest extent, and reduce the amount of resection, and then place the slide parts and curved parts respectively. The road components are poured into shape, and the interface is painted until smooth and connected. After cleaning and maintenance, it can be put into use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com