Shale gas horizontal well bedding fracture evaluation method based on array induction logging information

A technology of array induction and bedding fractures, which is applied in wellbore/well components, earthwork drilling and production of fluids, etc., can solve the problems of high price, low data and high cost, and achieves wide application range, simple method and practicability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

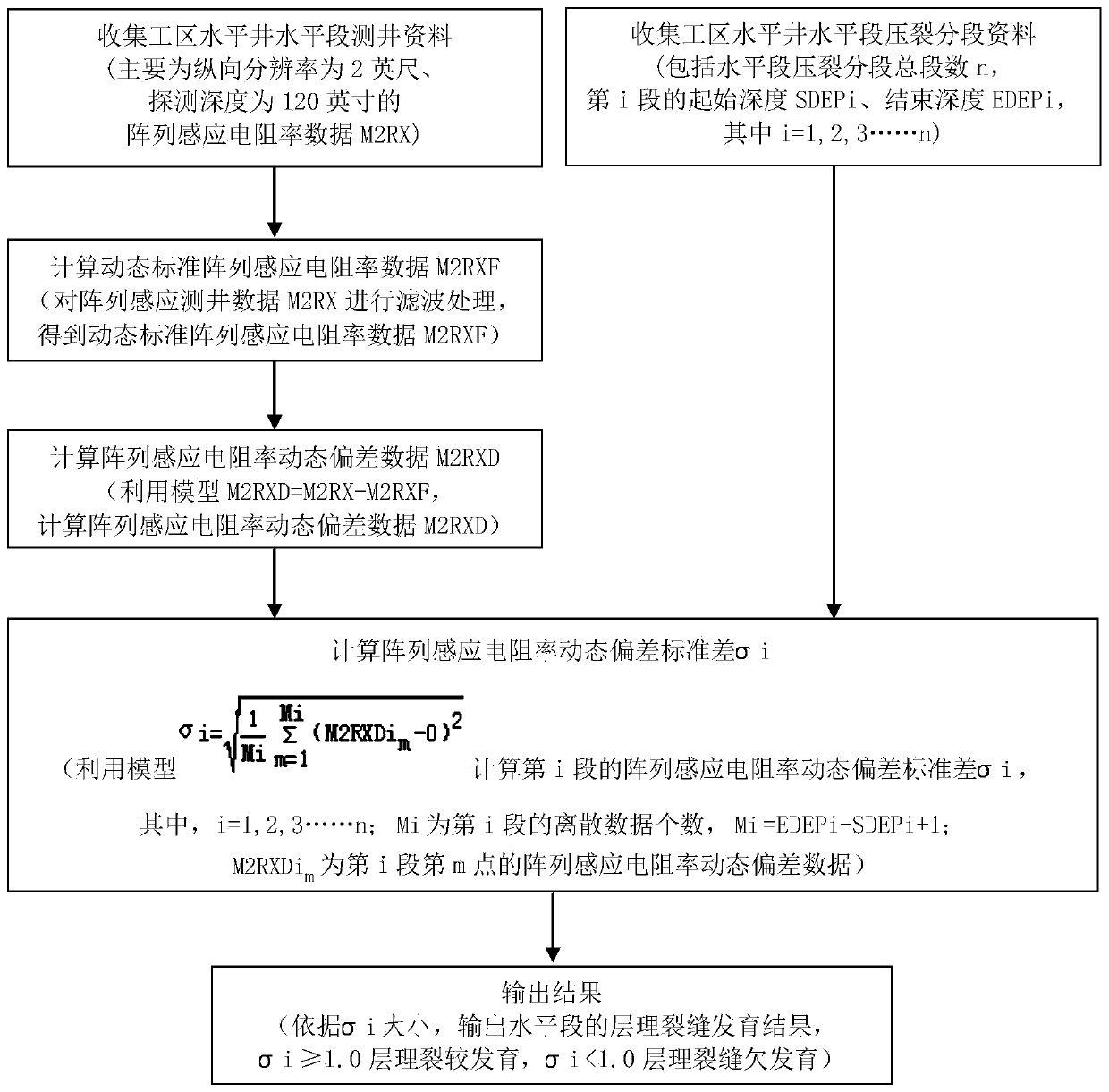

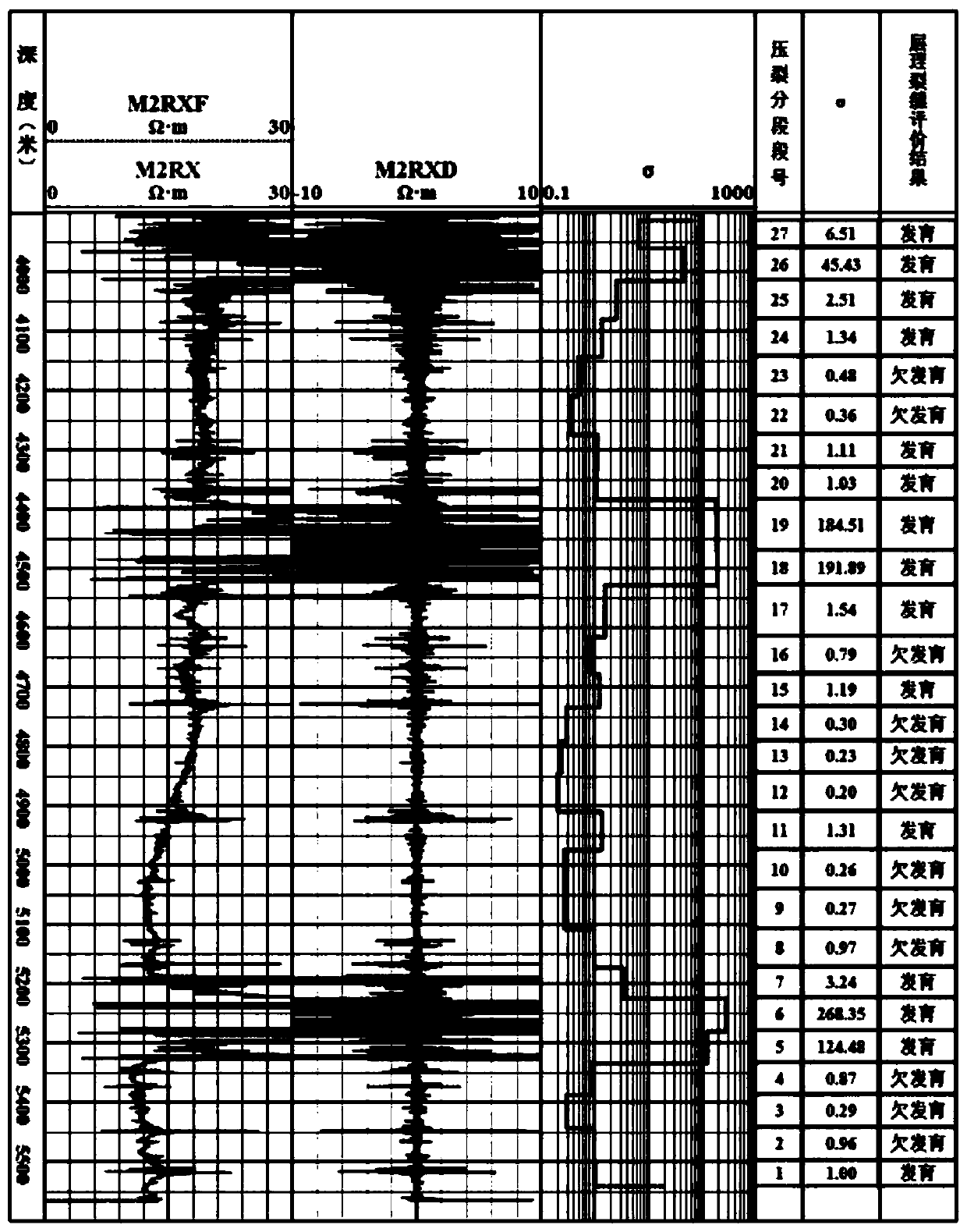

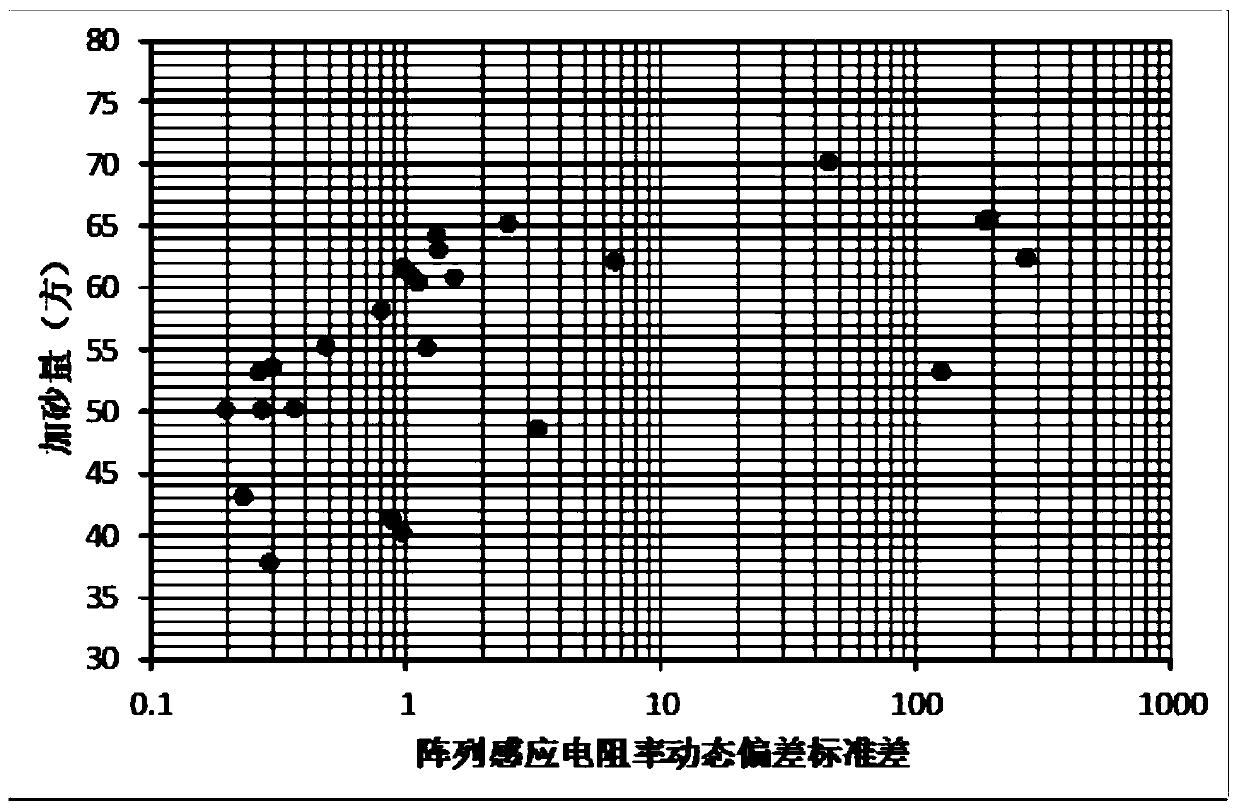

[0031] The present invention will be described in detail below with reference to the accompanying drawings.

[0032] Concrete steps of the present invention are:

[0033] 1) Collect the array induction resistivity data MARB with a vertical resolution of A feet and a detection depth of B inches in the horizontal section of the horizontal well in the work area,

[0034] The longitudinal resolution A feet is 1 foot, 2 feet or 4 feet,

[0035] The detection depth B inches is 10 inches, 20 inches, 30 inches, 60 inches, 90 inches or 120 inches;

[0036] The dimension of the array induction resistivity data MARB is Ω·m.

[0037] 2) Collect segmental data of fracturing in the horizontal section of the horizontal well in the work area.

[0038] The total number of fracturing segments in the horizontal section of the horizontal well in the work area n, the starting depth SDEPi of the i-th section, and the ending depth EDEPi, where i=1, 2, 3...n,

[0039] The starting depth SDEPi and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com