Breathing filter gluing machine

A breathing filter and gluing machine technology, which is applied in the field of gluing machines, can solve the problems of inconvenient object horizontal movement adjustment, low operating efficiency, no vertical lifting adjustment nozzle structure, etc., so as to improve flexibility and efficiency, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

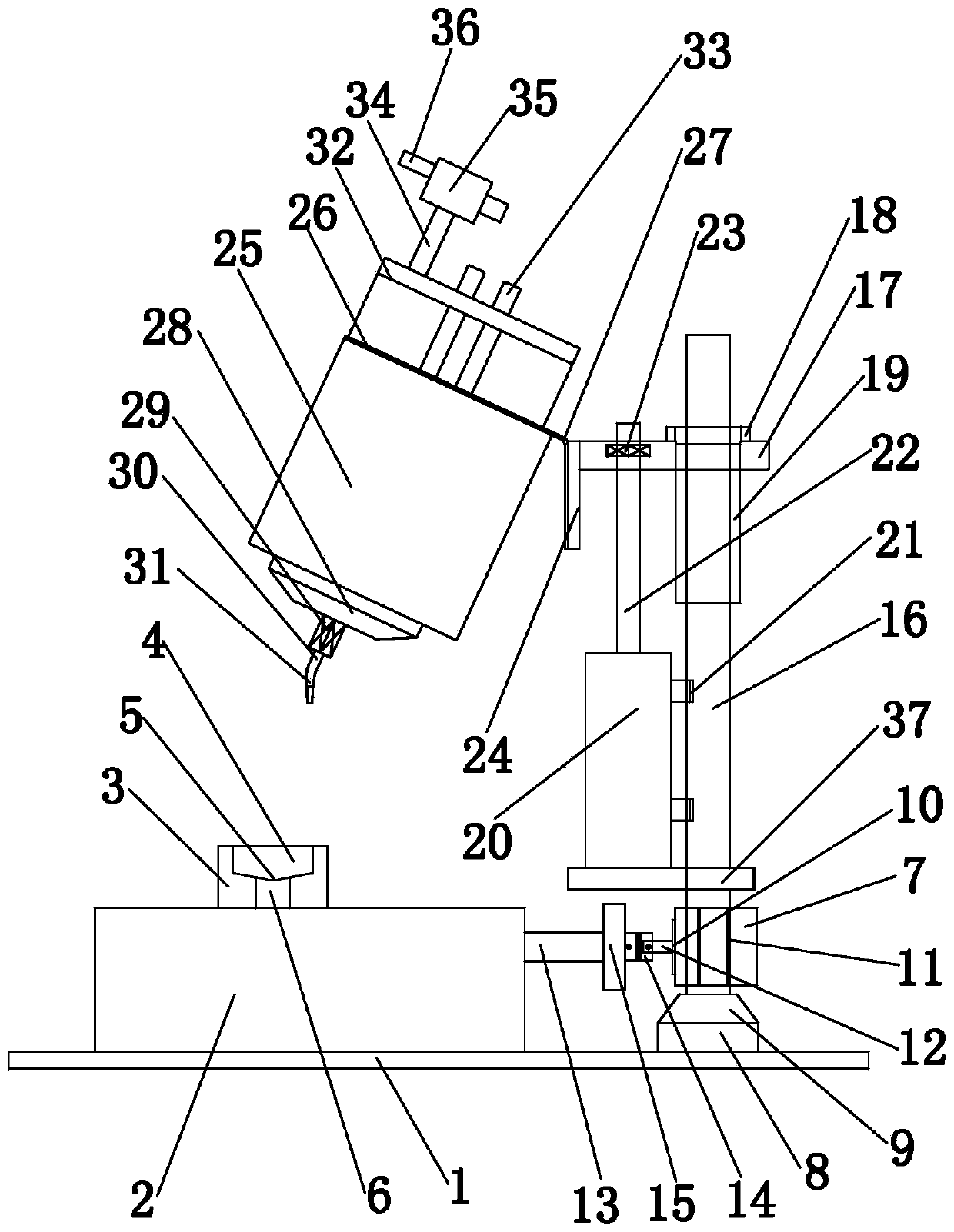

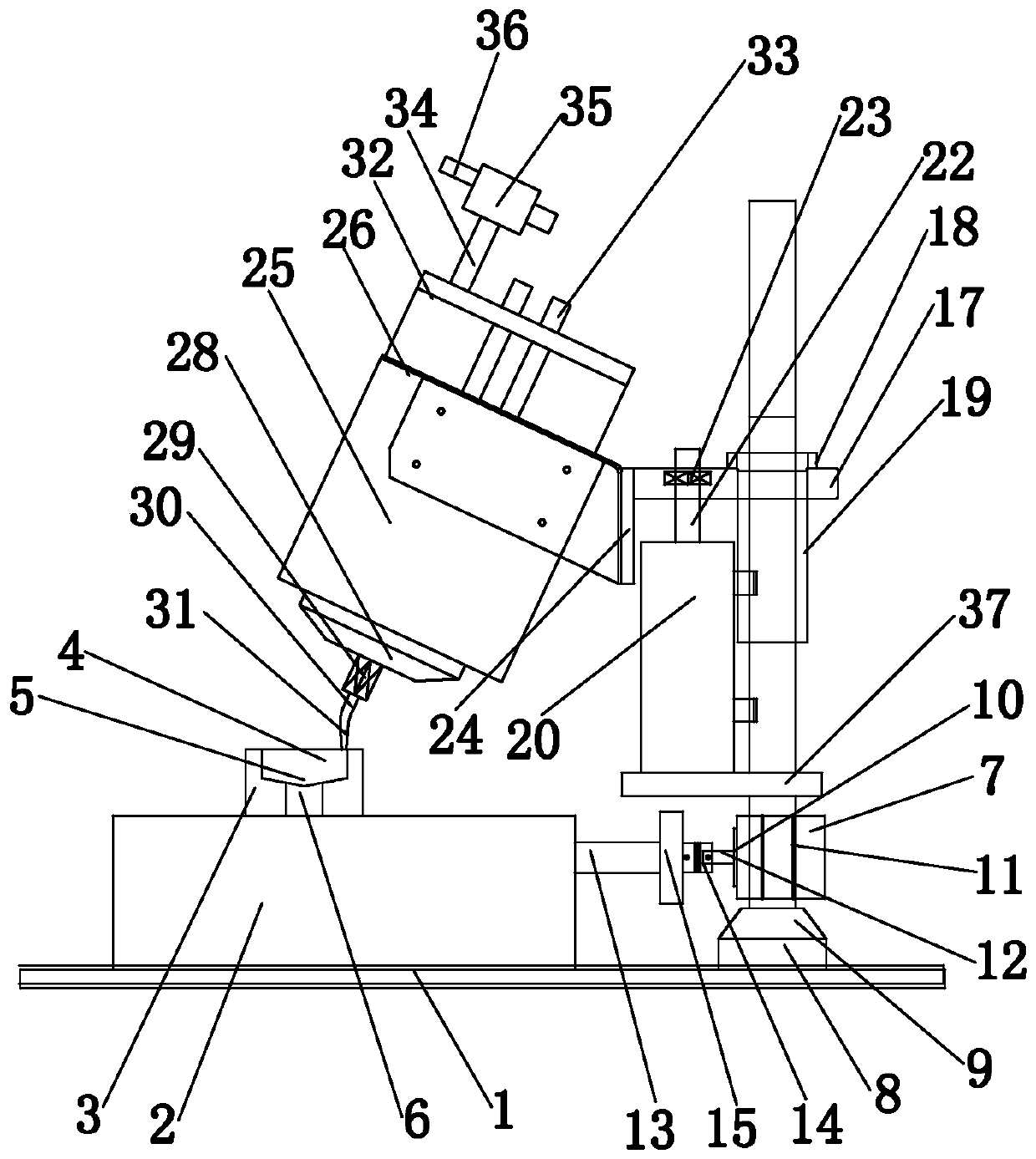

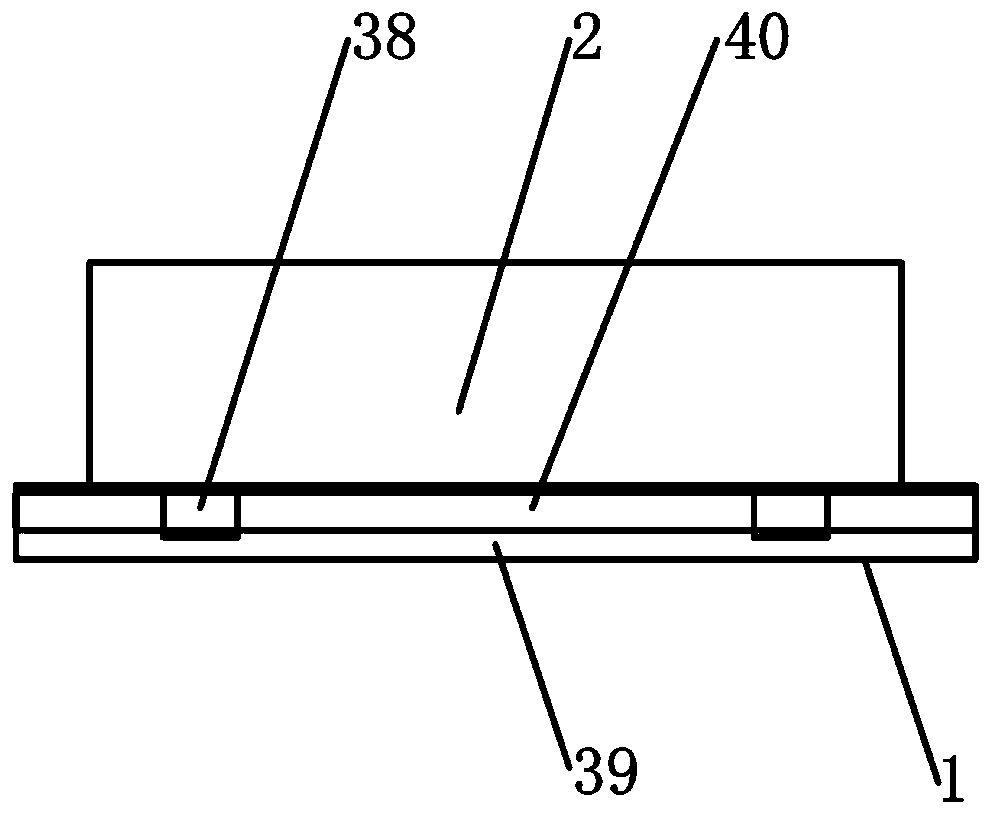

[0019] Such as Figure 1 to Figure 3 As shown, a breathing filter gluing machine includes a bottom plate 1, a moving seat 2 is arranged on the bottom plate 1, a loading seat 3 is provided on the top surface of the moving seat 2, and a loading chamber is provided on the top surface of the loading seat 3 4. The bottom plate 1 is provided with a fixed frame 7, and the fixed frame 7 is provided with a horizontal hydraulic cylinder 10. The front part of the horizontal hydraulic cylinder 10 is provided with a horizontal piston rod 12, and the front end of the horizontal piston rod 12 and the side of the movable seat 2 Connect; the top surface of fixed frame 7 is provided with cylinder positioning seat 37, and cylinder positioning seat 37 is provided with vertical guide shaft 16, and the outer peripheral surface of vertical guide shaft 16 is set with mobile frame 17, and one side of mobile frame 17 is set There is a moving tube 18, which is set on the outer peripheral surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com