Blasting-bead quality detecting and waste-rejecting device used in blasting-bead cigarette filter tip

A filter tip and blasting bead technology, applied in sorting and other directions, can solve the problems of essence volatilization, essence leakage, blasting bead crushing, etc., to achieve the effect of fast and accurate operation, ensure quality reliability, and limit position reliability and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

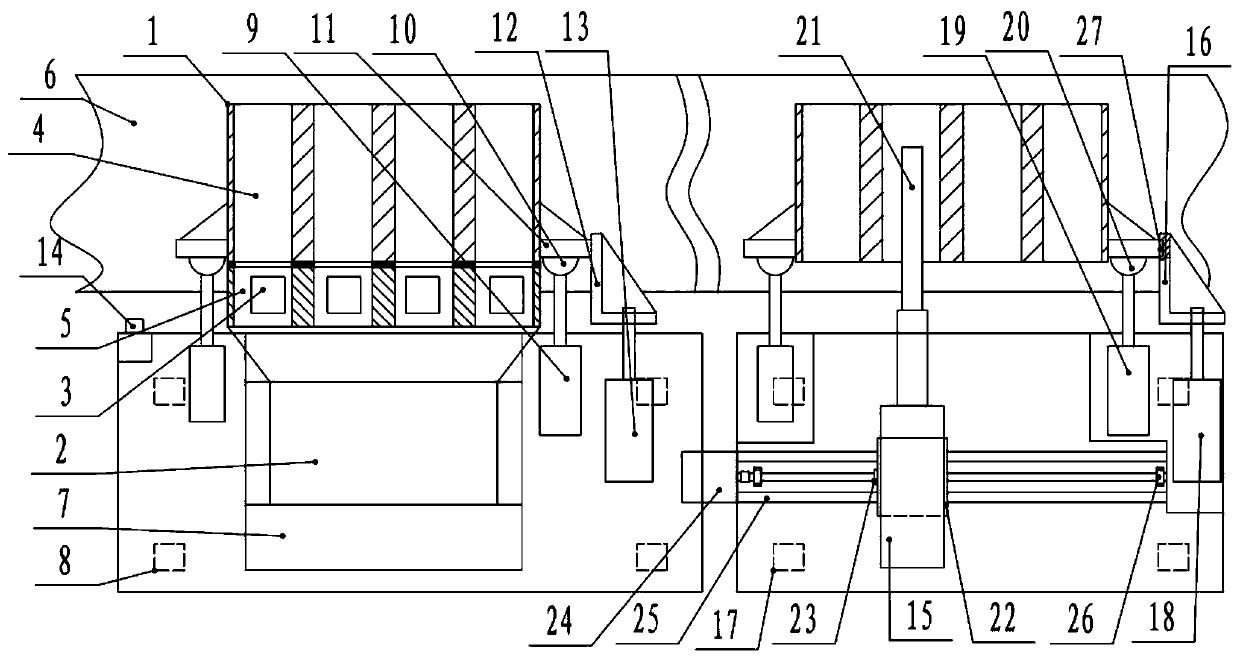

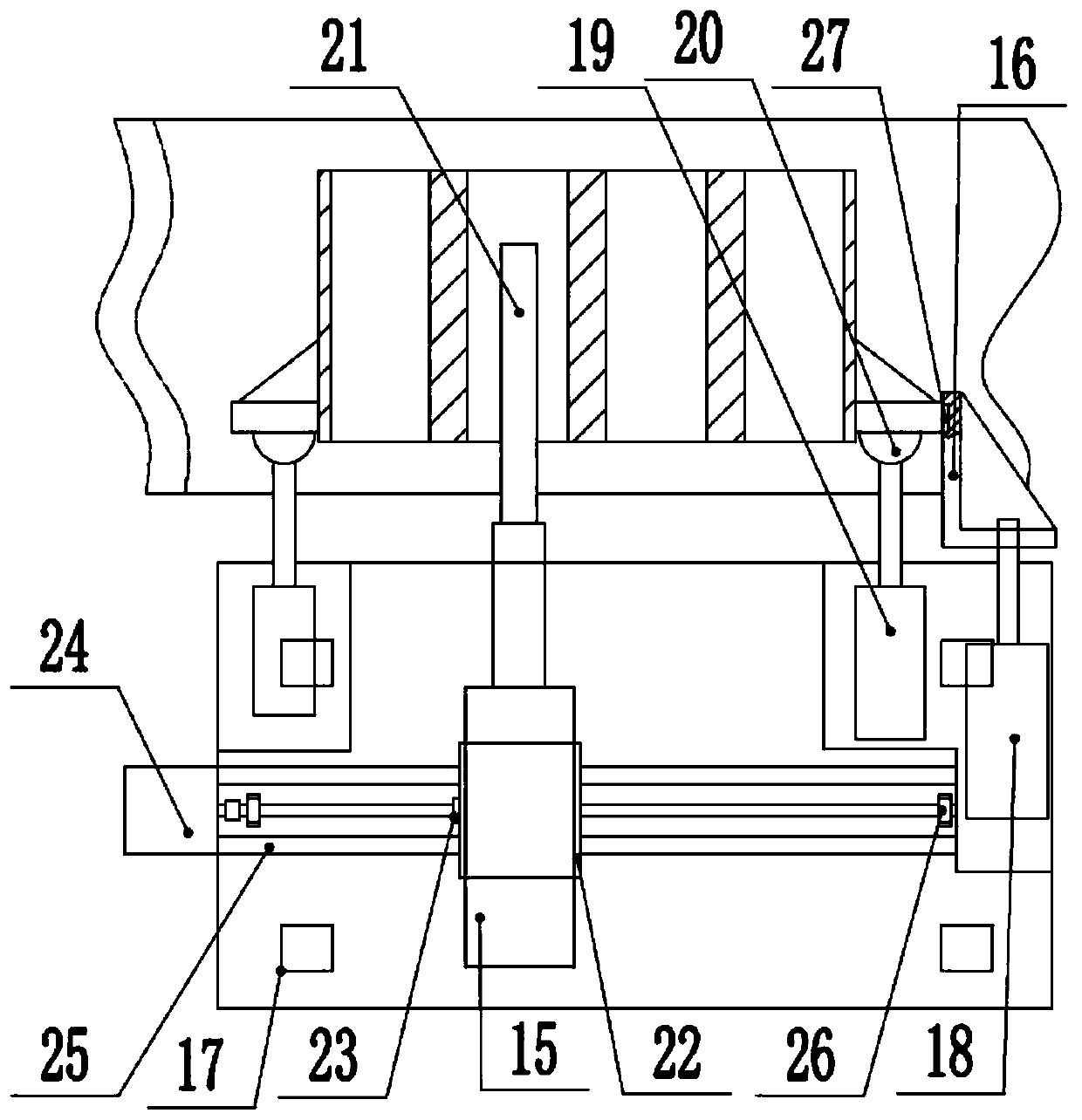

[0014] Embodiment 1: as Figure 1-Figure 4 As shown, a device for detecting and rejecting the quality of popping beads in the popping bead cigarette filter includes a push rod 21, a pushing cylinder 15, a lateral movement mechanism and a limit plate 16, and the pushing rod 21 is fixedly connected to the pushing cylinder 15 through a threaded portion. The threaded hole on the end face of the cylinder rod is pushed out and the cylinder 15 is connected to the support table 17 through a lateral movement mechanism. The push rod 14 can be stretched into the placement channel 4 of the placement box 1, and the limit plate 16 is fixedly connected to the second limit telescopic cylinder. On the cylinder rod of 18, the limit telescoping cylinder two 18 is fixedly connected on the support platform 17.

[0015] Preferably, the above-mentioned support table 17 is also equipped with two telescopic cylinders 19, the cylinder rod ends of the telescopic cylinders 19 are fixedly connected to the...

Embodiment 2

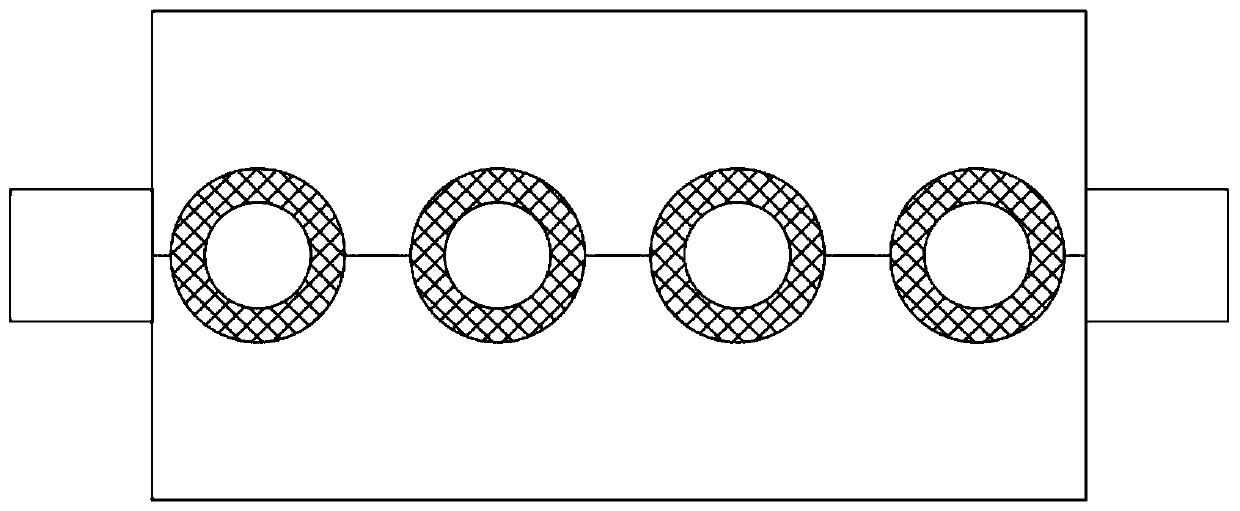

[0018] Embodiment 2: as Figure 1-Figure 3 As shown, a system for detecting the quality of popping beads in a popping bead cigarette filter includes a placement box 1, an exhaust fan 2 and an electronic nose 3. The placement box 1 is provided with a plurality of single cigarette placement channels 4, and the air inlet of the exhaust fan 2 It can be docked to the side of the storage box 1, and multiple detection channels 5 are arranged inside, and the multiple detection channels 5 are sealed and docked with multiple cigarette storage channels 4 one by one. The electronic nose 3 is installed in the detection channel 5, and the multiple detection channels 5 exit Collected to the exhaust fan 2, the exhaust gas in the cigarette is inhaled by the exhaust fan, and the electronic nose is used to detect the concentration of the puff essence to judge the quality of the puff essence in the cigarette filter. The detection method is simple, fast and accurate.

[0019] Preferably, the above...

Embodiment 4

[0026] Embodiment 4: a kind of detection method of quick-fried pearl quality detection system in quick-fried pearl cigarette filter tip, this method comprises the following steps:

[0027] (1) When the cigarette placement box coming from the conveyor belt is detected by the detection sensor, the limit telescopic cylinder is controlled to extend the cylinder rod, and the limit baffle is used to limit the placement box;

[0028] (2) Use the telescopic cylinder to stretch out the vacuum suction cup to limit and retract the storage box, seal the cigarette storage channel in the storage box and the detection channel, and place a cigarette in a cigarette storage channel;

[0029] (3) Start the exhaust fan to draw air, and the electronic nose of each detection channel detects the concentration of cigarette essence in the corresponding cigarette placement channel, converts it into an analog signal, and converts the analog signal into a digital signal and transmits it to the industrial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com