Manual cloth winding machine

A winding machine and fabric technology, which is applied in mechanical cleaning, thin material processing, winding strips, etc., can solve the problems of troublesome operation and untidy winding of fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

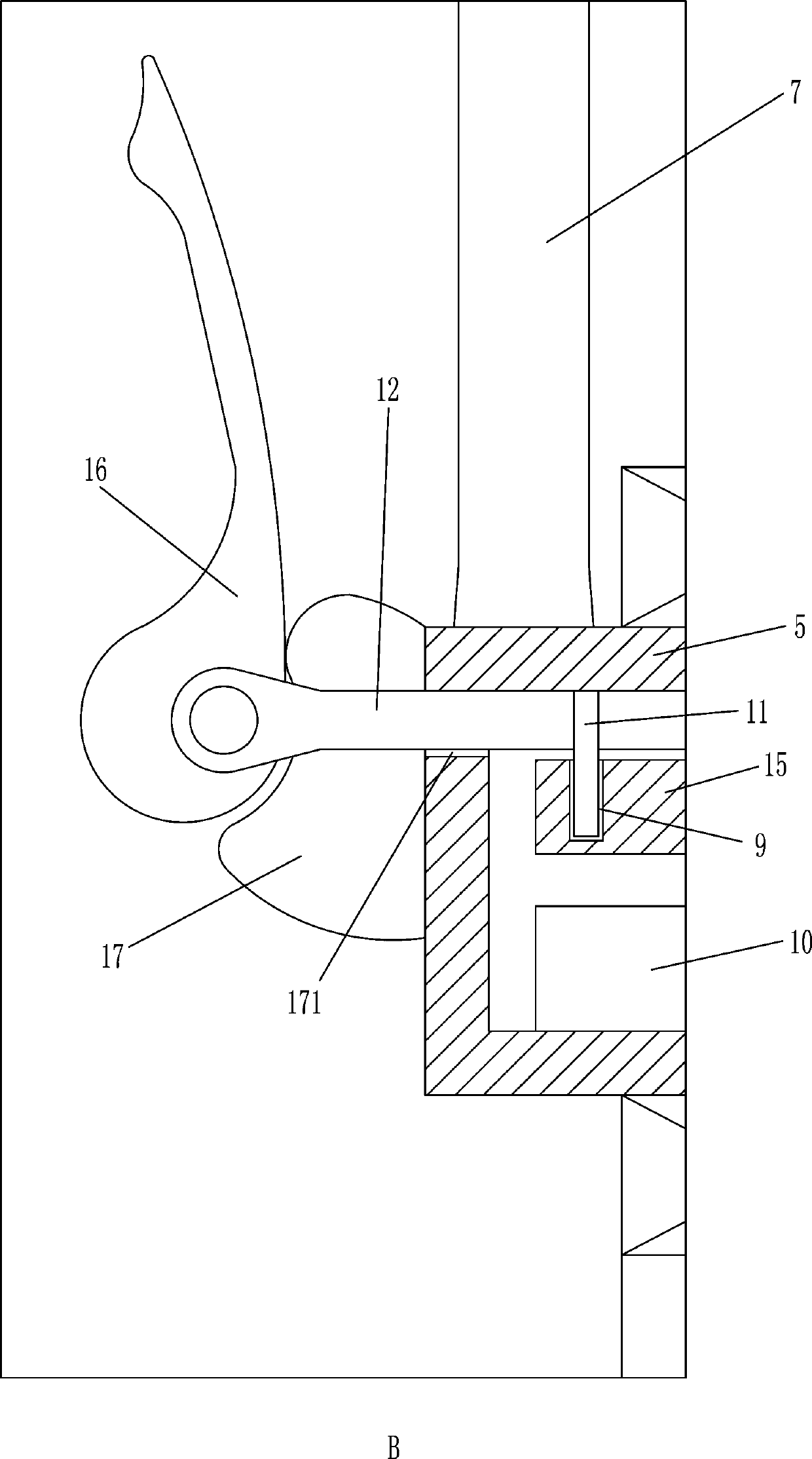

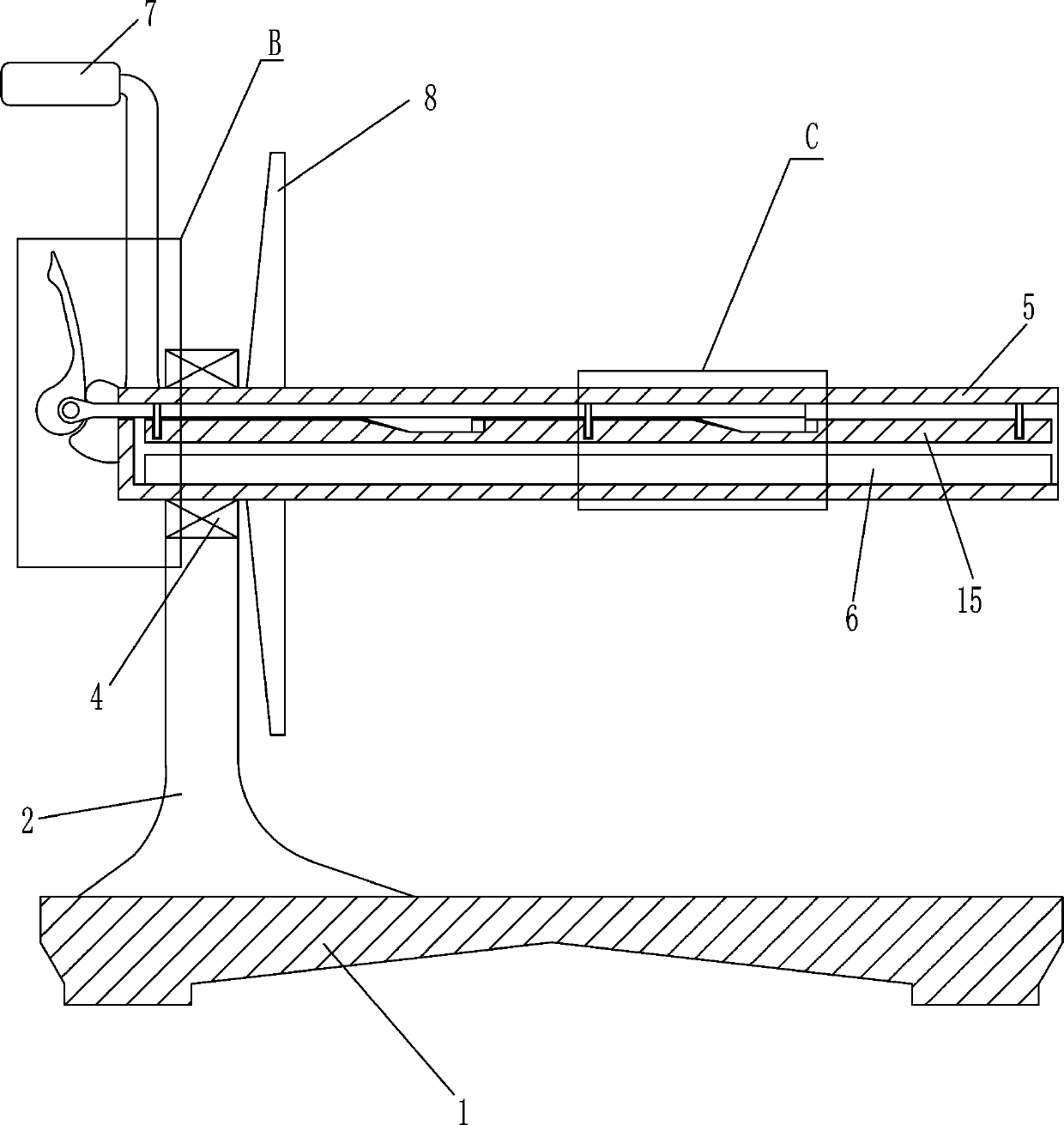

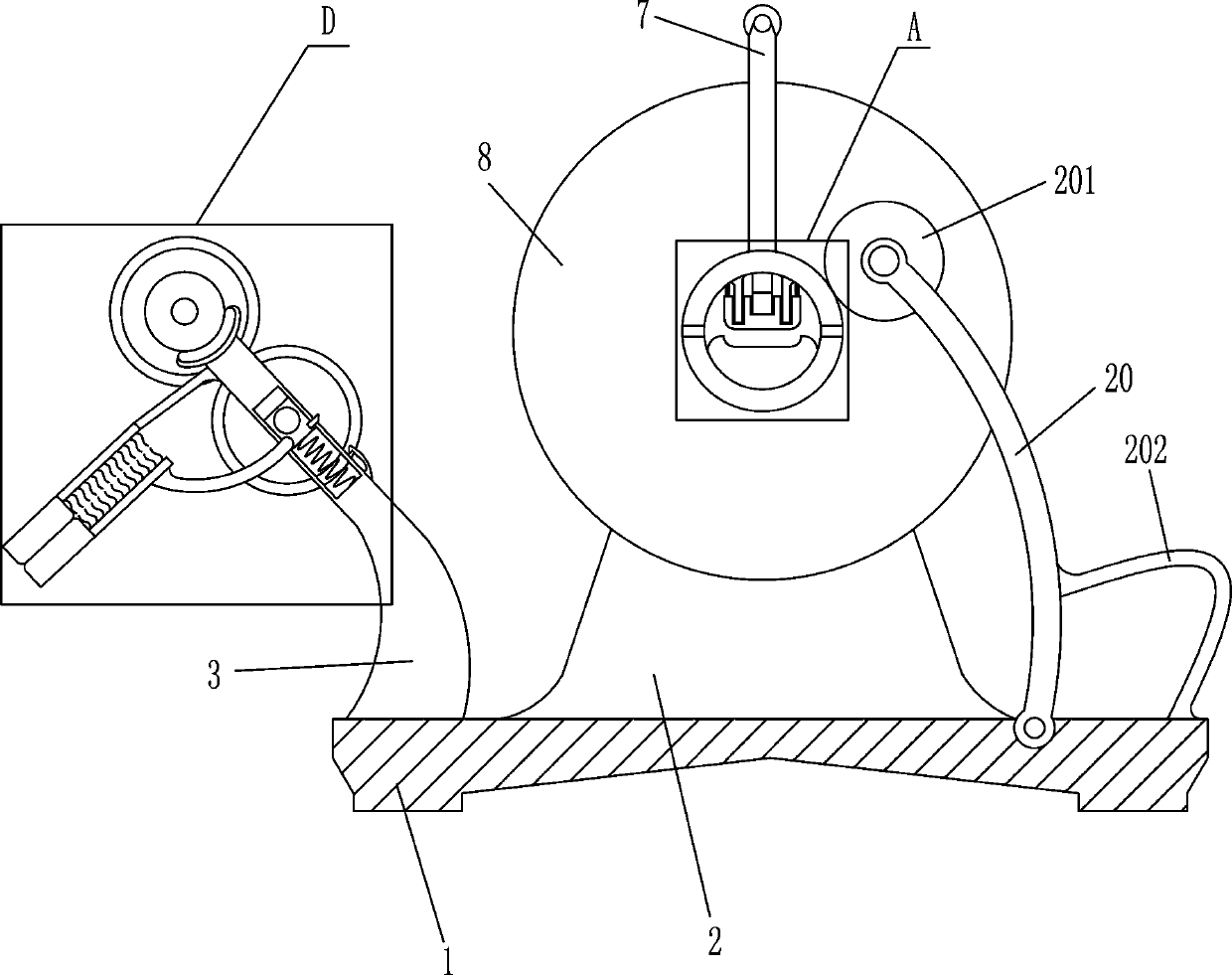

[0019] A manual fabric winder, such as Figure 1-5 As shown, it includes a base 1, a mounting plate 2, a support column 3, a bearing seat 4, a slotted tube 5, a first pressing plate 6, a rocking handle 7, a baffle 8 and a pressing device, and the middle rear side of the top of the base 1 is fixedly connected There is a mounting plate 2, the base 1 is connected with the mounting plate 2 by welding, the top of the mounting plate 2 is fixed with a bearing seat 4, and the bearing seat 4 is connected with a slotted tube 5 that can roll up the cloth, and the slotted tube 5 There is a pressing device that can compress the cloth. The rocker 7 is installed in the middle of the rear side of the outer top of the slotted tube 5. The rocker 7 is connected to the slotted tube 5 by welding, and the rocker 7 is located in the bearing seat 4. On the rear side, a baffle plate 8 that can limit the cloth is installed at the rear of the outer side of the slotted tube 5. The baffle plate 8 is locat...

Embodiment 2

[0021] A manual fabric winder, such as Figure 1-5 As shown, it includes a base 1, a mounting plate 2, a support column 3, a bearing seat 4, a slotted tube 5, a first pressing plate 6, a rocking handle 7, a baffle 8 and a pressing device, and the middle rear side of the top of the base 1 is fixedly connected There is a mounting plate 2, the top of the mounting plate 2 is fixed with a bearing seat 4, the bearing seat 4 is connected with a slotted tube 5 that can roll up the cloth, and the slotted tube 5 is provided with a pressing device that can compress the fabric, The rocker 7 is installed in the middle of the rear side of the outer top of the slotted tube 5, the rocker 7 is located at the rear of the bearing seat 4, and the rear of the outer side of the slotted tube 5 is installed with a baffle 8 that can limit the cloth, and the baffle 8 is located in the bearing. On the front side of the base 4 , a first pressing plate 6 is fixedly connected to the inner bottom of the slo...

Embodiment 3

[0024] A manual fabric winder, such as Figure 1-6 As shown, it includes a base 1, a mounting plate 2, a support column 3, a bearing seat 4, a slotted tube 5, a first pressing plate 6, a rocking handle 7, a baffle 8 and a pressing device, and the middle rear side of the top of the base 1 is fixedly connected There is a mounting plate 2, the top of the mounting plate 2 is fixed with a bearing seat 4, the bearing seat 4 is connected with a slotted tube 5 that can roll up the cloth, and the slotted tube 5 is provided with a pressing device that can compress the fabric, The rocker 7 is installed in the middle of the rear side of the outer top of the slotted tube 5, the rocker 7 is located at the rear of the bearing seat 4, and the rear of the outer side of the slotted tube 5 is installed with a baffle 8 that can limit the cloth, and the baffle 8 is located in the bearing. On the front side of the base 4 , a first pressing plate 6 is fixedly connected to the inner bottom of the slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com