Mine gravel treatment device capable of screening

A processing device and a technology for crushing stone, applied in the field of crushed stone processing in mines, can solve the problems of reducing the service life of crushing rollers, reducing the efficiency of production, affecting the precision of crushing, etc., so as to improve adaptability, improve processing effect, and ensure extrusion. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

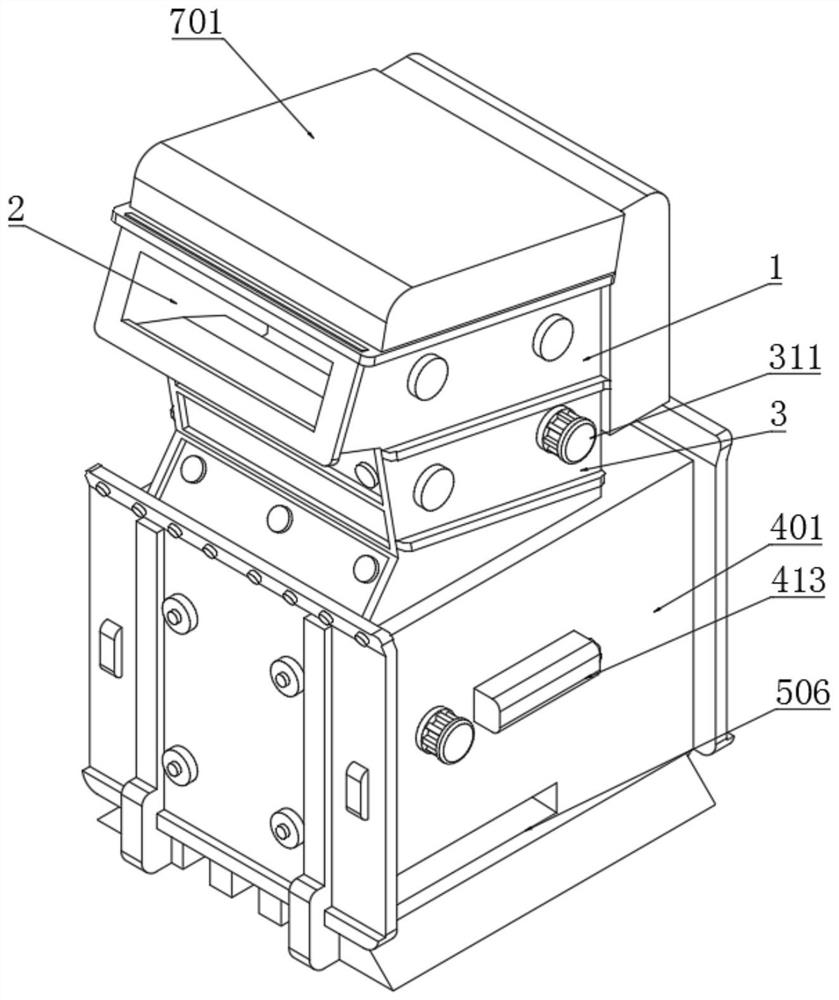

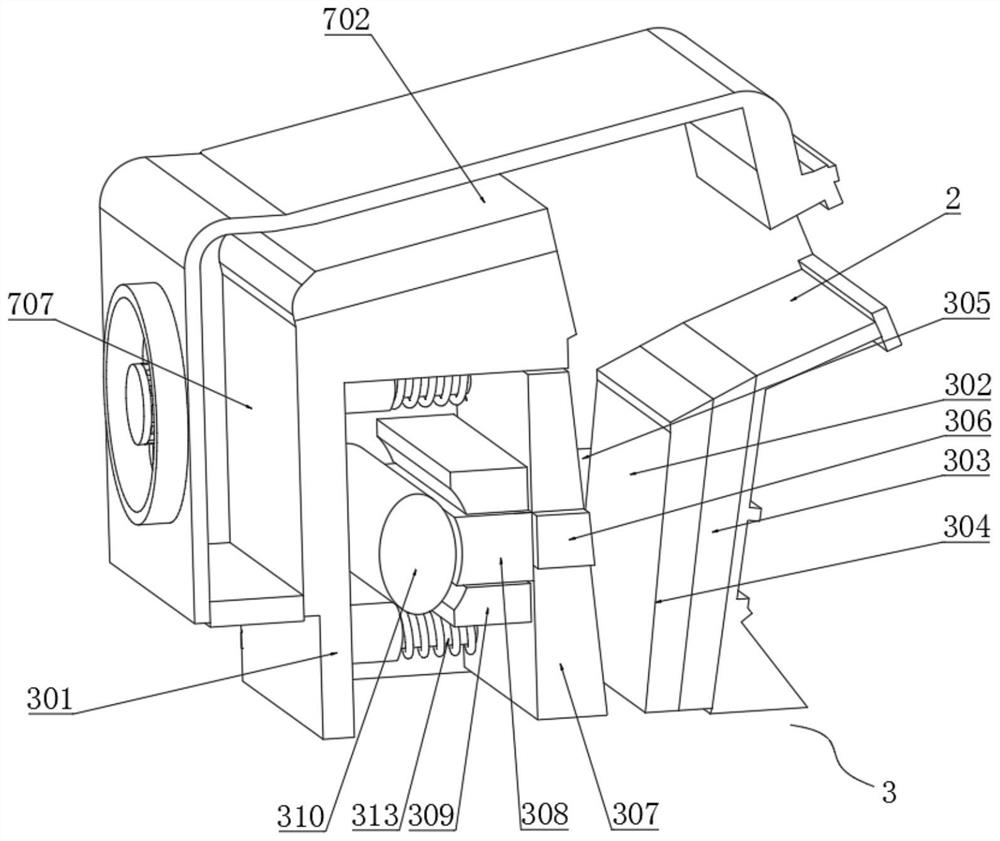

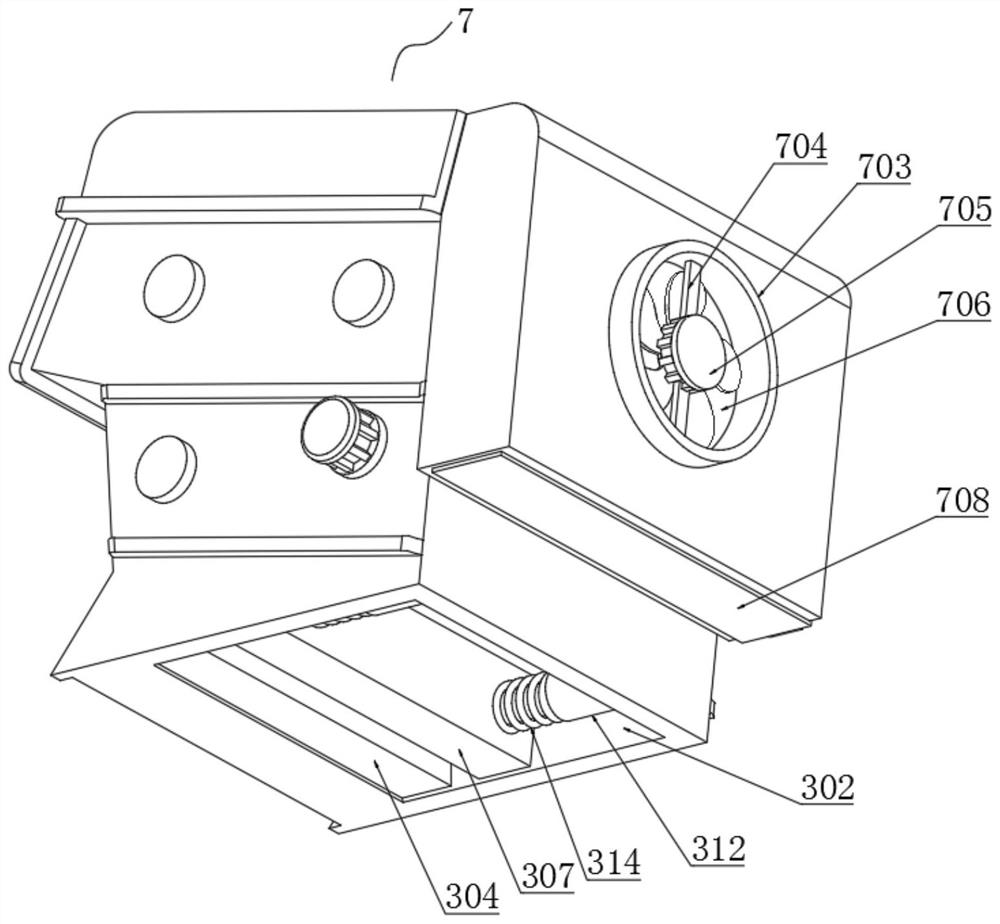

[0043] Example: such as Figure 1-7 As shown, the present invention provides a kind of technical scheme, a kind of mine gravel treatment device that can screen, comprises feed box 1, and feed box 1 end is provided with feed inlet 2, and feed box 1 bottom end is connected with bolt. Extrusion mechanism 3, extrusion mechanism 3 includes extrusion box 301, extrusion chamber 302, mounting plate 303, fixed splint 304, slide groove 305, slide plate 306, movable splint 307, push plate 308, limit plate 309, ellipse Rotating rod 310, first rotating motor 311, casing 312, fixed rod 313 and tension spring 314;

[0044] The bottom end of the feed box 1 is connected with an extrusion box 301 by bolts, and an extrusion chamber 302 is provided inside the extrusion chamber 301, and a mounting plate 303 is connected with a mounting plate 303 by bolts at one side of the inner wall of the extrusion chamber 302. One side of the inner wall of the chamber 302 is fixedly connected with a fixed spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com