A weft-knitted single-side pleated high-elastic fabric and its production process

A fabric and wrinkle technology, applied in the field of textile fabrics, can solve the problems of non-wrinkled high-elastic fabrics, difficult weaving tension control, and difficult to ensure the quality of the fabric surface, etc., to achieve bright color, soft touch, and good width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

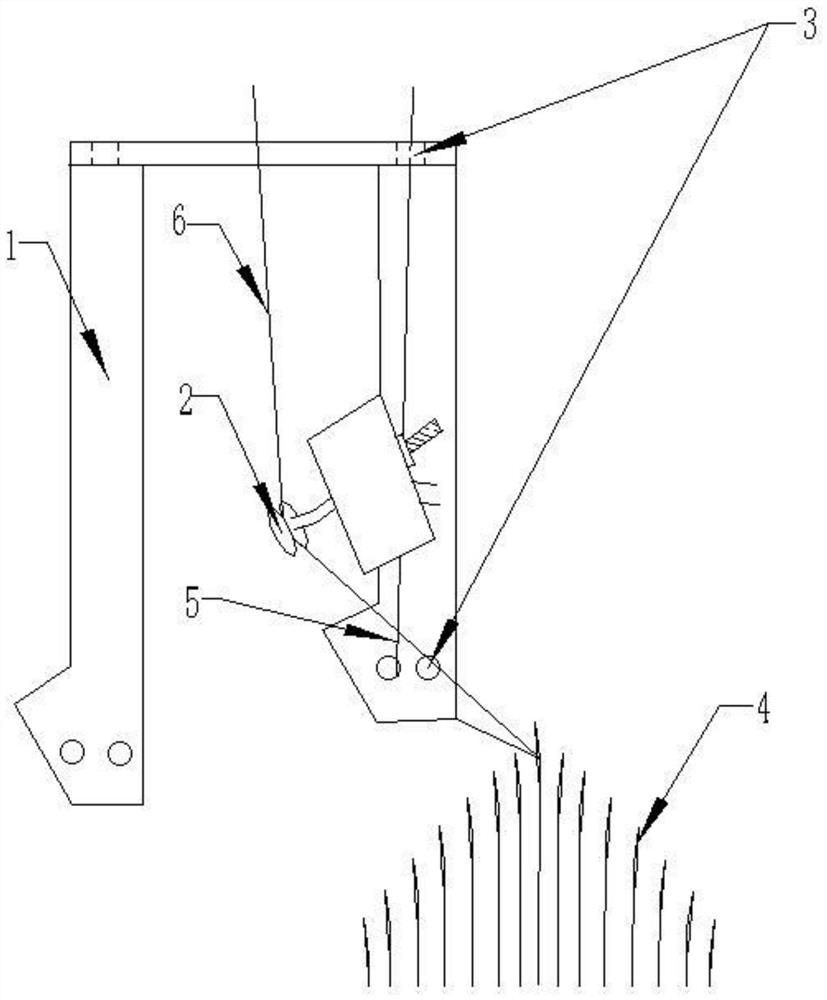

[0066] (1) Arrangement of knitting needles: the knitting needles of the upper dial of the knitting machine are arranged cyclically according to AB as a cyclic unit, and the knitting needles of the lower needle cylinder of the knitting machine are arranged cyclically according to BA as a cyclic unit;

[0067] (2) Threading: Solona fibers are woven through the porcelain eyes on the yarn nozzles into the knitting needles of the upper dial and lower cylinder of the 1st and 13th roads; the first combed cotton passes through the porcelain eyes on the yarn nozzles Insert the odd-numbered knitting needles in the 1-24 roads except the 1st and 13th roads, and the spandex is passed through the odd-numbered knitting needles in the 1-24 roads except the 1st and 13th roads through the guide wheel on the yarn nozzle Weaving; by adjusting the angle of the guide wheel, the angle between the spandex and the first combed cotton is 15 ° to penetrate the knitting needle, and the position of the gui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com