Support for draining pump and manufacturing method thereof

A technology for drainage pumps and fixing plates, which is applied in the field of support for drainage pumps and its manufacture, can solve the problems of reduced strength and rigidity, reduced natural frequency, fatigue of supporting parts, etc., to reduce strength, reduce vibration, and facilitate disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

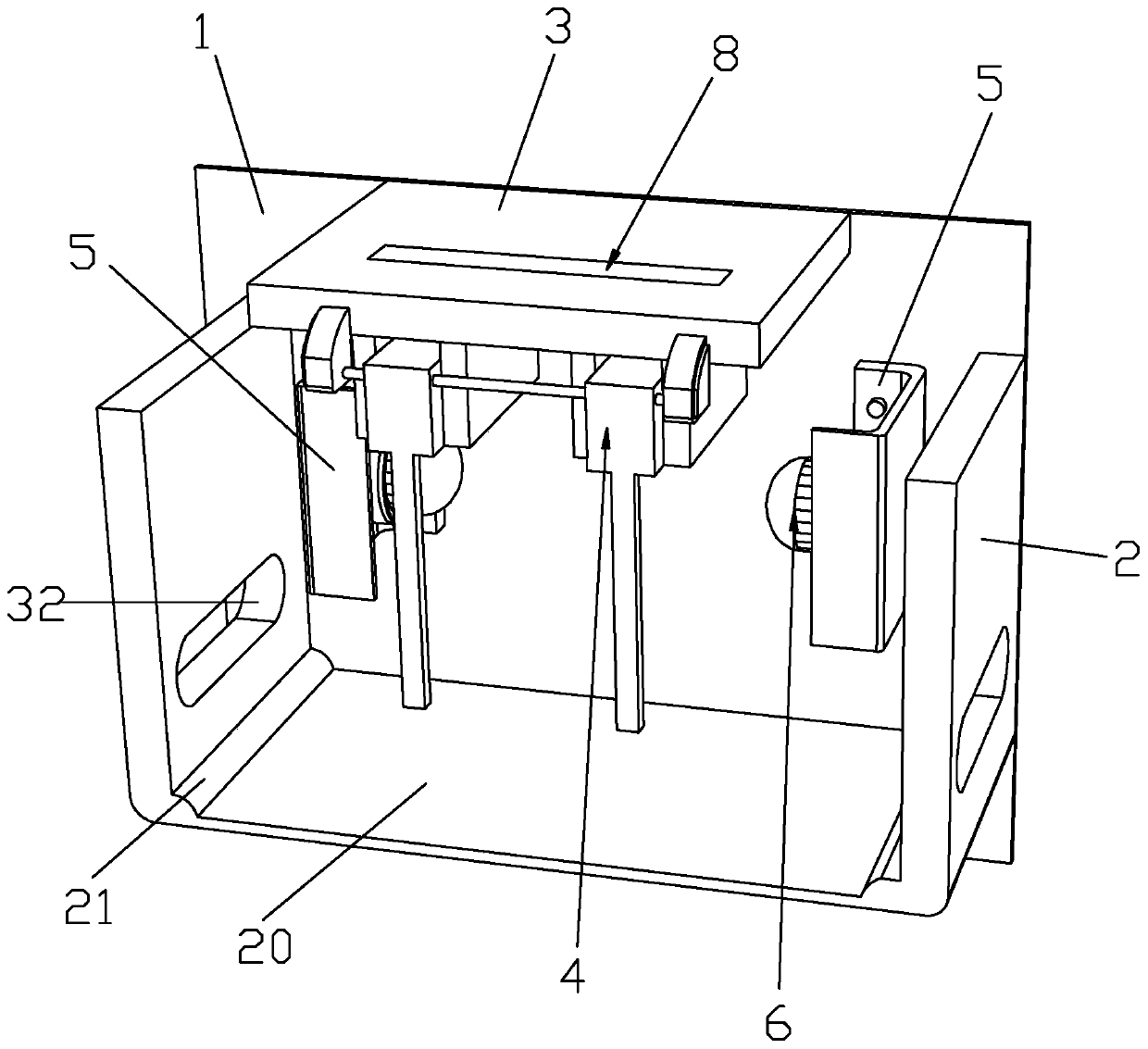

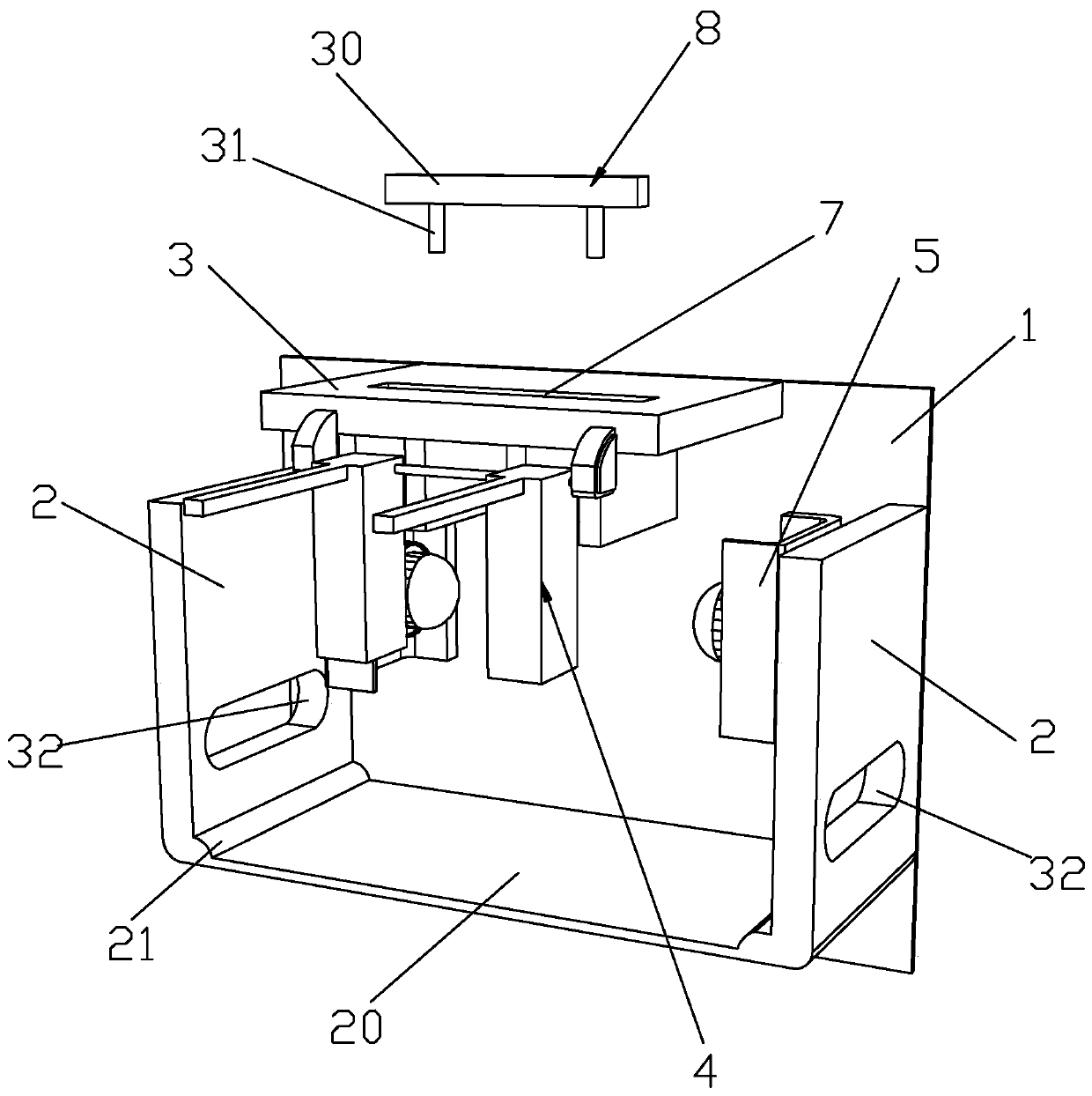

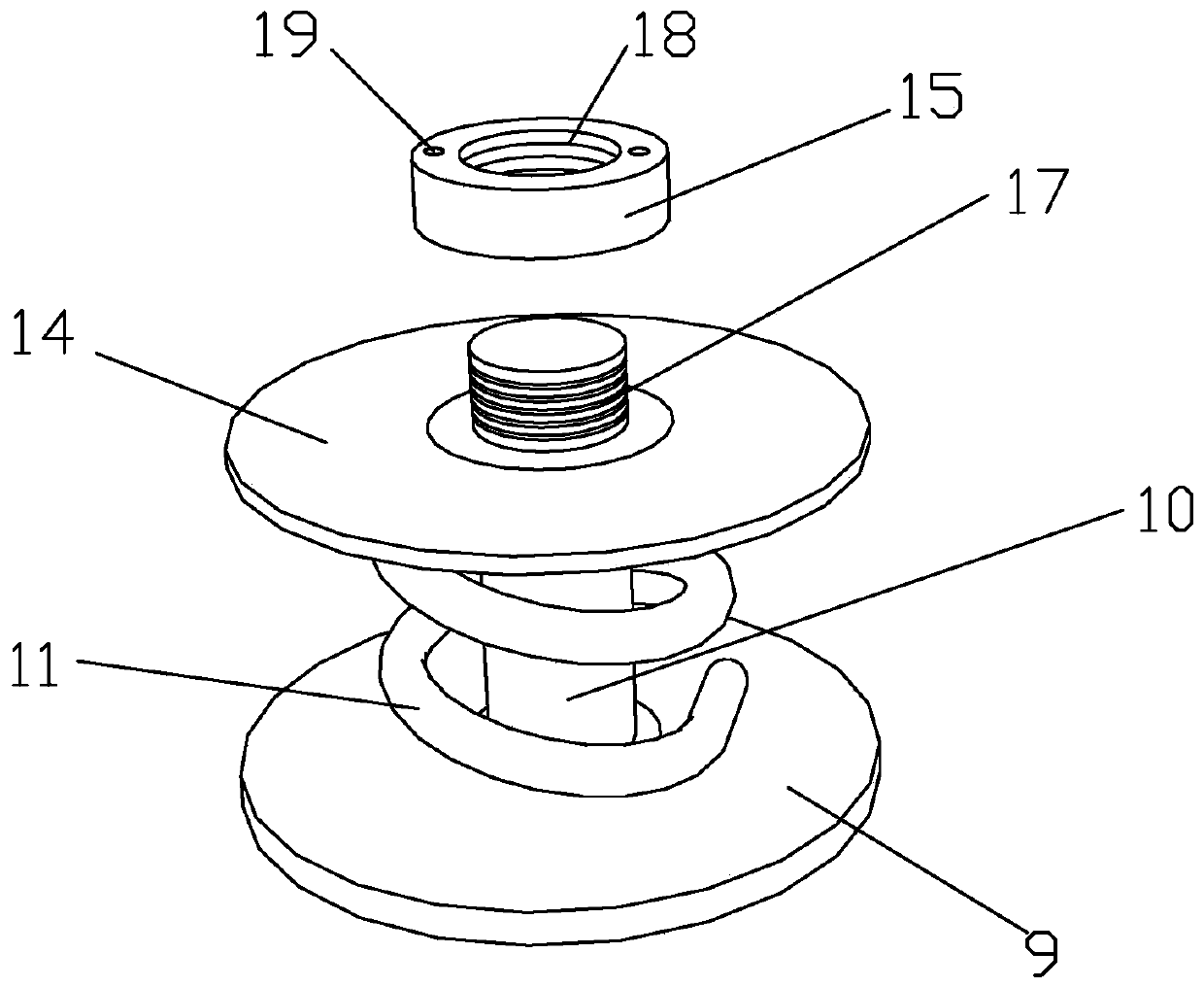

[0044] Such as Figure 1 to Figure 6 As shown, it is a bracket for a drainage pump according to the present invention, which includes a bracket main body 1. The bracket main body 1 is provided with a fixing plate 2 and a positioning plate 3. The fixing plate 2 has a U-shaped structure, and the fixing plate 2 plays a role in supporting the drainage pump. As a function, the fixing plate 2 has a U-shaped structure, which facilitates the installation of pipelines on both sides of the drainage pump. The fixing plate 2 is welded with the main body of the bracket 1, and a fixing device 4 is provided under the positioning plate 3, and the fixing device 4 is installed above the fixing plate 2, and connecting plates 5 and adjusting devices 6 are arranged on both sides of the fixing device 4, and the connecting plate 5 It is threadedly connected with the bracket main body 1, the adjustment device 6 is installed on the connecting plate 5, and the adjacent adjustment device 6 is oppositely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com