Intelligent fault diagnosis method under small sample based on attention mechanism element learning model

A technology of attention mechanism and intelligent diagnosis, applied in biological neural network models, computer components, character and pattern recognition, etc., can solve problems affecting the timeliness, effectiveness and versatility of state monitoring, complex working conditions, and generalization of algorithms low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

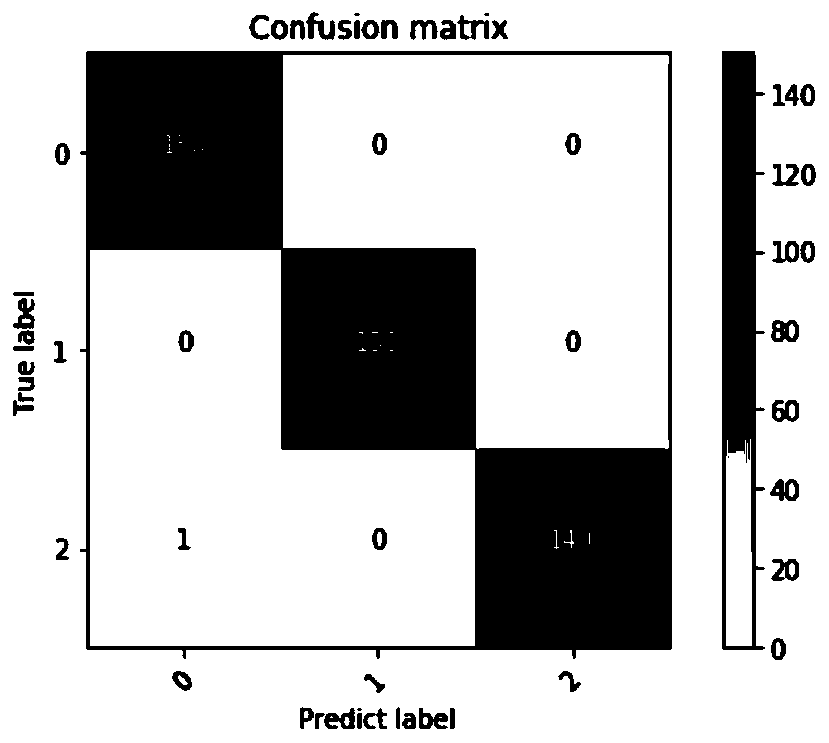

[0068] Take a motor bearing fault data set as an example to illustrate. This data set contains the data of three bearing operating states: normal, inner ring fault, and outer ring fault. At the same time, the mechanical signals of the corresponding operating states are collected at three speeds (10Hz, 20Hz, 30Hz). The running state contains 155 samples, and a total of 1395 samples. Take 15 samples at 30Hz speed as training data, and the remaining 450 samples as test data to construct a data set at the same speed; take 45 samples mixed with three speeds as training data, and the remaining 1350 samples as test The data is constructed as a data set at mixed speeds. The training sample data volume only accounts for 3.2% of the total sample data volume.

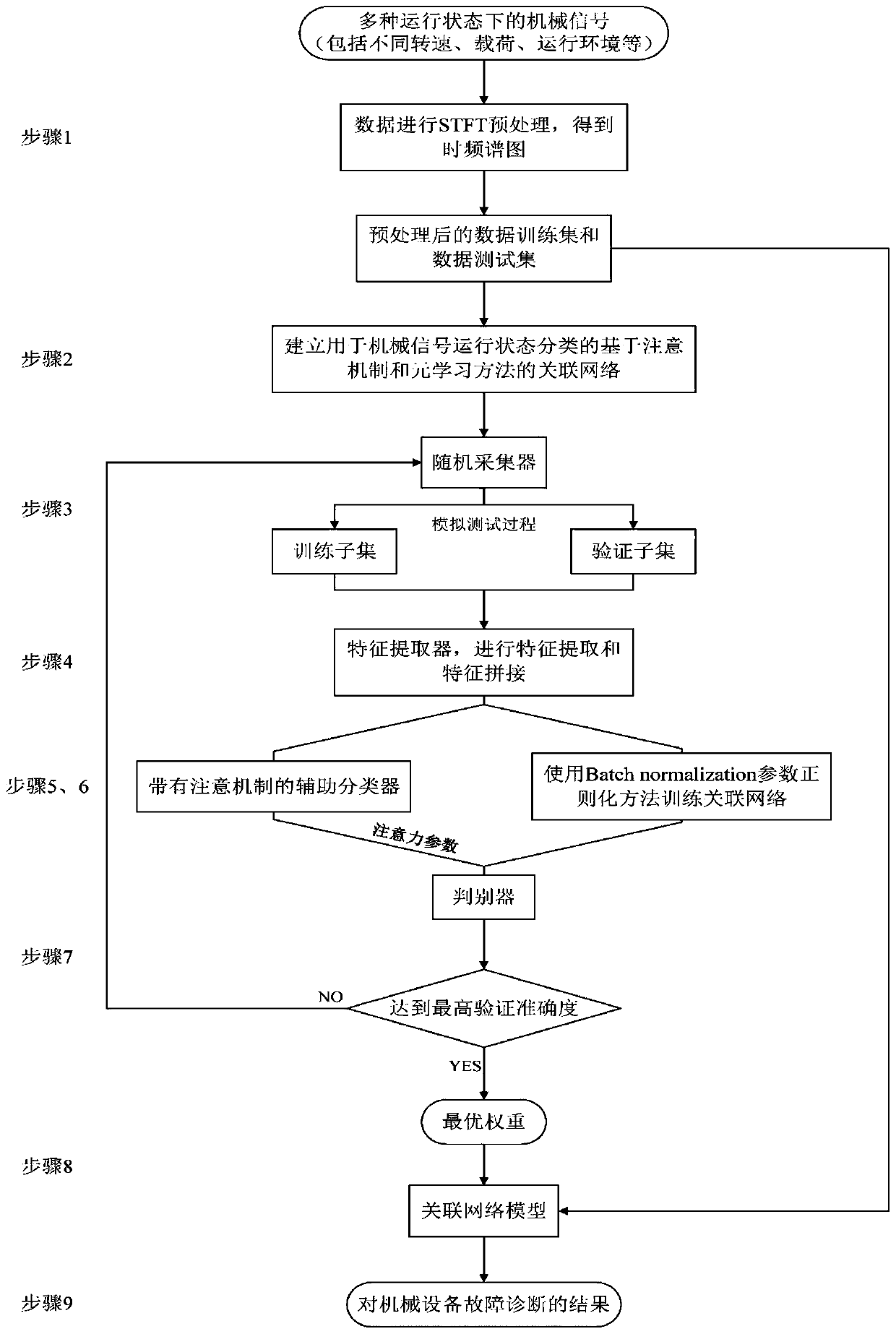

[0069] Such as figure 1 Shown, the present invention comprises the following steps:

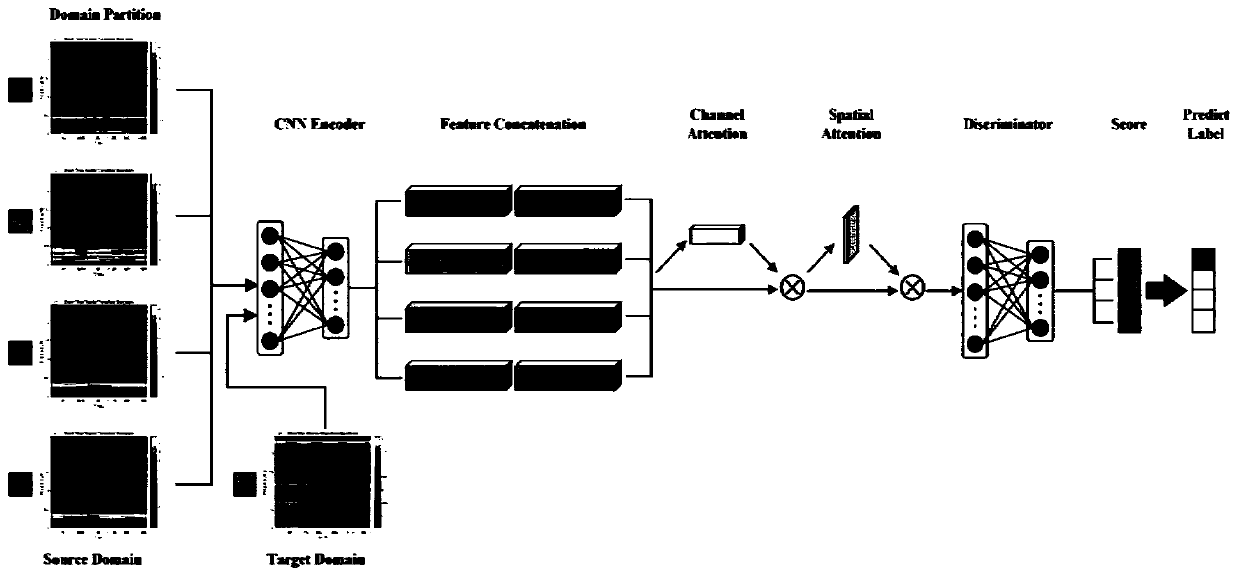

[0070] Step 1: First, perform short-time Fourier transform on the acquired data set to obtain its time-frequency diagram, then use the Resiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com