Valve Inserts and Air Bleed Valves

An air discharge, insert technology, applied in the direction of control valves, valve devices, vehicle components, etc., can solve the problems of opening stroke maintenance, difficult to build size, etc., to achieve the effect of increasing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

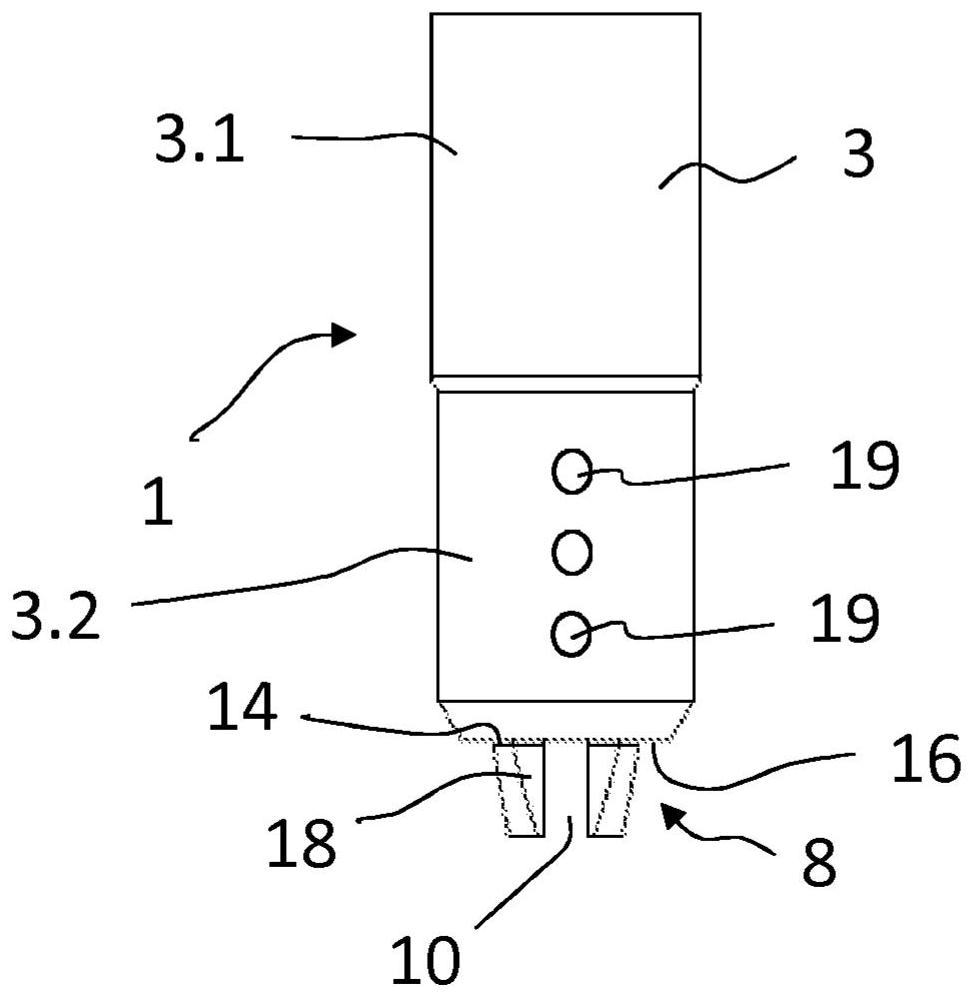

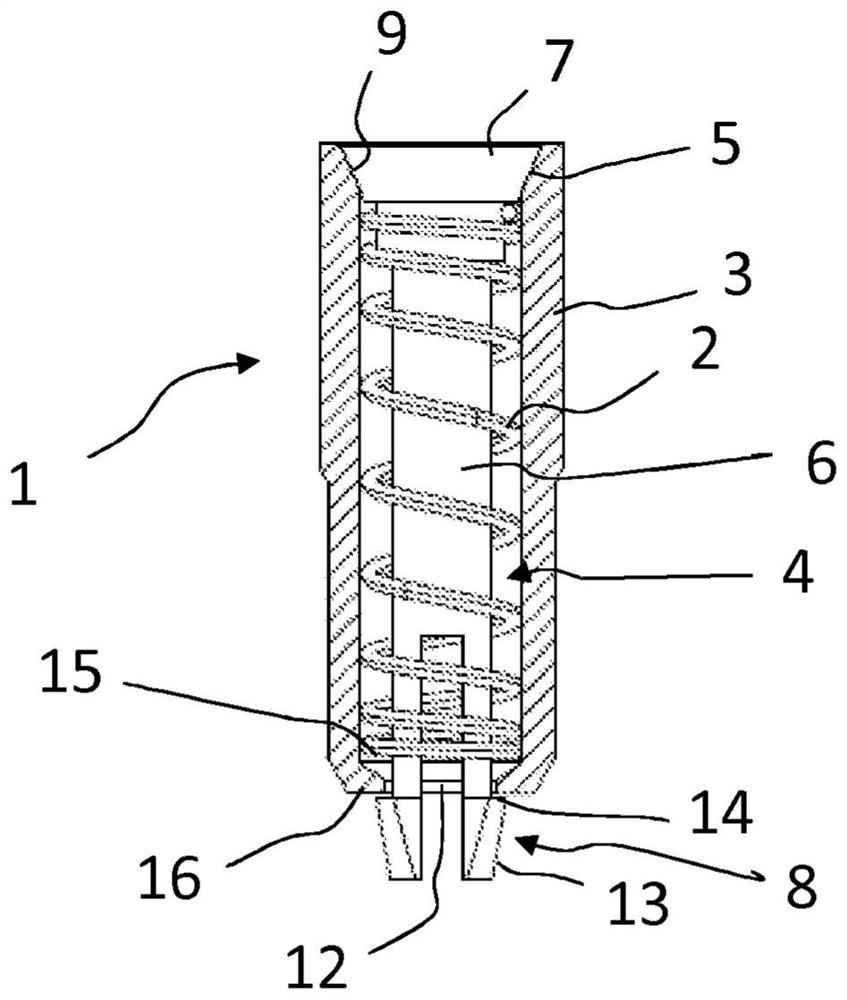

[0020] figure 1 and figure 2 Shown is a vent valve 1 for venting air from within a vulcanization mold, for example a vulcanization mold for vehicle tyres. Usually, a vulcanization mold includes 1000-4000 discharge valves 1 . The discharge valve 1 includes a valve sleeve 3 and a valve insert 4 inserted into the valve sleeve 3 . The valve sleeve 3 is attached to the discharge hole of the vulcanization mold by means such as press fit. The valve sleeve 3 is cylindrical. The outer diameter of the valve sleeve 3 is usually 1.5-4mm. exist figure 2 , the valve sleeve 3 is shown in cross section.

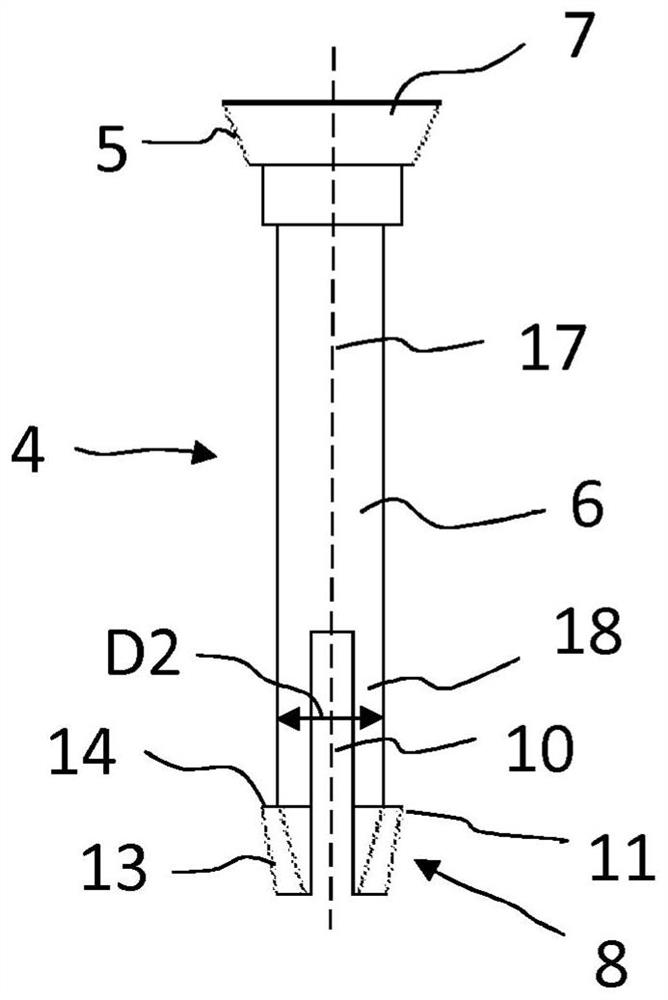

[0021] The valve insert 4 comprises a valve stem 6 provided at a first end with a valve disc 7 and at a second end of the valve stem 6 with a mechanism or means 8 for removing the valve insert 4 Attached to the valve sleeve 3. The valve insert 4 is attached to the valve sleeve 3 by a detachable connection. exist Figure 3-Figure 5 The valve insert 4 is shown in more detail in . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com