Insulation device for turbine casing, fixing device for insulation block and fixing method

一种涡轮壳体、保温装置的技术,应用在燃气轮机装置、喷气推进装置、机器/发动机等方向,能够解决作业工序增多等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

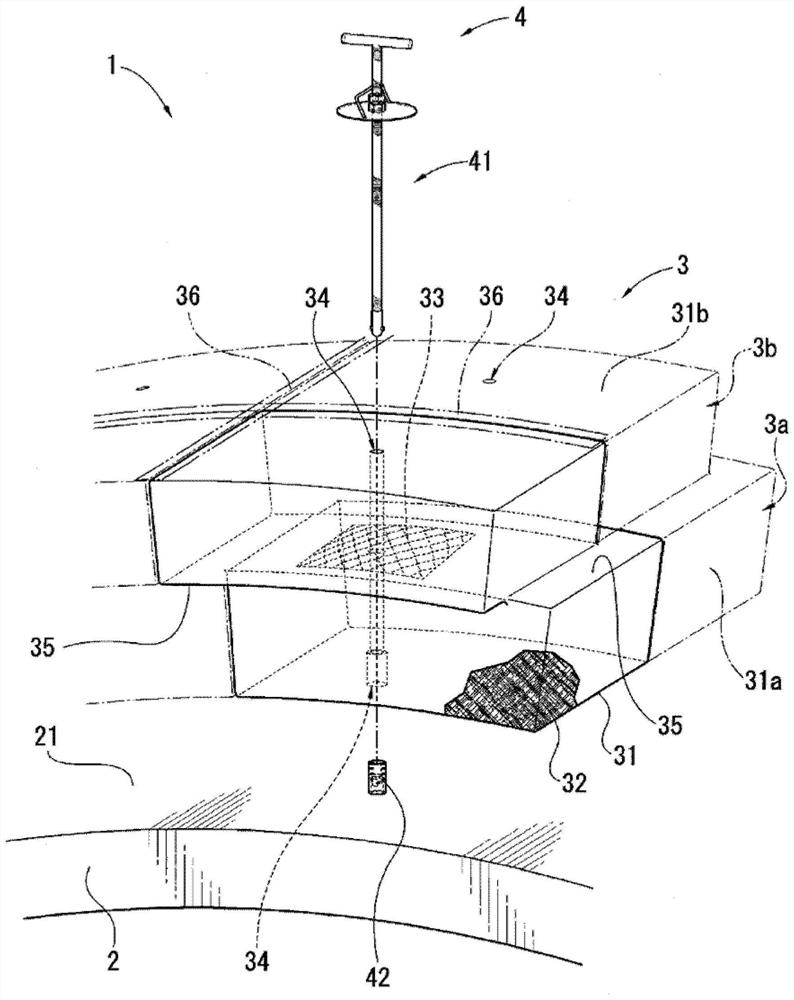

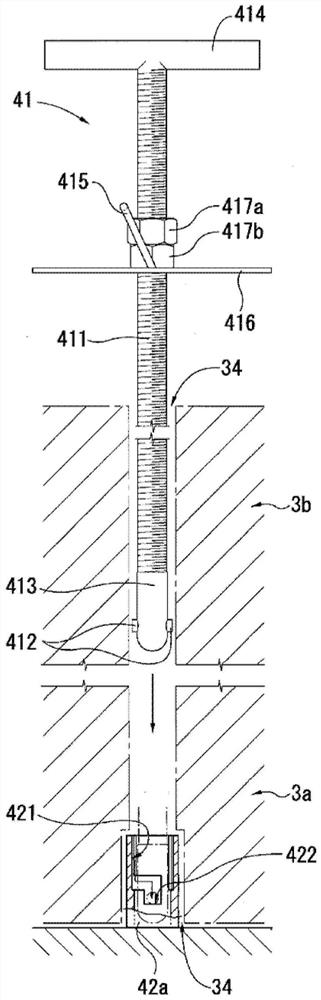

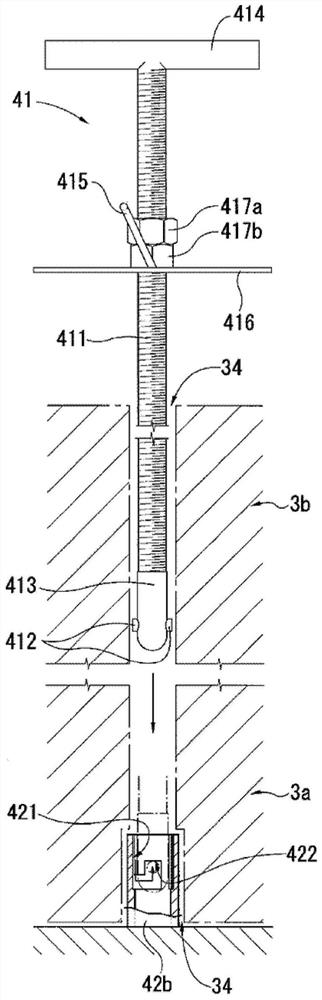

[0060] Hereinafter, embodiments of the present invention related to a heat insulating device for a turbine casing, a fixing tool for a heat insulating block for a turbine casing, and a fixing method for a heat insulating block for a turbine casing will be described with reference to the drawings.

[0061] use figure 1 The heat-retaining device for a turbine casing according to this embodiment will be described. For example, if figure 1 As shown, the turbine casing heat insulating device 1 covers the surface 21 of the turbine casing main body 2 of a turbine generator used in a power plant or the like to keep the turbine casing main body 2 warm. The thermal insulation device 1 includes a thermal insulation block 3 and a fixing tool 4 for fixing the thermal insulation block 3 to the surface 21 of the turbine casing main body 2 .

[0062] The thermal insulation block 3 has: a first thermal insulation block 3a, which directly covers the surface 21 of the turbine casing main bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com