Swivel Mounting Bracket

A mounting bracket and rotating technology, applied in the direction of supporting machines, connecting components, pins, etc., can solve the problems of complex fixing structure and fixing method, low supporting capacity of the mounting bracket, long construction time, etc., and achieve simple and rapid reset, Convenience and speed of construction and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

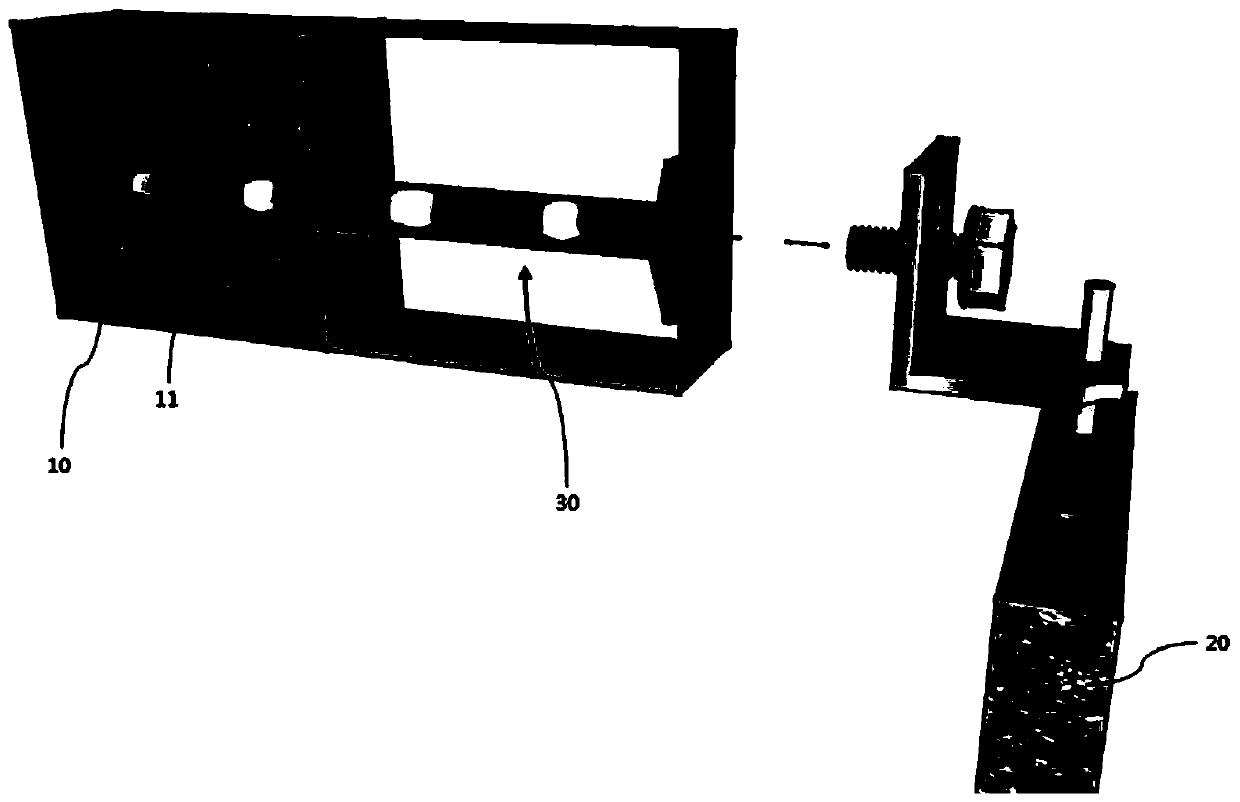

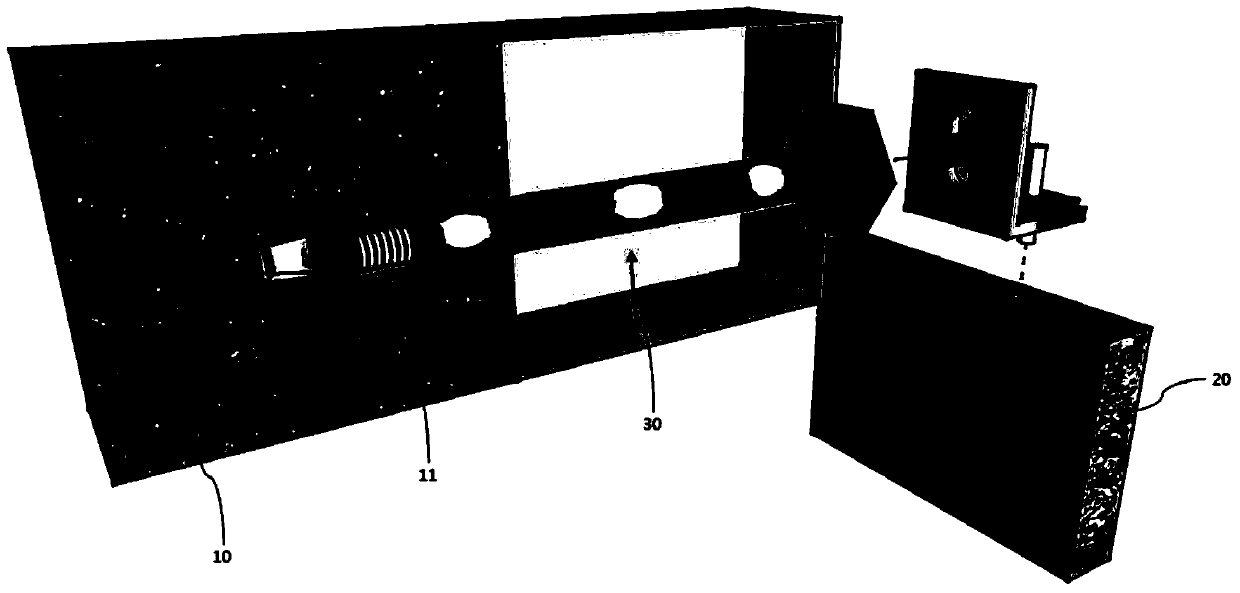

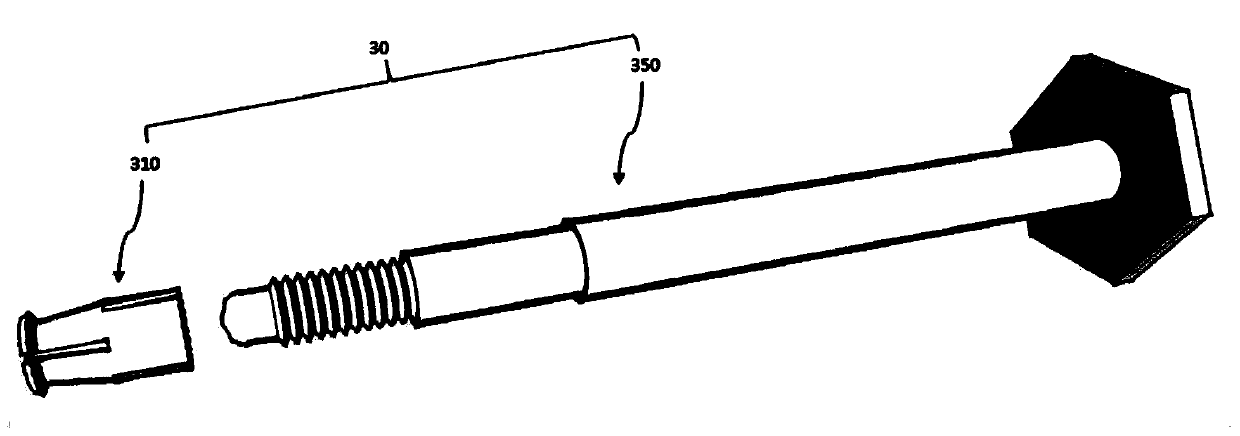

[0057] Hereinafter, some embodiments of the present invention will be described in detail with reference to illustrative drawings. The reference symbols are attached to the components in each figure, and the same symbols are used as far as possible even if the same components are marked on other figures. In addition, in describing the embodiments of the present invention, if it is judged that a specific description of a related well-known structure or function will hinder the understanding of the embodiments of the present invention, the detailed description thereof will be omitted.

[0058] In addition, terms such as first, second, A, B, (a), (b) and the like may be used in describing constituent elements of the embodiments of the present invention. The terminology is used only to distinguish its constituent elements from other constituent elements, and the nature, order, sequence, etc. of the constituent elements will not be limited by the terminology. When it is stated tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com