Automobile side plate welding and pressing tool

A side plate and automobile technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of reducing work efficiency, consuming labor, and not being able to pressurize and adjust, so as to reduce work efficiency and reduce labor force Effects that consume and increase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

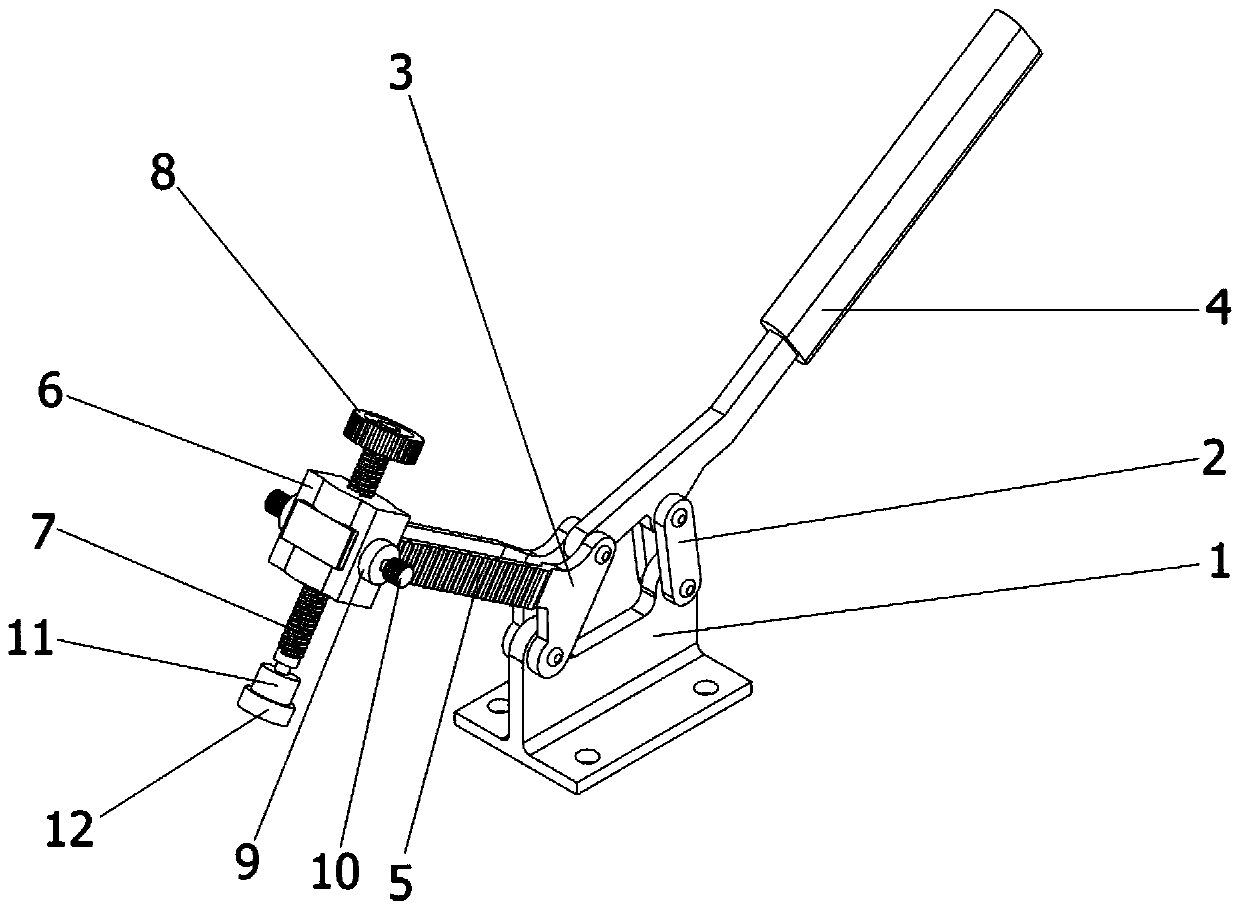

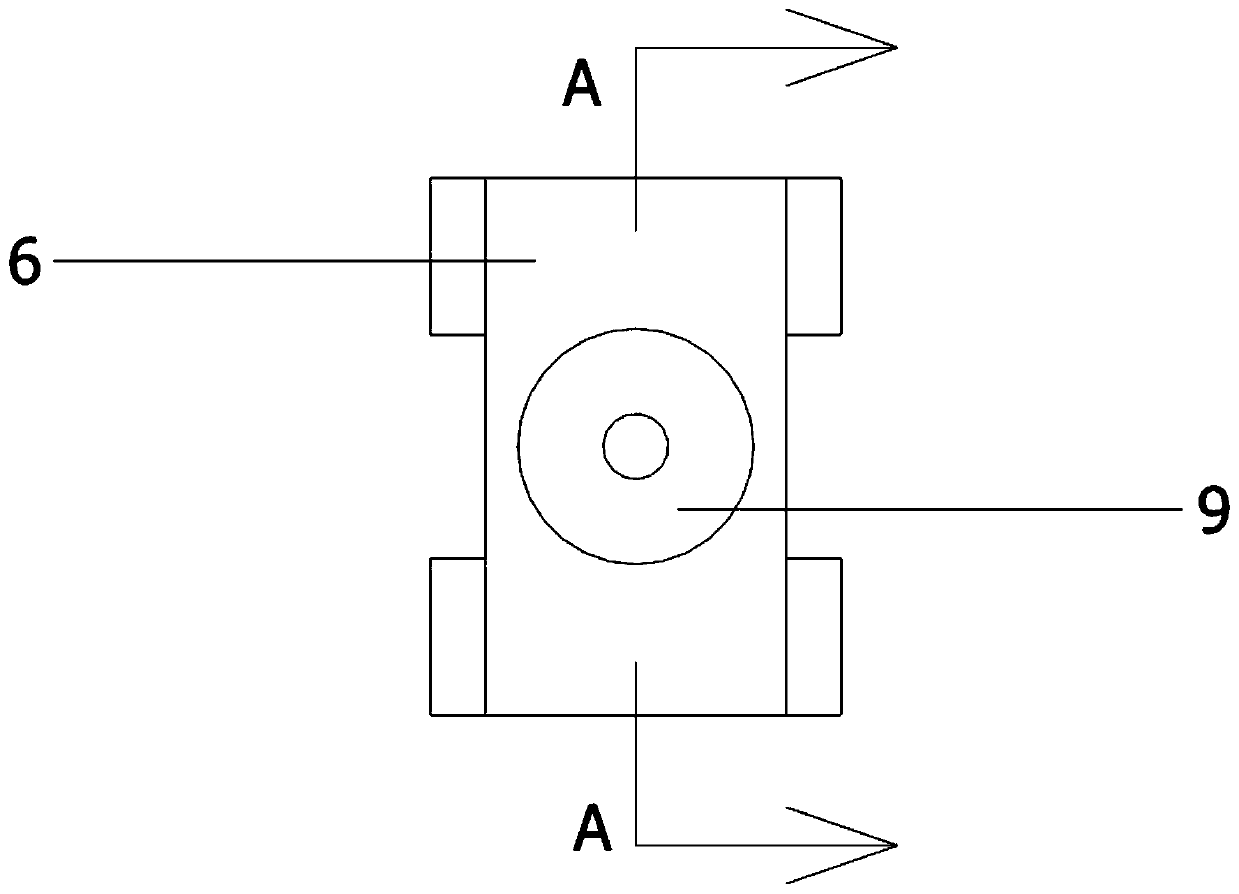

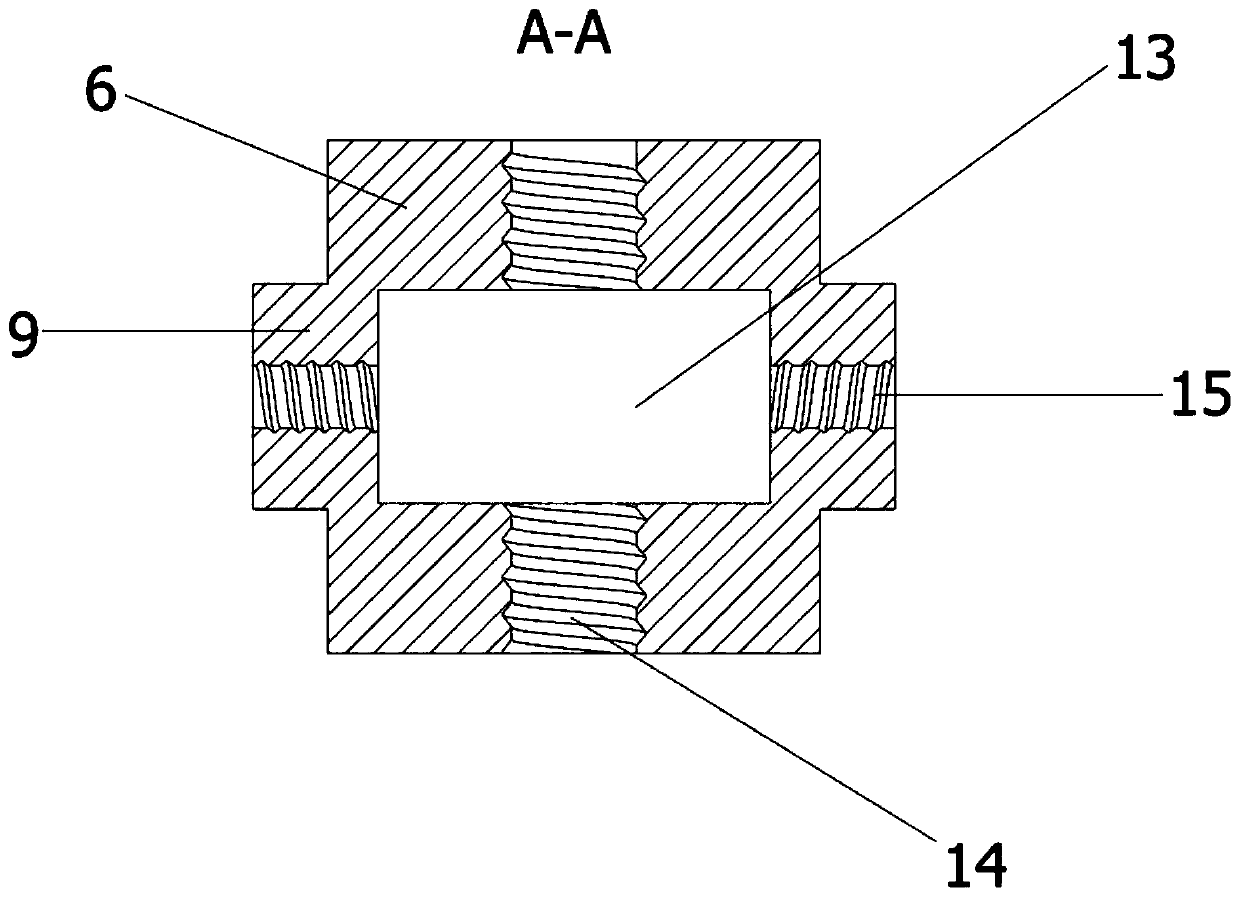

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032] The invention provides an automobile side plate welding and pressing tool, which includes a support 1, a first connecting block 2, a second connecting block 3, a handle 4, a pressing arm 5, a pressing head 6, a threaded rod 7, an adjusting hand wheel 8, Circular thickened block 9, manual screw 10, circular pressure block 11, circular rubber pad 12, rectangular through hole 13, first threaded through hole 14, second threaded through hole 15, T-shaped block 16 and T-shaped Card slot 17; the top of the front side of the support 1 is riveted with two symmetrically distributed second connecting blocks 3 by rivets, and the top of the rear side of the support 1 is riveted with two symmetrically distributed blocks 3 by rivets. The first connecting block 2; the upper ends of the two first connecting blocks 2 and the two second connecting blocks 3 are riveted with handles 4 through rivets, and the front ends of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com