Firing mechanism and hammering type nail shooting device with firing mechanism

A technology of firing mechanism and nail shooter, which is applied in the direction of nailing tools and manufacturing tools, can solve the problems of complex structure, high manufacturing cost, and poor reliability of nail shooters, and achieve a simple structure, low cost, and high stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

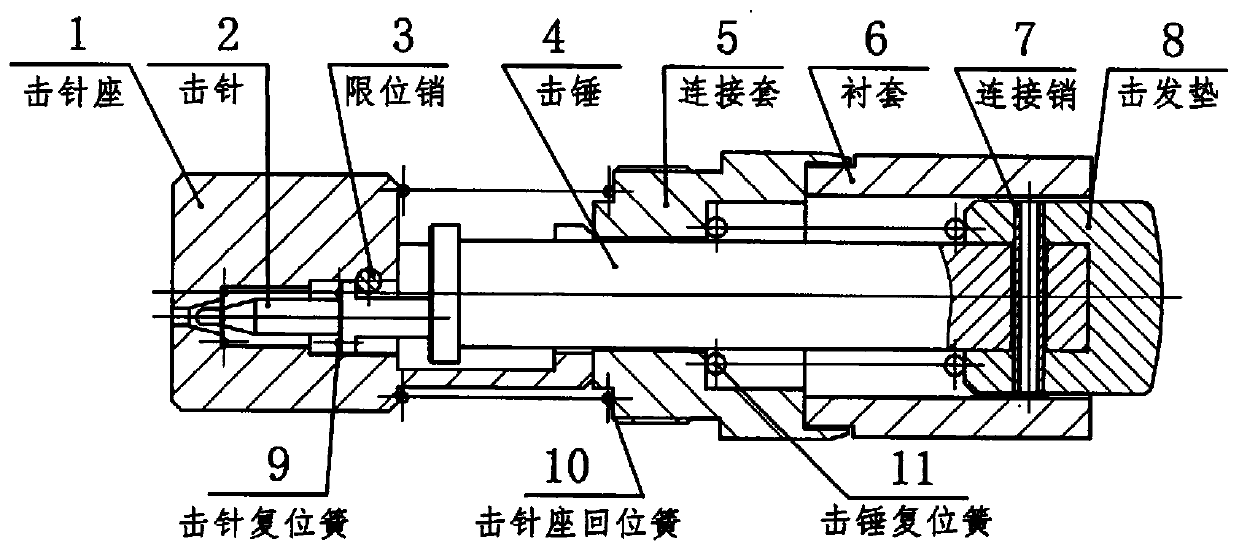

[0039] Figure 2 to Figure 5 Shown is a firing mechanism provided by the present invention, including a firing pin cover 11, a firing pin 12 and a hammer 14 for firing the firing pin 12; a resistance spring is provided between the hammer 145 and the firing pin cover 11 13.

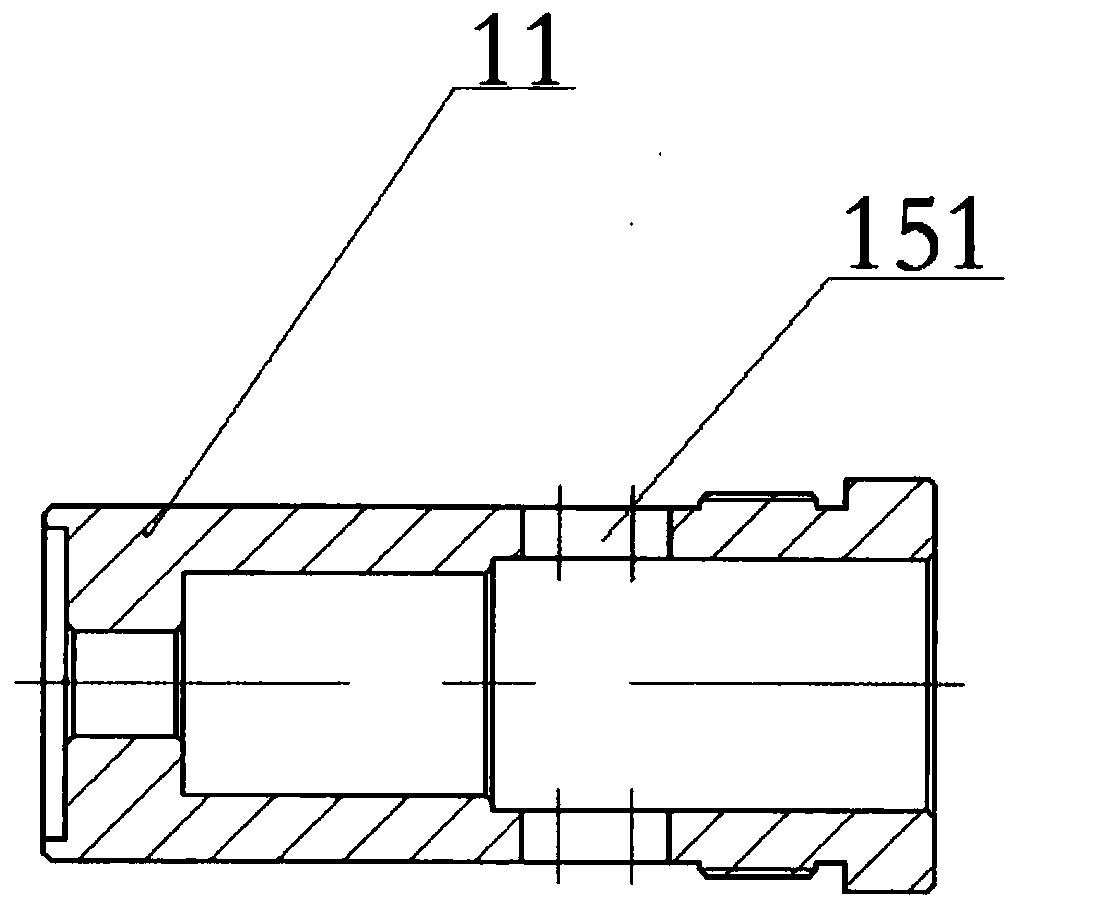

[0040] The interior of the firing pin cover 11 includes a firing pin 12 installation cavity, a resistance spring 13 installation cavity, and a hammer 14 installation cavity. And the diameter of the installation cavity of the firing pin 12 is greater than the diameter of the installation cavity of the resistance spring 13, and the diameter of the installation cavity of the resistance spring 13 is greater than the diameter of the installation cavity of the hammer 14, so that the connection between the installation cavity of the firing pin 12 and the resistance spring 13, the resistance The connection between the installation cavity of the spring 13 and the installation cavity of the hammer 14 is stepped; th...

Embodiment 2

[0049] The difference between this embodiment 2 and embodiment 1 is:

[0050] Embodiment 2 provides a firing mechanism. The firing pin 12 and the hammer 14 are integrated. Specifically, the firing pin 12 and the hammer 14 are integrally formed, or the firing pin 12 and the hammer 14 are welded and fixed; When the nailer falls freely, the hammer 14 moves forward rapidly under the action of inertia. When the hammer 14 is moving, the firing pin 12 integrally arranged with the hammer 14 moves synchronously with the hammer 14, and the hammer 14 is moving. During the process, due to the cooperation between the resistance spring 13 and the disc on the hammer 14, the resistance spring 13 can block the hammer 14, thereby greatly reducing the inertia of the hammer 14, so that the inertia of the firing pin 12 hitting the nail bullet Greatly reduced, effectively preventing the firing pin 12 from hitting the nail bullet, so that the nail shooter cannot be fired, so that the nail shooter me...

Embodiment 3

[0052] The difference between this embodiment 3 and embodiment 1, embodiment 2 is:

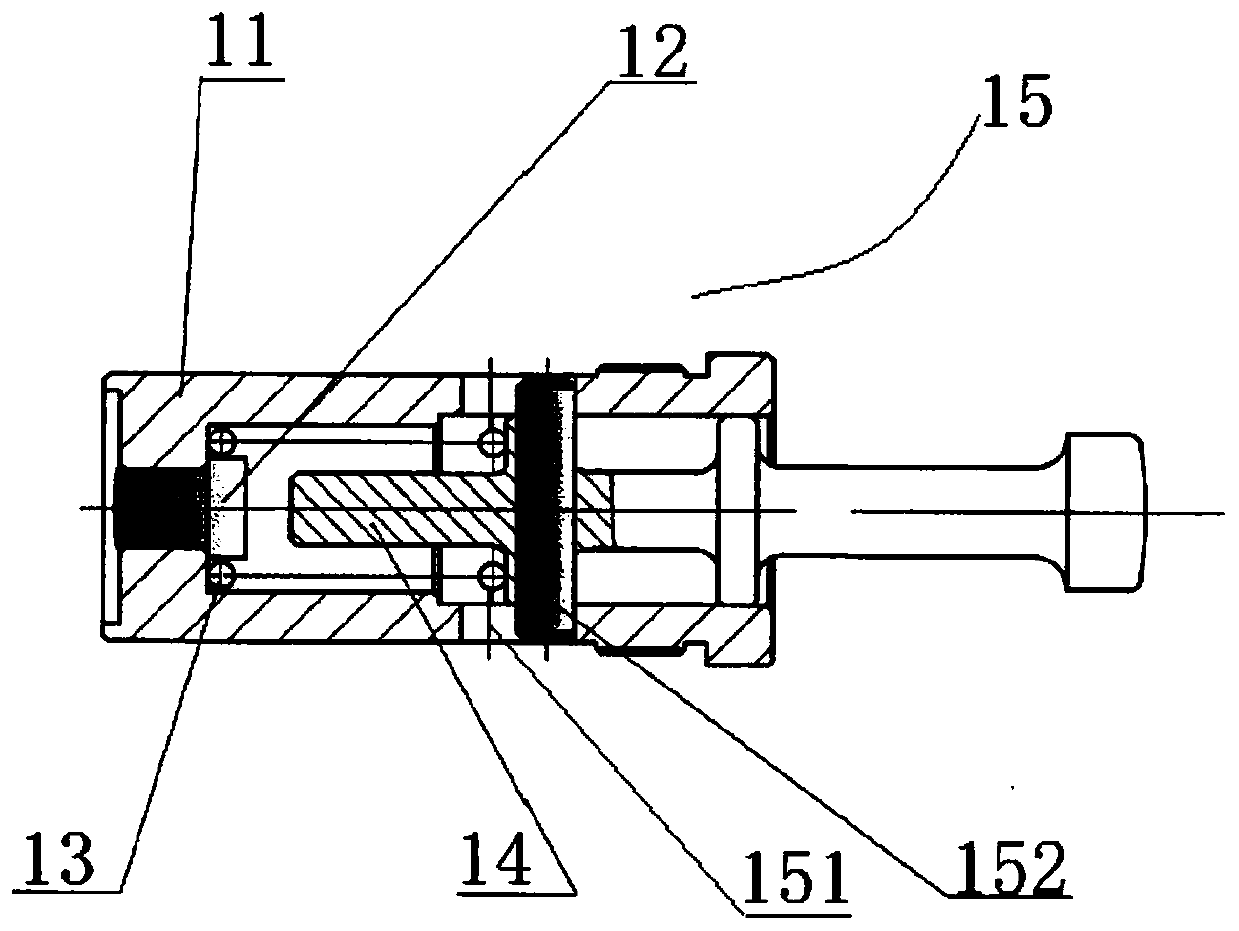

[0053] Such as Figure 6 to Figure 8 As shown, Embodiment 3 provides a hammer-type nail shooter, including a firing mechanism, a connecting mechanism and the above-mentioned firing mechanism; the firing mechanism and the firing mechanism are respectively installed at both ends of the connecting mechanism, and the tail of the firing pin Corresponds to the firing end of the firing mechanism.

[0054] The firing mechanism is used to fire the nail, and the firing mechanism is used to fire the nail bullet. When the nail bullet is fired, the nail bullet explodes, thereby driving the firing mechanism, so that the firing mechanism fires the nail The connecting mechanism is used for the connection between the firing mechanism and the firing mechanism, by corresponding the tail of the firing pin 12 in the firing mechanism to the firing end of the firing mechanism, so that the firing pin 12 can directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com