Large-scale heat transfer printing automatic production line

An automatic production line and thermal transfer printing technology, which is applied in transfer printing, rotary printing machines, printing, etc., can solve the problems of time-consuming, difficult to print out colors and patterns, and low precision of flat screen printing, and achieve the goal of improving quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

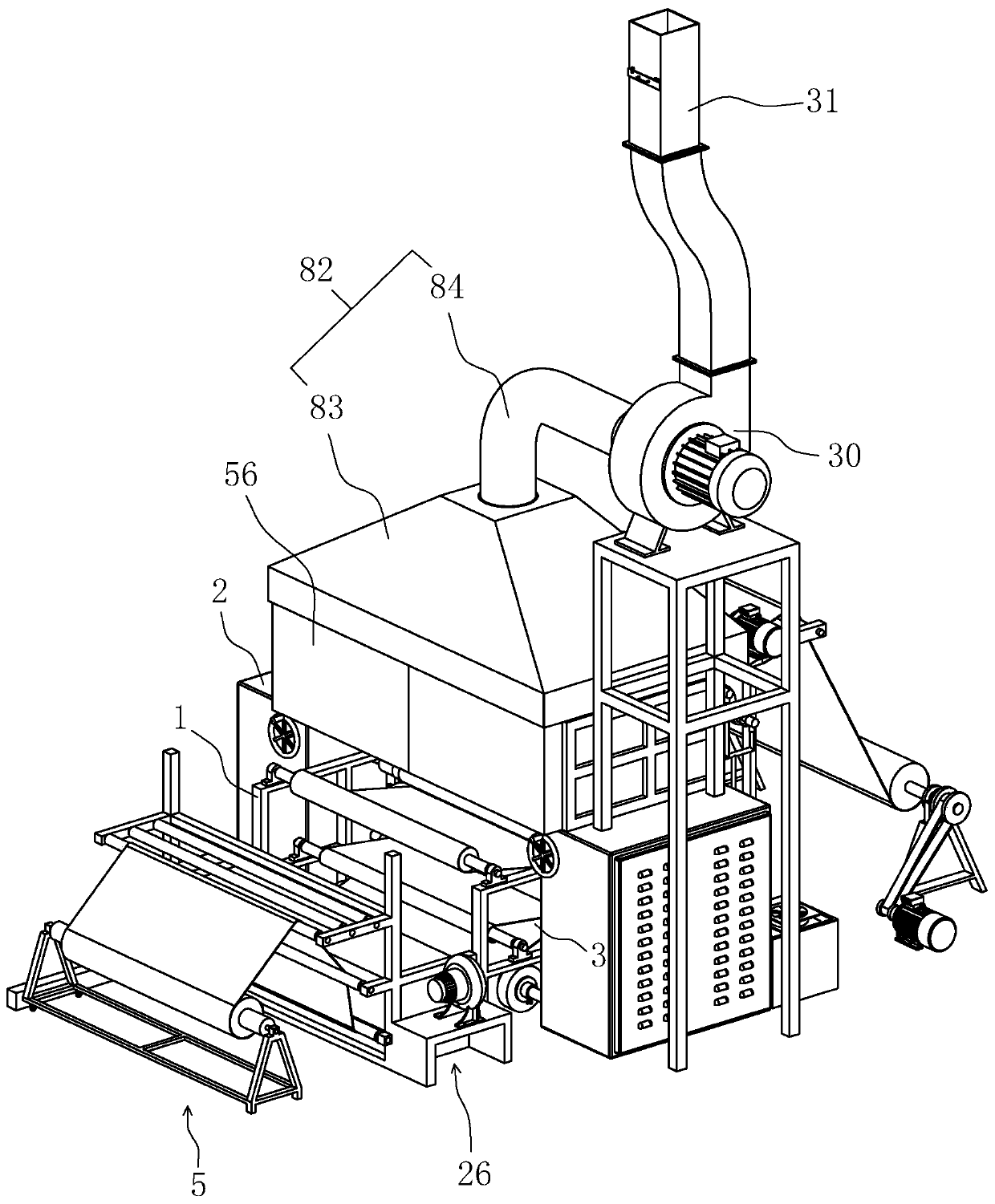

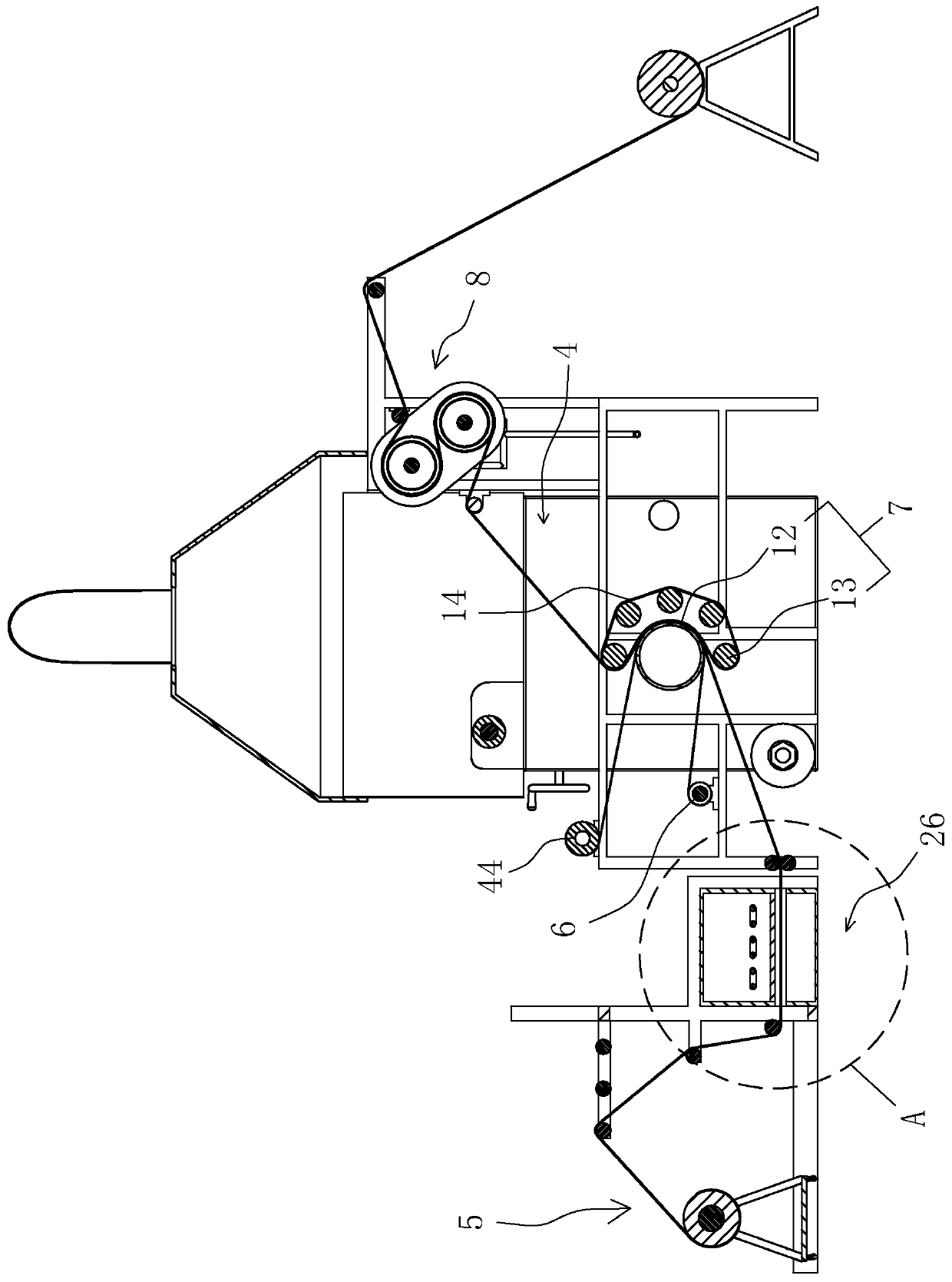

[0054] refer to figure 1 and figure 2 , a large-scale thermal transfer automatic production line, including a frame 1 and a casing 2, the casing 2 is fixedly arranged on the frame 1, and the casing 2 is provided with a cloth inlet 3 and a cloth outlet 4; the frame 1 faces The cloth upper assembly 5 and the shaping assembly 26 are arranged in sequence near the cloth inlet 3, the thermal transfer assembly 7 is arranged in the casing 2, and the frame 1 is arranged in turn near the cloth outlet 4 and away from the casing 2. The cooling assembly 8 and the cloth receiving assembly 9 are provided with a waste removal assembly 82 above the casing 2 for sucking the waste gas generated by the transfer.

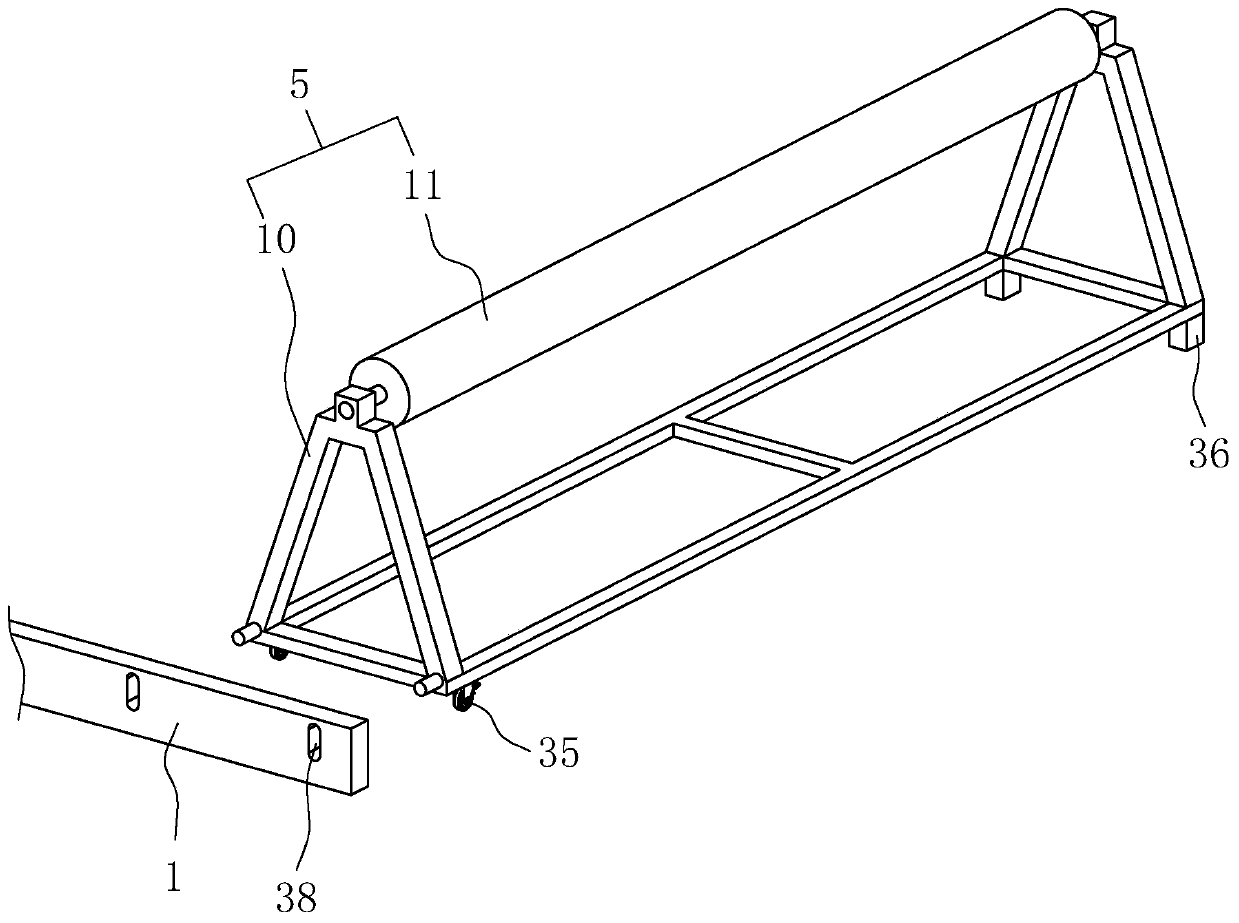

[0055] refer to image 3 , the upper cloth assembly 5 includes the upper cloth frame 10 and the upper cloth roller 11 which is rotatably arranged on the upper cloth frame 10, and the upper cloth roller 11 is connected with the upper cloth frame 10 through bearings; the upper cloth fr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap