Diamond coating on low-cobalt hard alloy surface and preparation method thereof

A diamond coating and cemented carbide technology, which is applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of low bonding strength between diamond coating and substrate, and achieve the ease of thermal diffusion and toughness. Good, reduce the effect of chemical pretreatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

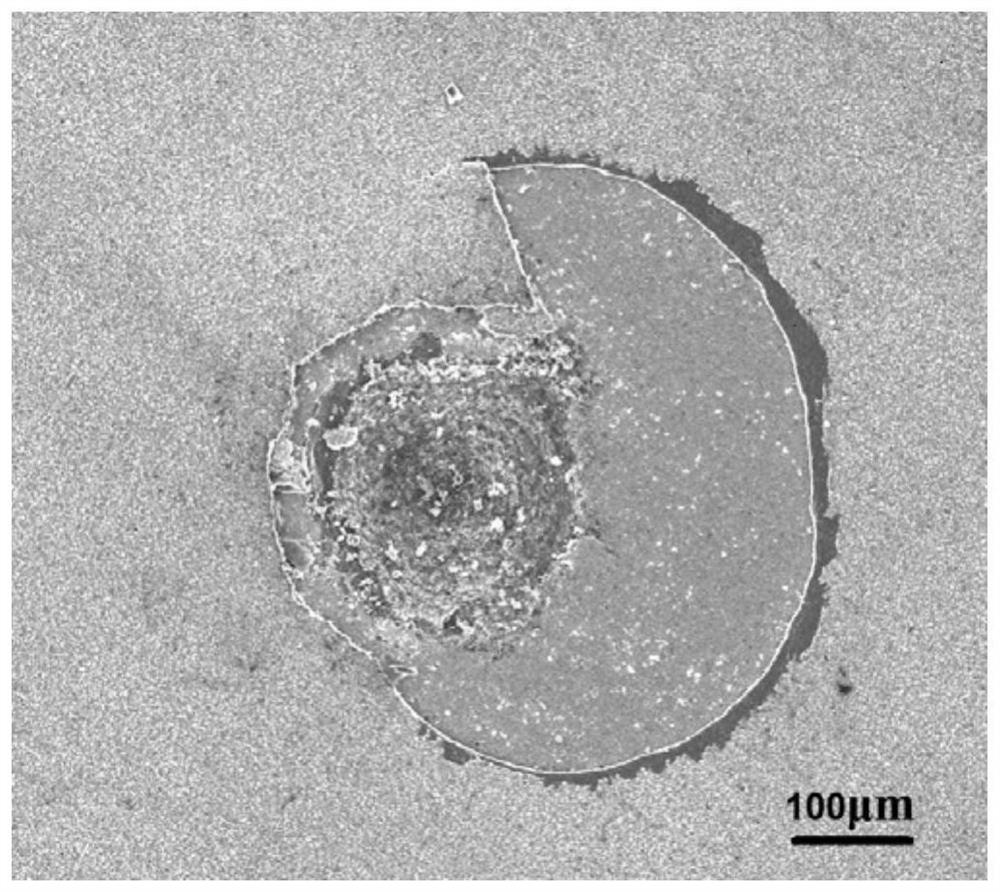

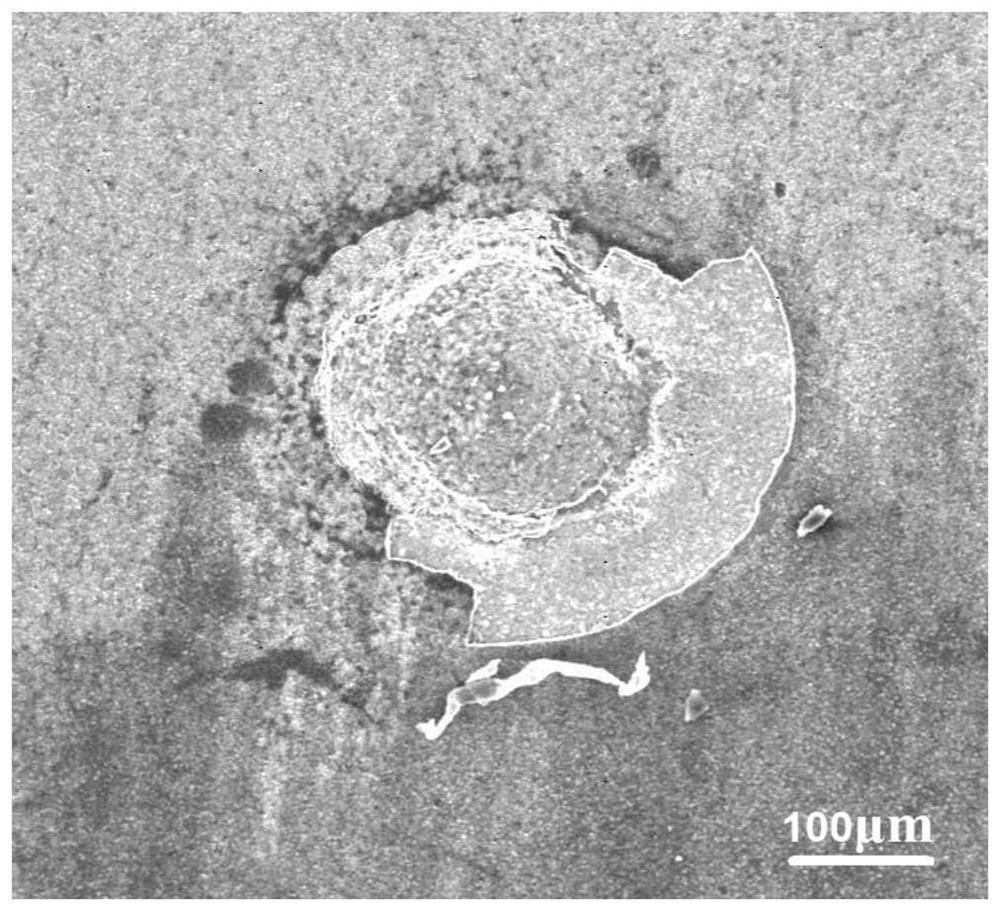

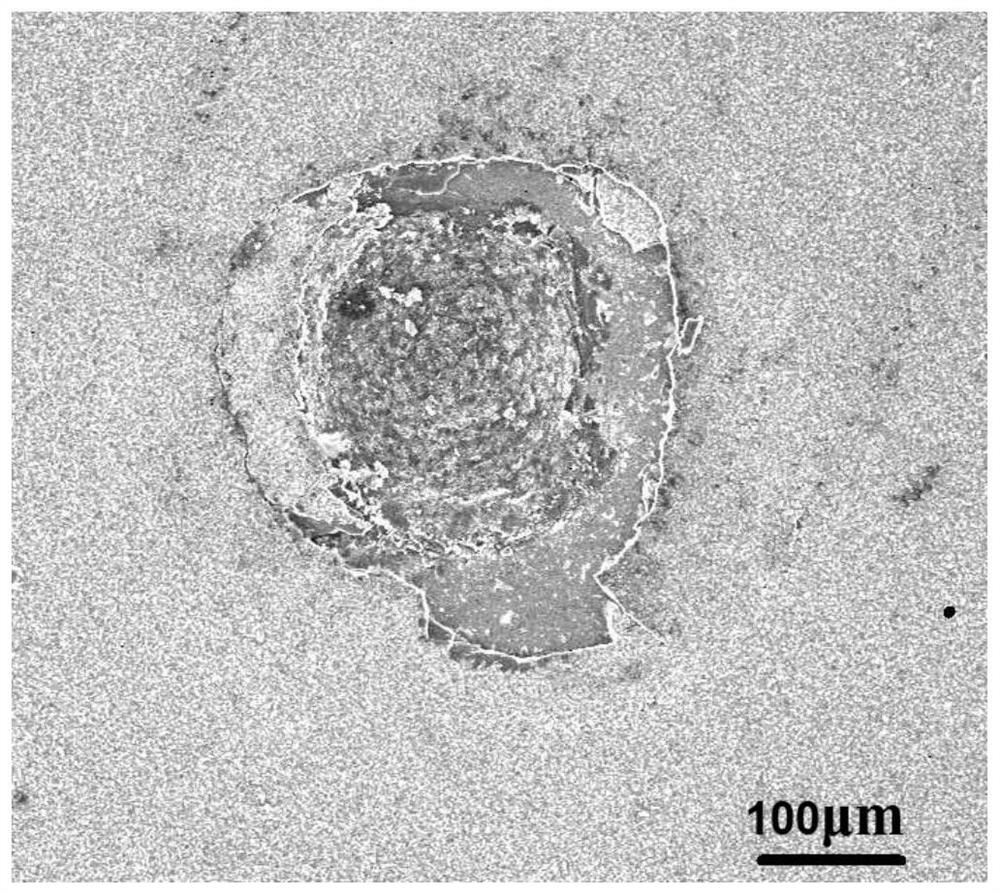

Image

Examples

Embodiment 1

[0030] Graphene enhanced low cobalt content (3wt.% Co) cemented carbide (0.3wt.% Graphene) depositing a diamond coating matrix.

[0031] (1) graphene dispersion: a precision electronic balance graphene powder 0.3g, poured into 100mL of absolute ethanol, using cell crushing device, set to 40KHz ultrasonic frequency; ultrasonic working time duty cycle is 1: 1 ; time of the ultrasonic oscillation for 4h.

[0032] (2) ball mill mixing: a precision electronic balance cobalt powder and tungsten carbide powder 96.709g 2.991g, together with graphene (1) - The alcohol solution was poured into a ball mill jar. Weigh 700g of 5mm diameter cemented carbide (WC-wt.3% Co) balls into a ball mill jar. 100mL of absolute ethanol was added in the ball mill jar, a ball mill is provided for the rotation speed of 400 rpm, milling time 8h.

[0033] (3) dried in vacuo: The milled slurry was placed in a vacuum oven dried. The pressure in the drying oven set to 15000 Pa, a heating temperature of 90 ℃, when ...

Embodiment 2

[0038] Graphene enhanced low cobalt content (3wt.% Co) cemented carbide (0.5wt.% Graphene) depositing a diamond coating matrix.

[0039](1) graphene dispersion: 0.5 g of graphene powder with precision electron balance, poured into 100 mL of anhydrous ethanol, using a cell pulverizer, set the ultrasonic frequency of 40 kHz; the duty cycle of ultrasound working hours is: 1: 1: 1: 1: 1; the time of ultrasonic oscillation is 4h.

[0040] (2) Ball mill mixing: 2.985 g of cobalt powder and 96.515 g of tungsten carbide powder were poured into the ball grinding with graphene - alcohol solution in (1) with a precision electronic balance. Cemented carbide (WC-WT.3% Co) ball with a diameter of 5 mm is weighed, and the ball mill is placed. 100 ml of anhydrous ethanol was added to the ball mill, and the rotational speed of the ball mill was 400 rpm and the ball milling time was 8 h.

[0041] (3) Vacuum drying: Put the slurry after the ball is placed in a vacuum drying tank and dried. Set the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com