Anti-perspiration treatment process of metal sheet and metal sheet, metal casing and electronic equipment

A metal sheet and processing technology, used in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of corrosion and fading of metal shells, affecting the aesthetics and user experience of electronic equipment, and achieve anti-sweat corrosion ability. Improve and ensure the stability of use and user experience, the effect of dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

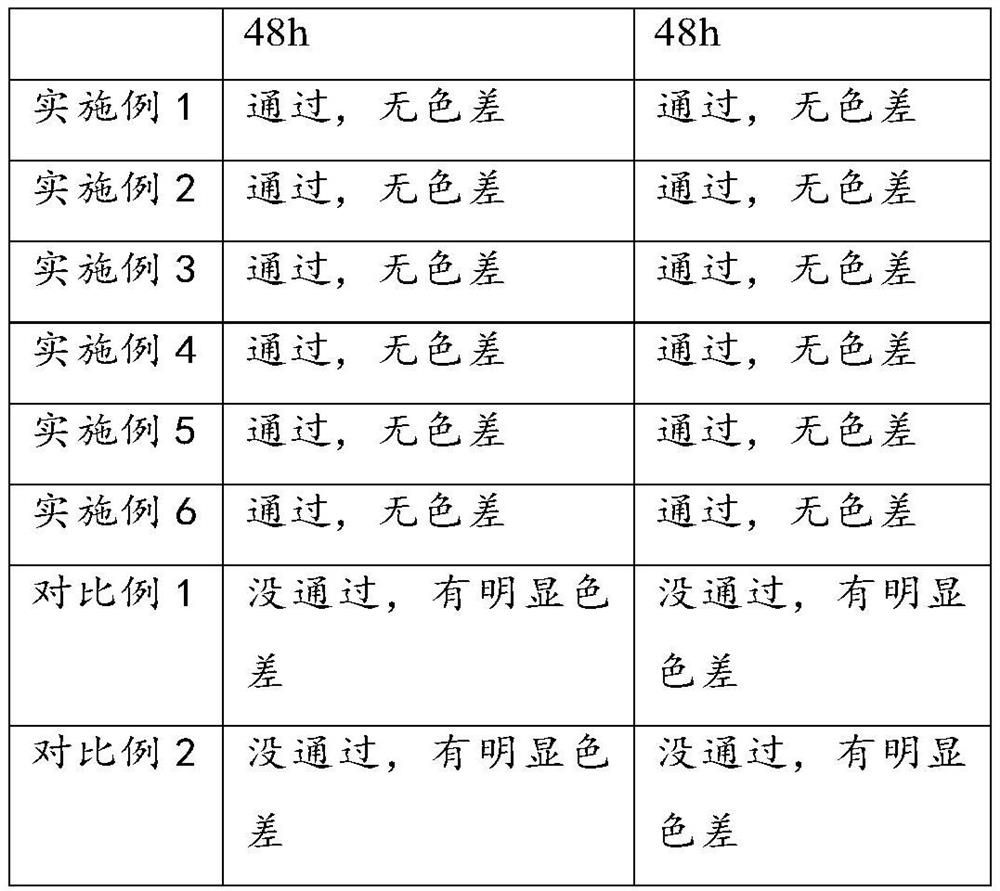

Embodiment 1

[0068] This embodiment provides an aluminum alloy plate, which is obtained by performing anti-perspiration treatment according to the following steps:

[0069] (1) Provide an aluminum alloy plate that has undergone degreasing, alkali etching and polishing treatment, and anodize the aluminum alloy plate with an anodic oxidation treatment solution, so that an oxide film with holes is formed on the surface of the aluminum alloy plate. The oxidation voltage of the oxidation treatment is 15V, the oxidation temperature is 8°C, and the oxidation time is 60 minutes; in the anodizing treatment solution, the concentration of sulfuric acid is 200g / L, Al 3+ The concentration is 12g / L;

[0070] (2) Place the anodized aluminum alloy plate in an organic dye solution for dyeing, wherein in the organic dye solution, the concentration of the organic dye is 1-3g / L, the pH value is 6-7, and the dyeing at room temperature is 300-600s ;

[0071] (3) Place the dyed aluminum alloy plate in the seal...

Embodiment 2

[0074] This embodiment provides a perspiration-resistant aluminum alloy plate. The difference between this embodiment and Embodiment 1 is that in step (1), the oxidation voltage of the anodic oxidation treatment is 12V, the oxidation temperature is 10°C, and the oxidation time is 55 minutes.

Embodiment 3

[0076] This embodiment provides a perspiration-resistant aluminum alloy plate. The difference between this embodiment and Embodiment 1 is that in step (1), the oxidation voltage of the anodic oxidation treatment is 18V, the oxidation temperature is 5°C, and the oxidation time is 65 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com