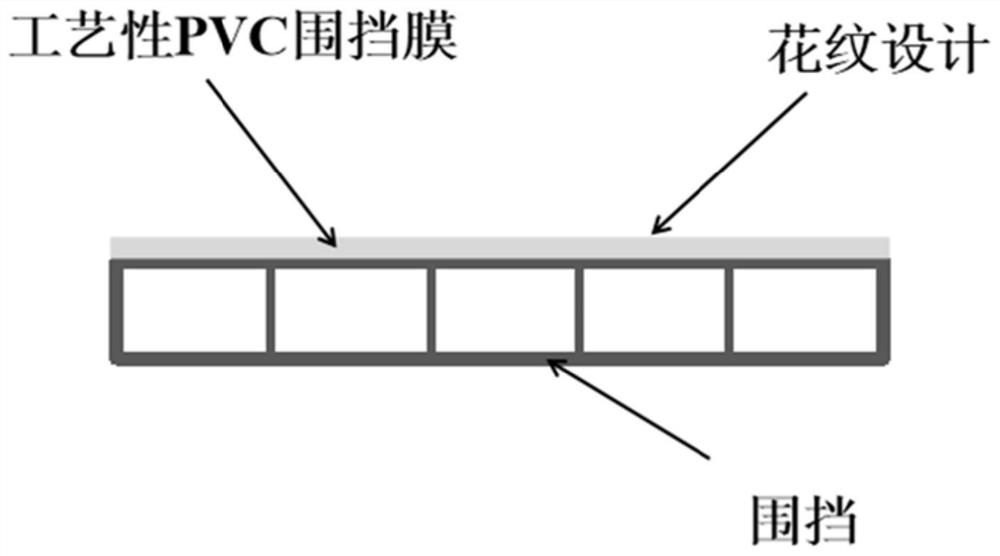

Technological PVC enclosure film and method prepared by using construction waste PVC

A technological and architectural technology, applied in printing post-processing, coating, printing, etc., can solve the problems of long installation time, short service life, and difficult to degrade, so as to improve living comfort, prolong service life, and beautify The effect of the urban environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

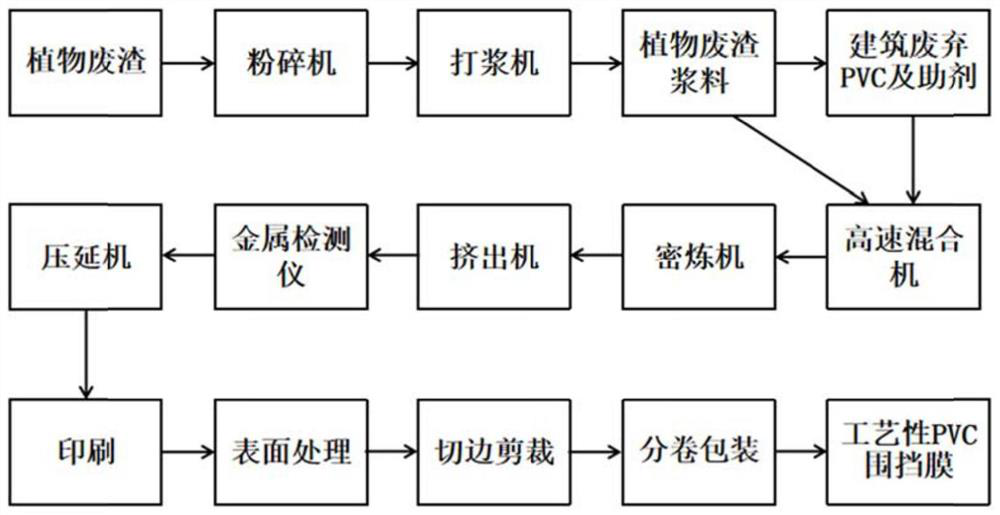

[0053] Method for preparing process PVC enclosures by building discarding PVC, figure 2 As shown, including the following steps:

[0054] (1) Disconnect the discarded sugar canesets and bamboo slag bleach, mixed into the pulverizer into plant waste powder and put it on the sieve plate, and screen the particle diameter plant waste slag powder in 100 megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload Plus water dilute the gum and the girder is 25 ° Sr.

[0055] (2) Remove the impurities of impurities, plasticizer, stabilizer, hollow glass micro-balls, etc., plasticizer, stabilizer, hollow glass micro-balls, etc., and in step (1), in the order of the first-solid retrorefluid, the temperature is 140 ° C, Mixing the high-speed mixer of 700R / min, mixed with each raw material, mix well after stirring for 15 min, and so...

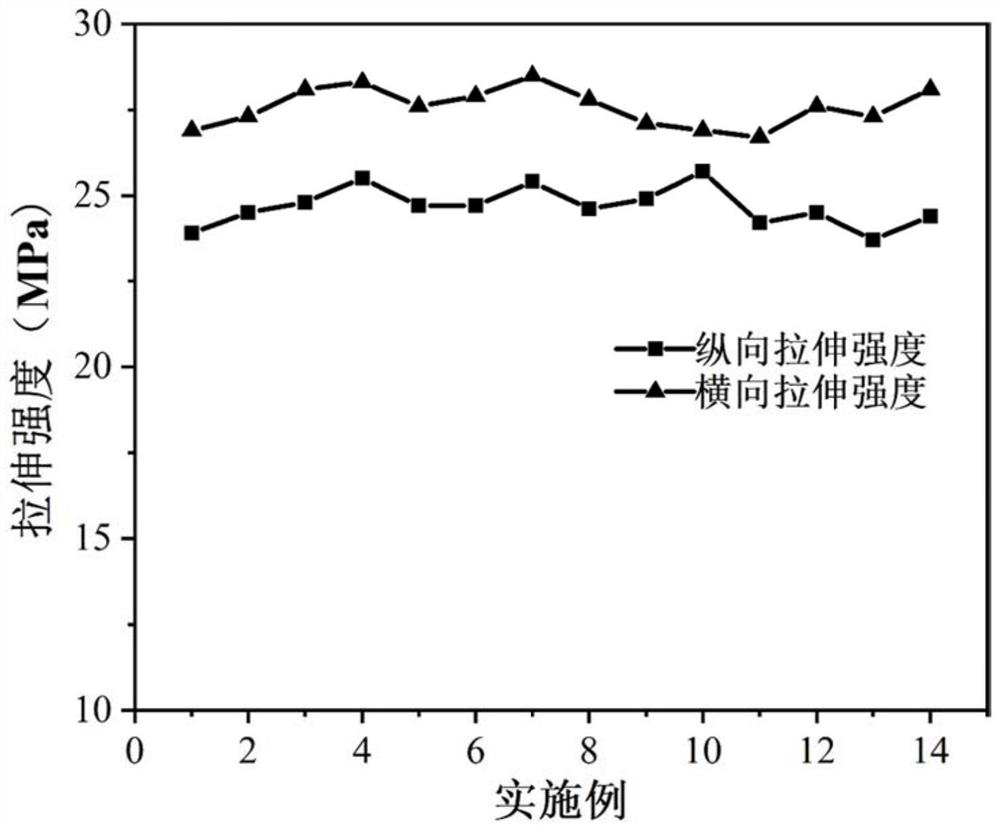

Embodiment 2

[0064] As compared with Example 1, the gilt in step (1) was raised from 25 ° SR to 30 ° SR, and the other conditions remain unchanged.

Embodiment 3

[0066] Compared with Example 1, the mixture of the construction of the PVC, stabilizer, plasticizer, and hollow glass microbeads were transferred from 140 ° C to 150 ° C, and the other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com