Intra-mold labeling device and method for special-shaped injection compression molding part

An in-mold labeling and special-shaped technology, which is applied in the field of in-mold labeling of special-shaped injection-compression plastic parts and in-mold labeling devices for special-shaped injection-compression plastic parts, to achieve the effect of improving efficiency, improving recovery rate, and not easy to age and fade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

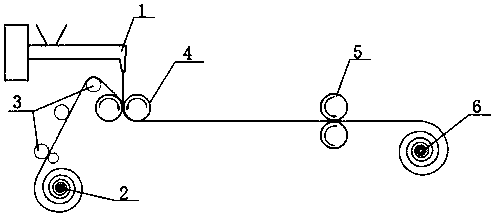

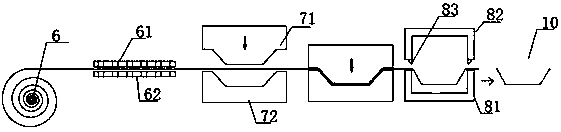

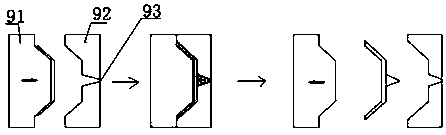

[0026] Such as Figure 1-3 Shown is the in-mold labeling device for special-shaped injection molding parts of the present invention, including finished coil forming components, special-shaped label preparation components and mold-closing injection molding components; finished coil forming components include sheet extrusion injection molding machine 1, printing Film roll 2, pressure tensioning assembly 3, film and sheet pressing assembly 4, pressing and exporting roll 5, finished coil winding roll 6; pressure tensioning assembly 3 is arranged above printing film roll 2; the described The film and sheet pressing assembly 4, the pressing lead-out roller 5 and the finished coil winding roller 6 are sequentially arranged at the right end of the pressure tensioning assembly 3; the sheet extrusion injection molding machine 1 is arranged at the film an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com