Rapid sock drying equipment

A technology for fast drying and socks, applied in the field of clothing, can solve the problems of low utilization rate of hot air, low drying efficiency, restricted gas circulation, etc., and achieve the effect of large circulation, uniform circulation, comprehensive and efficient drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

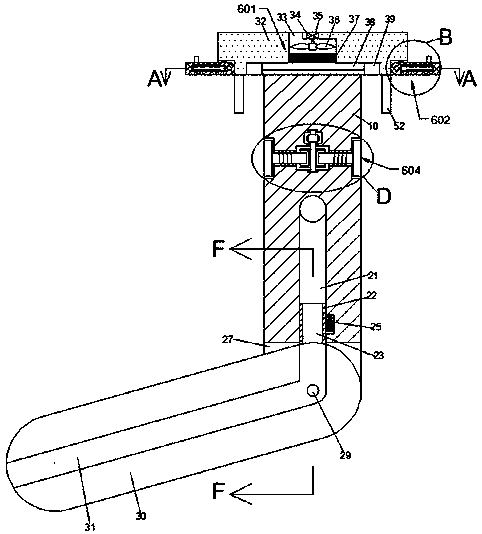

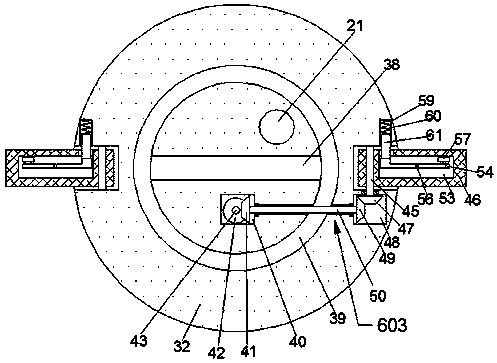

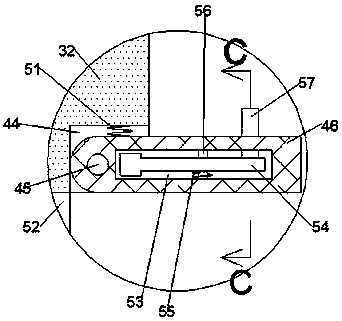

[0021] Combine below Figure 1-Figure 7 The present invention will be described in detail. For the convenience of description, the orientations mentioned below are now specified as follows: figure 1 The vertical, horizontal, front, and rear directions of the projection relationship are the same.

[0022] The invention relates to a fast drying equipment for socks, which is mainly used for drying socks. The invention will be further explained below in conjunction with the drawings of the invention:

[0023] The fast drying equipment for socks according to the present invention includes a heating block 32, and a heating device 601 is provided in the heating block 32. The heating device 601 can generate hot air when the heating device 601 works. It includes a ring-shaped ventilation cavity 39. The hot air generated by the heating device 601 is transported downward through the ventilation cavity 39. The left and right ends of the heating block 32 are provided with clamping devices 602. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com