Laser welding production line for chips and leg wires of electronic detonators

An electronic detonator and laser welding technology, applied in laser welding equipment, welding equipment, attack equipment, etc., can solve the problems of reducing the production output of electronic detonators and prolonging the processing hours of electronic detonators, so as to meet the needs of mass production operations and improve semi-automatic The effect of crimping efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

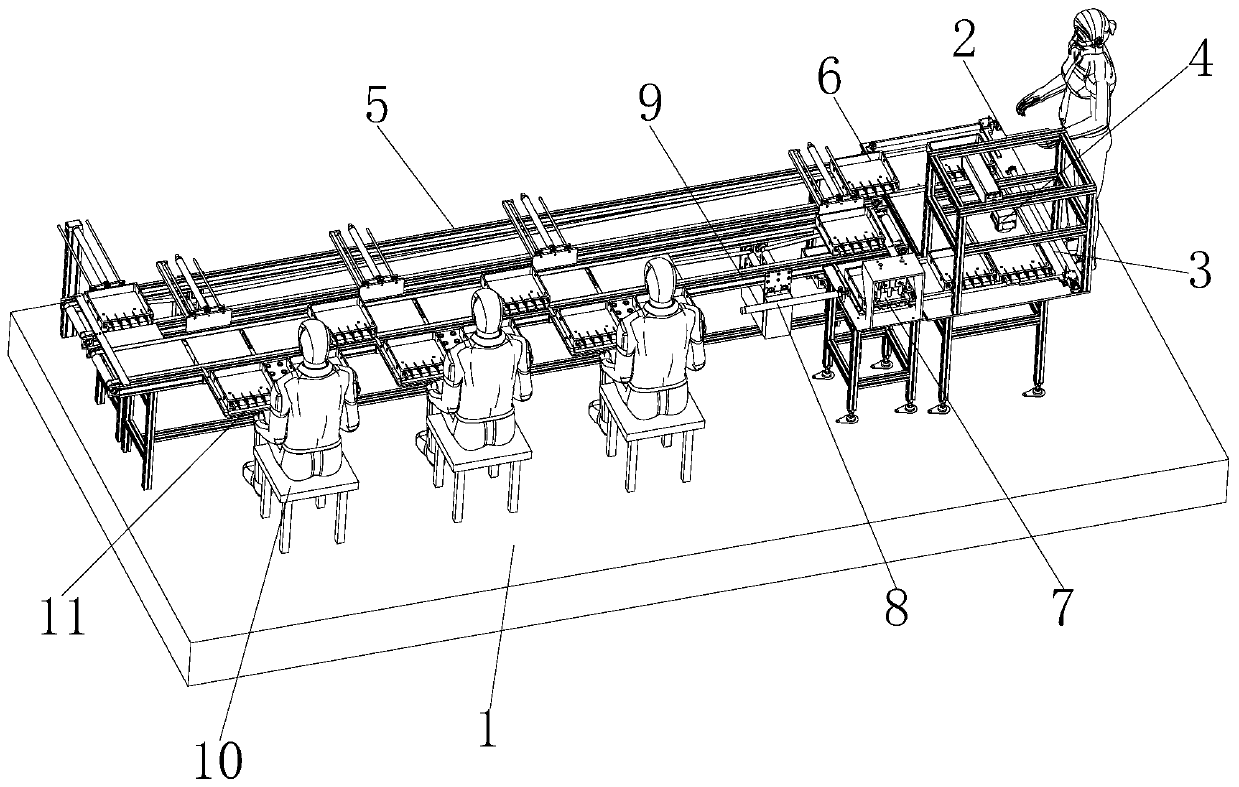

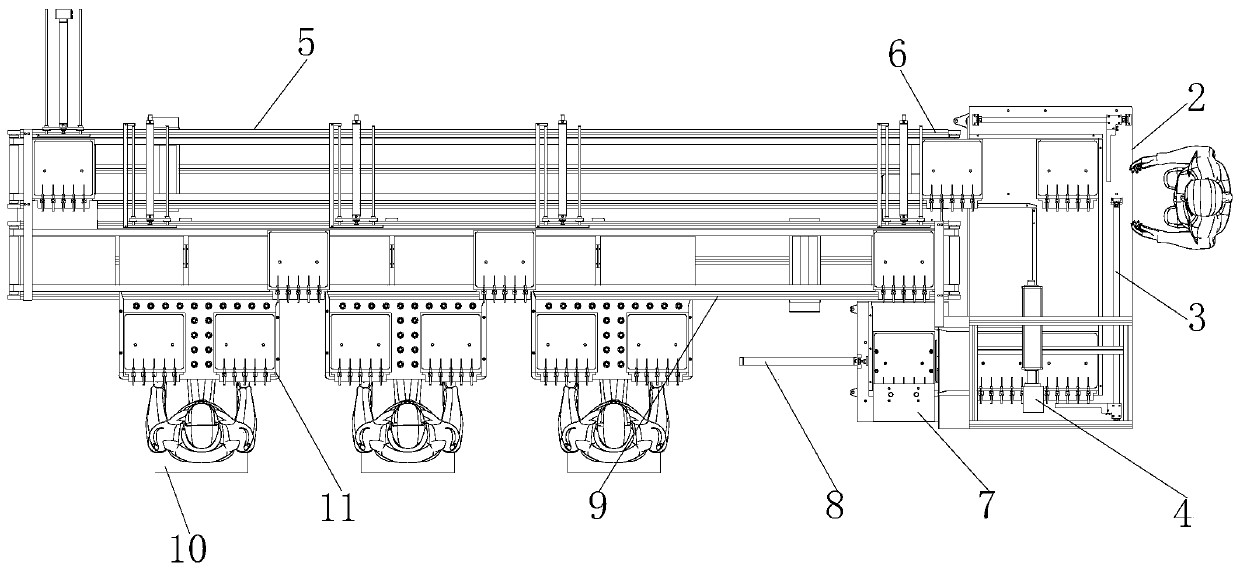

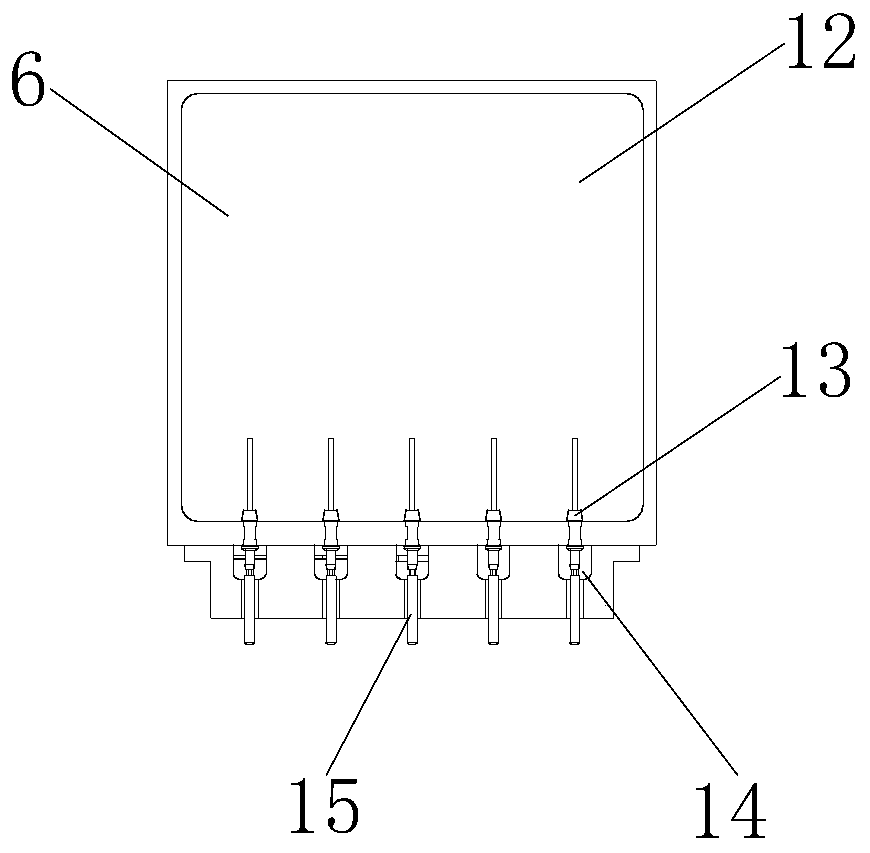

[0022] Please refer to figure 1 , figure 2 with image 3 ,in figure 1 The schematic structural view of the preferred embodiment of the electronic detonator chip foot wire laser welding production line provided by the present invention, figure 2 for figure 1 The equipment top view of the shown production line body, image 3 for figure 1 Structural front view of the empty mold shown. Electronic detonator chip leg laser welding production line, including: production line body 1 and product collection frame 2, the right side of the inner cavity of the product collection frame 2 is horizontally bolted with a second mold transfer cylinder 3, and the inner cavity of the product collection frame 2 is The center of the bottom is bolted with a laser welder 4, and the top on the left side of the product collection rack 2 is bolted with an empty mold retur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com