Walking system of immersed tube tunnel formworks, system and implement method of immersed tube tunnel formworks

A technology for immersed tunnels and walking systems, applied in tracks, roads, movable tracks, etc., can solve the problems of high construction cost and low construction efficiency, and achieve the effect of saving labor costs and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

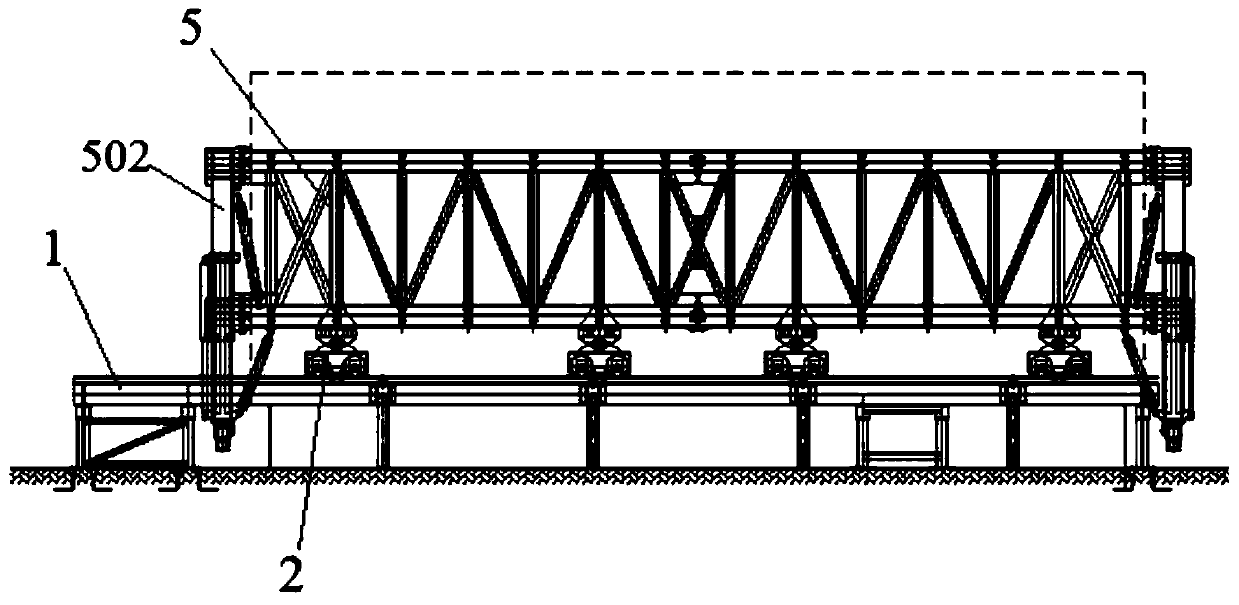

[0048] Such as figure 1 as shown, figure 1 It is the front view of the formwork walking system of the immersed tube tunnel, a kind of walking system of the formwork of the immersed tube tunnel, including a rail 1 and a traveling trolley 2 arranged on the rail 1 and capable of walking along the rail 1, on which the trolley 2 is set There is a fixed frame 5, and the fixed frame 5 is used to install the inner formwork 7 and the inner formwork support 6, and the two ends of the fixed frame 5 are provided with a fixed frame lifting mechanism 502, and the fixed frame lifting mechanism 502 is used for stretching to pouring The foundation separates the fixed frame 5 from the trolley 2, wherein the structural relationship between the fixed frame 5, the inner formwork 7 and the inner formwork support 6 is shown in Figure 4 .

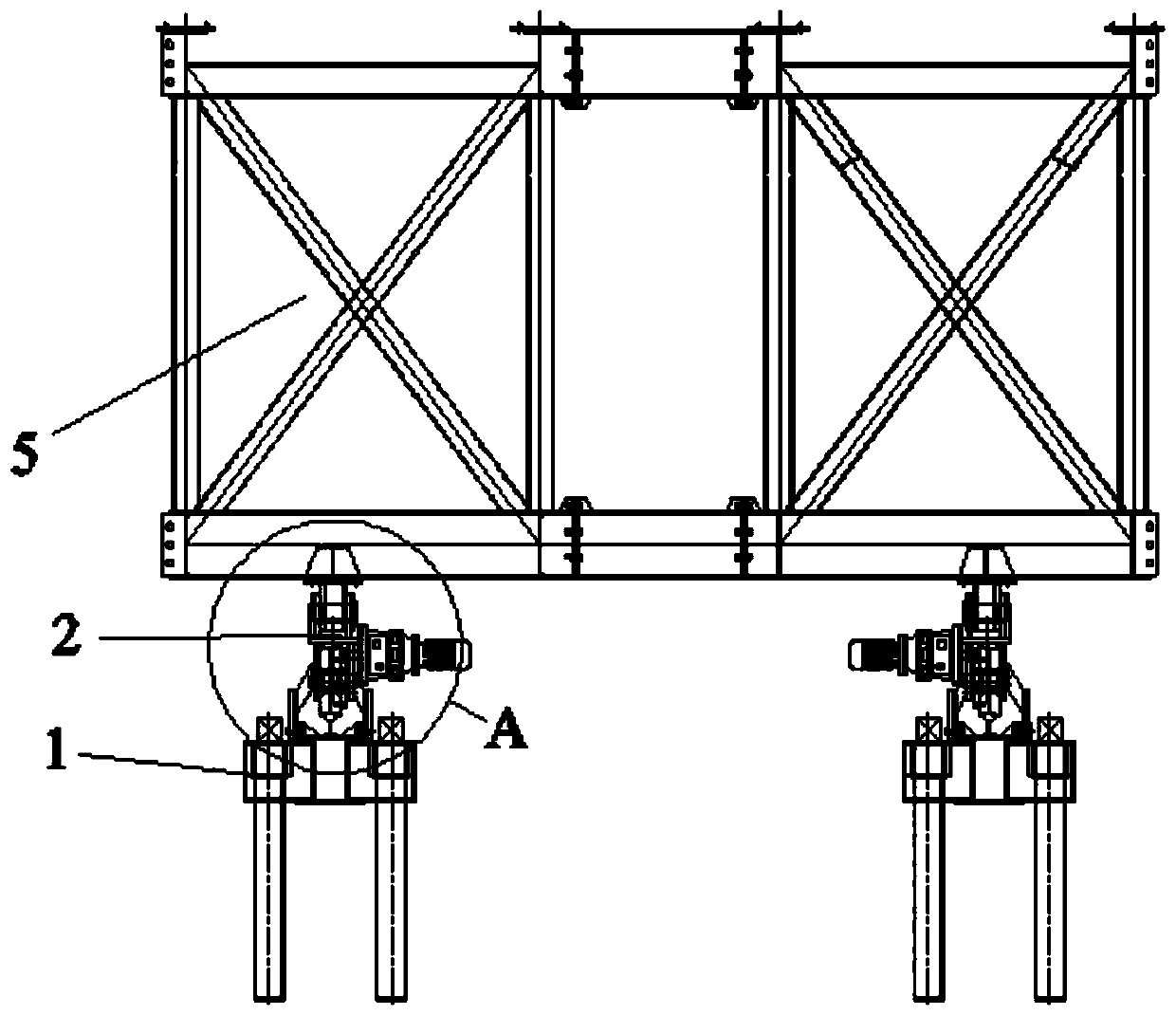

[0049] Such as figure 2 as shown, figure 2 is the side view of the formwork walking system of the immersed tube tunnel, figure 2 The connection relations...

Embodiment 2

[0076] An immersed tube tunnel formwork walking system, using the immersed tube tunnel formwork walking system as described in Embodiment 1, comprising an inner formwork support 6 with an inner formwork 7 arranged on the trolley 2, the inner formwork 7 includes a The first formwork and the second formwork of the overall formwork structure, the inner formwork support 6 includes a first support and a second support that can rotate relative to the first support, the first support is provided with the first formwork, the A second formwork is arranged on the second support, and a fixed frame elevating mechanism 502 is also arranged on the second support.

[0077] Wherein the concrete retractable structure of the inboard formwork support 6 with inboard formwork 7 sees Figure 4 .

[0078] Such as Figure 4 as shown, Figure 4 It is a schematic diagram of the connection relationship between the fixed frame 5, the inner formwork support 6 and the inner formwork 7, the inner formwor...

Embodiment 3

[0082] A method for implementing formwork walking of an immersed tube tunnel, using the formwork walking system of an immersed tube tunnel described in Embodiment 1, the steps are as follows:

[0083] Step 1, install the rail bracket 1022 to a predetermined position;

[0084] Step 2, install the track outrigger 1021 and the rail beam 101, and set the horizontal elevation;

[0085] Step 3, fixing the rail 103 on the rail beam 101, and setting the traveling trolley 2 on the rail 103;

[0086] Step 4: Set the fixed frame 5 on the trolley 2, and set the fixed frame elevating mechanism 502 at both ends of the fixed frame 5.

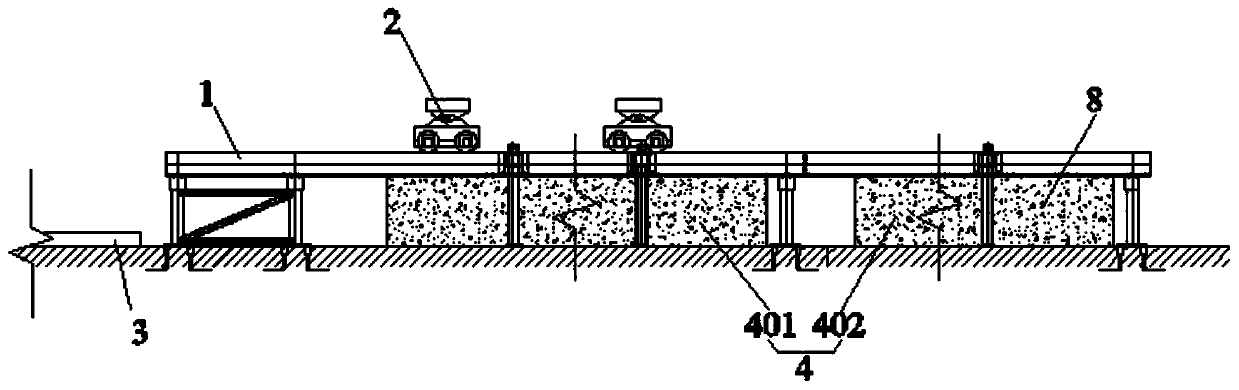

[0087] In step 1, the predetermined position is specifically the starting point of the formwork installation area 3 and the end point of the immersed tube pouring area 4, and a rail bracket 1022 can be optionally set between the starting point and the end point;

[0088] In step 2, the specific installation position of the track leg 1021 is along the length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com