Air return energy-saving device for fan

An energy-saving device and return air technology, which is applied to the components of the pumping device for elastic fluid, mechanical equipment, machines/engines, etc., can solve the problems of filter plate installation tilt, increase installation strength, and complicated installation, etc., to achieve Easy to replace the feet, fast installation, not easy to loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

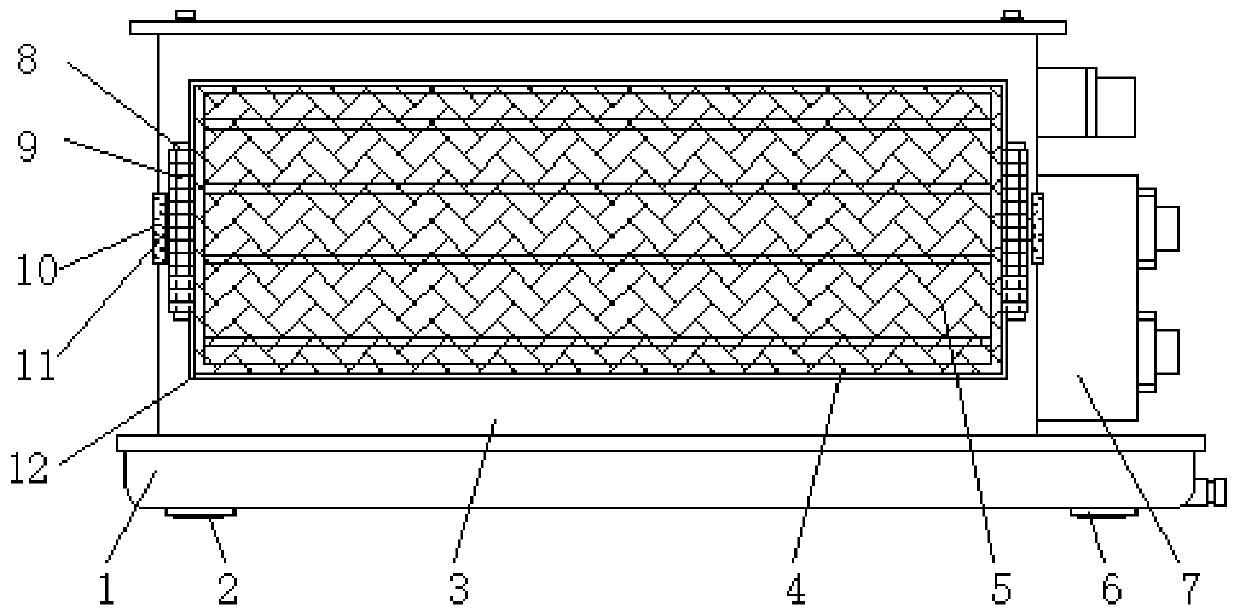

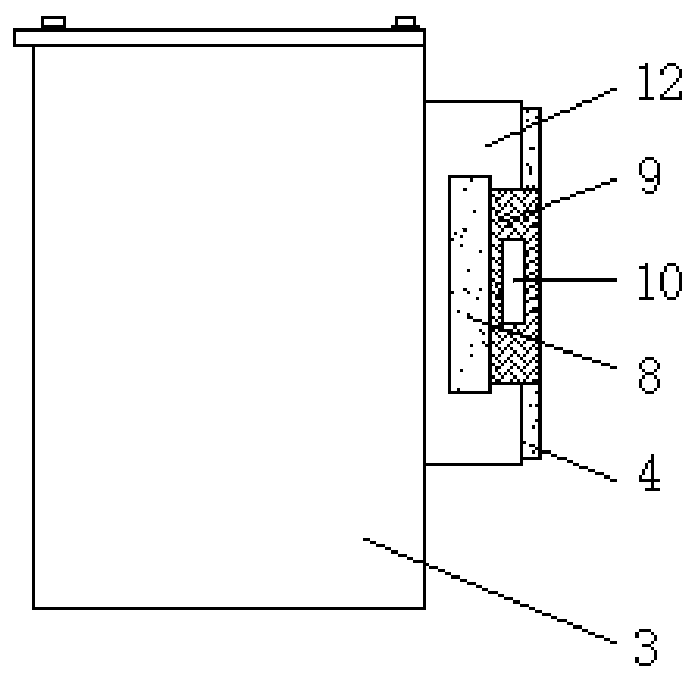

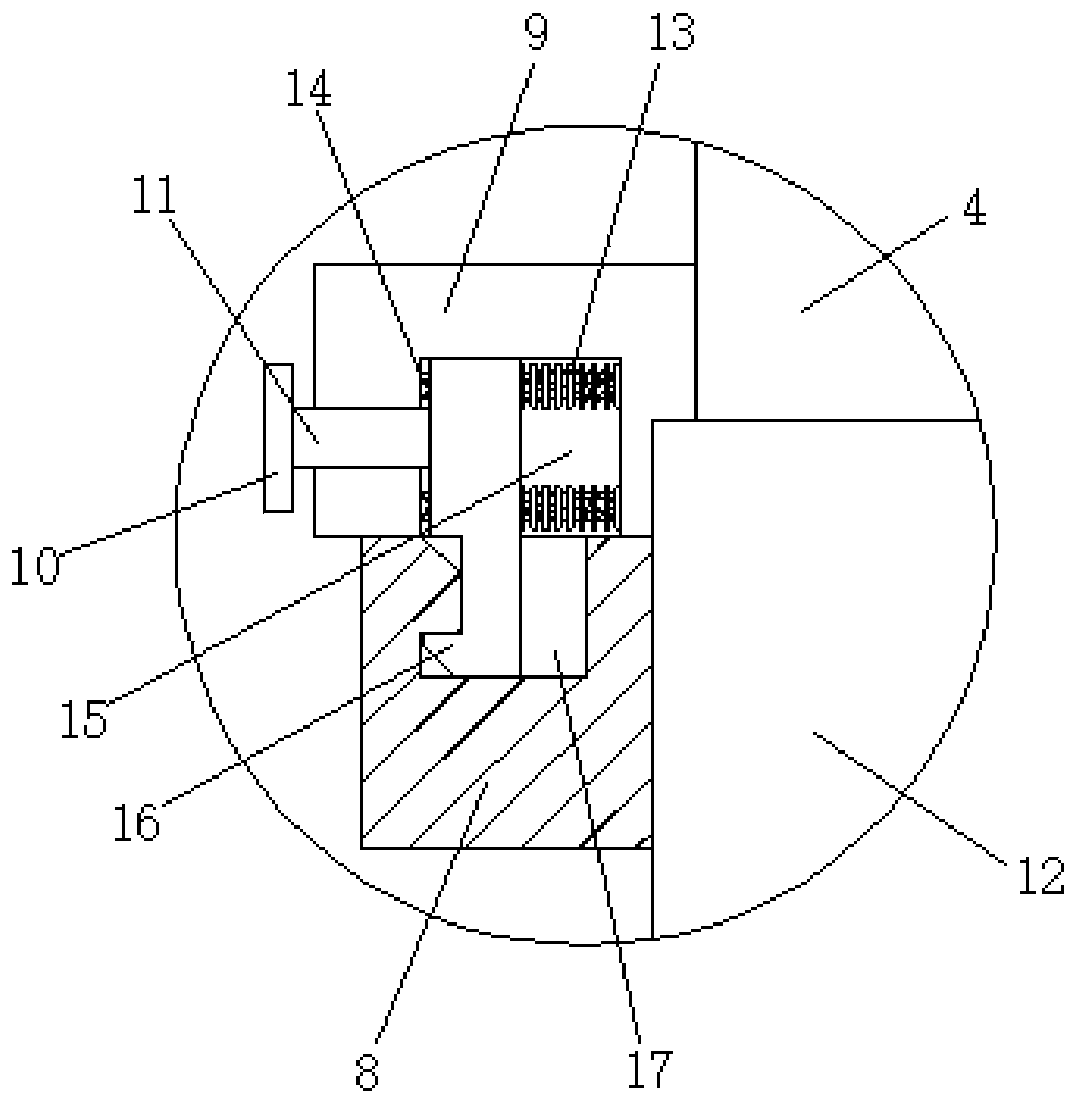

[0025] see Figure 1 to Figure 5 , the present invention provides a technical solution: a return air energy-saving device for fans, including a return air box 3, an installation shell 12 is connected to the surface of one end of the return air box 3, and a grid frame 4 is arranged at the end of the installation shell 12, and the inside of the grid frame 4 is connected There is a filter isolation plate 5, and installation blocks 9 are fixed on both sides of the net frame 4, and a storage tank 15 is provided at the bottom of the installation block 9, and a fixing plate 16 is arranged inside the storage tank 15, and the fixing plate 16 can be quickly snapped into the fixing groove 17 of the fixing block 8, so as to quickly install and limit the filter isolation plate 5, and avoid the traditional installation method being too complicated and prone to deviation. Both sides of the outer wall of the installation shell 12 are connected with fixing blocks 8, Through the designed fixed ...

Embodiment 2

[0027] see Figure 1 to Figure 6 , the present invention provides a technical solution: a return air energy-saving device for fans, including a return air box 3, an installation shell 12 is connected to the surface of one end of the return air box 3, and a grid frame 4 is arranged at the end of the installation shell 12, and the inside of the grid frame 4 is connected There is a filter isolation plate 5, and installation blocks 9 are fixed on both sides of the net frame 4, and a storage tank 15 is provided at the bottom of the installation block 9, and a fixing plate 16 is arranged inside the storage tank 15, and the fixing plate 16 can be quickly snapped into the fixing groove 17 of the fixing block 8, so as to quickly install and limit the filter isolation plate 5, and avoid the traditional installation method being too complicated and prone to deviation. Both sides of the outer wall of the installation shell 12 are connected with fixing blocks 8, Through the designed fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com