Braking device for a mechanism driven by an electric motor

A technology of braking device and motor, applied in the direction of brake type, deceleration device parts, mechanical equipment, etc., can solve the problems of large electric braking energy loss, easy aging, long use time of spring, etc., to achieve small energy loss, prevent The effect of heating and strengthening the fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

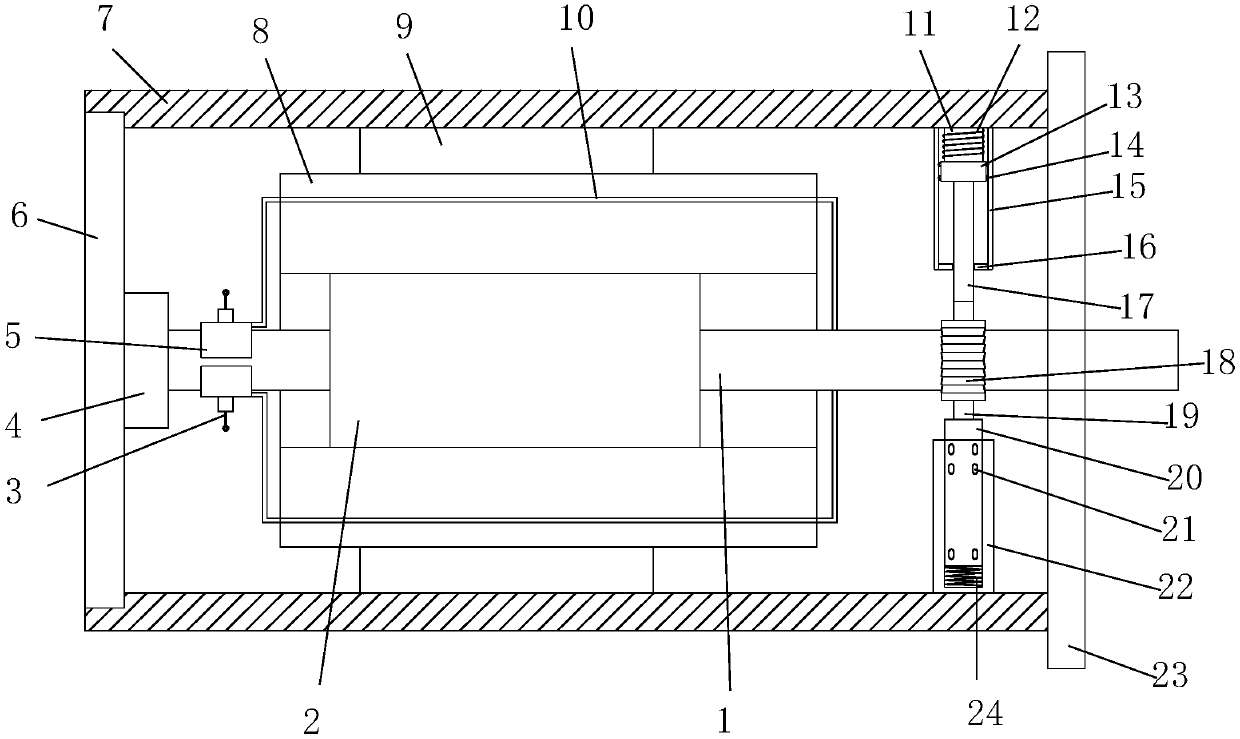

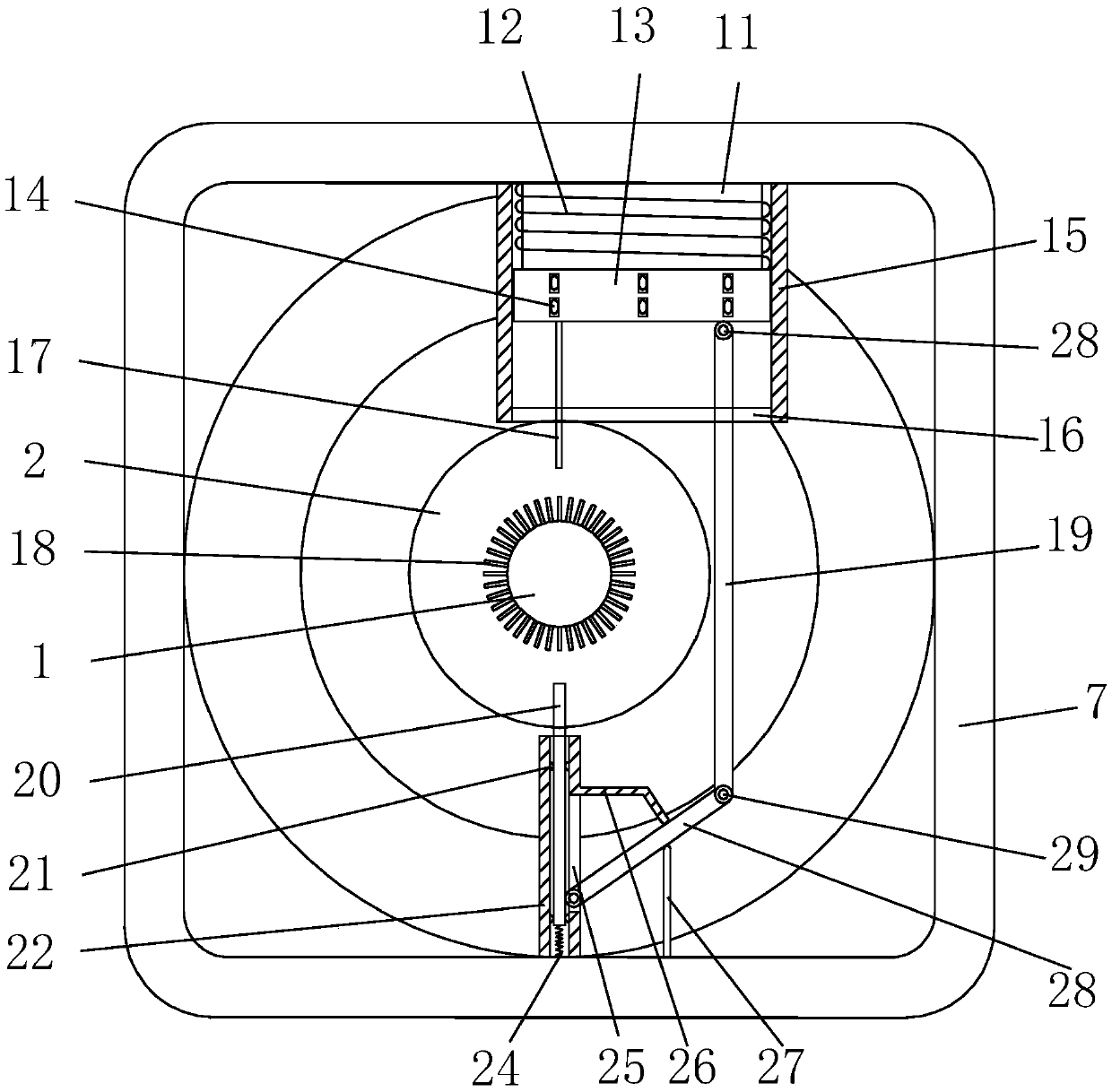

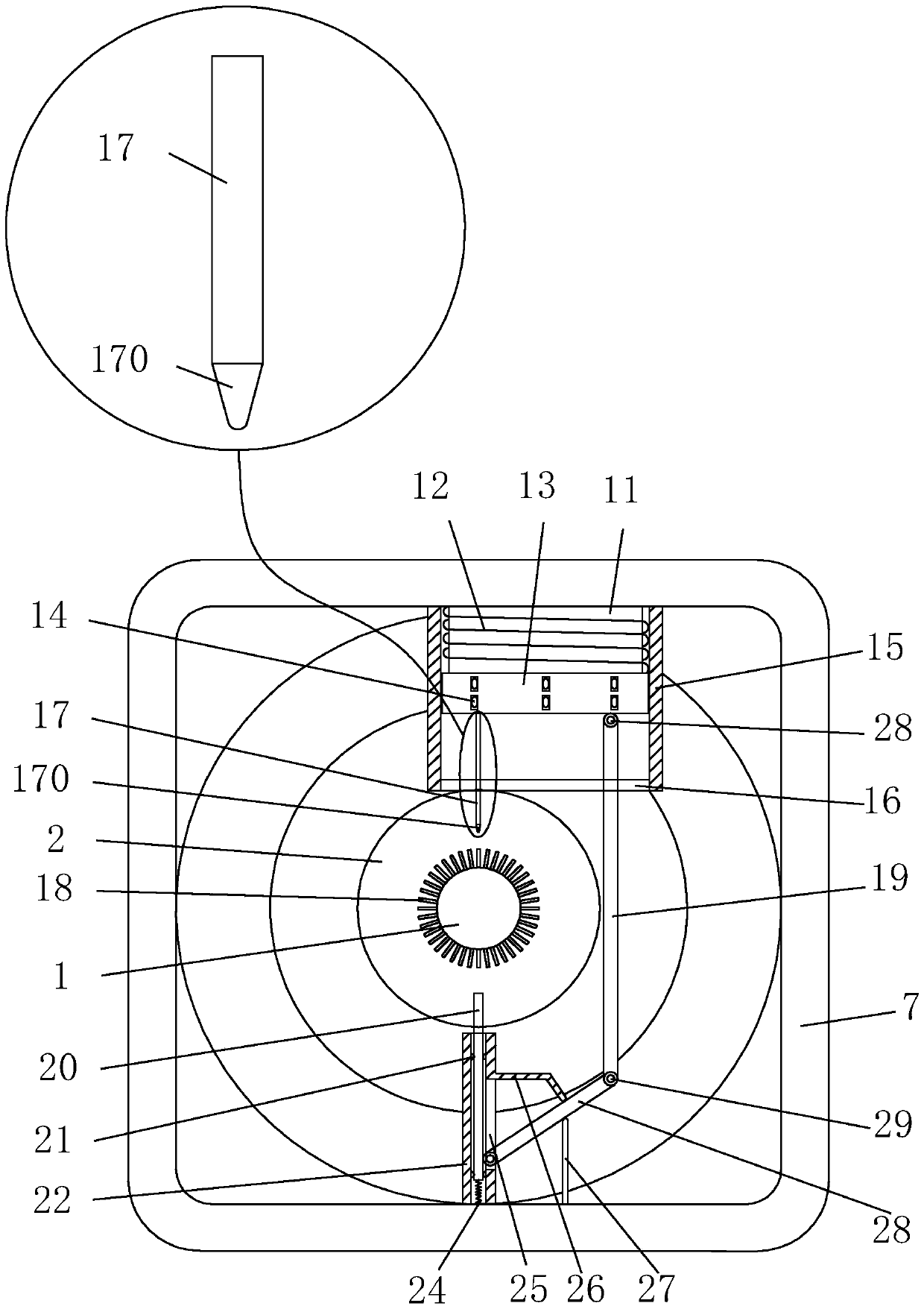

[0026] See Figure 1-Figure 6 , The present invention provides a technical solution for a brake device for a motor-driven mechanism: its structure includes a rotating shaft 1, a rotor core 2, a brush 3, a bearing 4, a commutator 5, a rear end cover 6, a housing 7, and a stator winding 8. Stator core 9, winding coil 10, core 11, coil 12, armature 13, roller I 14, upper guide rail 15, limit block 16, upper brake pad 17, blade 18, connecting rod I 19, lower brake pad 20, The roller II 21, the lower rail 22, the front end cover 23, the spring 24, the slot 25, the baffle 26, the vertical plate 27, the connecting rod II 28, the hinge 29, the rear end of the housing 7 is embedded with the rear end cover 6, the The front end cover 23 is arranged at the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com