Finned evaporator

A finned evaporator and fin technology, applied in the field of refrigeration systems, can solve the problems of not being suitable for small-volume refrigerators and the large volume of finned evaporators, and achieve improved heat exchange capacity, strong heat exchange capacity, and small area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

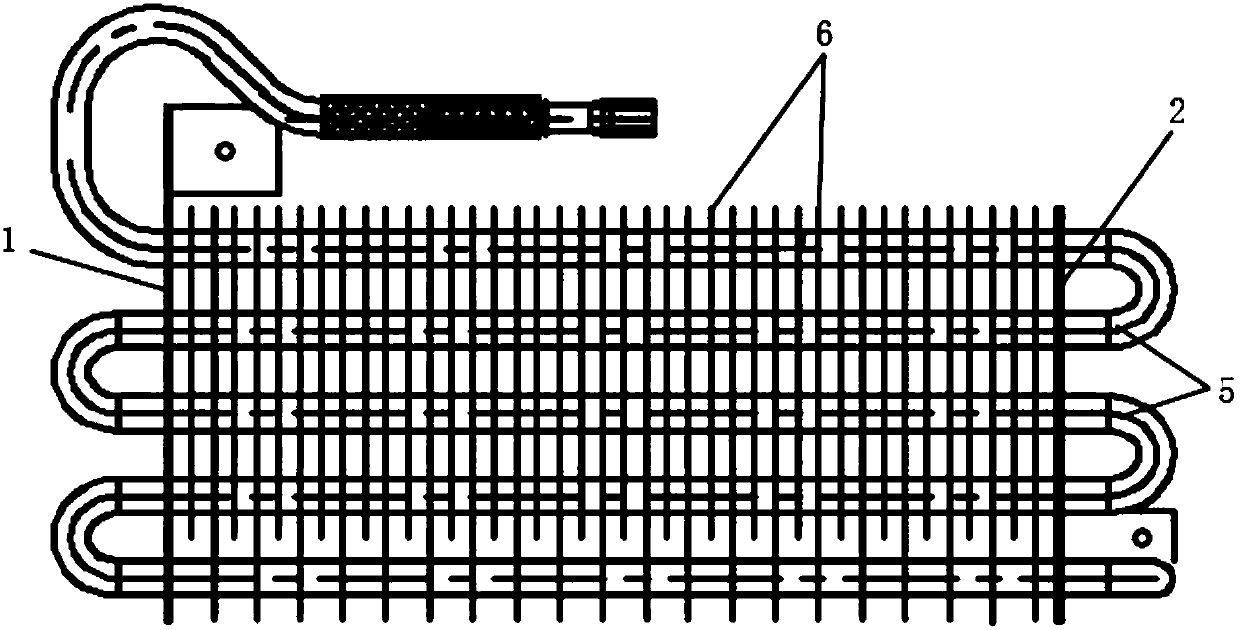

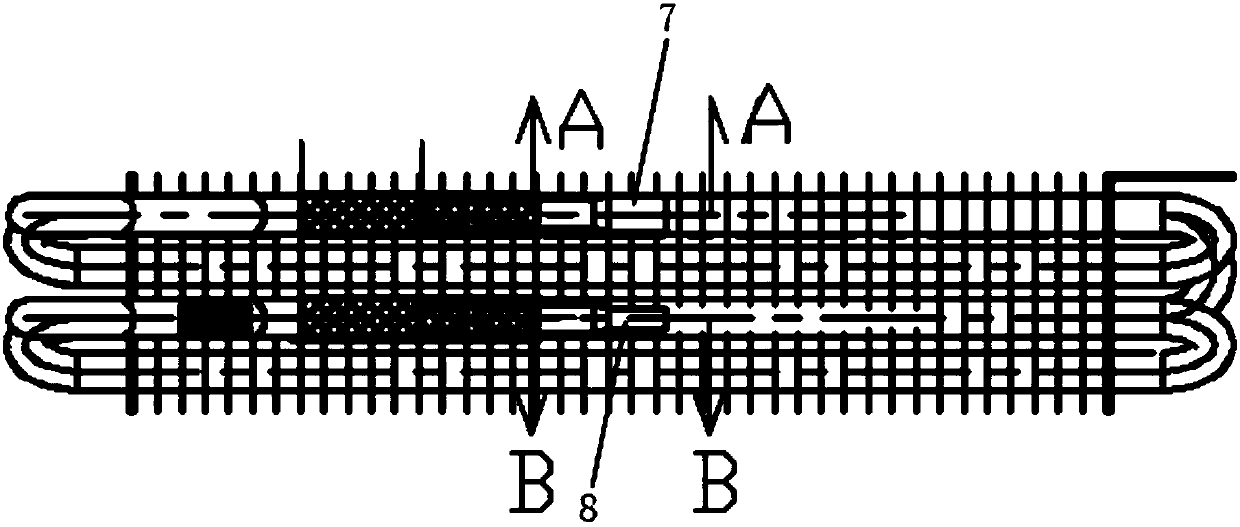

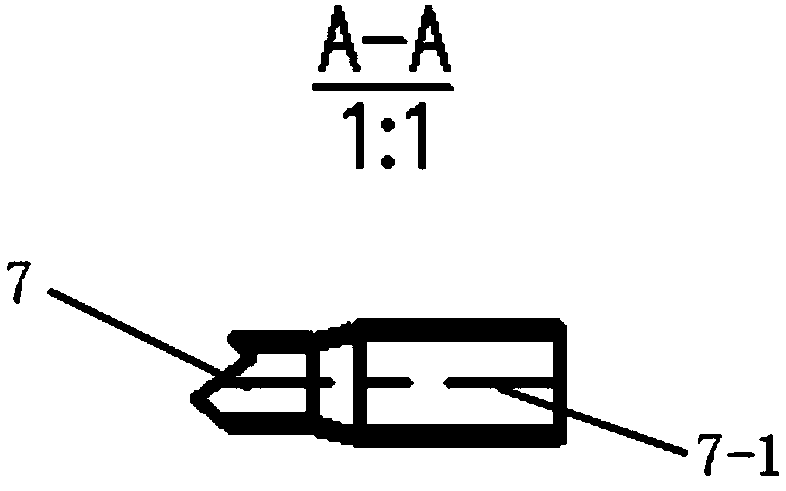

[0016] see attached Figure 1-6 As shown, a fin-type evaporator includes a first support 1 and a second support 2 arranged symmetrically on the left and right, a plurality of first notches 3 are arranged on the first support 1, and the second support 2 is provided with a plurality of second slots 4, the first slot 3, the second slot 4 and the horizontal plane are inclined at 60 degrees, the first slot 3 and the first slot 3 are parallel Arrangement, the second slot 4 and the second slot 4 are arranged in parallel, the first slot 3 and the second slot 4 are pierced with an evaporation coil 5, and the evaporation coil 5 is The material is aluminum and has a serpentine curved structure. Fins 6 are pierced on the evaporation coil 5 between the first bracket 1 and the second bracket 2, and the first connection is welded on the inlet and outlet of the evaporation coil 5 respectively. Pipe 7 and second connecting pipe 8, the material of the first connecting pipe 7 and the second con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com