Quantitative turnover box for small cigarette packs

A turnover box, quantitative technology, applied in the direction of boxes, rigid containers, containers, etc., can solve the problems of easily damaged small boxes, large cartons are not strong, difficult to calculate, etc., to save space for placement, stable transportation and circulation, Enhance the effect of less deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

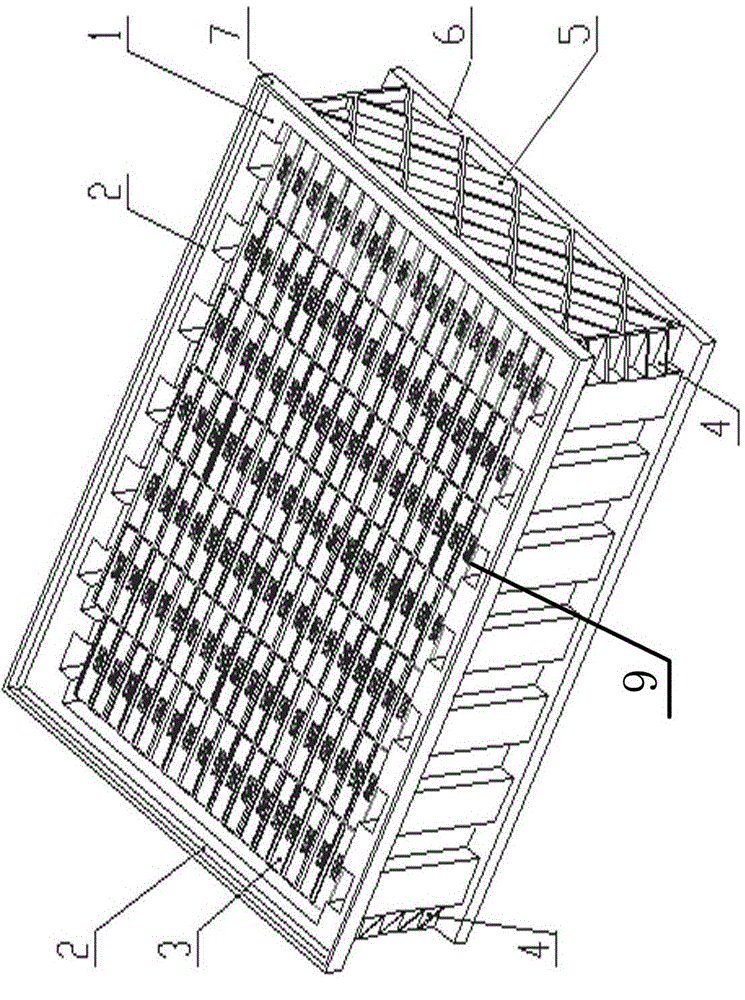

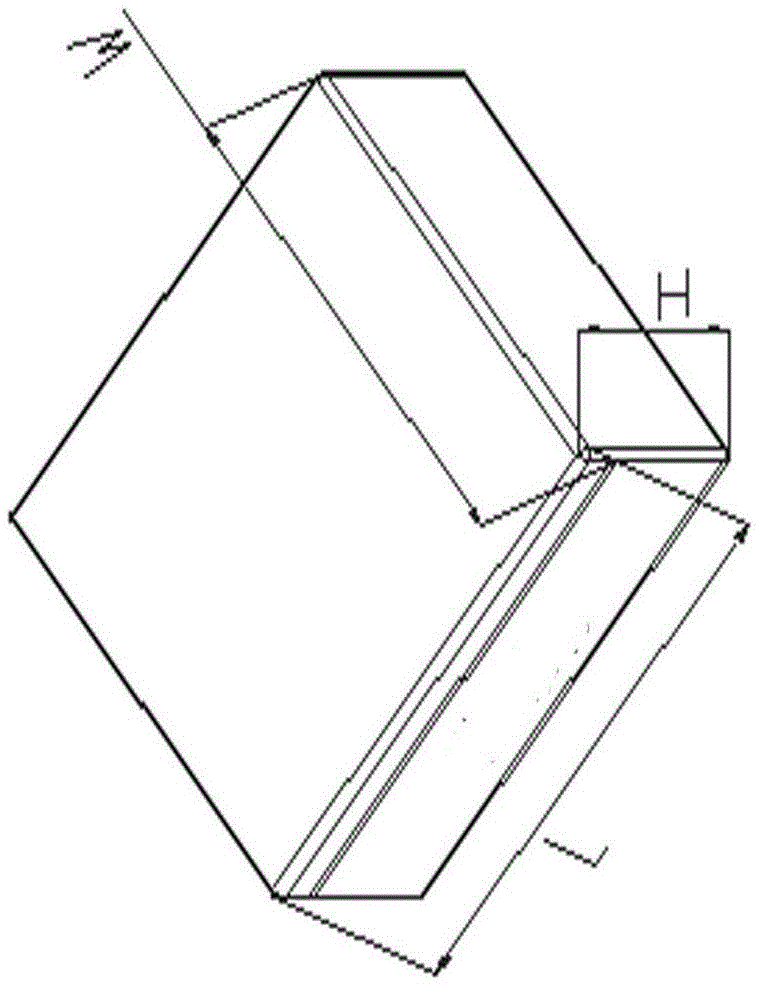

[0040] 1) Measure the external dimensions of the 16-pack "Yuxi Manor" small box 3 as length L=78.5, width W=67.5, and thickness H=19.0 (mm).

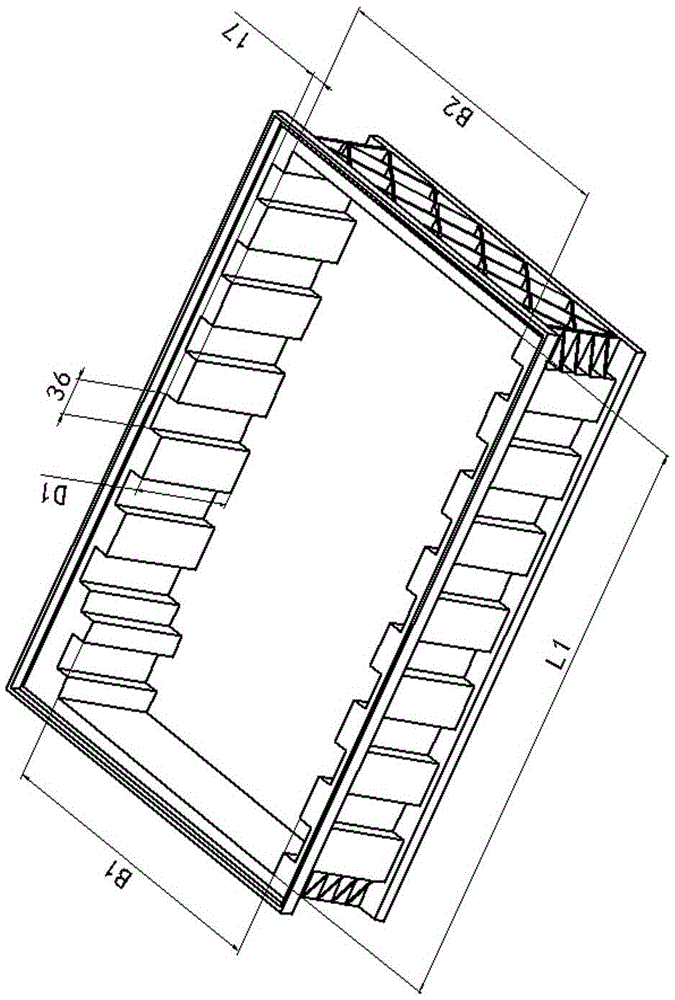

[0041] 2) The quantitative turnover box is designed with food-grade engineering plastics. The inner cavity length L1 of the quantitative turnover box body 1 is designed as a multiple of the length L=78.5mm of the 16-pack "Yuxi Manor" small box 3, which is 7 times, that is 78.5×7=549.5mm, leaving a positive deviation of 9.5mm, taking L1=559mm; the inner cavity width B1, B2 is designed according to the thickness H=19.0 (mm) of the 16-pack "Yuxi Manor" small box 3, and 17 times are used on one side, That is, 19.0×17=323mm, take 3mm positive deviation, B1=326mm, the other side adopts 18 times design, that is, 19.0×18=342mm, leave 3mm positive deviation, take B2=345mm; The width of the small box 3 is designed in multiples of W=67.5mm, and the design is doubled, that is, 67.5×2=135mm, with a positive deviation of 5mm, and D1=140mm; 2 layers,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com