Modular 3D modeling system with safety purse seine and metal plate outer cover for intelligent workshop

A workshop safety and modular technology, applied in the field of intelligent workshop, can solve the problems of difficult quality control, difficult maintenance, large working hours, etc., and achieve the effect of reducing research and development costs, reducing maintenance difficulty, and reducing the number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

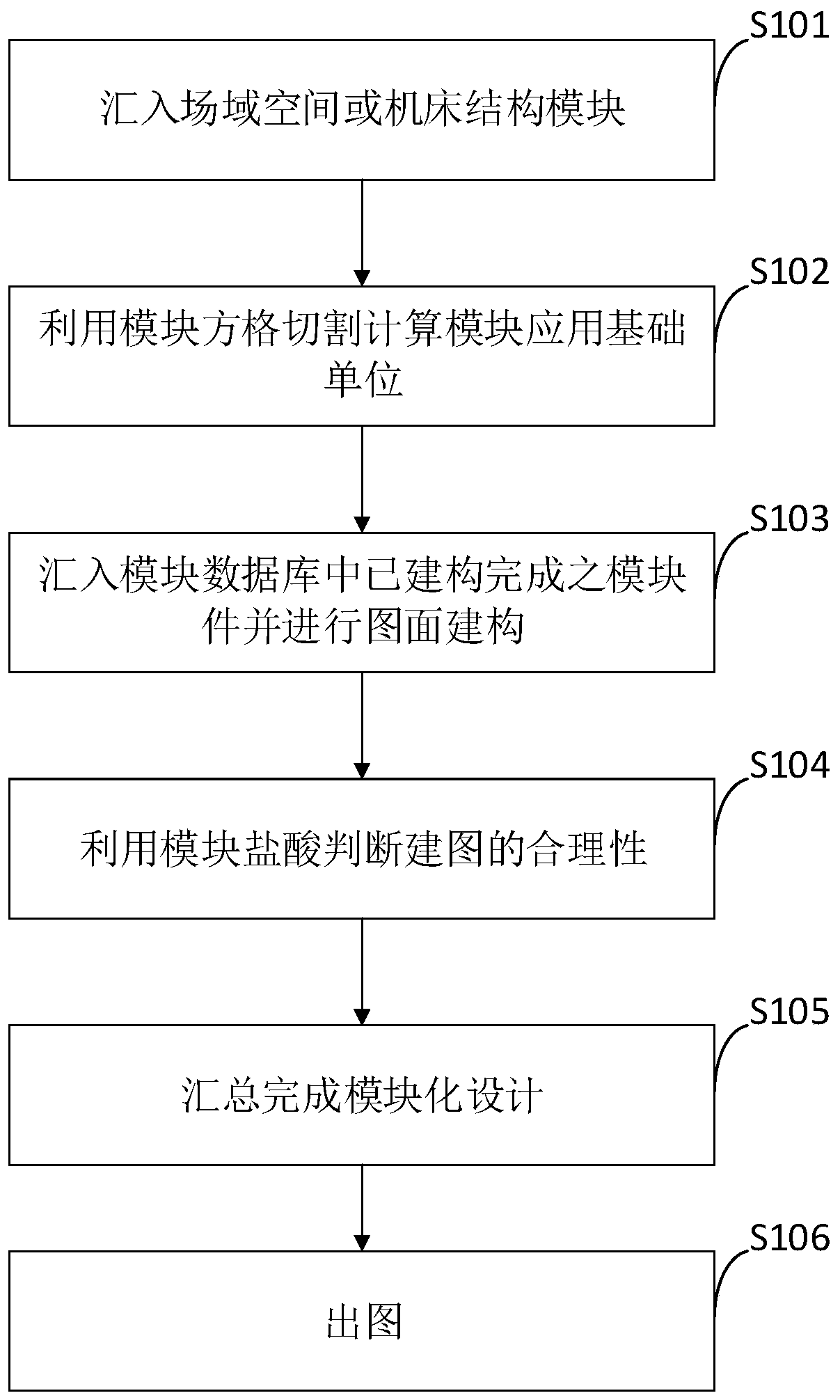

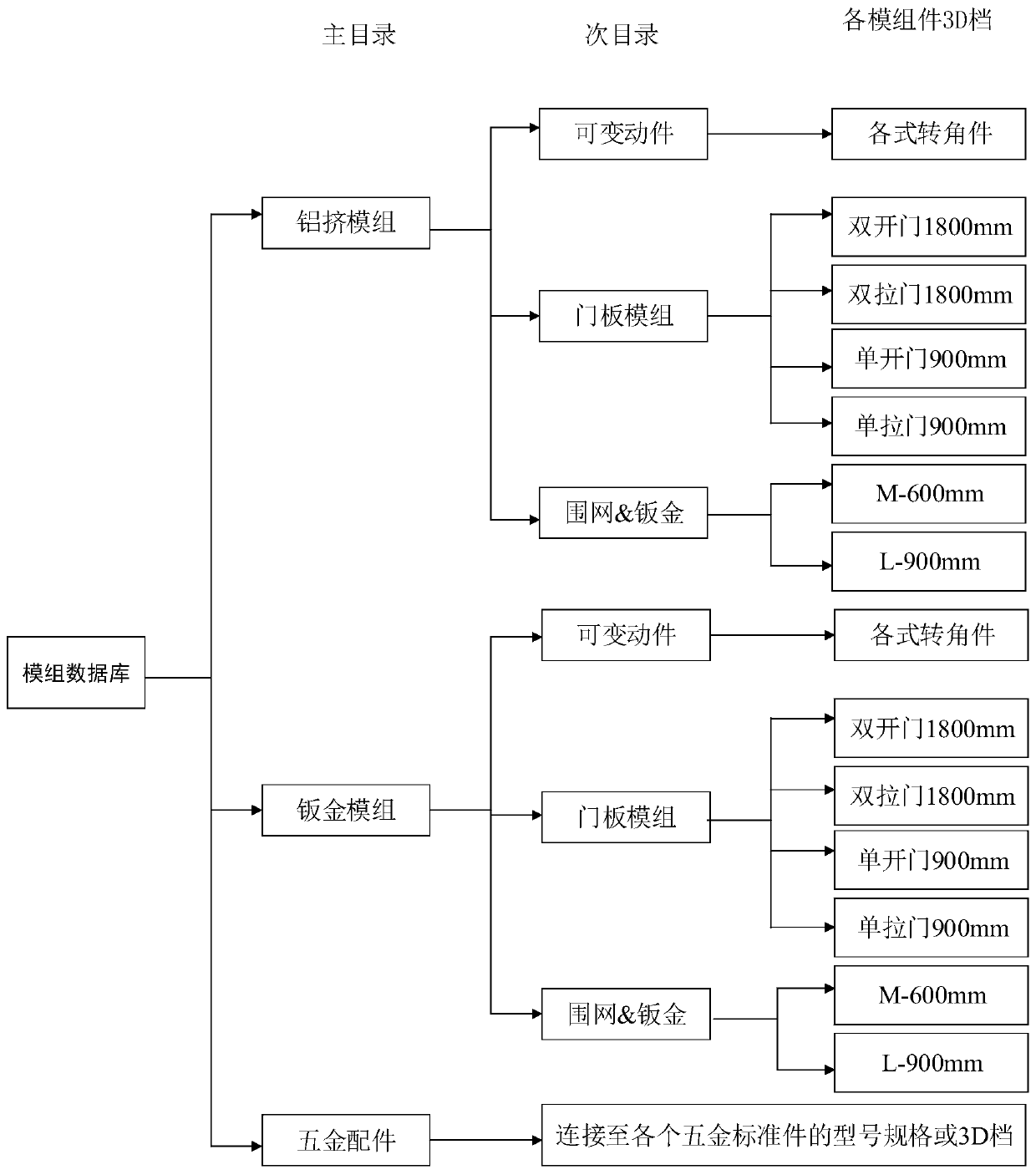

Method used

Image

Examples

Embodiment

[0078] For the prior art, the following problems exist:

[0079] 1) More than 90% of the hydraulic injection machines in the prior art do not have any module standardization at all.

[0080] 2) There is no standardization of modules due to full customization, which consumes considerable manpower and time costs in the design of sheet metal fences for hydraulic injection machines.

[0081] 3) After designing the sheet metal cover of one hydraulic injection machine, when designing the second hydraulic injection machine, the previous design is completely inapplicable, and everything goes back to the original point, which causes a vicious circle.

[0082] In order to solve the above problems, the present invention integrates various data sizes and components with the concept of modular database construction, but at that time, the construction of the relevant database and the combined application with software were only a conceptual stage, and only AutoCAD software was used for simp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com