Flexible board reinforcing and laminating method

A flexible board and reinforcement technology, used in printed circuit components, electrical components, printed circuit manufacturing, etc., can solve the problems of low patching efficiency, poor bonding, and high labor costs for the entire board, and achieve the elimination of complex and repetitive pastes. process, good machinability, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the following examples further describe the present invention in detail. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

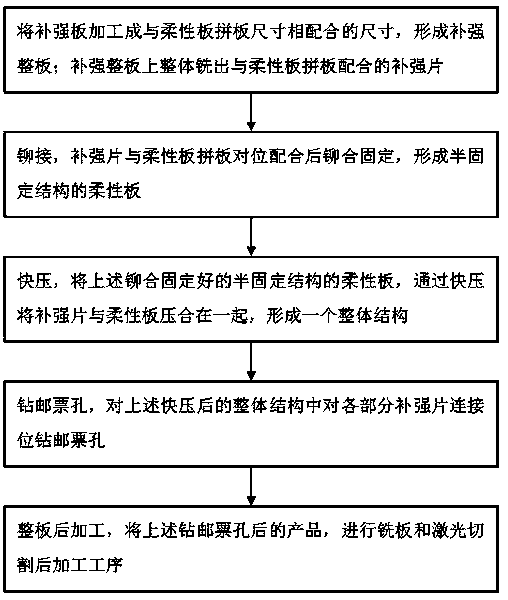

[0029] A method for reinforcing and laminating flexible boards, comprising the following steps: S1, processing the integral reinforcing sheet, processing the FR-4 reinforcing board into a size that matches the size of the flexible board to form a whole reinforced board; Reinforcing sheet that fits with the flexible board is milled out on the whole board; specifically, the following steps are included: S101: Mill the FR-4 reinforcement to the same size as the flexible board, S102: Follow the above changes In the final design, the reinforcing sheet milled in the first step is milled off the unnecessary area according to the graphic design; S103: remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com