Heavy-load transshipment docking AGV device

An equipment and automatic docking technology, applied in the field of cargo transportation and lifting, can solve the problems that the installed equipment cannot meet the function of carrying goods transfer, cannot meet the loading and unloading requirements of low-class transport aircraft, and does not meet the needs of the Air Force for rapid installation, etc., to avoid equipment. The effect of being unable to work, reducing the number of installed operators, and requiring low professional level of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

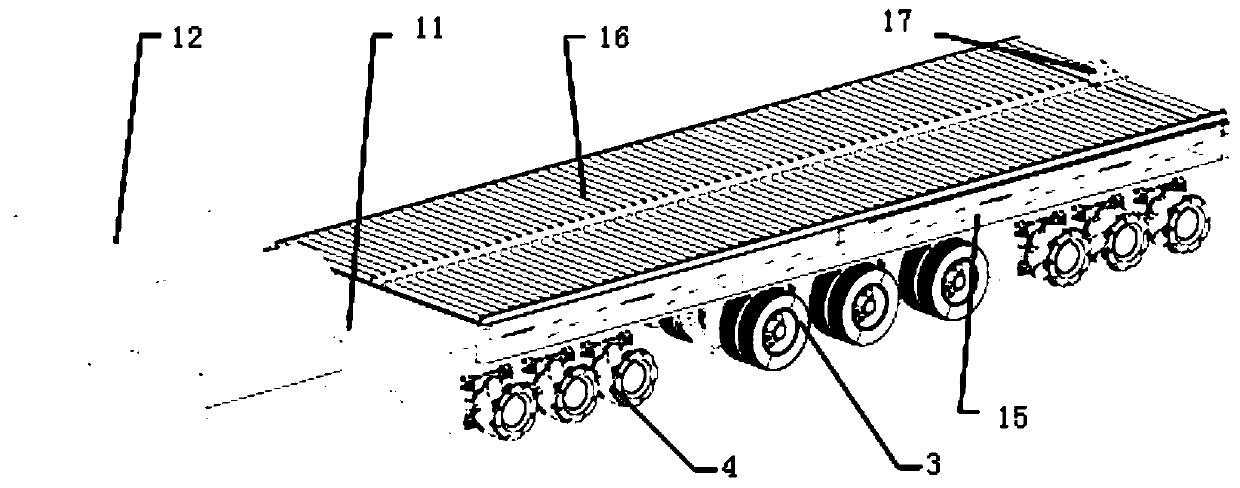

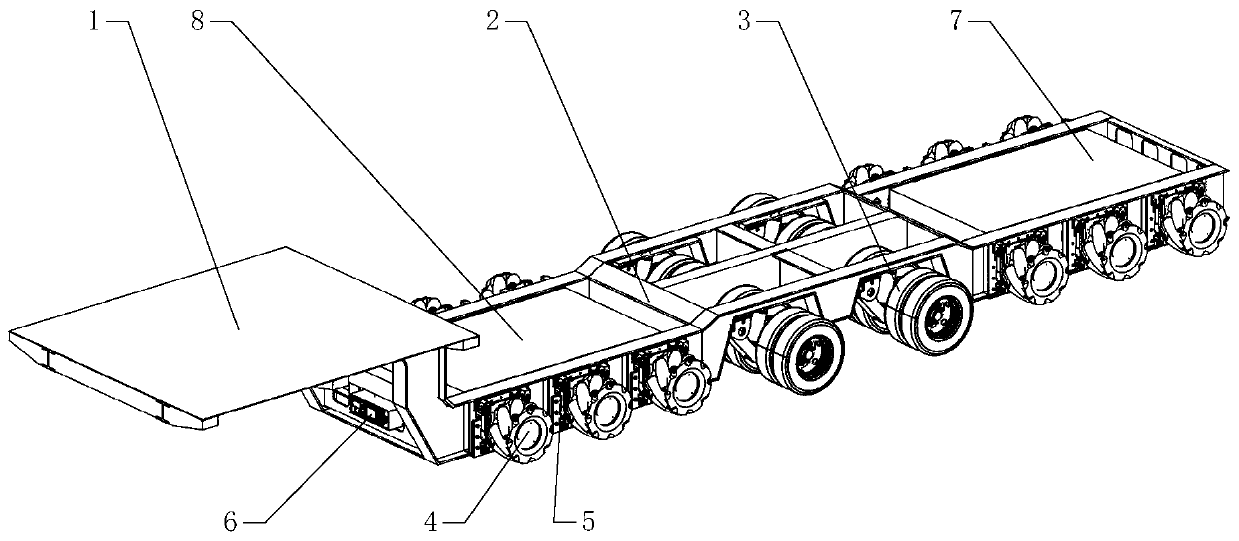

[0033] Such as figure 1 As shown, a heavy-duty transfer docking AGV device of the present invention is characterized in that it includes a semi-trailer platform and an omnidirectional mobile platform based on Mecanum wheels; the semi-trailer platform includes a gooseneck 1, a vehicle frame 2, hydraulic axis wheels 3 (hydraulic suspension wheels), axis wheel electric shafting, axis wheel suspension; the omnidirectional mobile platform based on mecanum wheels includes mecanum wheels 4, electric shafting, suspension; the mecanum wheels and electric shafting are installed on hanging on;

[0034] The gooseneck 1 is connected to the frame, which is the installation platform; the hydraulic axis wheel 3 is located between the front and rear two sets of mecanum wheels 4; each mecanum wheel and electric shaft system are installed on the suspension, and the oil cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com