U-shaped closed screw machine anti-gushing system capable of separating slag and water and anti-gushing method

A slag-water separation and anti-gush technology, which is applied in earthwork drilling, mining equipment, tunnels, etc., can solve the problems of poor anti-gush mechanism and single slag discharge method, so as to avoid gush, high promotion value, safety and efficiency The effect of excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

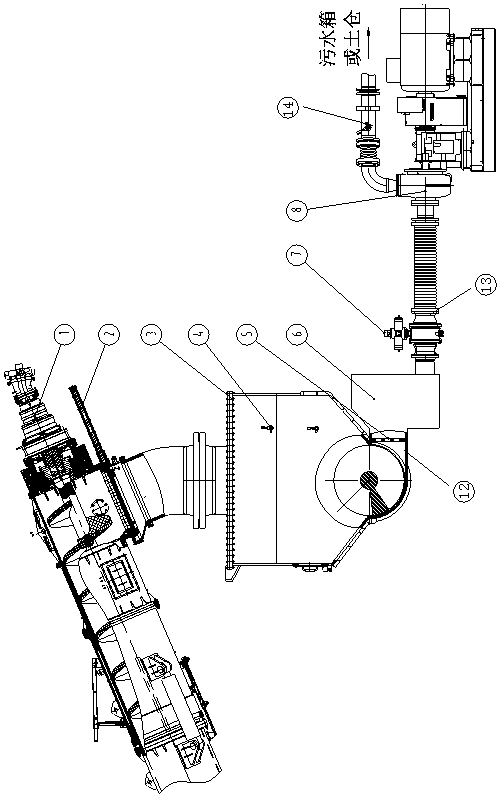

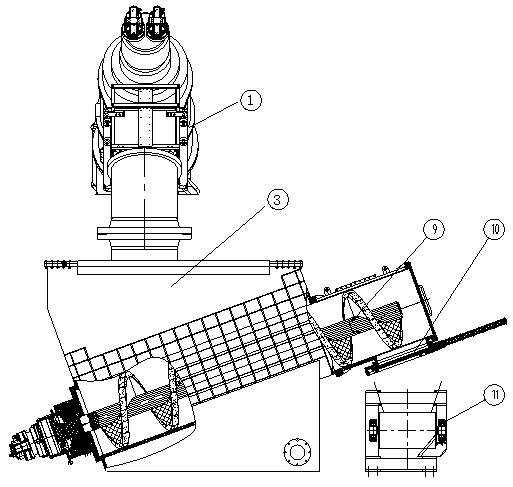

[0024] Embodiment 2, a U-shaped airtight screw machine anti-splash system capable of separating slag from water, the slag outlet of the first screw conveyor 1 is provided with a first gate 2, and the first gate is sealed with a U-shaped sealed box 3 Connection, the first gate is controlled by the oil cylinder to realize the closing and opening of the gate. If there is a problem with the U-shaped airtight structure, the first gate can be closed to overhaul the U-shaped airtight structure. The two ends of the second screw conveyor 9 protrude from the U-shaped sealed box 3, one end of the second screw conveyor 9 is connected with the driving mechanism, and the other end is provided with a second gate 10, which is controlled by an oil cylinder , when the working conditions require, the second gate is closed to realize the pressure-holding function of the U-shaped airtight structure; the second gate 10 corresponds to the rear matching continuous belt conveyor 11, and the muck coming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com