Backfill sampling device for project supervision

A technology of sampling device and backfilling soil, which is applied in the direction of sampling device, etc., can solve the problems such as easy drop of soil samples, closed protection of soil samples that cannot be taken out, and influence on sampling stability, so as to achieve increased stability, good material guiding effect, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

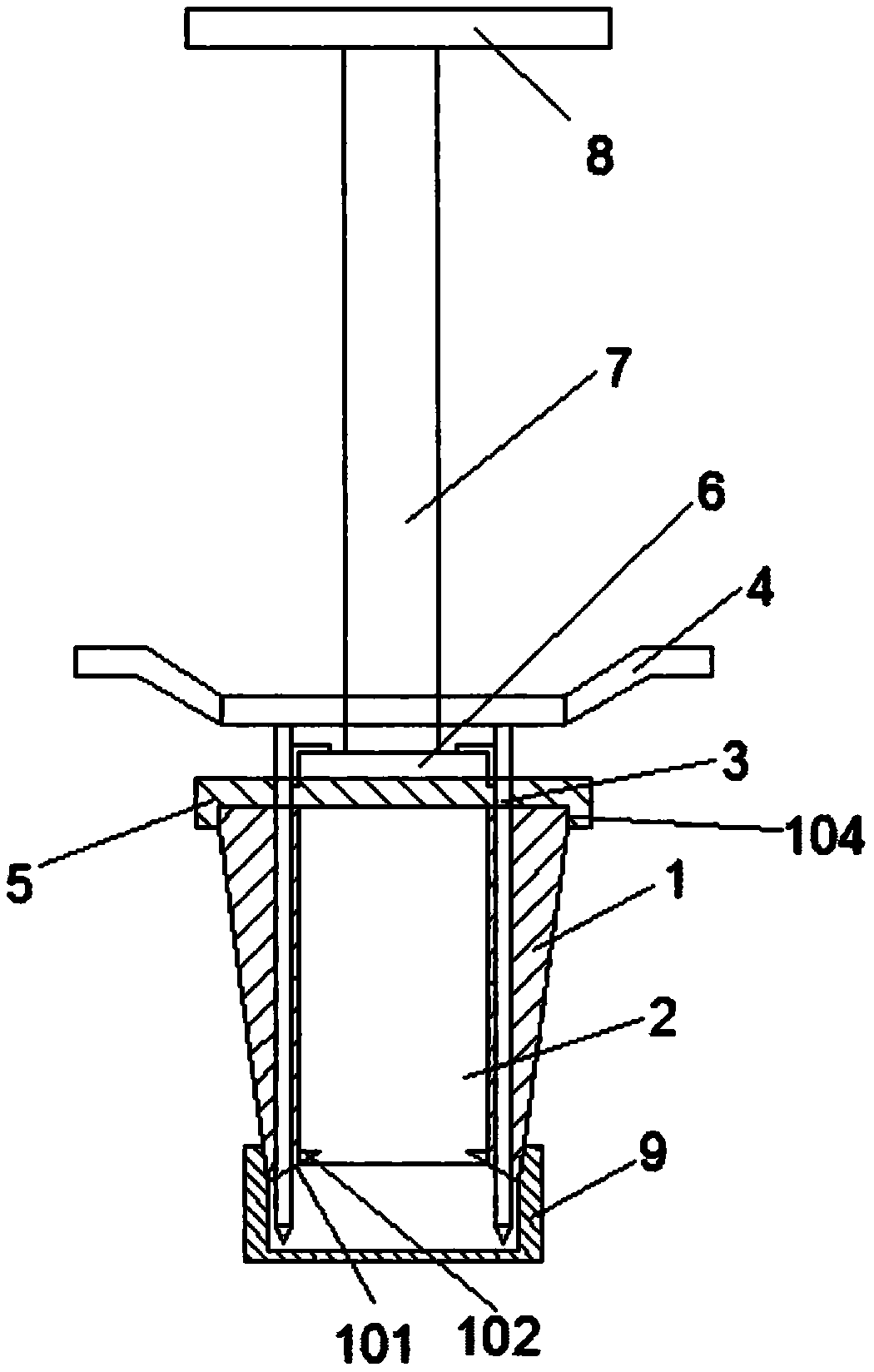

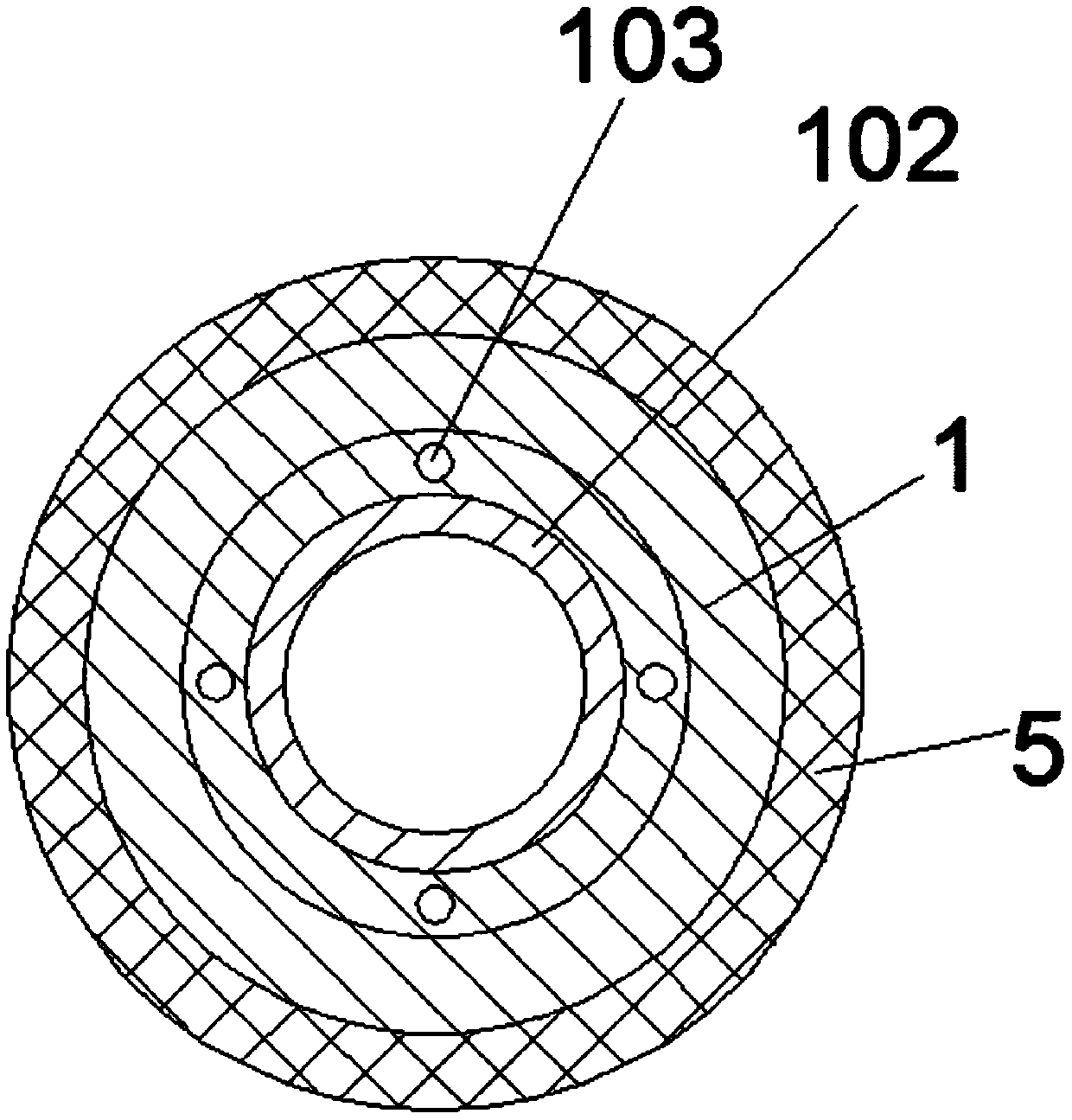

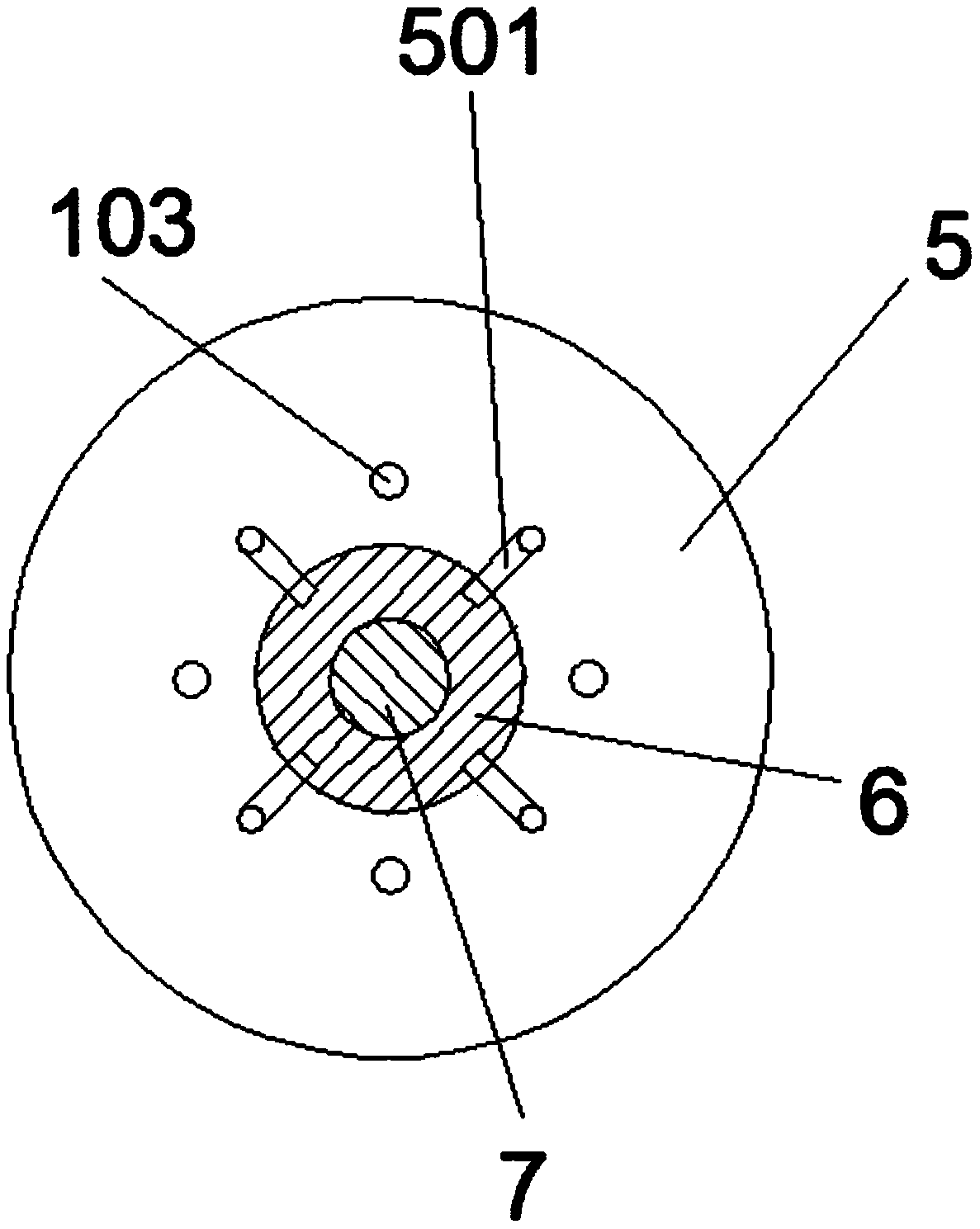

[0023] Such as Figure 1-5 as shown,

[0024] This embodiment provides a backfill soil sampling device for engineering supervision, comprising a sampling housing 1 with a conical structure on the outside. The inside of the sampling housing 1 is a cylindrical sampling cavity 2. A number of guiding and fixing columns 3 are evenly distributed, and the upper part of the guiding and fixing columns 3 is provided with a pressing plate 4. The upper part of the sampling housing 1 is threaded with a thrust cover 5, and the thrust cover 5 is movably connected with a push block 6. A threaded push rod 7 is formed on the push block 6, and the threaded push rod 7 is threadedly connected with the pressing plate 4. The end of the threaded push rod 7 is provided with an annular handle 8, and the end of the sampling housing 1 is provided with a Corresponding to the material guide port 101 of the cylindrical sampling cavity 2 , the inside of the sampling housing 1 is provided with an anti-backfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com