Device and method for monitoring thermal expansion stress and deformation of foamed concrete under confinement

A technology of foam concrete and thermal expansion, which is applied in the direction of measuring devices, thermal expansion coefficients of materials, instruments, etc., can solve the problems that the expansion stress and deformation of foam concrete cannot be measured, and the real-time and in-situ measurement of expansion stress and deformation of foam concrete cannot be realized. Achieve the effects of simple structure and working principle, convenient operation process and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

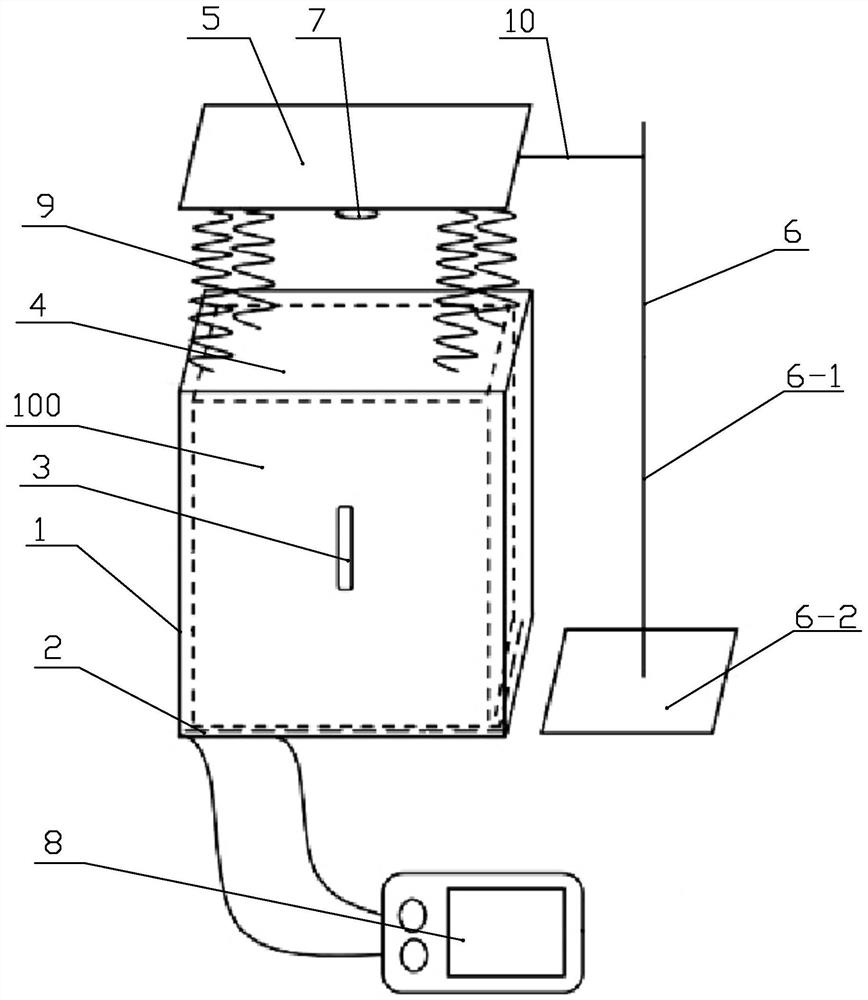

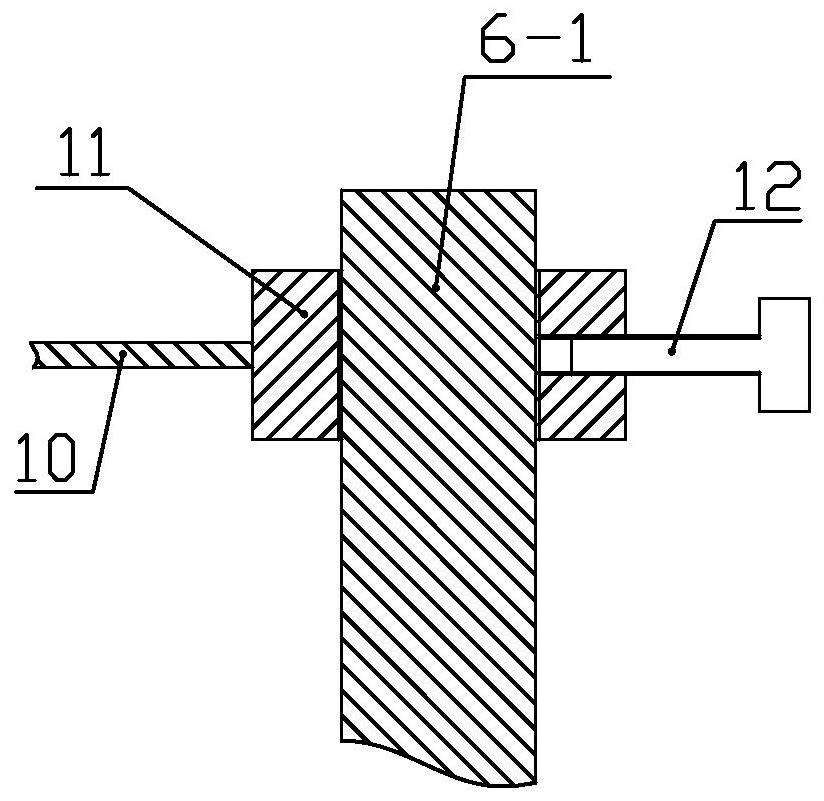

[0026] Embodiment 1: Combining figure 1 , 2 Describe this embodiment, the device for monitoring the thermal expansion stress and deformation of foamed concrete in a restrained state, which includes a mold 1, a heating plate 2, a temperature sensor 3, a cover plate 4, a slide plate 5, a slideway 6, a displacement sensor 7, and a temperature control box. 8 and a number of springs 9, the mold 1 is made of metal, the top of which is open, the foam concrete 100 is installed in the mold 1, the heating sheet 2 is installed at the bottom of the mold 1, and the temperature sensor 3 is installed on the side of the mold 1 , between the heating plate 2 and the temperature control box 8 and between the temperature sensor 3 and the temperature control box 8 are respectively connected by wires, the slideway 6 is vertically arranged on one side of the mold 1, The sliding plate 5 is arranged horizontally and is slidably connected to the slideway 6 along the vertical direction, a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com